Article contents

Chemomechanical effects of long-chain alcohols during nanoindentation

Published online by Cambridge University Press: 19 September 2011

Abstract

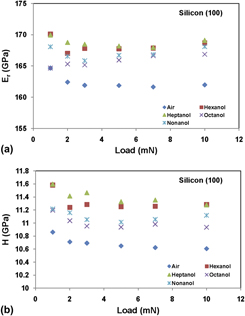

Surface and chemomechanical effects are very important in tribology, wear and friction, but are difficult to quantify due to being confined in the near-surface region. Nanoindentation techniques have been successfully used to investigate environmental effects on mechanical response. In this work, nanoindentation tests have been performed on various materials (silicon, fused silica, and gold nanofilms on a glass substrate) immersed in long-chain alcohols (i.e., 1-hexanol, 1-heptanol, 1-octanol, and 1-nonanol). The results consistently show an increase in mechanical properties for silicon and gold nanofilms immersed in the alcohols at shallow nanoindentation depths. The results for fused silica show little effect of immersion. The changes in the observed mechanical properties are attributed to the ability of the long-chain organic molecules to sustain elastic strains when they are in confined geometry. These long organic chains also distribute the normal stress of the indenter over a larger area on the sample surface thereby causing a decrease in the perceived contact area (Ac). As a result the long-chain alcohols modify both the Ac and the elastic compliance of the contact.

Keywords

- Type

- Articles

- Information

- Journal of Materials Research , Volume 27 , Issue 1: Focus Issue: Instrumented Indentation , 14 January 2012 , pp. 222 - 228

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 2

- Cited by