Article contents

Application of nonlinear ultrasonic technique to characterize the microresidual strain in metal

Published online by Cambridge University Press: 20 May 2019

Abstract

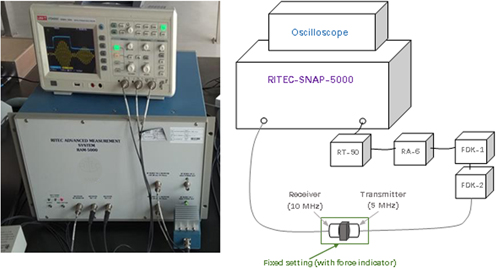

Residual strain often occurs in metal when it was subjected to the tension load, random vibration, or high impact. The mild steel was selected as the research object, and the feasibility of using nonlinear ultrasonic technique to characterize the residual strain was investigated in this paper. First, the mild steel specimens were stretched to several different kinds of stress, then the nonlinear effect as well as the microstrain of each sample was measured. The results indicate that the microstrain increases with increasing applied stress and reaches a maximum value of about 0.036% as the tensile stress increases to the elastic limit. Compared with the original specimen, the nonlinear parameter of tensile specimen gradually increased within the elastic limit. This result reveals that the variation of nonlinear parameter was related to microstrain in mild steel, because the microstructure observation demonstrated that the dislocation structure was basically unchanged within the elastic limit. This research indicates that the nonlinear ultrasonic method has the promising potential to characterize the microstrain in metals.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

Footnotes

Present address: Room1003, building Liu Qing, shuangqing road, Tsinghua University, Beijing 100084, China.

References

- 4

- Cited by