Published online by Cambridge University Press: 24 July 2017

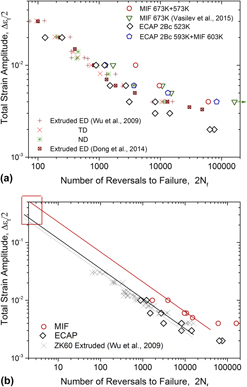

Complex wrought magnesium-based alloys suffer from poor ductility, strong yield asymmetry, and lower than desired fatigue performance. These unfavourable properties are exacerbated by the heterogeneity of the microstructure and strong texture forming in Mg alloys during conventional thermo-mechanical processing. For the user, severe plastic deformation (SPD) increases flexibility in tailoring the microstructures and selecting the properties to be emphasized in wrought Mg alloys. The effect of SPD by hot multiaxial forging and equal channel angular pressing on the formation of fine grain microstructure and on resultant mechanical properties is discussed. It is demonstrated that SPD is capable of substantial enhancement in ductility and tensile strength which gives rise to concurrent improvement of both low- and high-cycle fatigue properties. The main message of this overview is that the full potential for improving fatigue performance of Mg alloys can be taken advantage of by way of comprehensive understanding the role of the individual effects associated with the SPD-induced microstructures and textures.

Contributing Editor: Yuntian Zhu

Dedicated to Professor Dr. Haël Mughrabi on the occasion of his 80th birthday. It is my pleasure and honor to dedicate this paper to Professor Haël Mughrabi, who has been a mentor and a colleague to me over the years, in appreciation of his outstanding contributions and accomplishments in the area of fatigue of advanced materials.

This section of Journal of Materials Research is reserved for papers that are reviews of literature in a given area.