Article contents

The influence of cutting parameters on the defect structure of subsurface in orthogonal cutting of titanium alloy

Published online by Cambridge University Press: 17 October 2017

Abstract

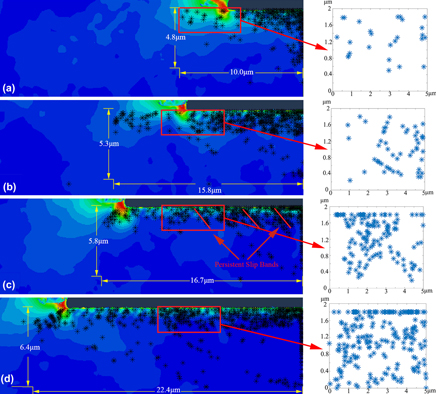

Subsurface microstructure alteration has been a major concern to implement micromachining of titanium alloy in the high-tech industry. To quantitatively promulgate the underlying mechanisms of this alteration, a discrete dislocation dynamics-based model is proposed and used to simulate the subsurface defects and their evolution under different cutting conditions. The model considers the subsurface dislocation configuration and inner stress distribution during the orthogonal cutting of titanium alloy. The results show that subsurface defect structure consists of plenty of dislocation dipoles, twining dislocation bands, and refined grains after cutting. In the primary shear zone, two different characteristics of subsurface damage layers can be found, the near-surface damage layer and deep-surface damage layer, which have different structural natures and distribution features. Moreover, it is found that high cutting speed and small depth of the cut can suppress the formation and propagation of subsurface defects. A powerful inner stress state would promote the distortion of the lattice and result in a microcrack within the subsurface matrix. The simulation results have been compared with experimental findings on the machined surface and subsurface of similar materials, and strong similarities were revealed and discussed.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 10

- Cited by