No CrossRef data available.

Published online by Cambridge University Press: 25 January 2016

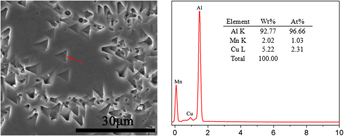

The effect of 0.5 wt% Mn addition on the microstructure and mechanical properties of cast Al–2Li–2Cu–0.8Mg–0.4Zn–0.2Zr (wt%) alloy was investigated. Results showed that the grain size of Mn-containing alloy was smaller than that of Mn-free alloy in both the as-cast and solution treated state. Al20Mn3Cu2 dispersoids were formed during solution treatment in the Mn-containing alloy. After aging at 175 °C for 32 h, a large volume fraction of coherent Al3Li/Al3(Li, Zr) particles were precipitated in both Mn-free and Mn-containing alloys, while more Guinier–Preston–Bagaratsky zones were observed in the Mn-free alloy. Mn addition improved the elongation significantly, which was 1.7% for Mn-free alloy and 3.3% for the alloy with 0.5 wt% Mn addition.