Article contents

A multiscale study of misfit dislocations in PbTe/PbSe(001) heteroepitaxy

Published online by Cambridge University Press: 29 April 2019

Abstract

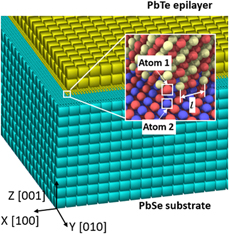

In this work, we investigate misfit dislocations in PbTe/PbSe heteroepitaxial systems using the concurrent atomistic–continuum (CAC) method. A potential model containing the long-range Coulombic interaction and short-range Buckingham potential is developed for the system. By considering the minimum potential energy of relaxed interface structures for various initial conditions and PbTe layer thicknesses, the equilibrium structure of misfit dislocations and the dislocation spacings in PbTe/PbSe(001) heteroepitaxial thin films are obtained as a function of the PbTe layer thicknesses grown on a PbSe substrate. The critical layer thickness above which misfit dislocations inevitably form, the structure of the misfit dislocations at the interfaces, and the dependence of average dislocation spacing on PbTe layer thickness are obtained and discussed. The simulation results provide an explanation for the narrowing of the spread of the distribution of misfit dislocation spacing as layer thickness increases in PbTe/PbSe(001) heteroepitaxy.

Keywords

- Type

- Invited Paper

- Information

- Journal of Materials Research , Volume 34 , Issue 13: Focus Issue: Intrinsic and Extrinsic Size Effects in Materials , 15 July 2019 , pp. 2306 - 2314

- Copyright

- Copyright © Materials Research Society 2019

References

- 10

- Cited by