Article contents

Deformation behavior of core–shell nanowire structures with coherent and semi-coherent interfaces

Published online by Cambridge University Press: 06 February 2019

Abstract

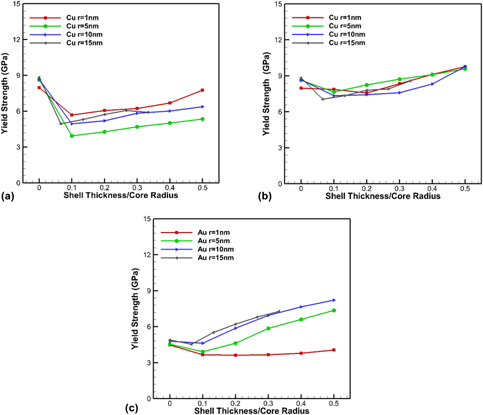

The mechanical properties of core–shell bimetallic composite nanowires, forming the bases of nanoporous metallic foams, have been investigated and compared with pure metal nanowires using molecular dynamics simulations. In the current study, pure copper and gold nanowires under uniaxial loading were tested at room temperature and compared to composite nanowires of the same materials (core) with a nickel coating (shell). The core radius ranged from 1 to 15 nm, and the shell thickness ranged from 0.1 to 5 nm. The tension strain was performed along the [001] direction under room temperature. Both coherent and semi-coherent composite nanowires were studied, and the effect of coating layer thickness was investigated. The strengthening mechanisms of the core–shell structures due to the presence of the two different types of interfaces were investigated for various nickel thicknesses. The atomistic simulation results revealed that the addition of the nickel shell strengthens the structure when the layer thickness exceeds a critical value.

Keywords

- Type

- Article

- Information

- Journal of Materials Research , Volume 34 , Issue 7: Focus Section: Interconnects and Interfaces in Energy Conversion Materials , 15 April 2019 , pp. 1093 - 1102

- Copyright

- Copyright © Materials Research Society 2019

References

- 7

- Cited by