Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Li, Tian-Xin

Miao, Jun-Wei

Guo, En-Yu

Huang, He

Wang, Jun

Lu, Yi-Ping

Wang, Tong-Min

Cao, Zhi-Qiang

and

Li, Ting-Ju

2021.

Tungsten-containing high-entropy alloys: a focused review of manufacturing routes, phase selection, mechanical properties, and irradiation resistance properties.

Tungsten,

Vol. 3,

Issue. 2,

p.

181.

Raman, Lavanya

Anupam, Ameey

Karthick, G.

Berndt, Christopher C.

Ang, Andrew Siao Ming

Narayana Murty, S V S

Fabijanic, Daniel

Murty, B S

and

Kottada, Ravi Sankar

2021.

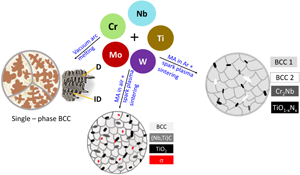

Strengthening mechanisms in CrMoNbTiW refractory high entropy alloy.

Materials Science and Engineering: A,

Vol. 819,

Issue. ,

p.

141503.

Kumar, Ashwani

Jayabalan, Bhagyaraj

Singh, Chetan

Jain, Jayant

Mukherjee, Subrata

Biswas, Krishanu

and

Singh, Sudhanshu S.

2022.

Processing and properties of yttria and lanthana dispersed ODS duplex stainless steels.

Materials Science and Engineering: A,

Vol. 837,

Issue. ,

p.

142746.

Shkodich, N.F.

Kuskov, K.V.

Sedegov, A.S.

Kovalev, I.D.

Panteleeva, A.V.

Vergunova, Yu.S.

Scheck, Yu.B.

Panina, E.

Stepanov, N.

Serhiienko, I.

and

Moskovskikh, D.

2022.

Refractory TaTiNb, TaTiNbZr, and TaTiNbZrX (X = Mo, W) high entropy alloys by combined use of high energy ball milling and spark plasma sintering: Structural characterization, mechanical properties, electrical resistivity, and thermal conductivity.

Journal of Alloys and Compounds,

Vol. 893,

Issue. ,

p.

162030.

Pandey, Vivek Kumar

Shadangi, Yagnesh

Shivam, Vikas

Sarma, B.N.

and

Mukhopadhyay, N.K.

2022.

Theoretical and experimental study on phase stability of TiVZrMoW refractory high entropy alloy.

Philosophical Magazine,

Vol. 102,

Issue. 6,

p.

480.

Sabban, Rushikesh

Dash, K.

Suwas, S.

and

Murty, B. S.

2022.

Strength–Ductility Synergy in High Entropy Alloys by Tuning the Thermo-Mechanical Process Parameters: A Comprehensive Review.

Journal of the Indian Institute of Science,

Vol. 102,

Issue. 1,

p.

91.

Chen, Bingqing

and

Zhuo, Longchao

2023.

Latest progress on refractory high entropy alloys: Composition, fabrication, post processing, performance, simulation and prospect.

International Journal of Refractory Metals and Hard Materials,

Vol. 110,

Issue. ,

p.

105993.

Olorundaisi, Emmanuel

Babalola, Bukola J.

Teffo, Moipone L.

Anamu, Ufoma S.

Olubambi, Peter A.

Fayomi, Juwon

and

Ogunmefun, Anthony O.

2023.

Phase prediction, microstructure, and mechanical properties of spark plasma sintered Ni–Al–Ti–Mn–Co–Fe–Cr high entropy alloys.

Discover Nano,

Vol. 18,

Issue. 1,

Ujah, Chika Oliver

Kallon, Daramy V. V.

and

Aigbodion, Victor Sunday

2024.

Corrosion characteristics of high-entropy alloys prepared by spark plasma sintering.

The International Journal of Advanced Manufacturing Technology,

Vol. 132,

Issue. 1-2,

p.

63.

Chen, Xin

Wang, Fei

Zhang, Xiang

Hu, Shanshan

Liu, Xingbo

Humphry-Baker, Samuel

Gao, Michael C.

He, Lingfeng

Lu, Yongfeng

and

Cui, Bai

2024.

Novel refractory high-entropy metal-ceramic composites with superior mechanical properties.

International Journal of Refractory Metals and Hard Materials,

Vol. 119,

Issue. ,

p.

106524.

Li, Wenjie

Raman, Lavanya

Debnath, Arindam

Ahn, Marcia

Lin, Shuang

Krajewski, Adam M.

Shang, Shunli

Priya, Shashank

Reinhart, Wesley F.

Liu, Zi-Kui

and

Beese, Allison M.

2024.

Design and validation of refractory alloys using machine learning, CALPHAD, and experiments.

International Journal of Refractory Metals and Hard Materials,

Vol. 121,

Issue. ,

p.

106673.

Martin, P.

Aguilar, C.

and

Cabrera, J.M.

2024.

A review on mechanical alloying and spark plasma sintering of refractory high-entropy alloys: Challenges, microstructures, and mechanical behavior.

Journal of Materials Research and Technology,

Vol. 30,

Issue. ,

p.

1900.

Gao, Shengqing

Li, Xiaoqiang

Pan, Cunliang

Fan, Jiafeng

Jiang, Qi

Yang, Chao

and

Qu, Shengguan

2024.

Effect of Ti content on microstructure and mechanical properties of TaMoNbCrTix refractory high-entropy alloy.

Materials Science and Engineering: A,

Vol. 898,

Issue. ,

p.

146394.

Hu, Yifei

Xu, Ang

Liu, Jilong

Wang, Ruoqi

and

Suo, Jinping

2025.

Enhancing the strength and toughness of WTaTiVN+Taμm heterogeneous alloys via nano Ti–V–N precipitation phase adjustment.

Journal of Materials Research and Technology,

Vol. 35,

Issue. ,

p.

2934.

Das, I.M.

Kumar, H.

Nagini, M.

Malladi, S.K.

Makineni, S.

Rajulapati, K.V.

Mandal, A.

and

Gollapudi, S.

2025.

Microstructure and mechanical properties of an aluminium composite with carbon-containing medium entropy alloy MoNbWTa0.5C0.5 reinforcement.

Intermetallics,

Vol. 182,

Issue. ,

p.

108776.

Raman, Lavanya

Anupam, Ameey

Karthick, G.

Berndt, Christopher C.

Ang, Andrew Siao Ming

Narayana Murty, S․ V․ S․

Fabijanic, Daniel

Murty, B․ S․

and

Kottada, Ravi Sankar

2025.

High temperature deformation behavior and microstructural evolution of an ultrafine-grained and multiphase CrMoNbTiW refractory high entropy alloy.

Acta Materialia,

Vol. 289,

Issue. ,

p.

120841.