Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Bekah, Sacheen

Rabiei, Reza

and

Barthelat, Francois

2011.

Structure, Scaling, and Performance of Natural Micro- and Nanocomposites.

BioNanoScience,

Vol. 1,

Issue. 1-2,

p.

53.

Humburg, Heide

Zhu, Deju

Beznia, Samia

and

Barthelat, Francois

2012.

Bio-inspired tapered fibers for composites with superior toughness.

Composites Science and Technology,

Vol. 72,

Issue. 9,

p.

1012.

Cavelier, Sacha

Barrett, Christopher J.

and

Barthelat, Francois

2012.

The Mechanical Performance of a Biomimetic Nanointerface Made of Multilayered Polyelectrolytes.

European Journal of Inorganic Chemistry,

Vol. 2012,

Issue. 32,

p.

5380.

Corni, I

Harvey, T J

Wharton, J A

Stokes, K R

Walsh, F C

and

Wood, R J K

2012.

A review of experimental techniques to produce a nacre-like structure.

Bioinspiration & Biomimetics,

Vol. 7,

Issue. 3,

p.

031001.

Chen, Po-Yu

McKittrick, Joanna

and

Meyers, Marc André

2012.

Biological materials: Functional adaptations and bioinspired designs.

Progress in Materials Science,

Vol. 57,

Issue. 8,

p.

1492.

Sun, Jiyu

and

Bhushan, Bharat

2012.

Hierarchical structure and mechanical properties of nacre: a review.

RSC Advances,

Vol. 2,

Issue. 20,

p.

7617.

Shao, Yue

Zhao, Hong-Ping

Feng, Xi-Qiao

and

Gao, Huajian

2012.

Discontinuous crack-bridging model for fracture toughness analysis of nacre.

Journal of the Mechanics and Physics of Solids,

Vol. 60,

Issue. 8,

p.

1400.

Barthelat, Francois

Dastjerdi, Ahmad Khayer

and

Rabiei, Reza

2013.

An improved failure criterion for biological and engineered staggered composites.

Journal of The Royal Society Interface,

Vol. 10,

Issue. 79,

p.

20120849.

Sullivan, Marianne

and

Prorok, Barton C.

2013.

Mechanics of Biological Systems and Materials, Volume 5.

p.

39.

Parratt, Kirsten

and

Yao, Nan

2013.

Nanostructured Biomaterials and Their Applications.

Nanomaterials,

Vol. 3,

Issue. 2,

p.

242.

Lasko, Galina

Burghard, Zaklina

Bill, Joachim

Schäfer, Immanuel

Weber, Ulrich

and

Schmauder, Siegfried

2013.

Simulation of Mechanical Properties of Bio‐Inspired TiO2/PE Nanocomposites.

Advanced Engineering Materials,

Vol. 15,

Issue. 10,

p.

908.

Li, Yaning

Ortiz, Christine

and

Boyce, Mary C.

2013.

A generalized mechanical model for suture interfaces of arbitrary geometry.

Journal of the Mechanics and Physics of Solids,

Vol. 61,

Issue. 4,

p.

1144.

Mirkhalaf, Mohammad

Zhu, Deju

and

Barthelat, Francois

2013.

Engineered Biomimicry.

p.

59.

Rabiei, Reza

Dastjerdi, Ahmad Khayer

and

Barthelat, Francois

2013.

Mechanics of Biological Systems and Materials, Volume 5.

p.

31.

Khayer Dastjerdi, Ahmad

Rabiei, Reza

and

Barthelat, Francois

2013.

The weak interfaces within tough natural composites: Experiments on three types of nacre.

Journal of the Mechanical Behavior of Biomedical Materials,

Vol. 19,

Issue. ,

p.

50.

Zhu, Deju

Humburg, Heide

and

Barthelat, Francois

2013.

Mechanics of Biological Systems and Materials, Volume 5.

p.

135.

Schäfer, I.

Lasko, G.

Do, T.A.

Pleiss, J.

Weber, U.

and

Schmauder, S.

2014.

Peptide–zinc oxide interaction: Finite element simulation using cohesive zone models based on molecular dynamics simulation.

Computational Materials Science,

Vol. 95,

Issue. ,

p.

320.

Shao, Yue

Zhao, Hong-Ping

and

Feng, Xi-Qiao

2014.

On flaw tolerance of nacre: a theoretical study.

Journal of The Royal Society Interface,

Vol. 11,

Issue. 92,

p.

20131016.

Liu, Qiang

Ma, Yongjun

Duan, Xiaohui

Zhou, Yong

Liu, Xun

and

Pei, Chonghua

2014.

Controlled crystallization of lamellar calcium carbonate crystals induced by solution of sticky rice polysaccharide (from Oryza sativa).

CrystEngComm,

Vol. 16,

Issue. 48,

p.

11042.

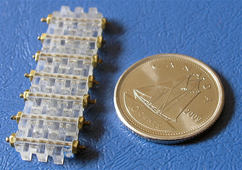

Chintapalli, Ravi Kiran

Mirkhalaf, Mohammad

Dastjerdi, Ahmad Khayer

and

Barthelat, Francois

2014.

Fabrication, testing and modeling of a new flexible armor inspired from natural fish scales and osteoderms.

Bioinspiration & Biomimetics,

Vol. 9,

Issue. 3,

p.

036005.