Article contents

Crack growth behavior in an aluminum alloy under very low stress amplitudes

Published online by Cambridge University Press: 18 July 2017

Abstract

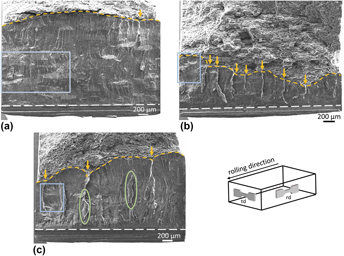

The near-threshold behavior of long cracks is studied in this paper using precracked flat dogbone specimens of a commercial aluminum alloy in peak-aged and overaged conditions. After introducing the initial crack in compression precracking, the crack was propagated approximately with the constant range of the stress intensity factor at values just above or below the corresponding threshold values. It was found that there were two major mechanisms which kept the crack from continuous extension. First, the crack front was pinned by primary precipitates. This effect was rather pronounced and lead to significant kinking in the crack front and ductile ridges on the fracture surface. The second mechanism was shear-controlled crack extension of very long cracks with plastic zones ahead of the crack tip, very similar to stage-I small cracks. Interaction with primary precipitates deflected the shear-controlled cracks but did not change the crack extension mode.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 32 , Issue 23: Focus Issue: Mechanical Properties and Microstructure of Advanced Metallic Alloys—in Honor of Prof. Haël Mughrabi PART A , 14 December 2017 , pp. 4354 - 4361

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Mathias Göken

References

REFERENCES

- 7

- Cited by