Article contents

The effect of solvent and electric field on the size distribution of iron oxide microdots: Exploitation of self-assembly strategies for photoelectrodes

Published online by Cambridge University Press: 17 January 2011

Abstract

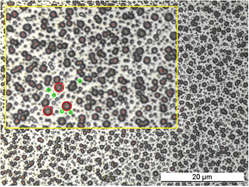

An increasing number of technologies benefit from or require patterned surfaces on a micro- and nanoscale. Methods developed to structure polymer films can be adapted to fabricate low-cost patterned ceramics using nonlithographic techniques, for example, dewetting and phase separation in thin films. In this paper we describe a simple patterning process that does not require a template and is able to produce Fe2O3 microdots with a spatial periodicity. Our method involves the dewetting of a silicon substrate by a thin metal oxide precursor film, in which the liquid film breaks up because of fluctuations in the film thickness induced by solvent evaporation or an external applied electric field. The patterning is followed by a thermal treatment at 550 °C to produce crystalline Fe2O3 microdots with a diameter range of 200 nm to 3 μm.

- Type

- Reviews

- Information

- Journal of Materials Research , Volume 26 , Issue 2: Focus Issue: Self-Assembly and Directed Assembly of Advanced Materials , 28 January 2011 , pp. 254 - 261

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 2

- Cited by