Article contents

Study on cross-sectional deformation of rectangular waveguide tube with different materials in rotary draw bending

Published online by Cambridge University Press: 05 September 2017

Abstract

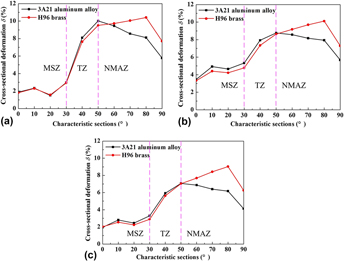

Material mechanical behavior of tube has an essential influence on cross-sectional deformation of rectangular waveguide tube in rotary draw bending (RDB) process. Thus, taking widely used 3A21 aluminum alloy and H96 brass rectangular tubes as research objects, the cross-sectional deformation of these tubes in RDB with and without mandrel was investigated using the reliable three-dimensional finite element models. The results show that when no mandrel is used, compared with 3A21 tube, the position of wrinkle initiation for H96 tube is closer to the final bending section, and the cross-sectional deformation of H96 tube along bending direction is more homogeneous. When a mandrel is used, in bending process, the cross-sectional deformation of 3A21 tube in mandrel support zone (MSZ) is in coincidence with that of H96 tube, and the deformation of 3A21 tube is larger in transition zone (TZ) while smaller in no mandrel affect zone (NMAZ) than that of H96 tube. In retracting mandrel or springback process, the cross-sectional deformation of 3A21 tube in MSZ and TZ is constantly larger than that of H96 tube, while in NMAZ, the deformation of both tubes reverses.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 5

- Cited by