Article contents

Effect of graphitic filler size and shape on the microstructure, electrical percolation behavior and thermal properties of nanostructured multilayered carbon films deposited onto paper substrates

Published online by Cambridge University Press: 05 December 2013

Abstract

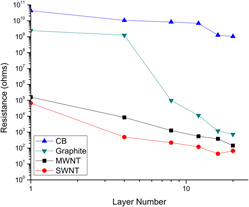

Dispersions containing 1 mg/mL of several carbon nanomaterials were used to deposit films containing 1 to 20 layers. The electrical properties of the composite films were characterized via impedance spectroscopy along two directions: in-plane on the film topmost surface and also through the thickness. It was found that carbon black nanoparticles never achieved full in-plane interconnection while the multiwalled carbon nanotube (MWNT) and single-walled carbon nanotube were already percolated at one layer. Graphite flakes showed a complete percolation curve that allowed its resistance to change by 6–7 orders of magnitude. The differences in the microstructure, electrical response, and thermal decomposition behavior of these carbon nanomaterial–paper substrate films were explained by detailed equivalent circuit analysis of the impedance spectra. Interpretation was supplemented by scanning electron microscopy images and thermal analysis via Differential Scanning Calorimetry/Thermogravimetric Analysis (DSC/TGA). Thru-plane electrical properties were for the most part similar, although only films with short MWNT showed a clearly infiltrated network structure.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 29 , Issue 3: Focus Issue: Graphene and Beyond , 14 February 2014 , pp. 472 - 484

- Copyright

- Copyright © Materials Research Society 2013

References

REFERENCES

- 8

- Cited by