Article contents

Effects of Mg2Sn intermetallic on the microstructure and tensile properties of Al–15% Mg2Si–X% Sn composite

Published online by Cambridge University Press: 22 November 2016

Abstract

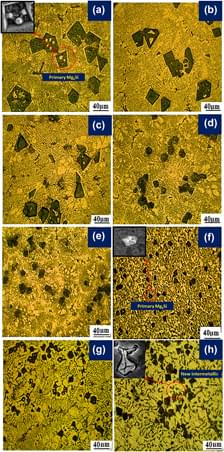

The effects of different Sn contents on the microstructure and tensile properties of an in situ prepared Al–15% Mg2Si composite were investigated. Adding 5 wt% Sn not only reduced the average size of Mg2Si primary particles from ∼55 µm to ∼10 µm, but also increased the ultimate tensile strength and elongation values. Mg2Sn intermetallic was identified in Al–15% Mg2Si–5% Sn composite and the lowest disregistry was also found for  $\left( {001} \right)_{{\rm{Mg}}_2 {\rm{Sn}}} {\parallel} \left( {001} \right)_{{\rm{Mg}}_{\rm{2}} {\rm{Si}}}$ , indicating that Mg2Sn can be a potent heterogeneous nucleation site for Mg2Si particles. Computer-aided cooling curve analysis revealed that Sn addition changes the solidification performance of the material by increasing both solidification time and recalescence undercooling and also reducing the growth temperature to some extent. The solidification behavior of the composite was also explained in terms of the presence of oxide bifilms in the liquid Al.

$\left( {001} \right)_{{\rm{Mg}}_2 {\rm{Sn}}} {\parallel} \left( {001} \right)_{{\rm{Mg}}_{\rm{2}} {\rm{Si}}}$ , indicating that Mg2Sn can be a potent heterogeneous nucleation site for Mg2Si particles. Computer-aided cooling curve analysis revealed that Sn addition changes the solidification performance of the material by increasing both solidification time and recalescence undercooling and also reducing the growth temperature to some extent. The solidification behavior of the composite was also explained in terms of the presence of oxide bifilms in the liquid Al.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 6

- Cited by