Article contents

Effect of SiCp volume fraction on the microstructure and tensile properties of SiCp/2024 Al-based composites prepared by powder thixoforming

Published online by Cambridge University Press: 30 August 2016

Abstract

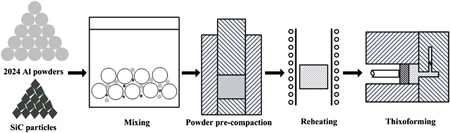

A new technology for preparing and forming ceramic particle-reinforced metal matrix composites, powder thixoforming, has been proposed. The effect of the SiCp volume fraction on the microstructure and tensile properties of thixoforged SiCp/2024 Al-based composites was studied. The results indicated that the volume fraction affected the effective liquid fraction, primary particle size and shape, and microstructure compactness. A composite with 10 vol% SiCp had the best comprehensive tensile properties, an ultimate tensile strength of 388 MPa, a yield strength of 295 MPa, and an elongation of 3.8%, representing increases of 29.3 and 33.5%, and a decrease of 63.5%, respectively, compared with the values for the thixoforged 2024 Al matrix alloy. During tensile testing, cracks were initiated in the secondary solidified structures, the debonded SiC/Al interface, and the cracked SiCp. For composites containing over 10 vol% SiCp, agglomerated SiCp acted as additional zones of crack initiation.

Keywords

- Type

- Articles

- Information

- Journal of Materials Research , Volume 31 , Issue 18: Focus Section: Reinventing Boron Chemistry for the 21st Century , 28 September 2016 , pp. 2850 - 2862

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 8

- Cited by