Article contents

3D multiscale modeling of fracture in metal matrix composites

Published online by Cambridge University Press: 06 March 2019

Abstract

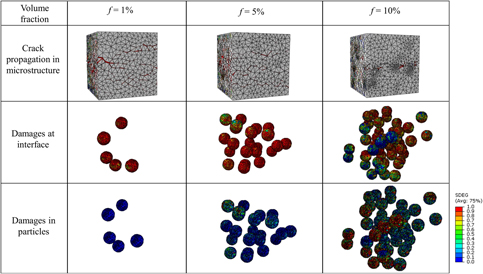

Metal matrix composites (MMCs) have great potential to replace monolithic metals in many engineering applications due to their enhanced properties, such as higher strength and stiffness, higher operating temperature, and better wear resistance. Despite their attractive mechanical properties, the application of MMCs has been limited primarily due to their high cost and relative low fracture toughness and reliability. Microstructure determines material fracture toughness through activation of different failure mechanisms. In this paper, a 3D multiscale modeling technique is introduced to resolve different failure mechanisms in MMCs. This approach includes 3D microstructure generation, meshing, and cohesive finite element method based failure analysis. Calculations carried out here concern Al/SiC MMCs and focus on primary fracture mechanisms which are correlated with microstructure characteristics, constituent properties, and deformation behaviors. Simulation results indicate that interface debonding not only creates tortuous crack paths via crack deflection and coalescence of microcracks but also leads to more pronounced plastic deformation, which largely contributes to the toughening of composite materials. Promotion of interface debonding through microstructure design can effectively improve the fracture toughness of MMCs.

Keywords

- Type

- Invited Paper

- Information

- Journal of Materials Research , Volume 34 , Issue 13: Focus Issue: Intrinsic and Extrinsic Size Effects in Materials , 15 July 2019 , pp. 2285 - 2294

- Copyright

- Copyright © Materials Research Society 2019

References

- 7

- Cited by