Article contents

Fabrication and characterization of YSZ/Al2O3 nano-composite coatings on Inconel by electrophoretic deposition

Published online by Cambridge University Press: 10 July 2017

Abstract

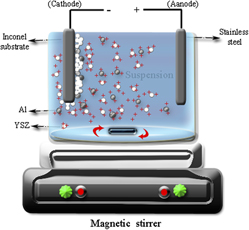

Nano-structured yttria stabilized zirconia (YSZ)/Al2O3 nano-composite coatings were prepared by electrophoretic deposition (EPD) in acetyl-acetone/ethanol solvents under the constant voltage of 40 V. High sintering temperature may damage the metal parts and also lead to high production costs. To overcome the disadvantages of high sintering temperatures, reaction bonding of Al was taken as the approach. It was found that a powder mixture of Al and YSZ can lower the sintering temperature. YSZ/Al green composites were deposited on the MCrAlY layer applied on Inconel alloy cathode. Iodine was added to the solutions as the stabilizing agent. According to differential thermal analysis (DTA) results, embedded Al particles oxidation started at 660 °C. Sintering process for YSZ/Al2O3 nano-composite coating occurred at 1150 °C for 4 h. A lower pinholes coating with the highest density due to the constraint of the substrate was obtained.

- Type

- Invited Articles

- Information

- Journal of Materials Research , Volume 32 , Issue 17: Focus Issue: Achieving Superior Ceramics and Coating Properties through Innovative Processing , 14 September 2017 , pp. 3402 - 3408

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Nahum Travitzky

References

REFERENCES

- 6

- Cited by