Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Savinov, Roman

Wang, Yachao

Wang, Jin

and

Shi, Jing

2021.

Comparison of microstructure and properties of CoCrFeMnNi high-entropy alloy from selective laser melting and directed energy deposition processes.

Procedia Manufacturing,

Vol. 53,

Issue. ,

p.

435.

Ullah, Abid

Ur Rehman, Asif

Salamci, Metin Uymaz

Pıtır, Fatih

and

Liu, Tingting

2022.

The influence of laser power and scanning speed on the microstructure and surface morphology of Cu2O parts in SLM.

Rapid Prototyping Journal,

Vol. 28,

Issue. 9,

p.

1796.

Cunha, Ângela

Marques, Ana

Silva, Mariana Rodrigues

Bartolomeu, Flávio

Silva, Filipe Samuel

Gasik, Michael

Trindade, Bruno

and

Carvalho, Óscar

2022.

Laser powder bed fusion of the steels used in the plastic injection mould industry: a review of the influence of processing parameters on the final properties.

The International Journal of Advanced Manufacturing Technology,

Vol. 121,

Issue. 7-8,

p.

4255.

Sefene, Eyob Messele

2022.

State-of-the-art of selective laser melting process: A comprehensive review.

Journal of Manufacturing Systems,

Vol. 63,

Issue. ,

p.

250.

Mostahsan, Amirhossein Jabbari

and

Farahmand, Farzam

2022.

Influence of cleaning process on mechanical properties and surface characteristics of selective laser melted Ti6Al4V parts prepared for medical implant applications.

Journal of Materials Research,

Vol. 37,

Issue. 16,

p.

2546.

AYDIN, Dilara Selma

ÖZSOY, Arif Lütfi

and

YILDIRIM, Çağrı Vakkas

2022.

Ti6Al4V Alaşımının SLM Yöntemiyle Üretilmesinde Taguchi Metodu Kullanılarak Proses Parametrelerinin Optimizasyonu.

International Journal of Innovative Engineering Applications,

Vol. 6,

Issue. 2,

p.

230.

Cerri, Emanuela

Ghio, Emanuele

and

Bolelli, Giovanni

2022.

Effect of surface roughness and industrial heat treatments on the microstructure and mechanical properties of Ti6Al4V alloy manufactured by laser powder bed fusion in different built orientations.

Materials Science and Engineering: A,

Vol. 851,

Issue. ,

p.

143635.

Praveen Kumar, D.

and

Vinoth Jebaraj, A.

2022.

Role of Volumetric Energy Density and Post-Heat Treatments to Achieve Stable Microstructure on Additive Manufactured Ti6Al4V Alloy.

Transactions of the Indian Institute of Metals,

Vol. 75,

Issue. 12,

p.

3077.

Yang, Guodong

Zhang, Jialian

Xie, Houbo

Li, Faliang

Huang, Zhong

Yuan, Gaoqian

Zhang, Jingzhe

Jia, Quanli

Zhang, Haijun

Yeprem, Hasibe Aygul

and

Zhang, Shaowei

2022.

Preparation of B4Cp/Al Composites via Selective Laser Melting and Their Tribological Properties.

Materials,

Vol. 15,

Issue. 23,

p.

8340.

Primus, Tomáš

Beránek, Libor

Pitrmuc, Zdeněk

Šimota, Jan

and

Zeman, Pavel

2022.

Laser polishing of additively manufactured 316L stainless steel with different construction angles.

The International Journal of Advanced Manufacturing Technology,

Vol. 121,

Issue. 5-6,

p.

3215.

Gao, Chaofeng

Tang, Huaping

Zhang, Shiheng

Ma, Zhibo

Bi, Yunjie

and

Rao, Jeremy-Heng

2022.

Process Optimization for Up-Facing Surface Finish of AlSi10Mg Alloy Produced by Laser Powder Bed Fusion.

Metals,

Vol. 12,

Issue. 12,

p.

2053.

Aufa, A.N.

Hassan, Mohamad Zaki

and

Ismail, Zarini

2022.

Recent advances in Ti-6Al-4V additively manufactured by selective laser melting for biomedical implants: Prospect development.

Journal of Alloys and Compounds,

Vol. 896,

Issue. ,

p.

163072.

Wang, Shuhao

Ning, Jinsheng

Zhu, Lida

Yang, Zhichao

Yan, Wentao

Dun, Yichao

Xue, Pengsheng

Xu, Peihua

Bose, Susmita

and

Bandyopadhyay, Amit

2022.

Role of porosity defects in metal 3D printing: Formation mechanisms, impacts on properties and mitigation strategies.

Materials Today,

Vol. 59,

Issue. ,

p.

133.

Soundarapandiyan, Gowtham

Leung, Chu Lun Alex

Johnston, Carol

Bhatt, Alisha

H.U. Khan, RAJA

McNutt, Phil

Atwood, Robert C.

Lee, Peter

Chen, Bo

and

Fitzpatrick, Michael E.

2022.

Effects of Ti6al4v Powder Oxidation on Process Dynamics in Laser Powder Bed Fusion Additive Manufacturing.

SSRN Electronic Journal ,

Duan, Weipeng

Wu, Meiping

Han, Jitai

Ma, Yiqing

and

Miao, Xiaojin

2022.

Effect of layer thickness on the overhanging surface quality manufactured by selective laser melting.

Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science,

Vol. 236,

Issue. 9,

p.

4818.

Elambasseril, Joe

Rogers, Jason

Wallbrink, Chris

Munk, David

Leary, Martin

and

Qian, M.

2023.

Laser powder bed fusion additive manufacturing (LPBF-AM): the influence of design features and LPBF variables on surface topography and effect on fatigue properties.

Critical Reviews in Solid State and Materials Sciences,

Vol. 48,

Issue. 1,

p.

132.

Soundarapandiyan, Gowtham

Leung, Chu Lun Alex

Johnston, Carol

Chen, Bo

Khan, Raja H.U.

McNutt, Phil

Bhatt, Alisha

Atwood, Robert C.

Lee, Peter D.

and

Fitzpatrick, Michael E.

2023.

In situ monitoring the effects of Ti6Al4V powder oxidation during laser powder bed fusion additive manufacturing.

International Journal of Machine Tools and Manufacture,

Vol. 190,

Issue. ,

p.

104049.

Rehman, Mudassar

Wang, Yanen

Ishfaq, Kashif

Mushtaq, Ray Tahir

Kumar, M. Saravana

and

Yang, Haiou

2023.

Potential assessment in laser powder bed fusion of bionic porous Ti scaffolds concerning compressive behavior, porosity, and surface roughness.

Journal of Manufacturing Processes,

Vol. 95,

Issue. ,

p.

461.

Lu, Xuben

Shu, Chang

Zheng, Zhiyu

Shu, Xuedao

Chen, Siyuan

Essa, Khamis

Li, Zixuan

and

Xu, Haijie

2023.

Effects of L-PBF Scanning Strategy and Sloping Angle on the Process Properties of TC11 Titanium Alloy.

Metals,

Vol. 13,

Issue. 5,

p.

983.

Praveen Kumar, Devaraj

and

Vinoth Jebaraj, Alfred

2023.

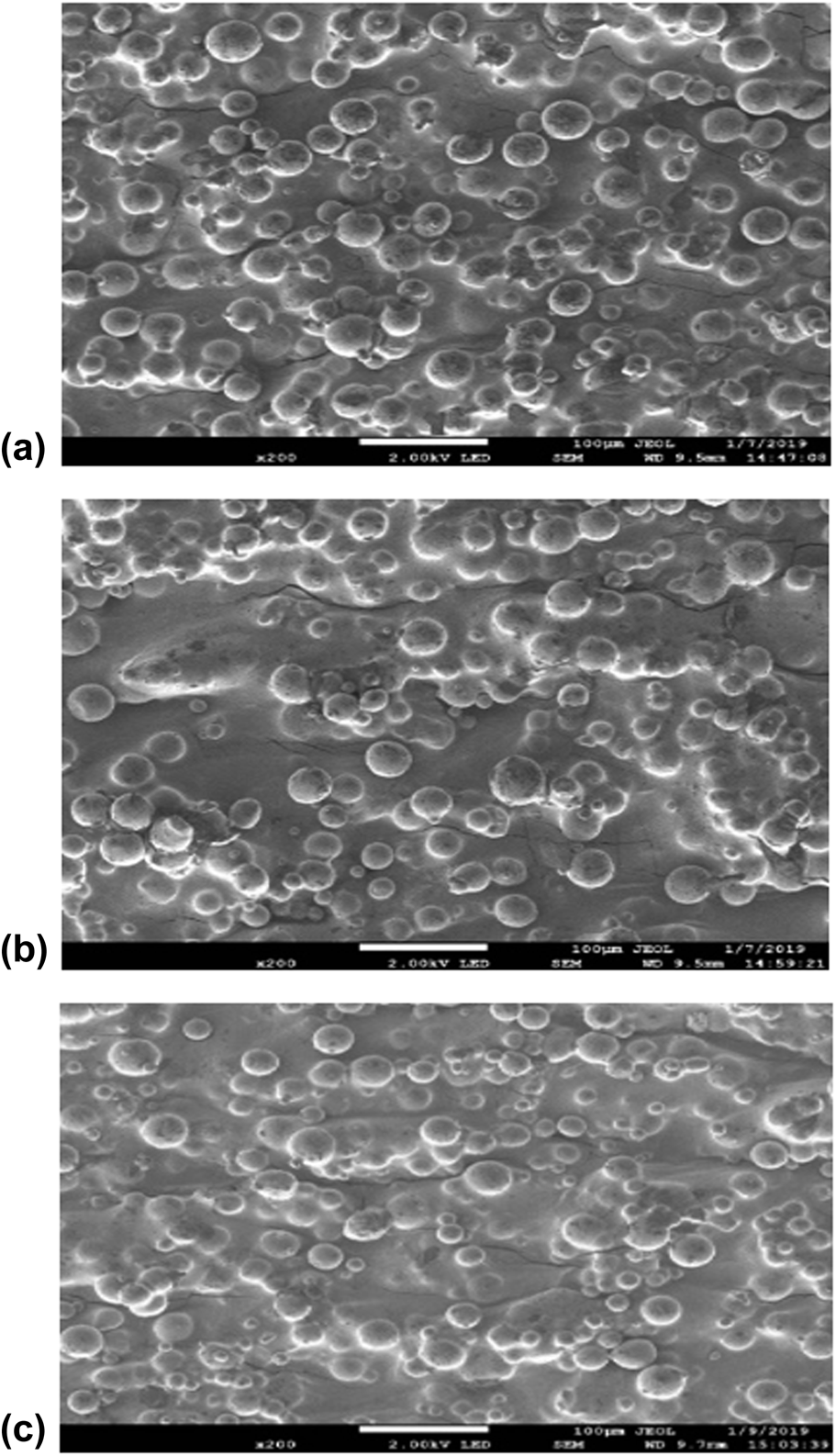

Surface morphology and dimensional accuracy of additively manufactured Ti-6Al-4V alloy: Effect of variable scanning speed with constant laser power in widespread energy density.

Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications,

Vol. 237,

Issue. 9,

p.

1964.