Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Jha, Kaushal K

Zhang, Shuo

Suksawang, Nakin

Wang, Ton-Lo

and

Agarwal, Arvind

2013.

Work-of-indentation as a means to characterize indenter geometry and load–displacement response of a material.

Journal of Physics D: Applied Physics,

Vol. 46,

Issue. 41,

p.

415501.

Martinez, Ricardo

and

Xu, L. Roy

2014.

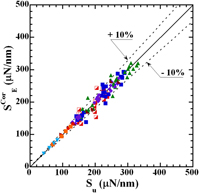

Comparison of the Young’s moduli of polymers measured from nanoindentation and bending experiments.

MRS Communications,

Vol. 4,

Issue. 3,

p.

89.

Jha, Kaushal K.

Suksawang, Nakin

and

Agarwal, Arvind

2014.

A new insight into the work-of-indentation approach used in the evaluation of material’s hardness from nanoindentation measurement with Berkovich indenter.

Computational Materials Science,

Vol. 85,

Issue. ,

p.

32.

Zhang, Jing

Wang, Chunbao

Yang, Fan

and

Du, Chang

2014.

Nanoindentation creep behavior of enamel biological nanocomposites.

RSC Adv.,

Vol. 4,

Issue. 77,

p.

41003.

Jha, K.

Suksawang, N.

and

Agarwal, A.

2015.

Determination of Nanomechanical Properties of Cementitious Materials Using an Energy-Based Approach.

p.

908.

Jha, Kaushal K.

Suksawang, Nakin

Lahiri, Debrupa

and

Agarwal, Arvind

2015.

A novel energy-based method to evaluate indentation modulus and hardness of cementitious materials from nanoindentation load–displacement data.

Materials and Structures,

Vol. 48,

Issue. 9,

p.

2915.

Milman, Yu. V.

Chugunova, S. I.

Goncharova, I. V.

and

Golubenko, А. А.

2018.

Plasticity of Materials Determined by the Indentation Method.

Uspehi Fiziki Metallov,

Vol. 19,

Issue. 3,

p.

271.

Xu, L. Roy

Martinez, Ricardo

and

Zhao, Kai

2019.

Measurements of Through-Thickness Young's Moduli of Fibrous Composite Laminates Using Nanoindentation.

Journal of Engineering Materials and Technology,

Vol. 141,

Issue. 3,

Contreras Romero, Elbert

Hurtado Macías, Abel

Méndez Nonell, Juan

Solís Canto, Oscar

and

Gómez Botero, Maryory

2019.

Mechanical and tribological properties of nanostructured TiAlN/TaN coatings deposited by DC magnetron sputtering.

Surface and Coatings Technology,

Vol. 378,

Issue. ,

p.

124941.

Xu, Shilang

Feng, Ying

Liu, Jiahan

and

Zeng, Qiang

2020.

Micro indentation fracture of cement paste assessed by energy-based method: The method improvement and affecting factors.

Construction and Building Materials,

Vol. 231,

Issue. ,

p.

117136.

Ma, Zhaoyang

Gamage, Ranjith Pathegama

and

Zhang, Chengpeng

2021.

Mechanical properties of α-quartz using nanoindentation tests and molecular dynamics simulations.

International Journal of Rock Mechanics and Mining Sciences,

Vol. 147,

Issue. ,

p.

104878.

Hasiak, Mariusz

Sobieszczańska, Beata

Łaszcz, Amadeusz

Biały, Michał

Chęcmanowski, Jacek

Zatoński, Tomasz

Bożemska, Edyta

and

Wawrzyńska, Magdalena

2021.

Production, Mechanical Properties and Biomedical Characterization of ZrTi-Based Bulk Metallic Glasses in Comparison with 316L Stainless Steel and Ti6Al4V Alloy.

Materials,

Vol. 15,

Issue. 1,

p.

252.

Jain, Abhilasha

Prabhu, Yogesh

Gunderov, Dmitry

Narayan, R. Lakshmi

Saini, Priyanka

Vincent, S.

Sudha, Priya

Bagde, Ashutosh D.

and

Bhatt, Jatin

2022.

Structural characterization, biocorrosion and in-vitro investigation on Zr62Cu22Al10Fe5Dy1 metallic glass for bio-implant applications.

Journal of Non-Crystalline Solids,

Vol. 598,

Issue. ,

p.

121928.

Milman, Yuly V.

Galanov, Boris A.

Goncharuk, Victor

Voskoboinik, Igor V.

and

Goncharova, Irina

2022.

Determination of New Plasticity Characteristic of Alloys at Mechanical Compression and Tensile Tests and the Influence of Structural Factors on Plasticity.

Solid State Phenomena,

Vol. 331,

Issue. ,

p.

11.

Liu, Cuicui

Peng, Jian

Xu, Zhigang

Shen, Qiang

and

Wang, Chuanbin

2023.

Combined Effect of Substrate Temperature and Sputtering Power on Phase Evolution and Mechanical Properties of Ta Hard Coatings.

Metals,

Vol. 13,

Issue. 3,

p.

583.

Umoh, G V

Gómez-Ovalle, A E

Cruz, M P

Leal-Pérez, J E

Obot, Okure U

Berrio, Héctor Urzola

Herrera-Basurto, Raúl

Mercader-Trejo, F

and

Hurtado-Macias, A

2024.

Nanomechanical-ferroelastics behavior, and the low-temperature ferroelectric manifestation of BiMnO3 thin films.

Physica Scripta,

Vol. 99,

Issue. 3,

p.

035962.

Kim, Young Mok

Jang, Tae Jin

Song, Wansu

Do, Hyeon-Seok

Oh, Sang-Ho

Lee, Gyeongbeom

Kim, Joungwook

Yang, Eunsoo

Lee, Byeong-Joo

Jang, Ho

and

Sohn, Seok Su

2024.

Si-enabled self-lubrication and wear resistance of CrCoNiSi medium-entropy alloy films.

Journal of Materials Research and Technology,

Vol. 30,

Issue. ,

p.

5429.

Geng, Zijian

Peng, Jian

Xu, Zhigang

He, Zhengfa

Guo, Xiang

Li, Wenjun

Wang, Chuanbin

and

Zhang, Lianmeng

2024.

Fabrication of amorphous AlMo0.5NbTa0.5TiZr RHEA coatings and the impact of deposition temperature on microstructure and properties.

Surface and Coatings Technology,

Vol. 487,

Issue. ,

p.

131036.

Li, Jiacheng

Xu, Zhigang

Xia, Yu

Gao, Peng

Peng, Jian

Shen, Qiang

and

Wang, Chuanbin

2024.

Strategy for preparing nanocrystalline Ta-N gradient layer with enhanced mechanical and tribological performance via microwave plasma nitriding.

Ceramics International,

Vol. 50,

Issue. 21,

p.

41636.

Martinez, Karla Cecilia Cisneros

Nemati, Ramin

and

Takhar, Pawan Singh

2024.

Micromechanical characterization of a wheat-based food material as a function of moisture content.

Journal of Food Measurement and Characterization,

Vol. 18,

Issue. 9,

p.

7728.