Article contents

Formation mechanism of the high-speed deformation characteristic microstructure based on dislocation slipping and twinning in α-titanium

Published online by Cambridge University Press: 21 November 2016

Abstract

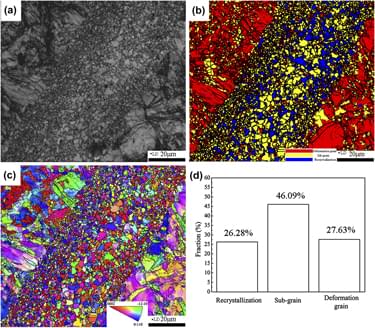

As-annealed commercial pure titanium (grade 1) was selected as a model material whose crystalline structure was hexagonal close-packed. The evolution of the microstructure and micro-orientation induced by high-speed compression was characterized to elaborate the formation mechanism of the high-speed deformation characteristic microstructure in α-titanium. Twinning played a coordinating role for dislocation slipping that was the main plastic deformation mechanism. The high-speed deformation characteristic microstructure of as-annealed commercial pure titanium was an adiabatic shear band (ASB) with an average width of 50 μm at a strain rate of 5400 s−1, whose initial grains were 0.5–1.0 μm in size. The formation and extension of ASB were attributed to the interaction between the shear stress and the adiabatic temperature rise. A formation model of ASB in α-Ti was proposed in terms of the formation mechanism of the high-speed deformation characteristic microstructure.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 5

- Cited by