Article contents

Fabrication of ultra-high-porosity cordierite foams by the thermo-foaming of powder dispersions in molten D-glucose anhydrous

Published online by Cambridge University Press: 23 May 2019

Abstract

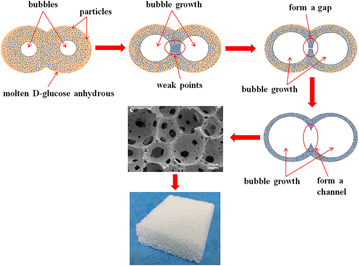

Cordierite foams were prepared by thermo-foaming of alumina–microsilica–talc powder dispersions in molten D-glucose anhydrous followed by reaction sintering at 1400 °C, which exhibited an interconnected cellular morphology and three-dimensional porous cell walls. The cordierite foam had a porosity of up to 96%, and its corresponding thermal conductivity was as low as 0.057 W/(m·K). The foam structures showed a great promise for gas filtration and gas catalytic support. The formation of interconnected cellular morphology, the variations of cell wall thickness, and cell size were explained from the perspective of viscosity and weak points in this paper. The linear shrinkage of cordierite foams having a density of 0.102–0.226 g/cm3 was in the range of 13.0–6.9%. And the compressive strength (0.05–0.28 MPa) was determined by the large cell size (1.1–1.3 mm), ultra-high porosity (91–96%), and characteristic of cordierite.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 4

- Cited by