Article contents

Effect of laser hatch style on densification behavior, microstructure, and tribological performance of aluminum alloys by selective laser melting

Published online by Cambridge University Press: 28 June 2018

Abstract

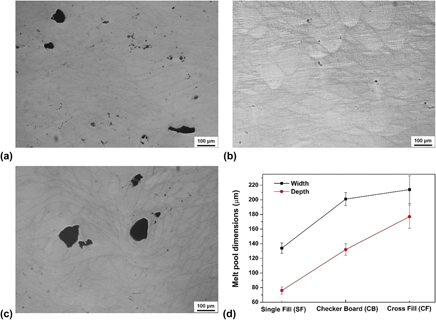

A systematic investigation of influence of the laser hatch style on densification behavior, microstructure, and tribological performance of aluminum parts’ preparation by selective laser melting (SLM) was implemented in this study. The scans with checker board (CB) style left better processing quality of surface morphology and few metallurgical defects to SLM parts in comparison with single fill and cross fill styles, hence leading to a relatively high densification level (99.42%). The CB style of shorter scan length left higher undercooling degree in small checker areas compared with other longer scan lengths, leading to finer equiaxed grains to the solidification microstructure. Accordingly, an enhanced mean microhardness of 129.7 HV0.1 was obtained in this hatch style, due to the grain refinement strengthening effect. The lowest coefficient of friction of 0.49 and wear rate of 2.43 × 10−4 mm3/(N m) were obtained. The improved densification level and formation of refined equiaxed grain and evenly distributed ring-shaped Si particles formed in CB parts changed the mechanism of material removal during sliding from the abrasion to adhesion of the tribolayer, significantly improving the wear resistance of SLM aluminum parts.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 10

- Cited by