Article contents

Compression deformation behavior of semisolid Al2O3np reinforced 7075 aluminum matrix composites with high solid fraction

Published online by Cambridge University Press: 21 November 2016

Abstract

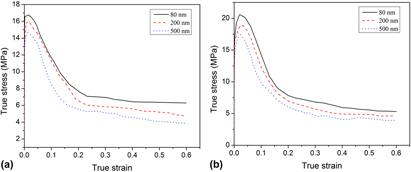

Semisolid forging is a type of semisolid metal processing with high solid fraction. However, the presence of nanosized particles has strong influences on flow behavior of the composites in the semisolid forging process. In this study, the compression deformation behavior of nanosized Al2O3 particles (Al2O3np) reinforced 7075 aluminum matrix composites with high solid fraction was investigated by conducting semisolid isothermal compression experiment. The microstructures after semisolid compression were characterized. The results showed that the true stress decreased with the increase of the deformation temperature and size of Al2O3np, the decrease of the strain rate and mass fraction of Al2O3np. After semisolid compression, deformation degree in large deformation zone was larger than that in free deformation zone. Besides, the solid grains in large deformation zone showed evidence of having undergone different degrees of plastic deformation under different deformation conditions. Simultaneously, the deformation mechanisms during the semisolid compression process were discussed.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 2

- Cited by