Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Niitsu, Kodai

Kimura, Yuta

Omori, Toshihiro

and

Kainuma, Ryosuke

2018.

Cryogenic superelasticity with large elastocaloric effect.

NPG Asia Materials,

Vol. 10,

Issue. 1,

p.

e457.

Uskoković, Vuk

Tang, Sean

and

Wu, Victoria M.

2018.

On Grounds of the Memory Effect in Amorphous and Crystalline Apatite: Kinetics of Crystallization and Biological Response.

ACS Applied Materials & Interfaces,

Vol. 10,

Issue. 17,

p.

14491.

Aaltio, Ilkka

Fukuda, Takashi

and

Kakeshita, Tomoyki

2019.

A Perspective on Elastocaloric Effect in Ti–Ni-Based Shape Memory Alloys.

Shape Memory and Superelasticity,

Vol. 5,

Issue. 3,

p.

230.

Niitsu, Kodai

Xu, Sheng

Kimura, Yuta

Omori, Toshihiro

and

Kainuma, Ryosuke

2019.

Cryogenic Superelasticity and Concomitant Elastocaloric Effect.

Materia Japan,

Vol. 58,

Issue. 1,

p.

44.

Liang, Chuanxin

Wang, Dong

Wang, Zhao

Ding, Xiangdong

and

Wang, Yunzhi

2020.

Revealing the atomistic mechanisms of strain glass transition in ferroelastics.

Acta Materialia,

Vol. 194,

Issue. ,

p.

134.

Niitsu, K.

Date, H.

and

Kainuma, R.

2020.

Thermal activation of stress-induced martensitic transformation in Ni-rich Ti-Ni alloys.

Scripta Materialia,

Vol. 186,

Issue. ,

p.

263.

Guo, Wenqian

Feng, Bo

Yang, Ying

Ren, Yang

Liu, Yinong

Yang, Hong

Yang, Qin

Cui, Lishan

Tong, Xin

and

Hao, Shijie

2022.

Effect of laser scanning speed on the microstructure, phase transformation and mechanical property of NiTi alloys fabricated by LPBF.

Materials & Design,

Vol. 215,

Issue. ,

p.

110460.

Niitsu, Kodai

Yano, Yoshiki

Kainuma, Ryosuke

and

Inui, Haruyuki

2022.

Thermal Activation Theory of Isothermal Martensitic Transformations: Classical Interpretation of Nonergodicity in Transformation Strain.

SSRN Electronic Journal ,

Niitsu, K.

Yano, Y.

Kainuma, R.

and

Inui, H.

2023.

Viscosity of superelasticity: A comprehensive interpretation of nonreciprocal isothermal dynamics, kinetic arrest, and nonergodic anelastic strain based on thermal activation of martensitic transformations.

Physical Review B,

Vol. 108,

Issue. 13,

Kimura, Yuta

Xu, Xiao

Han, Kwangsik

Niitsu, Kodai

Omori, Toshihiro

Umetsu, Rie Y.

and

Kainuma, Ryosuke

2023.

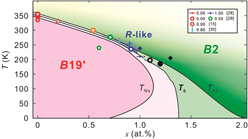

R-Phase Transformation in Ti<sub>50−</sub><i><sub>x</sub></i>Ni<sub>47+</sub><i><sub>x</sub></i>Fe<sub>3</sub> Shape Memory Alloys.

MATERIALS TRANSACTIONS,

Vol. 64,

Issue. 7,

p.

1591.

Ryklina, Elena

Polyakova, Kristina

Komarov, Victor

Murygin, Semen

Konopatsky, Anton

Andreev, Vladimir

and

Ulanov, Adilet

2024.

On Transformation and Stress–Strain–Temperature Behavior of Fine-Grained Ni-Rich NiTi Wire vs. Aging Mode.

Metals,

Vol. 15,

Issue. 1,

p.

3.

Li, Qiuzhen

Chen, Yuxuan

Liu, Yinong

Jiang, Daqiang

Yang, Youyi

Yang, Hong

Yu, Kaiyuan

Ren, Yang

and

Cui, Lishan

2024.

Non-linear temperature dependences of pseudoelastic stress and stress hysteresis of a nanocrystalline Ni47Ti50Fe3 alloy.

Acta Materialia,

Vol. 265,

Issue. ,

p.

119625.

Chu, Hanchi

Zhao, Zhihao

Fang, Jiaye

Xiao, Yao

Lin, Jianping

and

Min, Junying

2025.

Ni nanosegregation reduces temperature dependence of stress-induced martensitic transformation in Ni50.9Ti49.1 shape memory alloy.

Journal of Materials Research and Technology,

Vol. 35,

Issue. ,

p.

4996.