Article contents

Effect of rotating magnetic field on the fading effect of Al–5Ti–1B in commercial pure Al

Published online by Cambridge University Press: 12 August 2014

Abstract

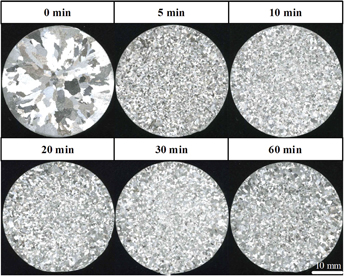

This study aims at understanding the effects of rotating magnetic field (RMF) on the fading effect of Al–5Ti–1B in commercial pure Al. The results indicate that fading effect is obvious after adding Al–5Ti–1B to Al with a holding time of 20 min. It is fair to claim that the fading effect can be eliminated to a great extent when RMF with magnetic flux densities of 6 and 12 mT is applied until the temperature decreases to 662 °C, which is mainly attributed to the homogeneous distribution of TiB2 particles caused by forced convection. However, refinement performance of pure Al by Al–5Ti–1B can be greatly weakened by RMF with an increase in magnetic flux density to 18 mT, since strong convection aggravates the agglomeration of TiB2 particles. In addition, the inoculated Al treated by a RMF of 6 mT until solidification exhibits a coarser solidification structure compared to that treated until the temperature decreased to 662 °C, which is mainly due to the prolongation of solidification time caused by Joule heat under RMF as proved by thermal analysis.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2014

References

REFERENCES

- 10

- Cited by