Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Khanna, Rohit

Rajeev, Ganapathiyankavu Pisharam

Takadama, Hiroaki

and

Rao Bakshi, Srinivasa

2017.

Fabrication of dense alumina layer on Ti alloy hybrid by cold metal transfer and micro-arc oxidation methods.

Journal of Materials Research,

Vol. 32,

Issue. 17,

p.

3415.

Zhou, Xianglong

Zhang, Gang

Shi, Yu

Zhu, Ming

and

Yang, Fuqian

2017.

Microstructures and mechanical behavior of aluminum-copper lap joints.

Materials Science and Engineering: A,

Vol. 705,

Issue. ,

p.

105.

Jayabalakrishnan, D.

and

Balasubramanian, M.

2018.

Eccentric-weave FSW between Cu and AA 6061-T6 with reinforced Graphene nanoparticles.

Materials and Manufacturing Processes,

Vol. 33,

Issue. 3,

p.

333.

Liu, Yan

Yao, Yu

Ye, Haiqing

and

Zhang, Luxin

2018.

Study on microstructure and properties of dissimilar welded joints of steel and aluminum by CMT welding process.

IOP Conference Series: Materials Science and Engineering,

Vol. 382,

Issue. ,

p.

042025.

Furuya, H. S.

Sato, Y. S.

Kokawa, H.

Huang, T.

and

Xiao, R. S.

2018.

Improvement of Interfacial Strength with the Addition of Ni in Al/Cu Dissimilar Joints Produced via Laser Brazing.

Metallurgical and Materials Transactions A,

Vol. 49,

Issue. 12,

p.

6215.

Ko, Sang-Jin

An, Jeong-Hun

Kim, Yong-Sang

and

Kim, Jung-Gu

2019.

Failure analysis of an Al Cu joint manufactured by eutectic diffusion bonding in evaporator tubes.

Engineering Failure Analysis,

Vol. 98,

Issue. ,

p.

167.

Zhang, Hengming

Shi, Yu

Gu, Yufen

and

Li, Chunkai

2020.

Effect of Different Filler Wires on Mechanical Property and Conductivity of Aluminum-Copper Joints.

Materials,

Vol. 13,

Issue. 16,

p.

3648.

Fan, Ding

Yang, Nan

Huang, Jiankang

and

Yu, Xiaoquan

2021.

Plasma arc welding-brazing of aluminum to copper with SiO2 nanoparticles strengthening.

Journal of Manufacturing Processes,

Vol. 69,

Issue. ,

p.

253.

Furuya, Hiroki S.

Yabu, Sakiko

Sato, Yutaka S.

and

Kokawa, Hiroyuki

2021.

Microstructural Control of the Interface Layer for Strength Enhancement of Dissimilar Al/Cu Joints via Ni Addition during TIG Arc Brazing.

Metals,

Vol. 11,

Issue. 3,

p.

491.

Harati, Ehsan

and

Kah, Paul

2022.

Laser welding of aluminum battery tab to variable Al/Cu busbars in Li-ion battery joint.

AIMS Materials Science,

Vol. 9,

Issue. 6,

p.

884.

Dang, Zongyu

Qin, Guoliang

and

Li, Tongyi

2023.

Microstructure evolution and tensile strength of Al/Cu inertia friction welded joint.

Journal of Materials Research and Technology,

Vol. 27,

Issue. ,

p.

4023.

Mondal, Mounarik

Shin, Joonghan

and

Lee, Donkyoung

2023.

Effect of bottom sheet thickness on weld properties during laser lap welding of aluminum and copper.

The International Journal of Advanced Manufacturing Technology,

Vol. 128,

Issue. 9-10,

p.

4635.

Guo, Jinchang

Li, Chunkai

Bian, Jianxiao

Zhang, Jianrui

and

Geng, Baolong

2023.

Microstructures and Electrical Resistivity of Aluminum–Copper Joints.

Metals,

Vol. 13,

Issue. 8,

p.

1474.

Xu, Wenhu

Yang, Jin

Peng, Mingjian

Zhao, Yixuan

Liu, Hongbin

Deng, Peiran

Gao, Yanfeng

and

Zhang, Hua

2023.

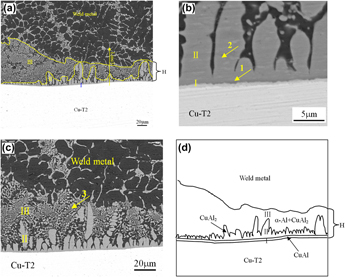

Characteristics of Torch-Offset Cold Metal Transition-Cycle Step Welding of 5052Al Alloy with T2 Copper via Al-12Si Filler.

Journal of Materials Engineering and Performance,

Vol. 32,

Issue. 2,

p.

587.

Wang, Leilei

Li, Nian

Wei, Xinlong

Ling, Xiang

and

Li, Qingsheng

2023.

Effects of nickel layer on interfacial micro-structure distribution and macro-mechanical properties for vacuum-brazed dissimilar steel joints.

Welding in the World,

Vol. 67,

Issue. 10,

p.

2391.

Kaisheva, Darina

Kotlarski, Georgi

Ormanova, Maria

Anchev, Angel

Dunchev, Vladimir

Stoyanov, Borislav

and

Valkov, Stefan

2024.

Electron Beam Welding of Copper and Aluminum Alloy with Magnetron Sputtered Titanium Filler.

Crystals,

Vol. 14,

Issue. 9,

p.

752.

He, Huan

Liu, Zhaoxian

Zhang, Lixin

Liu, Zheng

Tian, Xu

Guo, Dehua

Guo, Zhiwen

Yang, Yarong

Fu, Ao

and

Zhao, Wenzhen

2024.

Microstructure and Properties of Dissimilar Butt Joints of Aluminum to Copper by Cold Metal Transfer with Preheating.

JOM,

Vol. 76,

Issue. 9,

p.

5149.

Kumar, Nikhil

Pamarthi, Venkat Vivek

Harris, Christopher

Burbidge, Elliot

and

Masters, Iain

2024.

Dual-mode laser beam welding of similar and dissimilar material tab-to-busbar for electric vehicle battery pack.

Journal of Advanced Joining Processes,

Vol. 10,

Issue. ,

p.

100250.