Published online by Cambridge University Press: 13 December 2016

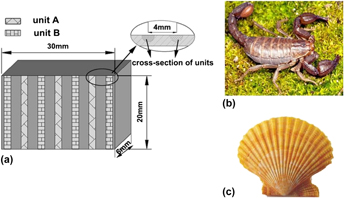

Wear resistance plays an important role to ensure the machining precision of machine tool using gray cast iron guide rail. Bio-inspired surfaces imitating the cuticle of desert scorpion and shell archetype with alternate units were prepared on gray cast iron using biomimetic coupling laser remelting in air and water. Samples consisting of striature bionic units with various distributions were examined under dry sliding condition using a home-made wear testing machine. It was found that samples with bionic units displayed better wear resistance than the untreated gray cast iron. While samples with bionic units processed in water by laser returned highest wear resistance in the short run, samples with alternatively distributed units (processed by laser) presented better wear resistance in the long run. However, to understand the stress distributions and the wear mechanism of the samples finite element method was used in this study. Based on the experimental evidences, a two-stage wear mechanism was proposed.