Article contents

Comparative evaluation of hot corrosion resistance of nanostructured AlCrN and TiAlN coatings on cobalt-based superalloys

Published online by Cambridge University Press: 25 March 2018

Abstract

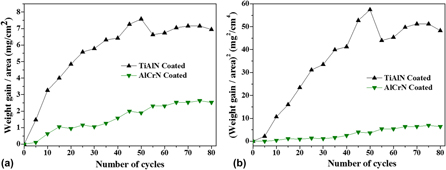

Molten vanadate-induced hot corrosion is the major cause of failure of superalloys which are generally used at higher temperatures (such as in internal combustion engines, gas turbines, high temperature tooling and dies, and petrochemical industries and marines). This effect can be minimized by applying thermally stable coatings over the superalloy. In this aspect, the current work investigates the effect of nanostructured aluminum chromium nitride (AlCrN) and titanium aluminum nitride (TiAlN) coatings on the hot corrosion behavior of Co-based superalloy, Superco-605, in an aggressive environment of Na2SO4–60% V2O5 (ratio by weight) at 700 °C up to 80 cycles. Each cycle consisted of 1 h heating at 700 °C followed by 20 min cooling in an ambient temperature. Hot corrosion kinetics was studied using the thermogravimetric technique and found to follow the parabolic rate law. The corrosion surface morphology and phases formed during hot corrosion were studied using field emission scanning electron microscopy equipped with energy dispersive spectroscopy and X-ray diffraction techniques. It was found that AlCrN coating had a better hot corrosion resistance than TiAlN coating.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 8

- Cited by