Article contents

Binary collision of CMAS droplets—Part II: Unequal-sized droplets

Published online by Cambridge University Press: 08 July 2020

Abstract

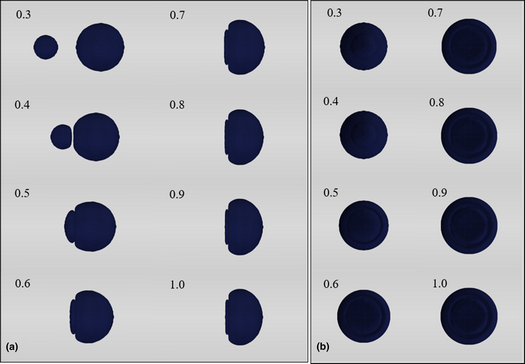

The analysis presented in Part I of this study on the binary collision of equal molten calcium–magnesium–alumino–silicate (CMAS) droplets is extended to investigate the flow and interfacial dynamics of unequal CMAS droplet collision. Numerical investigations of head-on, off-center, and grazing collisions of two CMAS droplets of size 1 and 2 mm are conducted at pressure and temperature of 20 atm and 1548 K, respectively, that are representative of a gas-turbine combustor. At these conditions, the physical properties of CMAS are density, ρCMAS = 2690 kg/m3, surface tension between CMAS/air, σCMAS = 0.40 N/m, and viscosity, μCMAS = 11.0 N-s/m2. The primary difference between the CMAS and a fictitious fluid with viscosity 1/10 of CMAS was higher deformation for the lower viscosity case, leading to stretching and subsequent breakup of the liquid structure. These mechanisms are supported by the time evolution of surface, kinetic, and viscous dissipation energies.

Keywords

- Type

- Invited Paper

- Information

- Journal of Materials Research , Volume 35 , Issue 17: Focus Issue: Sand-phobic Thermal/Environmental Barrier Coatings for Gas Turbine Engines , 14 September 2020 , pp. 2275 - 2287

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

References

- 13

- Cited by