Article contents

Effect of electropulsing-ultrasonic surface treatment on the surface properties and the corrosion behavior of 45 steel

Published online by Cambridge University Press: 16 May 2016

Abstract

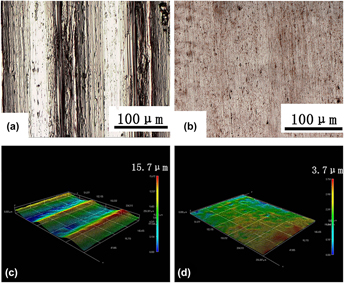

In the present study, the surface properties and the corrosion behavior of a nanocrystalline surface layer fabricated on 45 steel by electropulsing-ultrasonic surface treatment (EUST) were investigated. EUST offered the specimen a smooth (R a < 0.33 µm) surface layer with nanoscale grains and compressive stress by the synergistic effect of high-energy electropulsing processing and ultrasonic impact. Open-circuit potential, potentiodynamic polarization, and electrochemical impedance spectroscopy studies indicated that EUST-induced surface nanocrystallization decreased the corrosion susceptibility of 45 steel in 3.5 wt% NaCl aqueous solution, leading to a decrease in corrosion current density (i corr) by 55% and an increase in charge transfer resistance (R ct) by 36%. The enhancement in surface comprehensive mechanical properties and corrosion resistance can be explained in terms of the decrease in surface roughness, the extent of grain refinement and the change of stress state, which were closely related to the introduction of high-energy electropulsing processing.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

A correction has been issued for this article:

- 2

- Cited by

Linked content

Please note a has been issued for this article.