Article contents

A polycrystalline SiC-on-Si architecture for capacitive pressure sensing applications beyond 400 °C: Process development and device performance

Published online by Cambridge University Press: 16 August 2012

Abstract

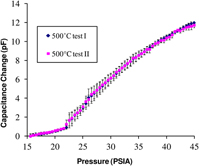

To overcome the low fabrication yield associated with single crystalline 3C–SiC diaphragm-based high temperature capacitive pressure sensors fabricated by wafer bonding, we have developed an alternative based on a polycrystalline SiC-on-Si architecture. The capacitive pressure sensing element, i.e., a thin film diaphragm, was fabricated using low stress and high conductivity low-pressure chemical vapor deposition poly-SiC thin films, and the sensing architecture was formed by wafer bonding a poly-SiC film to a Si substrate using phosphosilicate glass bonding films. With a geometric aspect ratio of up to 800:1 and a maximum deflection load eight times or more to their thickness, the poly-SiC diaphragm-based sensors presented repeatable pressure sensing characteristics up to 500 °C.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 28 , Issue 1: Focus Issue: Silicon Carbide – Materials, Processing and Devices , 14 January 2013 , pp. 120 - 128

- Copyright

- Copyright © Materials Research Society 2012

References

REFERENCES

- 3

- Cited by