Article contents

The effect of tribolayers on the behavior friction of X40CrMoV5/Fe360B steel couple in an open sliding contact

Published online by Cambridge University Press: 14 March 2017

Abstract

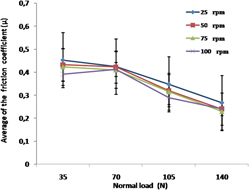

Metal working tools are generally exposed to hard conditions, and the control of their excessive wear is of a crucial importance for the metal working process. Indeed, tribo-layers as mechanically mixed layers and wear debris are completely involved in the wear behavior. This paper undertakes the study of the frictional behavior and wear of X40CrMoV5 (AISI H13) tool steel as a function of speed rotation at room temperature. The utmost objective of this research work is to assess some wear mechanisms of this tool steel used at room temperature. The tribological experiments were accomplished on high temperature pin-on-disc tribometer with an open sliding contact. The pin material was X40CrMoV5 steel and the disc material was Fe360B steel. The investigations were accomplished for different rotatory speeds of the disc ranging from 25 rpm to 100 rpm, and different nominal pressure. SEM and EDS explored the development surface damage and oxides tribo-layers. It was concluded that the increase of the rotation speed of the disc and the nominal pressure reduce the friction coefficient by the creation of a wear protective layer.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 2

- Cited by