Article contents

Microstructure dependent fatigue crack growth characteristics in the Ni–17Mo–7Cr base superalloy before and after thermal exposure

Published online by Cambridge University Press: 21 November 2016

Abstract

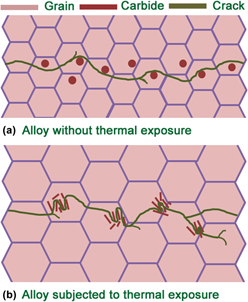

The fatigue crack growth (FCG) tests were performed on a Ni–17Mo–7Cr base superalloy before and after thermal exposure to investigate the influence of microstructural variation on the alloy's FCG behavior. It was observed that the original alloy consists of Ni matrix and MoC particles. When the alloy was aged at 1350 °C for 0.5 h, the MoC melts together with circumambient Ni matrix, forming a eutectic–like structure. The microstructural analysis shows that, for original alloy, the crack basically propagates in the matrix. When it encounters the particles, the crack meanders to avoid them, creating a linear da/dN–ΔK curve. As the crack approaches the eutectic-like structures within the aged alloy, however, it cuts through them but circumvents tiny particles within the structures, producing torturous crack paths and waved da/dN–ΔK curve. The aged alloy has a higher FCG resistance in contrast to original alloy.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 1

- Cited by