Article contents

Lithium-assisted creep deformation behavior of Sn nanoparticle electrode with fracture-resistant ability

Published online by Cambridge University Press: 04 December 2019

Abstract

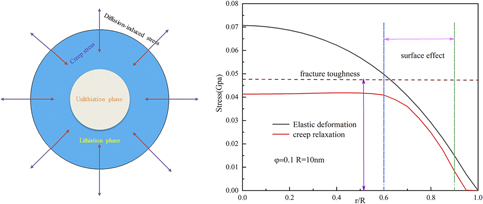

Mechanical fracture of electrodes will occur during lithiation caused by large volume changes, which leads to the capacity loss of the lithium-ion battery. Herein, we present a new analytical model to investigate the effect of creep deformation on stress relaxation and fracture of the lithiated tin (Sn) electrode under the galvanostatic and potentiostatic operation. Interestingly, it is found that the presence of creep can improve fracture resistance and toughness of the Sn electrode. In addition, the surface effect has the capacity to weaken the creep deformation effectively. And the different size of the Sn electrode shows different effects for creep deformation. This conclusion explains the difference in charging conditions, and the mechanism of stress change inside the electrode is also different. Deeply, the base on our model, the stress strength factor, and critical size of the electrode have been evaluated under galvanostatic and potentiostatic operation with creep deformation effects. Finally, the safety area during lithiation is established to determine the critical size of the Sn electrode. And the presence of creep deformation may significantly increase critical dimensions of the electrode. These results will provide a valuable basis to design the durable electrodes.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 3

- Cited by