No CrossRef data available.

Article contents

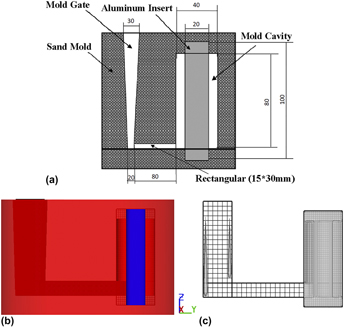

Prediction of the contact time through modeling of heat transfer and fluid flow in compound casting process of Al/Mg light metals

Published online by Cambridge University Press: 25 April 2017

Abstract

In this study, the time that molten magnesium is in contact with the aluminum insert before solidification was predicted by solving the conservation equations of mass, momentum, and energy during compound casting of dissimilar Al/Mg couples. For this purpose, a three-dimensional transient model and FLOW-3D software were utilized and distributions of temperature and velocity vectors in the fluid over time were obtained. Then, the contact time at the bottom, middle, and top of aluminum insert in its interface with the magnesium melt was calculated. The results of simulation show that the contact time decreases from about 1.7 s at bottom to 1.6 s at middle and 0.8 s at top of the interface, respectively. This is consistent with the experimental metallographic observations which indicate a decrease in the thickness of formed intermetallic compounds from bottom to middle and top of the Al/Mg interface.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert