Article contents

Effect of bainite in microstructure on hydrogen diffusion and trapping behavior of ferritic steel used for sour service application

Published online by Cambridge University Press: 19 December 2016

Abstract

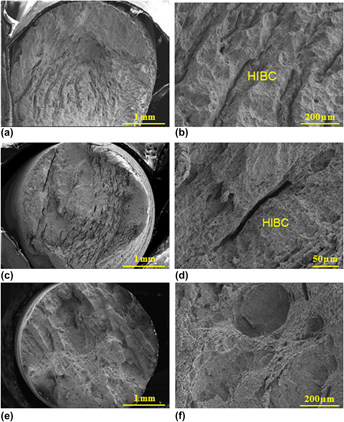

To clarify the effect of bainite in microstructure on hydrogen diffusion and trapping behavior and susceptibility to hydrogen assisted cracking of API grade linepipe steel, three specimens with different fraction of bainite in the microstructure are used. Firstly, hydrogen diffusion and trapping behaviors of the steels are studied by utilizing the electrochemical permeation technique. For fundamental analysis on the experimental data, a variety of diffusion parameters were determined by curve-fitting with a theoretical diffusion equation based on numerical finite difference method (FDM). It indicates that the steel with higher fraction of bainite exhibits much higher sub-surface hydrogen concentration and much lower apparent hydrogen diffusivity. This behavior can be understood by the fact that the steel containing higher fraction of bainite in the microstructure has higher concentration of reversible traps and consequent larger diffusible hydrogen, leading to much slower diffusion kinetics of hydrogen atoms. Consequently, the susceptibility to hydrogen induced cracking (HIC) and sulfide stress cracking (SSC) of the steel with higher fraction of bainite increases significantly.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 9

- Cited by