Published online by Cambridge University Press: 19 June 2020

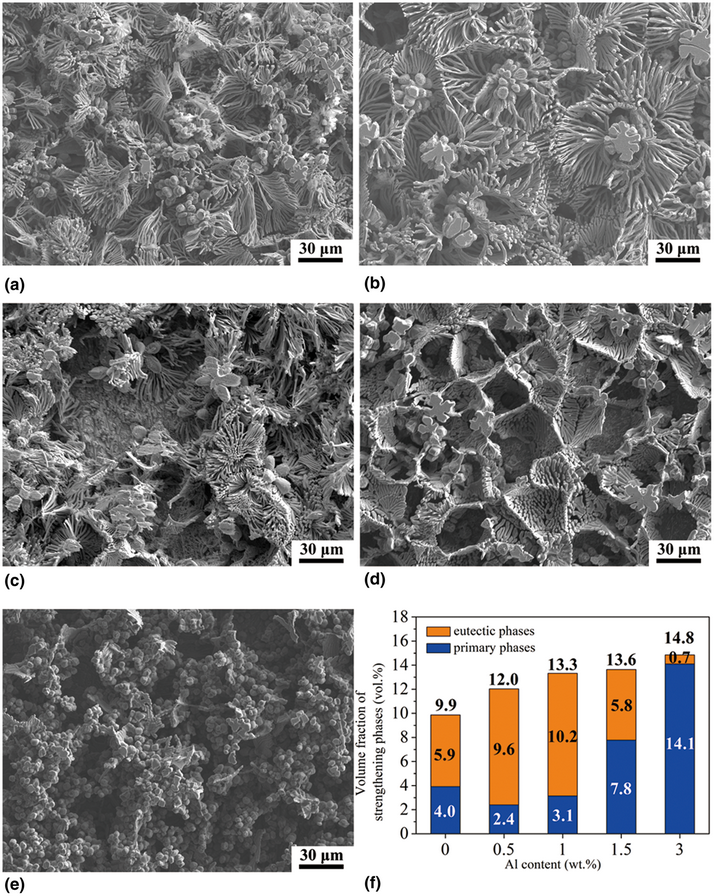

In the present study, the effect of Al addition on microstructure evolution, mechanical properties, and wear performances of a newly developed Ni–Si-containing complex brass was studied. The results showed that with increasing Al content from 0 to 3 wt%, the corresponding strengthening phase evolves from δ-Ni2Si to [Ni(Al)]2Si phases. Simultaneously, it is of great interest that the increasing Al addition also brings about a remarkable change in morphology of the secondary strengthening phase from dendrite and thin rod to regular block. Additionally, the hardness, yield strength and tensile strength of complex brass effectively increase with increasing Al content, and the fracture mechanism transforms from cleavage failure and microvoids accumulation fracture to cleavage failure. It was also found that the brass with adding 3 wt% Al exhibits the solidification microstructure with the uniform distribution of the block-shaped strengthening phase and has the best wear resistance. This present study provides a potential strategy for further improving the comprehensive performance of existing complex brass.