Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Feng, Yifei

Chen, Xia

Li, Yangyang

You, Wenhao

Li, Xianzhuo

and

Chen, Bin

2022.

First-principles calculations to investigate mechanical, thermodynamic and electronic properties of Al2CuMg intermetallic compound under pressure effect.

Computational Condensed Matter,

Vol. 33,

Issue. ,

p.

e00738.

Yasuhara, Akira

and

Sannomiya, Takumi

2022.

Atomically Localized Ordered Phase and Segregation at Grain Boundaries in Au–Ag–Cu Ternary Alloy Nanoparticles.

The Journal of Physical Chemistry C,

Vol. 126,

Issue. 2,

p.

1160.

Chen, Xuanliang

O, Minho

and

Kobayashi, Equo

2022.

Enhanced mechanical properties in an Al-Mg-Cu alloy processed by the combination of cyclic deformation and aging heat treatment.

Journal of Alloys and Compounds,

Vol. 911,

Issue. ,

p.

165070.

Prakashaiah, B. G.

Jayaprakash, Gururaj Kudur

and

Rani, B. E. Amitha

2022.

A Study of Corrosion Behavior of (E)-2-(3,4-dihydroxybenzylidene)hydrazinecarbothioamide and Bis [[3,4-dihydroxyphenylmethylene] Carbonothioicdihydrazide]-Sealed Anodized AA2024-T3.

Journal of Bio- and Tribo-Corrosion,

Vol. 8,

Issue. 3,

Masoumi Khalilabad, Mahdi

Zedan, Yasser

Texier, Damien

Jahazi, Mohammad

and

Bocher, Philippe

2022.

Effect of heat treatments on microstructural and mechanical characteristics of dissimilar friction stir welded 2198/2024 aluminum alloys.

Journal of Adhesion Science and Technology,

Vol. 36,

Issue. 3,

p.

221.

Zafar, Humaira

Khushaim, Muna

Ravaux, Florent

and

Anjum, Dalaver H.

2022.

Scale-Dependent Structure–Property Correlations of Precipitation-Hardened Aluminum Alloys: A Review.

JOM,

Vol. 74,

Issue. 2,

p.

361.

Reza-E-Rabby, Md.

Wang, Tianhao

Canfield, Nathan

Graff, Daniel

Roosendaal, Timothy

and

Whalen, Scott

2022.

Light Metals 2022.

p.

301.

Reza-E-Rabby, Md.

Wang, Tianhao

Canfield, Nathan

Roosendaal, Timothy

Taysom, Brandon Scott

Graff, Daniel

Herling, Darrell

and

Whalen, Scott

2022.

Effect of various post-extrusion tempering on performance of AA2024 tubes fabricated by shear assisted processing and extrusion.

CIRP Journal of Manufacturing Science and Technology,

Vol. 37,

Issue. ,

p.

454.

Pancho, Antonio

Puchkov, Y. A.

Dung, Mai Xuan

and

Georgina, Almeida

2022.

Residual stresses reduction for 2024 aluminum drill rod in geologic drilling applying cryogenic treatment.

Vol. 2559,

Issue. ,

p.

030008.

Reimann, Maximilian Kai

and

Pöttgen, Rainer

2023.

Magnesium and barium in two substructures: BaTMg2 (T = Pd, Ag, Pt, Au) and the isotypic cadmium compound BaAuCd2 with MgCuAl2 type structure.

Zeitschrift für Kristallographie - Crystalline Materials,

Vol. 238,

Issue. 1-2,

p.

57.

Seo, Namhyuk

Jeon, Junhyub

Lee, Sang-Hwa

Euh, Kwangjun

Kim, Su-Hyeon

Ahn, Tae-Young

Son, Seung Bae

Lee, Seok-Jae

and

Jung, Jae-Gil

2023.

Revealing complex precipitation behavior of multicomponent Al83Zn5Cu5Mg5Li2 alloy.

Journal of Alloys and Compounds,

Vol. 944,

Issue. ,

p.

169192.

Trdan, Uroš

Klobčar, Damjan

Berthe, Laurent

Šturm, Roman

and

Bergant, Zoran

2023.

High-cycle fatigue enhancement of dissimilar 2017A-T451/7075-T651 Al alloy joint fabricated by a single pass FSW without any post-processing.

Journal of Materials Research and Technology,

Vol. 25,

Issue. ,

p.

2333.

Daoud, Mohamed E.

Taha, Inas

Helal, Mohamed

Kamoutsi, H.

Haidemenopoulos, G.N.

Khan, Kamran A.

and

Anjum, Dalaver H.

2024.

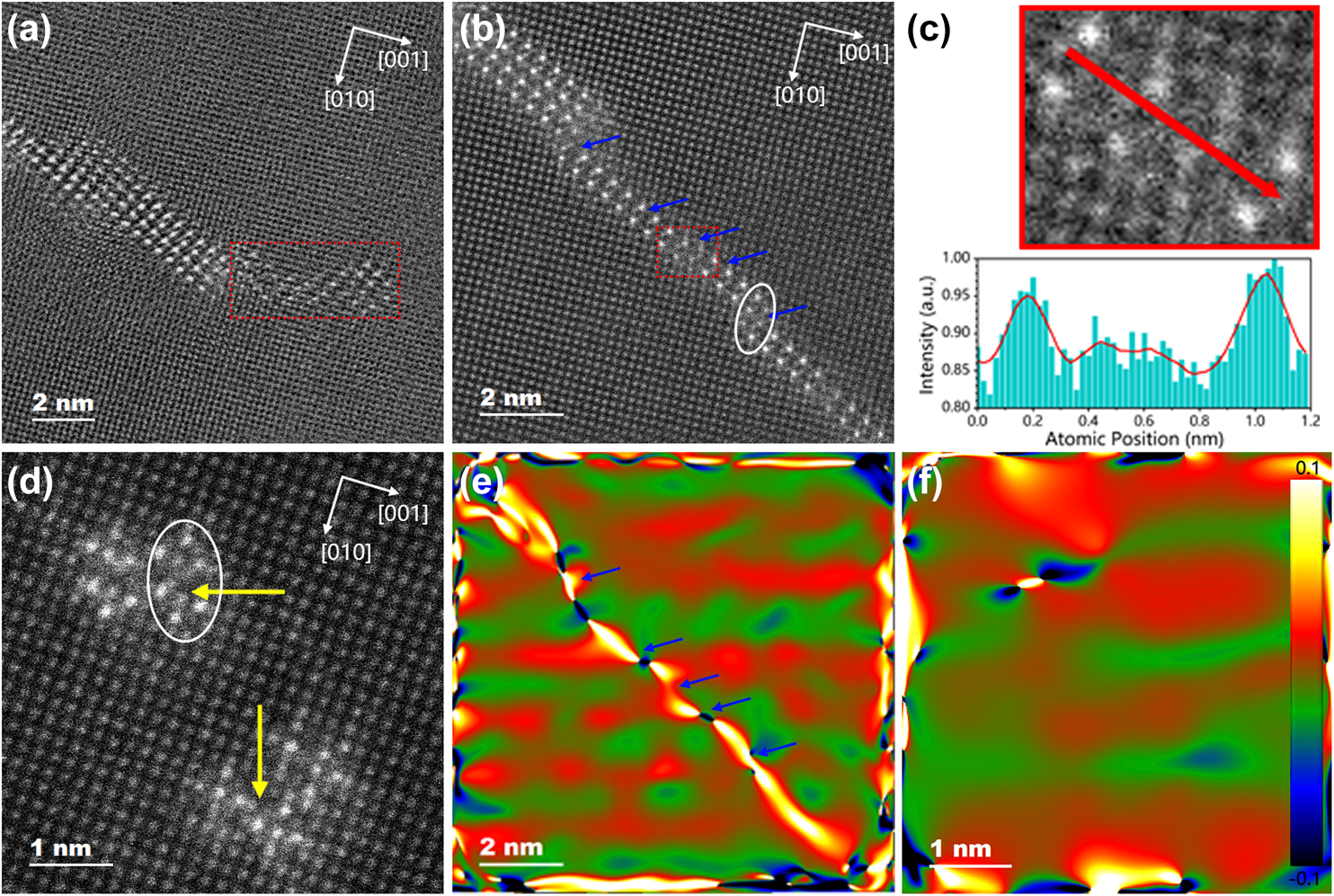

Nanoscale mapping of residual stresses in Al 2024 alloys using correlative and multimodal scanning transmission electron microscopy.

Heliyon,

Vol. 10,

Issue. 9,

p.

e30280.

Tai, Cheng-Ling

Chiu, Yu-Ning

Chen, Chu-Jen

Lin, Shih-Kang

Lin, Hsin-Chih

Misra, R. Devesh Kumar

Yang, Yo-Lun

Hsiao, Chien-Nan

Tsao, Cheng-Si

and

Chung, Tsai-Fu

2025.

Phenomenological understanding of the contribution of bulk and grain boundary precipitates on strengthening in prolonged-aged Al-Zn-Mg-Cu aluminium alloys.

Materials Today Advances,

Vol. 25,

Issue. ,

p.

100557.