Article contents

Deformation-mechanism dependent stretchability of nanocrystalline gold films on flexible substrates

Published online by Cambridge University Press: 05 September 2017

Abstract

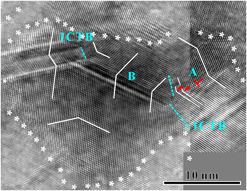

Stretchability of polyimide-supported nanocrystalline Au films with a thickness ranging from 930 to 20 nm was evaluated by uniaxial tensile testing. The results show that the fracture strain gradually decreased with decreasing the film thickness. Such degraded stretchability depends on plastic deformation mechanisms associated with the length scales. As the film thickness is larger than 90 nm, local thinning in the grown grains contributed to the high stretchability. Full dislocation behaviors including dislocation pileup in the 930 nm-thick film, the activation of Frank–Read dislocation source in the 170 nm-thick film and the grain boundary dislocation source in the 90 nm-thick film were dominated plastic deformation. As the film thickness is less than 40 nm, low stretchability of thin films resulted from intergranular fracture, and partial dislocation behaviors became prevailed. Evident grain growth happened in the films studied except for the 20 nm-thick film, which is expected to be involved in the stretchability of the nanocrystalline metal films on flexible substrates.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: George M. Pharr

References

REFERENCES

- 12

- Cited by