1. Introduction

Surface roughness profoundly impacts turbulent boundary layers. Relative to a smooth surface, roughness increases not only drag but also heat and mass transfer, with consequences for efficiency, emissions and the climate. In international shipping, for example, biofouled-roughened ship hulls increase fuel consumption by tens of billions of dollars annually, along with a proportional increase in greenhouse gas emissions. Yet our ability to manage the consequences is paced by our skill in predicting the drag of rough surfaces, a longstanding problem in fluid mechanics (Raupach, Antonia & Rajagopalan Reference Raupach, Antonia and Rajagopalan1991; Jiménez Reference Jiménez2004; Flack & Schultz Reference Flack and Schultz2010; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021).

Roughness effects cannot be easily generalized. Barnacles on ship hulls do not engender drag in the same way as trees in the atmospheric surface layer. However, the opposite extreme view, that roughness effects cannot be generalized at all, is also unfounded. It has long been appreciated that, everything else being equal, the larger the roughness size, the greater the drag (Nikuradse Reference Nikuradse1933). And, for a given size, the roughness plan density (the ratio of roughness plan area to wall area), plays a key role in determining drag (Schlichting Reference Schlichting1937). This knowledge is subsequently codified in models and frequently refined as new data become available to address model weaknesses (Flack & Chung Reference Flack and Chung2022).

Roughness models are formulas for drag that are fitted to topographical parameters. Topographical parameters only depend on the roughness geometry. In this way, models link drag with roughness features that are likely to matter. For example, the roughness frontal density is important because pressure drag is proportional to the frontal area (Simpson Reference Simpson1973). Skewness captures the observation that peaks are more draggy than valleys (Flack & Schultz Reference Flack and Schultz2010; Jelly & Busse Reference Jelly and Busse2018) and effective slope captures the observation that steeper slopes are more draggy than shallow slopes (Napoli, Armenio & De Marchis Reference Napoli, Armenio and De Marchis2008). As it became clear which sets of these parameters are independent (Placidi & Ganapathisubramani Reference Placidi and Ganapathisubramani2015; Thakkar, Busse & Sandham Reference Thakkar, Busse and Sandham2017), and with ready access to rapid prototyping both in laboratory experiments (computer numerical control machining) and in numerical simulations (immersed boundaries), research shifted to systematic sweeps in parameter space (Schultz, Kavanagh & Swain Reference Schultz, Kavanagh and Swain1999; Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2015; Forooghi et al. Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017; Barros, Schultz & Flack Reference Barros, Schultz and Flack2018; Kuwata & Kawaguchi Reference Kuwata and Kawaguchi2019; Flack, Schultz & Barros Reference Flack, Schultz and Barros2020; Ma et al. Reference Ma, Xu, Sung and Huang2020; Jouybari et al. Reference Jouybari, Yuan, Brereton and Murillo2021; Jelly et al. Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022; Yang et al. Reference Yang, Stroh, Chung and Forooghi2022). Machine learning tools have now been brought to bear on the rapidly growing dataset. To account for the many types of surfaces, more extensive statistical features (Jouybari et al. Reference Jouybari, Yuan, Brereton and Murillo2021), and even the surface elevation probability density functions and power-spectral densities are taken as input (Yang et al. Reference Yang, Stroh, Lee, Bagheri, Frohnapfel and Forooghi2023; Yousefi et al. Reference Yousefi, Hora, Yang, Veron and Giometto2024). As the roughness parameter space is infinite, with unfamiliar surfaces or unexpected behaviour reported from time to time (Barros et al. Reference Barros, Schultz and Flack2018; Nugroho et al. Reference Nugroho, Monty, Utama, Ganapathisubramani and Hutchins2021; Womack et al. Reference Womack, Volino, Meneveau and Schultz2022; Hutchins et al. Reference Hutchins, Ganapathisubramani, Schultz and Pullin2023), physically interpretable predictions are essential for reliability (Brunton, Noack & Koumoutsakos Reference Brunton, Noack and Koumoutsakos2020), but how to do so is an active area of research.

One approach to physical interpretability is to use topographical parameters motivated by or derived from flow physics. In addition to interpretability, topographical parameters are relatively easy to port, e.g. in a dynamic procedure of a large-eddy simulation (Anderson & Meneveau Reference Anderson and Meneveau2011) or in a neural network. A benefit of interpretability is the underlying physical hypothesis can be tested and advanced. Ideally, only a few parameters and a few fitting constants are used. One enduring parameter is the frontal solidity (Schlichting Reference Schlichting1937; Jiménez Reference Jiménez2004) or closely related parameters such as the effective slope. When roughness features are sparsely spaced, the higher the frontal solidity, the higher the drag. However, when roughness features are densely packed to shelter one another from the oncoming flow, the higher the frontal solidity, the lower the drag. This sheltering effect is described comprehensively by Grimmond & Oke (Reference Grimmond and Oke1999) and encapsulated in the formula of Macdonald, Griffiths & Hall (Reference Macdonald, Griffiths and Hall1998), whose predictive skill was found to be impressive in untested parameter spaces (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). Sheltering was extended in a series of studies (Yang & Meneveau Reference Yang and Meneveau2016, Reference Yang and Meneveau2017; Yang et al. Reference Yang, Sadique, Mittal and Meneveau2016; Sadique et al. Reference Sadique, Yang, Meneveau and Mittal2017) to directly predict drag from surface elevation maps of tall prisms, fractal and directional surfaces, bypassing the use of topographical parameters. In addition to regular surfaces, sheltering also applies to irregular surfaces (Yang et al. Reference Yang, Stroh, Chung and Forooghi2022) and it turns out that sheltering also plays a decisive role on heat transfer (Abu Rowin et al. Reference Abu Rowin, Zhong, Saurav, Jelly, Hutchins and Chung2024). Although frontal solidity was used and discussed hand in hand with sheltering, by itself the frontal solidity does not encapsulate our current understanding of roughness flow physics. For example, the frontal solidity does not discriminate between the differences in pressure drag due to gentle vs steep roughness slopes. A related point is that the frontal solidity needs to be used with the plan solidity or skewness to differentiate sparse surfaces with occasional spikes from wavy surfaces. Although the link between pressure drag and frontal area is proportional, the addition of plan solidity or skewness is somewhat ad hoc. In addition, frontal solidity, even with the inclusion of skewness or plan solidity, cannot account for clustering, which can alter levels of sheltering of roughness elements (Sarakinos & Busse Reference Sarakinos and Busse2022).

The present effort is focused on a physics-based analysis to determine and propose a geometric parameter, called the wind-shade roughness factor, which by itself has predictive capabilities. In the future, it can also be combined with other parameters and further extend possible machine learning approaches, or, more simply, be used as single parameter. The proposed predictive model based on the wind-shade roughness factor is easily implemented by other researchers, and to further ease of implementation, the code and some example applications are provided as a computational notebook together with this paper. The intended use for the present roughness model is routine calculations based on available elevation maps, reduced to a simple geometric parameter like the skewness or effective slope, without involving complicated solutions to non-local partial differential equations (e.g. solving Laplace's equation) such as the force-partitioning-inspired method (Aghaei-Jouybari et al. Reference Aghaei-Jouybari, Seo, Yuan, Mittal and Meneveau2022) or having to perform fluid dynamics simulations. Moreover, the number of fitting constants required to reproduce data should be much smaller than the number of data points available for validation.

In the present paper, the wind-shade factor can be seen as a geometric parameter that combines both effects of plan and frontal solidities, or skewness and effective slope. Its physical derivation is presented in § 2 while the effects of viscosity for transitional roughness are added in § 3. Predictions and comparisons with data are given in § 4, and the impact of various modelling choices is analysed in § 5. Results for transitionally rough surfaces are considered in § 6. Concluding remarks are provided in § 7.

2. The wind-shade roughness model

We consider a rough surface whose elevation is given by a single-valued function ![]() $h(x,y)$. The first goal is to estimate the form (pressure) drag force arising when this surface is placed in a turbulent flow, under fully rough conditions. For such conditions, the representation should depend only upon the surface geometry, the direction of the flow with respect to that geometry (e.g. an angle

$h(x,y)$. The first goal is to estimate the form (pressure) drag force arising when this surface is placed in a turbulent flow, under fully rough conditions. For such conditions, the representation should depend only upon the surface geometry, the direction of the flow with respect to that geometry (e.g. an angle ![]() $\phi$) and the turbulence spreading angle

$\phi$) and the turbulence spreading angle ![]() $\theta$. The overall tangential force per unit mass in the two horizontal directions,

$\theta$. The overall tangential force per unit mass in the two horizontal directions, ![]() $f_x$ and

$f_x$ and ![]() $f_y$, is expressed as an area integral of the pressure-caused kinematic wall stress along the entire surface

$f_y$, is expressed as an area integral of the pressure-caused kinematic wall stress along the entire surface

and similarly for ![]() $f_y$ involving the local slope in the

$f_y$ involving the local slope in the ![]() $y$ direction,

$y$ direction, ![]() $\partial h/\partial y$. Mathematically speaking, we only require the function

$\partial h/\partial y$. Mathematically speaking, we only require the function ![]() $h(x,y)$ to be single valued (e.g. wall-attached cubes would involve Heaviside functions, and delta-Dirac functions for the surface's local slopes which when integrated lead to terms proportional to projected frontal area). In practice, most often the integration is done numerically, for which we assume

$h(x,y)$ to be single valued (e.g. wall-attached cubes would involve Heaviside functions, and delta-Dirac functions for the surface's local slopes which when integrated lead to terms proportional to projected frontal area). In practice, most often the integration is done numerically, for which we assume ![]() $h(x,y)$ to be discretized on a fine grid and its gradients determined using (e.g.) finite differencing. The stress

$h(x,y)$ to be discretized on a fine grid and its gradients determined using (e.g.) finite differencing. The stress ![]() $\tau _{xz}^p(x,y)$ is the pressure (form) drag force per unit planform area of the rough surface. The pressure field

$\tau _{xz}^p(x,y)$ is the pressure (form) drag force per unit planform area of the rough surface. The pressure field ![]() $p(x,y)$ is relative to some reference pressure

$p(x,y)$ is relative to some reference pressure ![]() $p_\infty =0$. The factor

$p_\infty =0$. The factor ![]() $F^{sh}(x,y;\phi,\theta )$ is the sheltering function described in the next section.

$F^{sh}(x,y;\phi,\theta )$ is the sheltering function described in the next section.

2.1. Sheltering function

The sheltering function ![]() $F^{sh}(x,y;\theta )$ is defined as

$F^{sh}(x,y;\theta )$ is defined as

where ![]() $\beta (x,y)$ is the angle made by any given point with its upstream horizon, while

$\beta (x,y)$ is the angle made by any given point with its upstream horizon, while ![]() $\theta$ is the turbulence spreading angle which will be considered a model parameter. Also,

$\theta$ is the turbulence spreading angle which will be considered a model parameter. Also, ![]() $H(x)$ is the Heaviside function. The sheltering function requires knowledge of the angle

$H(x)$ is the Heaviside function. The sheltering function requires knowledge of the angle ![]() $\beta (x,y)$, the angle between the horizontal direction and a point's ‘backward horizon’ point (Dozier, Bruno & Downey Reference Dozier, Bruno and Downey1981). To define the backward horizon function, it is convenient to assume that the

$\beta (x,y)$, the angle between the horizontal direction and a point's ‘backward horizon’ point (Dozier, Bruno & Downey Reference Dozier, Bruno and Downey1981). To define the backward horizon function, it is convenient to assume that the ![]() $x$ direction is aligned with the incoming velocity

$x$ direction is aligned with the incoming velocity ![]() $u_i$, i.e.

$u_i$, i.e. ![]() $u_2=0$ (any dependence on

$u_2=0$ (any dependence on ![]() $\phi$ omitted henceforth from the notation). The function

$\phi$ omitted henceforth from the notation). The function ![]() $x_b(x)$ is called the ‘backward horizon function’ of point

$x_b(x)$ is called the ‘backward horizon function’ of point ![]() $x$ (Dozier et al. Reference Dozier, Bruno and Downey1981) and is the position of the visible horizon looking into the negative direction (or upstream towards the incoming flow) from point

$x$ (Dozier et al. Reference Dozier, Bruno and Downey1981) and is the position of the visible horizon looking into the negative direction (or upstream towards the incoming flow) from point ![]() $x$. For the maximum of

$x$. For the maximum of ![]() $h(x,y)$, one sets

$h(x,y)$, one sets ![]() $x_b(x)=x$. Then the horizon angle at point

$x_b(x)=x$. Then the horizon angle at point ![]() $(x,y)$ is given by

$(x,y)$ is given by

Figure 1 shows the various angles for any given position ![]() $x$ as well as the horizon function

$x$ as well as the horizon function ![]() $x_b(x)$. The angle distribution

$x_b(x)$. The angle distribution ![]() $\beta (x,y)$ depends only upon the surface geometry via the backward horizon function and need only be determined once for a given surface (i.e. it does not depend upon the turbulence spreading angle

$\beta (x,y)$ depends only upon the surface geometry via the backward horizon function and need only be determined once for a given surface (i.e. it does not depend upon the turbulence spreading angle ![]() $\theta$). The landscape shading literature (e.g. Dozier et al. Reference Dozier, Bruno and Downey1981) includes fast,

$\theta$). The landscape shading literature (e.g. Dozier et al. Reference Dozier, Bruno and Downey1981) includes fast, ![]() $O(N)$ (where N is the number of discrete points along x), algorithms to determine the horizon function

$O(N)$ (where N is the number of discrete points along x), algorithms to determine the horizon function ![]() $x_b(x)$. With these methods, evaluation of the sheltering factor

$x_b(x)$. With these methods, evaluation of the sheltering factor ![]() $F^{sh}(x,y;\theta )$ can be done very efficiently for any given

$F^{sh}(x,y;\theta )$ can be done very efficiently for any given ![]() $\theta$ since

$\theta$ since ![]() $\beta (x,y)$ can be pre-computed for a given surface.

$\beta (x,y)$ can be pre-computed for a given surface.

Figure 1. Sketch of surface, turbulence spreading angle ![]() $\theta$ and backward horizon angle

$\theta$ and backward horizon angle ![]() $\beta (x,y)$ for any given point

$\beta (x,y)$ for any given point ![]() $(x,y)$. Since in the example shown the point

$(x,y)$. Since in the example shown the point ![]() $x$ has a backward horizon angle

$x$ has a backward horizon angle ![]() $\beta$ that is larger than the turbulence spreading angle

$\beta$ that is larger than the turbulence spreading angle ![]() $\theta$, point

$\theta$, point ![]() $x$ is considered sheltered (wind shaded).

$x$ is considered sheltered (wind shaded).

As illustration, in figure 2 we show a sample surface (case of turbine-type roughness with transverse (![]() $y$-aligned) ridges from Jelly et al. Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022) for two angles:

$y$-aligned) ridges from Jelly et al. Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022) for two angles: ![]() $\theta =5^\circ$ (a) and

$\theta =5^\circ$ (a) and ![]() $\theta =15^\circ$ (b). Black regions are shaded regions. The drag (and hence the effective hydrodynamic roughness height for case (b) is expected to be larger due to more frontal area being exposed to the flow.

$\theta =15^\circ$ (b). Black regions are shaded regions. The drag (and hence the effective hydrodynamic roughness height for case (b) is expected to be larger due to more frontal area being exposed to the flow.

Figure 2. Surface and its shaded regions for two angles ![]() $\theta =5^{\circ }$ (a) and

$\theta =5^{\circ }$ (a) and ![]() $\theta =15^{\circ }$ (b). Computation of shaded region is based on the fast algorithm of Dozier et al. (Reference Dozier, Bruno and Downey1981), separately for each

$\theta =15^{\circ }$ (b). Computation of shaded region is based on the fast algorithm of Dozier et al. (Reference Dozier, Bruno and Downey1981), separately for each ![]() $x$-line in the direction of the incoming flow velocity

$x$-line in the direction of the incoming flow velocity ![]() $u_1$. In this and all subsequent elevation map visualizations, in order to represent the appropriate relative dimensions and surface slopes, the axes are normalized by a single scale

$u_1$. In this and all subsequent elevation map visualizations, in order to represent the appropriate relative dimensions and surface slopes, the axes are normalized by a single scale ![]() $L_y$, the width of the domain, i.e.

$L_y$, the width of the domain, i.e. ![]() $x_s=x/L_y$,

$x_s=x/L_y$, ![]() $y_s=y/L_y$ and

$y_s=y/L_y$ and ![]() $h_s=h/L_y$. The surface height is indicated by colours, ranging from light yellow to dark purple from highest to lowest elevation of each surface, respectively. Wind-shaded portions of the surface are indicated in black.

$h_s=h/L_y$. The surface height is indicated by colours, ranging from light yellow to dark purple from highest to lowest elevation of each surface, respectively. Wind-shaded portions of the surface are indicated in black.

2.2. Modelled pressure distribution

To determine the pressure distribution ![]() $p(x,y)$, it is useful to select a reference velocity. We chose a notional velocity denoted by

$p(x,y)$, it is useful to select a reference velocity. We chose a notional velocity denoted by ![]() $U_k$ representing the velocity at a height

$U_k$ representing the velocity at a height ![]() $z_k$ above the mean surface elevation (note that the index

$z_k$ above the mean surface elevation (note that the index ![]() $k$ here refers to roughness height, often denoted by the letter

$k$ here refers to roughness height, often denoted by the letter ![]() $k$, and is not meant as a vector element index). The height

$k$, and is not meant as a vector element index). The height ![]() $z_k$ is assumed to be sufficiently large so that the time-averaged mean velocity there can be assumed to be independent of

$z_k$ is assumed to be sufficiently large so that the time-averaged mean velocity there can be assumed to be independent of ![]() $(x,y)$. We thus aim for a height just above the roughness sublayer where assuming that the time-averaged streamwise velocity is constant over

$(x,y)$. We thus aim for a height just above the roughness sublayer where assuming that the time-averaged streamwise velocity is constant over ![]() $(x,y)$ is appropriate.

$(x,y)$ is appropriate.

We now turn to the pressure (form) drag model. We use the piecewise potential ramp flow approach (Ayala et al. Reference Ayala, Sadek, Ferčák, Cal, Gayme and Meneveau2024) (see figure 3) to model ![]() $p(x,y)$. We simplify any sloping portion of a roughness element or portions of a surface as a planar ramp inclined at an angle

$p(x,y)$. We simplify any sloping portion of a roughness element or portions of a surface as a planar ramp inclined at an angle ![]() $\alpha$. The ramp angle is obtained from

$\alpha$. The ramp angle is obtained from ![]() $\alpha = \arctan |\boldsymbol {\nabla }_h h|$ (i.e. based on the absolute value of the surface slope, for reasons to be explained below), and

$\alpha = \arctan |\boldsymbol {\nabla }_h h|$ (i.e. based on the absolute value of the surface slope, for reasons to be explained below), and ![]() $\boldsymbol {\nabla }_h$ is the gradient in the horizontal plane,

$\boldsymbol {\nabla }_h$ is the gradient in the horizontal plane, ![]() $\boldsymbol {\nabla }_h=\partial _x {\boldsymbol {i}}+\partial _y\kern0.09em {\boldsymbol {j}}$. We assume at the bottom of each ramp flow, there is a stagnation point (solid circle in figure 3b) and at the top of the ramp the velocity is

$\boldsymbol {\nabla }_h=\partial _x {\boldsymbol {i}}+\partial _y\kern0.09em {\boldsymbol {j}}$. We assume at the bottom of each ramp flow, there is a stagnation point (solid circle in figure 3b) and at the top of the ramp the velocity is ![]() $U_k$ and the pressure there is equal to the reference pressure

$U_k$ and the pressure there is equal to the reference pressure ![]() $p_\infty =0$, i.e. we assume plug flow between height

$p_\infty =0$, i.e. we assume plug flow between height ![]() $z_k$ and the ramp top. Evidently, this is a strong assumption but is necessary if we wish to apply a potential flow description that is purely ‘local’, i.e. is agnostic of flow conditions at other locations and far above the surface.

$z_k$ and the ramp top. Evidently, this is a strong assumption but is necessary if we wish to apply a potential flow description that is purely ‘local’, i.e. is agnostic of flow conditions at other locations and far above the surface.

Figure 3. Sketch of surface discretized at horizontal resolution ![]() $\Delta x$ and (b) potential flow over a ramp at angle

$\Delta x$ and (b) potential flow over a ramp at angle ![]() $\alpha$ (Ayala et al. Reference Ayala, Sadek, Ferčák, Cal, Gayme and Meneveau2024) assumed to be locally valid over the surface at horizontal discretization length

$\alpha$ (Ayala et al. Reference Ayala, Sadek, Ferčák, Cal, Gayme and Meneveau2024) assumed to be locally valid over the surface at horizontal discretization length ![]() $\Delta x$. In (a,b) the surface slope is assumed to be only in the

$\Delta x$. In (a,b) the surface slope is assumed to be only in the ![]() $x$ direction, i.e.

$x$ direction, i.e. ![]() $\hat {n}_x=1$. The lowest point of the ramp has a stagnation point while at the end point the velocity magnitude is assumed to be

$\hat {n}_x=1$. The lowest point of the ramp has a stagnation point while at the end point the velocity magnitude is assumed to be ![]() $U_{ref}$ and pressure is

$U_{ref}$ and pressure is ![]() $p_\infty =0$. (c) Shows a sketch of isosurface contours (surface seen from above), the local normal vector

$p_\infty =0$. (c) Shows a sketch of isosurface contours (surface seen from above), the local normal vector ![]() $\hat {\boldsymbol {n}} = \boldsymbol {\nabla }_h h/|\boldsymbol {\nabla }_h h|$, the incoming velocity

$\hat {\boldsymbol {n}} = \boldsymbol {\nabla }_h h/|\boldsymbol {\nabla }_h h|$, the incoming velocity ![]() $U_k$ in the

$U_k$ in the ![]() $x$ direction and the incoming velocity normal to the surface becomes

$x$ direction and the incoming velocity normal to the surface becomes ![]() $U_{ref} = U_k \hat {n}_x$.

$U_{ref} = U_k \hat {n}_x$.

Following the development in Ayala et al. (Reference Ayala, Sadek, Ferčák, Cal, Gayme and Meneveau2024), we use the known solution for potential flow over a ramp, for which the streamfunction in polar coordinates is given by ![]() $\psi (r,\theta ) = B r^n \sin [n(\theta -\alpha )]$, with

$\psi (r,\theta ) = B r^n \sin [n(\theta -\alpha )]$, with ![]() $n={\rm \pi} /({\rm \pi} -\alpha )$ and

$n={\rm \pi} /({\rm \pi} -\alpha )$ and ![]() $B$ is the streamfunction amplitude to be expressed later as a function of the local velocity magnitude. The radial coordinate runs from

$B$ is the streamfunction amplitude to be expressed later as a function of the local velocity magnitude. The radial coordinate runs from ![]() $r=0$ at the stagnation point to

$r=0$ at the stagnation point to ![]() $r={\ell }_r$ at the top of the ramp, where the velocity is a known reference velocity

$r={\ell }_r$ at the top of the ramp, where the velocity is a known reference velocity ![]() $U_{ref}$ and the pressure is

$U_{ref}$ and the pressure is ![]() $p_\infty =0$. The radial (tangential to the surface) velocity component along the ramp surface is

$p_\infty =0$. The radial (tangential to the surface) velocity component along the ramp surface is ![]() $V_r=-(1/r)\partial \psi /\partial \theta$ evaluated at

$V_r=-(1/r)\partial \psi /\partial \theta$ evaluated at ![]() $\theta =\alpha$. It results in

$\theta =\alpha$. It results in ![]() $V_r(r) = n B \, (r/\ell _r)^{n-1}$, which can be seen to fix

$V_r(r) = n B \, (r/\ell _r)^{n-1}$, which can be seen to fix ![]() $n B = U_{ref}$. Using the Bernoulli equation to evaluate the pressure difference between points at the crest and along the surface yields

$n B = U_{ref}$. Using the Bernoulli equation to evaluate the pressure difference between points at the crest and along the surface yields

\begin{equation} \frac{1}{\rho} \, p(r) = \frac{1}{2} U_{ref}^2 \left[ 1 - \left(\frac{r}{\ell_r}\right)^{2\alpha/({\rm \pi}-\alpha)}\right]. \end{equation}

\begin{equation} \frac{1}{\rho} \, p(r) = \frac{1}{2} U_{ref}^2 \left[ 1 - \left(\frac{r}{\ell_r}\right)^{2\alpha/({\rm \pi}-\alpha)}\right]. \end{equation}

Only the horizontal velocity normal to the surface is expected to generate a pressure differential, i.e. the reference velocity ![]() $U_{ref}$ would vanish if the surface does not present a component standing normal to the incoming flow direction. This effect can be taken into account by setting

$U_{ref}$ would vanish if the surface does not present a component standing normal to the incoming flow direction. This effect can be taken into account by setting ![]() $U_{ref} = U_k \hat {n}_x$, where

$U_{ref} = U_k \hat {n}_x$, where

is based on the horizontal gradient of the elevation map ![]() $h(x,y)$. For a surface that is inclined normal to the incoming flow, e.g. front faces of wall-attached cubes,

$h(x,y)$. For a surface that is inclined normal to the incoming flow, e.g. front faces of wall-attached cubes, ![]() $\hat {n}_x=1$ and thus

$\hat {n}_x=1$ and thus ![]() $U_{ref} = U_k$. On the side faces of such cubes,

$U_{ref} = U_k$. On the side faces of such cubes, ![]() $\hat {n}_x$ and

$\hat {n}_x$ and ![]() $U_{ref}$ vanish, as the flow skims past such surfaces with no pressure buildup from the potential flow ramp model (see figure 3c).

$U_{ref}$ vanish, as the flow skims past such surfaces with no pressure buildup from the potential flow ramp model (see figure 3c).

Next, we compute the mean pressure on the ramp segment, ![]() $\bar {p}={\ell _r}^{-1}\int _{r=0}^{\ell _r} p(r) \, {\rm d}r$, which results in

$\bar {p}={\ell _r}^{-1}\int _{r=0}^{\ell _r} p(r) \, {\rm d}r$, which results in

To obtain the pressure force in the ![]() $x$ direction, i.e. in order to derive the form provided in (2.1), we multiply by the projected surface area vector

$x$ direction, i.e. in order to derive the form provided in (2.1), we multiply by the projected surface area vector ![]() $|\boldsymbol {\nabla }_h h| \hat {n}_x \Delta x \Delta y$, where

$|\boldsymbol {\nabla }_h h| \hat {n}_x \Delta x \Delta y$, where ![]() $\Delta x$ and

$\Delta x$ and ![]() $\Delta y$ are the horizontal spatial resolutions describing the surface (and the length

$\Delta y$ are the horizontal spatial resolutions describing the surface (and the length ![]() $\ell _r$ used to evaluate the mean pressure is

$\ell _r$ used to evaluate the mean pressure is ![]() $\ell _r \sim (\Delta x \Delta y)^{1/2}$). Including the shading function, the resulting local kinematic wall stress in the

$\ell _r \sim (\Delta x \Delta y)^{1/2}$). Including the shading function, the resulting local kinematic wall stress in the ![]() $x$-direction coming from pressure (i.e. dividing the pressure force by the planform area

$x$-direction coming from pressure (i.e. dividing the pressure force by the planform area ![]() $\Delta x \Delta y$ and density) can be written as

$\Delta x \Delta y$ and density) can be written as

For small slopes, we have ![]() $\alpha \approx |\boldsymbol {\nabla }_h h| \ll {\rm \pi}$, and then the pressure drag is quadratic with slope (as is known to be the case for small-amplitude waves Jeffreys Reference Jeffreys1925). However, for present applications, in which for certain types of surfaces the local slopes could go up to

$\alpha \approx |\boldsymbol {\nabla }_h h| \ll {\rm \pi}$, and then the pressure drag is quadratic with slope (as is known to be the case for small-amplitude waves Jeffreys Reference Jeffreys1925). However, for present applications, in which for certain types of surfaces the local slopes could go up to ![]() ${\rm \pi} /2$ (vertical segments, although with finite resolution discretely representing

${\rm \pi} /2$ (vertical segments, although with finite resolution discretely representing ![]() $h(x,y)$, some small deviations from vertical are unavoidable), we do not use nor need this small angle approximation.

$h(x,y)$, some small deviations from vertical are unavoidable), we do not use nor need this small angle approximation.

Now, instead of following Ayala et al. (Reference Ayala, Sadek, Ferčák, Cal, Gayme and Meneveau2024) in which only the windward facing portion of the surface feels a pressure force (the leeside portion was assumed to exhibit either flow separation or incipient separation such that the pressure force there was neglected), we here allow for pressure recovery for downward facing portions of the surface. To model the absence of pressure recovery in separated or nearly separated region we here rely entirely on the sheltering function ![]() $F^{sh}(x,y;\theta )$ treated in subsection 2.1. Without flow separation, the potential flow ramp model predicts a flow along a downward ramp with the stagnation pressure at the bottom of the ramp and a resulting force in the negative

$F^{sh}(x,y;\theta )$ treated in subsection 2.1. Without flow separation, the potential flow ramp model predicts a flow along a downward ramp with the stagnation pressure at the bottom of the ramp and a resulting force in the negative ![]() $x$ direction, i.e. pressure recovery. The sign of the resulting force is given by the surface slope in the

$x$ direction, i.e. pressure recovery. The sign of the resulting force is given by the surface slope in the ![]() $x$-direction (

$x$-direction (![]() $\partial h/\partial x$) but the magnitude is the same independent of flow direction (for inviscid flow). By choosing to define the angle

$\partial h/\partial x$) but the magnitude is the same independent of flow direction (for inviscid flow). By choosing to define the angle ![]() $\alpha$ using an absolute value of the ramp slope and use

$\alpha$ using an absolute value of the ramp slope and use ![]() $\partial h/\partial x$ to determine the direction of force, we enable pressure recovery on backward sloping parts of the surface that are not in the sheltered portions of the surface (for surfaces to be studied in this work, however, this effect appears to be of negligible importance).

$\partial h/\partial x$ to determine the direction of force, we enable pressure recovery on backward sloping parts of the surface that are not in the sheltered portions of the surface (for surfaces to be studied in this work, however, this effect appears to be of negligible importance).

2.3. Wind-shade factor

Combining the sheltering and inviscid pressure models, we write the total (kinematic) force for a flow in the ![]() $x$ direction (

$x$ direction (![]() $i=1$) as

$i=1$) as

and the averaging is performed over the entire surface, i.e. over all ![]() $(x,y)$. This expression can be solved for the velocity

$(x,y)$. This expression can be solved for the velocity ![]() $U_k$ normalized by friction velocity

$U_k$ normalized by friction velocity ![]() $u_\tau$ as follows:

$u_\tau$ as follows:

where it is useful to define the streamwise (longitudinal, ‘L’) wind-shade factor ![]() ${\mathcal {W}}_{L}$ using a surface average

${\mathcal {W}}_{L}$ using a surface average

The averaging operation is meant to indicate the surface integral as in (2.8) divided by plan area ![]() $A$. It is important to note that, owing to the fact that potential flow is purely dependent on surface geometry, the wind-shade factor

$A$. It is important to note that, owing to the fact that potential flow is purely dependent on surface geometry, the wind-shade factor ![]() ${\mathcal {W}}_{L}$ is also a purely geometric quantity depending only on the surface height distribution, the mean flow direction relative to the surface and the assumed turbulence angle

${\mathcal {W}}_{L}$ is also a purely geometric quantity depending only on the surface height distribution, the mean flow direction relative to the surface and the assumed turbulence angle ![]() $\theta$.

$\theta$.

For future reference, we point out that, for certain surfaces with directional preference (e.g. inclined ridge-like features), one can also define a transverse wind-shade factor ![]() ${\mathcal {W}}_T$ according to

${\mathcal {W}}_T$ according to

It involves the pressure force built up due to streamwise velocity but projected onto the transverse direction as a result of the local slope ![]() $\partial h/\partial y$. This transverse factor represents the surface-induced drag force in a direction perpendicular to the incoming flow due to anisotropy of the surface topography.

$\partial h/\partial y$. This transverse factor represents the surface-induced drag force in a direction perpendicular to the incoming flow due to anisotropy of the surface topography.

2.4. Reference height

In order to relate the estimated drag force and wind-shade factor to roughness (![]() $z_0$) or equivalent sandgrain (

$z_0$) or equivalent sandgrain (![]() $k_s$) roughness lengths, we must choose an appropriate height to evaluate the log law. The common wisdom is that the roughness sublayer extends to approximately 2–3 times the representative heights of roughness elements, (Jiménez Reference Jiménez2004; Flack, Schultz & Connelly Reference Flack, Schultz and Connelly2007), although further dependencies on in-plane roughness length scales are also known to affect the height of the sublayer (Raupach, Thom & Edwards Reference Raupach, Thom and Edwards1980; Meyers, Ganapathisubramani & Cal Reference Meyers, Ganapathisubramani and Cal2019; Sharma & García-Mayoral Reference Sharma and García-Mayoral2020; Endrikat et al. Reference Endrikat, Newton, Modesti, García-Mayoral, Hutchins and Chung2022). For general surfaces, the height of roughness elements is difficult to specify and a more general definition for arbitrary functions

$k_s$) roughness lengths, we must choose an appropriate height to evaluate the log law. The common wisdom is that the roughness sublayer extends to approximately 2–3 times the representative heights of roughness elements, (Jiménez Reference Jiménez2004; Flack, Schultz & Connelly Reference Flack, Schultz and Connelly2007), although further dependencies on in-plane roughness length scales are also known to affect the height of the sublayer (Raupach, Thom & Edwards Reference Raupach, Thom and Edwards1980; Meyers, Ganapathisubramani & Cal Reference Meyers, Ganapathisubramani and Cal2019; Sharma & García-Mayoral Reference Sharma and García-Mayoral2020; Endrikat et al. Reference Endrikat, Newton, Modesti, García-Mayoral, Hutchins and Chung2022). For general surfaces, the height of roughness elements is difficult to specify and a more general definition for arbitrary functions ![]() $h(x,y)$ must be devised. Using the mean elevation

$h(x,y)$ must be devised. Using the mean elevation ![]() $\bar {k} = \langle h \rangle$ as the baseline height, we define a dominant positive height

$\bar {k} = \langle h \rangle$ as the baseline height, we define a dominant positive height ![]() $k_{p}^\prime$ according to

$k_{p}^\prime$ according to

\begin{equation} \left.\begin{gathered} k_{p}^\prime = \langle [R(h^\prime)]^p\rangle^{1/p},\quad{\rm where}\ h^\prime = h-\langle h\rangle,\\ {\rm and}\\ R(z)=z\quad {\rm if}\ z \geqslant 0,\quad R(z)=0\quad {\rm if}\ z < 0, \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} k_{p}^\prime = \langle [R(h^\prime)]^p\rangle^{1/p},\quad{\rm where}\ h^\prime = h-\langle h\rangle,\\ {\rm and}\\ R(z)=z\quad {\rm if}\ z \geqslant 0,\quad R(z)=0\quad {\rm if}\ z < 0, \end{gathered}\right\} \end{equation}

is the ramp function. As ![]() $p \to \infty$, the scale

$p \to \infty$, the scale ![]() $k_{p}^\prime$ tends to the maximum positive deviation above the mean height over the entire surface. A choice of

$k_{p}^\prime$ tends to the maximum positive deviation above the mean height over the entire surface. A choice of ![]() $p=8$ turns out to be sufficiently high to both emphasize the highest points but still include weak contributions from the entire surface for statistical robustness, for practical applications.

$p=8$ turns out to be sufficiently high to both emphasize the highest points but still include weak contributions from the entire surface for statistical robustness, for practical applications.

As the reference height where we evaluate the log law and where we assume the reference velocity ![]() $U_k$ is constant (i.e. the mean velocity only depends on

$U_k$ is constant (i.e. the mean velocity only depends on ![]() $z$ and not on

$z$ and not on ![]() $(x,y)$), we select a height

$(x,y)$), we select a height ![]() $\bar {k}+a_p k_{p}^\prime$, with

$\bar {k}+a_p k_{p}^\prime$, with ![]() $a_p=3$, a choice motivated by the observations that the roughness sublayer extends to approximately 3 times the characteristic element heights. Since

$a_p=3$, a choice motivated by the observations that the roughness sublayer extends to approximately 3 times the characteristic element heights. Since ![]() $a_p$ is somewhat arbitrarily chosen, we can regard this parameter as an adjustable one, but as a first approximation the choice

$a_p$ is somewhat arbitrarily chosen, we can regard this parameter as an adjustable one, but as a first approximation the choice ![]() $a_p=3$ appears reasonable. The sketch in figure 4 illustrates three types of surfaces and the resulting reference heights given the maximal positive height fluctuation away from the mean.

$a_p=3$ appears reasonable. The sketch in figure 4 illustrates three types of surfaces and the resulting reference heights given the maximal positive height fluctuation away from the mean.

Figure 4. Sketch of surfaces with height distribution ![]() $h(x,y)$ and near zero (a), positive (b) and negative (c) skewness. Also shown are the mean height

$h(x,y)$ and near zero (a), positive (b) and negative (c) skewness. Also shown are the mean height ![]() $\bar {k}$, the dominant positive height

$\bar {k}$, the dominant positive height ![]() $k_{p}^\prime$ and the resulting reference height

$k_{p}^\prime$ and the resulting reference height ![]() $a_p k_{p}^\prime$ (with

$a_p k_{p}^\prime$ (with ![]() $a_p \sim 3$ to be used in the model) above the mean height.

$a_p \sim 3$ to be used in the model) above the mean height.

With these assumptions, equivalent roughness scales ![]() $z_{0}$ and sandgrain-roughness heights

$z_{0}$ and sandgrain-roughness heights ![]() $k_s$ can be obtained as usual (Jiménez Reference Jiménez2004) from

$k_s$ can be obtained as usual (Jiménez Reference Jiménez2004) from ![]() $U_k^+ = (1/\kappa ) \ln (z_k/z_0) = (1/\kappa ) \ln (z_k/k_s) + 8.5$, with

$U_k^+ = (1/\kappa ) \ln (z_k/z_0) = (1/\kappa ) \ln (z_k/k_s) + 8.5$, with ![]() $z_k=a_p k_{p}^\prime$, and hence

$z_k=a_p k_{p}^\prime$, and hence

and similarly for ![]() $k_s$. Additionally, an overall reference scale for surface height will be chosen as

$k_s$. Additionally, an overall reference scale for surface height will be chosen as ![]() $k_{rms} = \langle (h-\bar {k})^2\rangle ^{1/2}$, the root mean square (r.m.s.) of the surface height function

$k_{rms} = \langle (h-\bar {k})^2\rangle ^{1/2}$, the root mean square (r.m.s.) of the surface height function ![]() $h(x,y)$ over all

$h(x,y)$ over all ![]() $(x,y)$. This choice facilitates comparison with datasets for which

$(x,y)$. This choice facilitates comparison with datasets for which ![]() $k_{rms}$ is often prescribed and known.

$k_{rms}$ is often prescribed and known.

Finally the wind-shade model for sandgrain-roughness normalized by r.m.s. height is given by

with ![]() $U_k^+ = {\mathcal {W}}_L^{-1/2}$ for the case of fully rough conditions (see § 3 below for transitionally rough cases). It is important to point out that we are not assuming that, physically, the height

$U_k^+ = {\mathcal {W}}_L^{-1/2}$ for the case of fully rough conditions (see § 3 below for transitionally rough cases). It is important to point out that we are not assuming that, physically, the height ![]() $z_k=a_p k_p^\prime$ falls in the logarithmic layer, but are using (2.13) or (2.14) as a definition of

$z_k=a_p k_p^\prime$ falls in the logarithmic layer, but are using (2.13) or (2.14) as a definition of ![]() $k_s$ or

$k_s$ or ![]() $z_0$: For a given velocity

$z_0$: For a given velocity ![]() $U_k$ at height

$U_k$ at height ![]() $z_k$, what is the length scale

$z_k$, what is the length scale ![]() $k_s$ or

$k_s$ or ![]() $z_0$ that, when entered into the simple log law, will predict the correct friction velocity or stress?

$z_0$ that, when entered into the simple log law, will predict the correct friction velocity or stress?

2.5. Turbulence spreading angle

The angle ![]() $\theta$ describing the effect of turbulent mixing at the reference height determines the strength of the sheltering effect. If the angle is large, the sheltering region will decrease rapidly in size and increase drag due to larger exposed downstream roughness features (see figure 2). Conversely, for smoothly rounded surfaces, increasing

$\theta$ describing the effect of turbulent mixing at the reference height determines the strength of the sheltering effect. If the angle is large, the sheltering region will decrease rapidly in size and increase drag due to larger exposed downstream roughness features (see figure 2). Conversely, for smoothly rounded surfaces, increasing ![]() $\theta$ will lead to delayed separation on the back sides of rounded roughness elements and hence to partial pressure recovery, which would decrease the drag.

$\theta$ will lead to delayed separation on the back sides of rounded roughness elements and hence to partial pressure recovery, which would decrease the drag.

For the default model, we assume a constant angle and chose ![]() $10^\circ$ as representative of values expected from the literature (e.g. Abu Rowin et al. Reference Abu Rowin, Zhong, Saurav, Jelly, Hutchins and Chung2024). Another option, as proposed in Yang et al. (Reference Yang, Sadique, Mittal and Meneveau2016), is to assume that the turbulence spreading angle

$10^\circ$ as representative of values expected from the literature (e.g. Abu Rowin et al. Reference Abu Rowin, Zhong, Saurav, Jelly, Hutchins and Chung2024). Another option, as proposed in Yang et al. (Reference Yang, Sadique, Mittal and Meneveau2016), is to assume that the turbulence spreading angle ![]() $\theta$ is proportional the ratio of vertical r.m.s. turbulence velocity (which is of same order as

$\theta$ is proportional the ratio of vertical r.m.s. turbulence velocity (which is of same order as ![]() $u_\tau$) and the streamwise advection velocity

$u_\tau$) and the streamwise advection velocity ![]() $U_k$ at the reference height, i.e.

$U_k$ at the reference height, i.e.

The wind-shade factor and the angle must then be determined iteratively. (Equation (2.15) is meant for cases when ![]() ${\mathcal {W}}_T=0$, since otherwise the friction velocity

${\mathcal {W}}_T=0$, since otherwise the friction velocity ![]() $u_\tau$ would also be expected to depend on

$u_\tau$ would also be expected to depend on ![]() ${\mathcal {W}}_T$.)

${\mathcal {W}}_T$.)

2.6. Near-wall velocity profile

A further refinement relates to the assumed velocity near the roughness elements. The definition of the wind-shade factor ![]() ${\mathcal {W}}_{L}$ relies on the assumption that the velocity is constant (plug flow) from

${\mathcal {W}}_{L}$ relies on the assumption that the velocity is constant (plug flow) from ![]() $z_k$ down to near the crest of any of the surface features or roughness elements. For surfaces with a few large-scale elements and many very small-scale elements (e.g. multiscale roughness), this may lead to a drag over-prediction caused by the small-scale elements that in reality might be exposed to a smaller velocity there. A possible remedy is to assume a 1/7 velocity power-law profile impinging on the roughness elements of the form

$z_k$ down to near the crest of any of the surface features or roughness elements. For surfaces with a few large-scale elements and many very small-scale elements (e.g. multiscale roughness), this may lead to a drag over-prediction caused by the small-scale elements that in reality might be exposed to a smaller velocity there. A possible remedy is to assume a 1/7 velocity power-law profile impinging on the roughness elements of the form ![]() $U(z) = U_k [(h(x,y)-h_{min})/(h_{max}-h_{min})]^{1/7}$. In this case, the definition of the wind-shade factor becomes

$U(z) = U_k [(h(x,y)-h_{min})/(h_{max}-h_{min})]^{1/7}$. In this case, the definition of the wind-shade factor becomes

\begin{equation} {\mathcal{W}}_{L,vel} = \left\langle \left(\frac{h(x,y)-h_{min}}{h_{max}-h_{min}}\right)^{2/7}\, \hat{n}_x^2(x,y) \, \frac{\alpha}{{\rm \pi}+\alpha} \, \frac{\partial h}{\partial x} \, F^{sh}(x,y;\theta) \right\rangle_{x,y}. \end{equation}

\begin{equation} {\mathcal{W}}_{L,vel} = \left\langle \left(\frac{h(x,y)-h_{min}}{h_{max}-h_{min}}\right)^{2/7}\, \hat{n}_x^2(x,y) \, \frac{\alpha}{{\rm \pi}+\alpha} \, \frac{\partial h}{\partial x} \, F^{sh}(x,y;\theta) \right\rangle_{x,y}. \end{equation}The introduction of a factor that decreases to zero near the minimum of the surface may improve the predictive power of the wind-shade factor. Note that this expression is still purely dependent on the surface geometry, although as with the pressure distribution model, it is fluid mechanics inspired.

At this stage, it is useful also to comment on connections to existing parameters. For instance, for vertical surfaces with ![]() $\alpha ={\rm \pi} /2$, the slope correction term

$\alpha ={\rm \pi} /2$, the slope correction term ![]() $\alpha /({\rm \pi} + \alpha ) = 1/3$, and the flow-direction correction is

$\alpha /({\rm \pi} + \alpha ) = 1/3$, and the flow-direction correction is ![]() $\hat {n}_x^2 = 1$, and if the wind shading

$\hat {n}_x^2 = 1$, and if the wind shading ![]() $F^{sh} = 1$ if

$F^{sh} = 1$ if ![]() $\partial h/\partial x > 0$ and

$\partial h/\partial x > 0$ and ![]() $0$ otherwise, then we recover one third of the frontal solidity as the model's prediction. In terms of the formula of Macdonald et al. (Reference Macdonald, Griffiths and Hall1998) that accounts for densely packed roughness features, choosing as wind shading

$0$ otherwise, then we recover one third of the frontal solidity as the model's prediction. In terms of the formula of Macdonald et al. (Reference Macdonald, Griffiths and Hall1998) that accounts for densely packed roughness features, choosing as wind shading ![]() $F^{sh} = 1$ for sparse roughness and

$F^{sh} = 1$ for sparse roughness and ![]() $F^{sh} = 0$ for dense roughness is similar to the damping factor introduced that is also

$F^{sh} = 0$ for dense roughness is similar to the damping factor introduced that is also ![]() $1$ and

$1$ and ![]() $0$ as the plan solidity varies between

$0$ as the plan solidity varies between ![]() $0$ and

$0$ and ![]() $1$, respectively. However, in the present model,

$1$, respectively. However, in the present model, ![]() $F^{sh}$ is linked in more detail with the underlying flow physics given its detailed

$F^{sh}$ is linked in more detail with the underlying flow physics given its detailed ![]() $(x,y)$ dependence that can also be locally correlated to the value of

$(x,y)$ dependence that can also be locally correlated to the value of ![]() $\alpha (x,y)$. The inclusion of the slope correction

$\alpha (x,y)$. The inclusion of the slope correction ![]() $\alpha /({\rm \pi} +\alpha )$ is expected to discriminate between spiky vs undulating surfaces, an argument usually given to include the surface skewness as relevant parameter. Moreover, directional and clustering effects are all naturally accounted for.

$\alpha /({\rm \pi} +\alpha )$ is expected to discriminate between spiky vs undulating surfaces, an argument usually given to include the surface skewness as relevant parameter. Moreover, directional and clustering effects are all naturally accounted for.

3. Effects of viscosity: transitionally rough flows

Since in many cases viscous effects are expected to be important (transitionally rough cases), we now include the contributions from viscous stresses. Following Raupach (Reference Raupach1992), we model the local kinematic viscous stress as a function of the assumed velocity ![]() $U_k$ using a friction factor

$U_k$ using a friction factor

The smooth-surface friction factor ![]() $c_f$ can be written in terms of a Reynolds number

$c_f$ can be written in terms of a Reynolds number ![]() $Re_k=z_k U_k/\nu$ based on the height

$Re_k=z_k U_k/\nu$ based on the height ![]() $z_k=a_p k_p^\prime$ and velocity there,

$z_k=a_p k_p^\prime$ and velocity there, ![]() $U_k$. The viscous stress

$U_k$. The viscous stress ![]() $\tau ^{\nu }_{xz}$ acts in the unsheltered regions. To include the sheltering we multiply by the average of the sheltering function

$\tau ^{\nu }_{xz}$ acts in the unsheltered regions. To include the sheltering we multiply by the average of the sheltering function ![]() $\langle F^{sh}\rangle$. However, for transitionally and hydrodynamically smooth surfaces the sheltering effect decreases and must entirely vanish in the limit of a smooth surface, regardless of the existence of geometric roughness. For hydrodynamically smooth cases, the flow around geometric roughness elements becomes essentially low Reynolds number (tending to Stokes flow), with more and more attached flow and no sheltering. Hence, we introduce the average viscous sheltering factor

$\langle F^{sh}\rangle$. However, for transitionally and hydrodynamically smooth surfaces the sheltering effect decreases and must entirely vanish in the limit of a smooth surface, regardless of the existence of geometric roughness. For hydrodynamically smooth cases, the flow around geometric roughness elements becomes essentially low Reynolds number (tending to Stokes flow), with more and more attached flow and no sheltering. Hence, we introduce the average viscous sheltering factor

which switches from the rough limit ![]() $\bar {F}_\nu ^{sh} = \langle F^{sh}\rangle$ (expected when

$\bar {F}_\nu ^{sh} = \langle F^{sh}\rangle$ (expected when ![]() $z_k^+ \gg 10$) to

$z_k^+ \gg 10$) to ![]() $\bar {F}_\nu ^{sh} =1$ when approaching hydrodynamically smooth-surface behaviour (expected when

$\bar {F}_\nu ^{sh} =1$ when approaching hydrodynamically smooth-surface behaviour (expected when ![]() $z_k^+ \ll 10$). Strictly speaking, we should make a similar adjustment to the wind shade factor

$z_k^+ \ll 10$). Strictly speaking, we should make a similar adjustment to the wind shade factor ![]() ${\mathcal {W}}_{L}$, since in the limit of transitionally and hydrodynamically smooth surfaces one would expect an absence of flow separation, and therefore full pressure recovery, over the backward facing surfaces. However, one would then need to transition to a low Reynolds number model for pressure, instead of the quadratic inviscid model used for defining

${\mathcal {W}}_{L}$, since in the limit of transitionally and hydrodynamically smooth surfaces one would expect an absence of flow separation, and therefore full pressure recovery, over the backward facing surfaces. However, one would then need to transition to a low Reynolds number model for pressure, instead of the quadratic inviscid model used for defining ![]() ${\mathcal {W}}_{L}$. In practice, since the viscous

${\mathcal {W}}_{L}$. In practice, since the viscous ![]() $c_f$ term dominates at low

$c_f$ term dominates at low ![]() $Re_k$, such an adjustment would have very little impact on results, and in the interests of simplicity such adjustments are omitted, and the definition of

$Re_k$, such an adjustment would have very little impact on results, and in the interests of simplicity such adjustments are omitted, and the definition of ![]() ${\mathcal {W}}_{L}$ based on a purely inviscid quadratic drag law is retained.

${\mathcal {W}}_{L}$ based on a purely inviscid quadratic drag law is retained.

The total drag force can then be written as

or, solving again for ![]() $U_k^+$,

$U_k^+$,

since ![]() $U_k$ (and thus

$U_k$ (and thus ![]() $Re_k$) is assumed to be the same over entire surface. We also recall that

$Re_k$) is assumed to be the same over entire surface. We also recall that ![]() $Re_k = U_k z_k/\nu = U_k^+ z_k^+ = U_k^+ (z_k /k_{rms}) k_{rms}^+$ with

$Re_k = U_k z_k/\nu = U_k^+ z_k^+ = U_k^+ (z_k /k_{rms}) k_{rms}^+$ with ![]() $z_k=a_p k_p^\prime$, which for a prescribed value of

$z_k=a_p k_p^\prime$, which for a prescribed value of ![]() $k_{rms}^+$ and known geometric ratio

$k_{rms}^+$ and known geometric ratio ![]() $(a_p k_p^\prime /k_{rms})$ enables us to determine the Reynolds number in terms of

$(a_p k_p^\prime /k_{rms})$ enables us to determine the Reynolds number in terms of ![]() $U_k^+$.

$U_k^+$.

Next, the friction factor must be determined. We use the generalized Moody diagram fit (Meneveau Reference Meneveau2020), appropriately rewritten in its simplest form according to

This is a fit to the numerical solution of the one-dimensional equilibrium fully developed (parallel flow) wall-bounded flow problem. It represents a generalization of the Moody diagram method relating wall stress to bulk velocity but here used only for the smooth line of the Moody diagram, or the skin-friction law for a smooth wall, where ![]() ${Re}_k$ replaces the outer Reynolds number. Also, the input parameter

${Re}_k$ replaces the outer Reynolds number. Also, the input parameter ![]() ${Re}_k$ is expressed at some reference height

${Re}_k$ is expressed at some reference height ![]() $z_k^+$ that may fall in the logarithmic or viscous sublayer, instead of an outer-layer height as is usual for the Moody diagram. For more details, see Meneveau (Reference Meneveau2020). Thus, in the limit of small Reynolds number (i.e. when

$z_k^+$ that may fall in the logarithmic or viscous sublayer, instead of an outer-layer height as is usual for the Moody diagram. For more details, see Meneveau (Reference Meneveau2020). Thus, in the limit of small Reynolds number (i.e. when ![]() $z_k^+ \sim 1$, and the velocity profile up to maximal height is linear), the limiting behaviour is

$z_k^+ \sim 1$, and the velocity profile up to maximal height is linear), the limiting behaviour is ![]() $c_f \to 2/Re_k$ and

$c_f \to 2/Re_k$ and ![]() $\bar {F}_\nu ^{sh}(z_k^+)\to 1$. For

$\bar {F}_\nu ^{sh}(z_k^+)\to 1$. For ![]() $k \sim x^{1/2}$, this trend is similar to Blasius. For increasing Reynolds number, the friction factor fitting function goes to a

$k \sim x^{1/2}$, this trend is similar to Blasius. For increasing Reynolds number, the friction factor fitting function goes to a ![]() $Re_k^{1/5}$ high Reynolds number behaviour.

$Re_k^{1/5}$ high Reynolds number behaviour.

To solve (3.4) we can employ numerical iteration. Since the weakest dependence is on the ![]() $c_f$ function, it is convenient to simply iterate the rapidly converging expression

$c_f$ function, it is convenient to simply iterate the rapidly converging expression

always recalling that ![]() $z_k^+ = (a_p k_p^\prime /k_{rms}) k_{rms}^+$, and starting with some initial guess (e.g. near frictionless

$z_k^+ = (a_p k_p^\prime /k_{rms}) k_{rms}^+$, and starting with some initial guess (e.g. near frictionless ![]() $c_f^{(n=0)}=10^{-14}$). Once

$c_f^{(n=0)}=10^{-14}$). Once ![]() $U_k^+$ has been determined, the equivalent sandgrain roughness

$U_k^+$ has been determined, the equivalent sandgrain roughness ![]() $k_s$ is again determined via (2.14).

$k_s$ is again determined via (2.14).

4. Results

4.1. Suite of surfaces from roughness database and others

In this section we apply the wind-shade roughness model to over 100 surfaces for which the full height distribution ![]() $h(x,y)$ is known and the equivalent sandgrain roughness

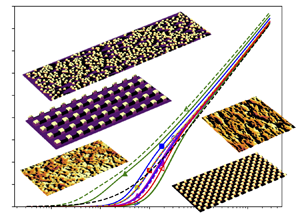

$h(x,y)$ is known and the equivalent sandgrain roughness ![]() $k_s$ has been measured. Appendix A lists the datasets considered (most of the surfaces are obtained from a public database at https://roughnessdatabase.org). Summarizing, they include 3 rough turbine blade-type surfaces from Jelly et al. (Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022) (isotropic and with dominant streamwise or spanwise aligned ridges), 26 cases studied numerically by Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021) including several types of sandgrain bumps, regular bumps, sinusoidal surfaces and one wall-attached cube case, 7 cases of rough surfaces studied experimentally in Flack et al. (Reference Flack, Schultz and Barros2020), truncated cones in random arrangements and along regular staggered arrays, each in 8 different densities studied experimentally in Womack et al. (Reference Womack, Volino, Meneveau and Schultz2022). Also included are 3 eggbox sinusoidal surfaces from the numerical study of Abu Rowin et al. (Reference Abu Rowin, Zhong, Saurav, Jelly, Hutchins and Chung2024), a large collection of 31 surfaces from Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) studied numerically, 3 power-law surfaces with spectral exponents

$k_s$ has been measured. Appendix A lists the datasets considered (most of the surfaces are obtained from a public database at https://roughnessdatabase.org). Summarizing, they include 3 rough turbine blade-type surfaces from Jelly et al. (Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022) (isotropic and with dominant streamwise or spanwise aligned ridges), 26 cases studied numerically by Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021) including several types of sandgrain bumps, regular bumps, sinusoidal surfaces and one wall-attached cube case, 7 cases of rough surfaces studied experimentally in Flack et al. (Reference Flack, Schultz and Barros2020), truncated cones in random arrangements and along regular staggered arrays, each in 8 different densities studied experimentally in Womack et al. (Reference Womack, Volino, Meneveau and Schultz2022). Also included are 3 eggbox sinusoidal surfaces from the numerical study of Abu Rowin et al. (Reference Abu Rowin, Zhong, Saurav, Jelly, Hutchins and Chung2024), a large collection of 31 surfaces from Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) studied numerically, 3 power-law surfaces with spectral exponents ![]() $-1.5$,

$-1.5$, ![]() $-1$ and

$-1$ and ![]() $-0.5$ studied experimentally by Barros et al. (Reference Barros, Schultz and Flack2018), surfaces with closely packed cubes with 7 different densities from Xu et al. (Reference Xu, Altland, Yang and Kunz2021) and, finally, 4 cases of multiscale block surfaces studied experimentally by Medjnoun et al. (Reference Medjnoun, Rodriguez-Lopez, Ferreira, Griffiths, Meyers and Ganapathisubramani2021) with up to 3 generations. For a subset of 12 of these surfaces, the panels in figure 5 show the surface elevation and sheltered regions shown as black shadows.

$-0.5$ studied experimentally by Barros et al. (Reference Barros, Schultz and Flack2018), surfaces with closely packed cubes with 7 different densities from Xu et al. (Reference Xu, Altland, Yang and Kunz2021) and, finally, 4 cases of multiscale block surfaces studied experimentally by Medjnoun et al. (Reference Medjnoun, Rodriguez-Lopez, Ferreira, Griffiths, Meyers and Ganapathisubramani2021) with up to 3 generations. For a subset of 12 of these surfaces, the panels in figure 5 show the surface elevation and sheltered regions shown as black shadows.

Figure 5. Representative sample of 12 (out of 104) surfaces considered in this study. Black regions are sheltered regions for ![]() $\theta =10^\circ$. Details about the surfaces are provided in Appendix A. Surfaces shown are from (a) Jelly et al. (Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022),

$\theta =10^\circ$. Details about the surfaces are provided in Appendix A. Surfaces shown are from (a) Jelly et al. (Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022), ![]() $y$-aligned ridges; from Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021): (b) case C19 (random ellipsoids), (c) case C29 (sinusoidal), (d) and case C45 (wall-attached cubes); (e) from Flack et al. (Reference Flack, Schultz and Barros2020): rough-surface case 1 (specifically, panel 1 from case 1); ( f) from Womack et al. (Reference Womack, Volino, Meneveau and Schultz2022) truncated cones, random case R48, and (g) regular staggered case S57; (h) from Abu Rowin et al. (Reference Abu Rowin, Zhong, Saurav, Jelly, Hutchins and Chung2024) intermediate eggbox (case 0p018); (i) from Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) case A7060 and (j) case C7088; (k) from Barros et al. (Reference Barros, Schultz and Flack2018) power-law random surface with spectral exponent p=-0.5; and (l) 3-generation multiscale block surface by Medjnoun et al. (Reference Medjnoun, Rodriguez-Lopez, Ferreira, Griffiths, Meyers and Ganapathisubramani2021), case iter 123. The surface height is indicated by colours, ranging from light yellow to dark purple from highest to lowest elevation of each surface, respectively. Shaded portions of the surface are indicated in black.

$y$-aligned ridges; from Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021): (b) case C19 (random ellipsoids), (c) case C29 (sinusoidal), (d) and case C45 (wall-attached cubes); (e) from Flack et al. (Reference Flack, Schultz and Barros2020): rough-surface case 1 (specifically, panel 1 from case 1); ( f) from Womack et al. (Reference Womack, Volino, Meneveau and Schultz2022) truncated cones, random case R48, and (g) regular staggered case S57; (h) from Abu Rowin et al. (Reference Abu Rowin, Zhong, Saurav, Jelly, Hutchins and Chung2024) intermediate eggbox (case 0p018); (i) from Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) case A7060 and (j) case C7088; (k) from Barros et al. (Reference Barros, Schultz and Flack2018) power-law random surface with spectral exponent p=-0.5; and (l) 3-generation multiscale block surface by Medjnoun et al. (Reference Medjnoun, Rodriguez-Lopez, Ferreira, Griffiths, Meyers and Ganapathisubramani2021), case iter 123. The surface height is indicated by colours, ranging from light yellow to dark purple from highest to lowest elevation of each surface, respectively. Shaded portions of the surface are indicated in black.

For each of the 104 surfaces, we first compute the wind-shade factor ![]() ${\mathcal {W}}_{L}$ according to its definition in (2.10). We use the turbulence spreading angle

${\mathcal {W}}_{L}$ according to its definition in (2.10). We use the turbulence spreading angle ![]() $\theta = 10^\circ$. Then, with the known experimental conditions for each surface expressed as the known

$\theta = 10^\circ$. Then, with the known experimental conditions for each surface expressed as the known ![]() $k_{rms}^+$, we determine the effects of viscosity by finding

$k_{rms}^+$, we determine the effects of viscosity by finding ![]() $U_k^+$ according to (3.6). The predicted roughness scale follows from (2.14) using

$U_k^+$ according to (3.6). The predicted roughness scale follows from (2.14) using ![]() $a_p=3$. The results are shown in figure 6 as scatter plots of predicted/modelled (

$a_p=3$. The results are shown in figure 6 as scatter plots of predicted/modelled (![]() $k_{s-mod}$) vs measured (

$k_{s-mod}$) vs measured (![]() $k_{s-data}$) sandgrain-roughness scale, each normalized by

$k_{s-data}$) sandgrain-roughness scale, each normalized by ![]() $k_{rms}$. The correlation coefficient is approximately 77 %. It is also useful to compare the average logarithmic error magnitude, i.e.

$k_{rms}$. The correlation coefficient is approximately 77 %. It is also useful to compare the average logarithmic error magnitude, i.e. ![]() $e=\langle | \log _{10}(k_{s-mod}/k_{s-data})|\rangle$. The mean error is

$e=\langle | \log _{10}(k_{s-mod}/k_{s-data})|\rangle$. The mean error is ![]() $e=0.16$ for the wind-shade model. The level of agreement between modelled and measured roughness scale over a large range of surface classes is encouraging.

$e=0.16$ for the wind-shade model. The level of agreement between modelled and measured roughness scale over a large range of surface classes is encouraging.

Figure 6. Sandgrain roughness predicted by the model with ![]() $\theta =10^\circ$ and

$\theta =10^\circ$ and ![]() $a_p=3$, vs measured

$a_p=3$, vs measured ![]() $k_s$ values from data, for all 104 surface cases considered in this work. Data from Jelly et al. (Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022) (red solid squares), 26 cases from Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021) (blue solid circles), wall-attached cubes from Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021) (blue solid square), rough surfaces from Flack et al. (Reference Flack, Schultz and Barros2020) (7 cases, green solid triangles), truncated cones from Womack et al. (Reference Womack, Volino, Meneveau and Schultz2022) (random: maroon triangles, staggered regular: maroon squares), 3 eggbox sinusoidal surface from Abu Rowin et al. (Reference Abu Rowin, Zhong, Saurav, Jelly, Hutchins and Chung2024) (yellow full circles), 31 cases from Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) (blue sideways open triangles), 3 power-law surfaces with exponent

$k_s$ values from data, for all 104 surface cases considered in this work. Data from Jelly et al. (Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022) (red solid squares), 26 cases from Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021) (blue solid circles), wall-attached cubes from Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021) (blue solid square), rough surfaces from Flack et al. (Reference Flack, Schultz and Barros2020) (7 cases, green solid triangles), truncated cones from Womack et al. (Reference Womack, Volino, Meneveau and Schultz2022) (random: maroon triangles, staggered regular: maroon squares), 3 eggbox sinusoidal surface from Abu Rowin et al. (Reference Abu Rowin, Zhong, Saurav, Jelly, Hutchins and Chung2024) (yellow full circles), 31 cases from Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) (blue sideways open triangles), 3 power-law surfaces with exponent ![]() $-1.5$,

$-1.5$, ![]() $-1$ and

$-1$ and ![]() $-0.5$ from Barros et al. (Reference Barros, Schultz and Flack2018) (green open triangles), surface with 7 cases of closely packed cubes (closed sideways red triangles) from Xu et al. (Reference Xu, Altland, Yang and Kunz2021) and 4 cases of multiscale blocks (open sideways red triangles) from Medjnoun et al. (Reference Medjnoun, Rodriguez-Lopez, Ferreira, Griffiths, Meyers and Ganapathisubramani2021). Panel (a) shows the results in linear units, while panel (b) shows the ratio of modelled to measured sandgrain roughness in logarithmic units.

$-0.5$ from Barros et al. (Reference Barros, Schultz and Flack2018) (green open triangles), surface with 7 cases of closely packed cubes (closed sideways red triangles) from Xu et al. (Reference Xu, Altland, Yang and Kunz2021) and 4 cases of multiscale blocks (open sideways red triangles) from Medjnoun et al. (Reference Medjnoun, Rodriguez-Lopez, Ferreira, Griffiths, Meyers and Ganapathisubramani2021). Panel (a) shows the results in linear units, while panel (b) shows the ratio of modelled to measured sandgrain roughness in logarithmic units.

For comparison with other common roughness models derived from particular datasets, in figure 7(a) we show predictions using the correlations as listed in Flack & Chung (Reference Flack and Chung2022) from Flack et al. (Reference Flack, Schultz and Barros2020) and from Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017), referred to as ![]() $k_{s-Fla}$ and

$k_{s-Fla}$ and ![]() $k_{s-For}$, respectively. These models are implemented here as follows:

$k_{s-For}$, respectively. These models are implemented here as follows:

\begin{gather} k_{s-Fla} = k_{rms} \left\{\begin{array}{@{}ll@{}} 2.48 [1+({\min}(1.5,S_k))]^{2.24} & S_k > 0\\ 2.11 & S_k = 0 \\ 2.73 [2+({\max}({-}0.7,S_k))]^{{-}0.45} & S_k < 0 \end{array} \right. \end{gather}

\begin{gather} k_{s-Fla} = k_{rms} \left\{\begin{array}{@{}ll@{}} 2.48 [1+({\min}(1.5,S_k))]^{2.24} & S_k > 0\\ 2.11 & S_k = 0 \\ 2.73 [2+({\max}({-}0.7,S_k))]^{{-}0.45} & S_k < 0 \end{array} \right. \end{gather}

where the first includes clipping of the skewness factor ![]() $S_k$ into the domain of validity of the fit,

$S_k$ into the domain of validity of the fit, ![]() $ES_x=\langle |\partial h/\partial x| \rangle$ is the average slope magnitude and

$ES_x=\langle |\partial h/\partial x| \rangle$ is the average slope magnitude and ![]() $k_t$ is the samples’ peak-to-trough scale, defined as

$k_t$ is the samples’ peak-to-trough scale, defined as ![]() $k_t={\max }(h)-{\min }(h)$. (This definition differs slightly from that used by Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) – the latter included subdivision of the surface into parts whose extent is specified based on additional parameters – but for present comparative purposes the effects on qualitative trends are relatively small.) Over the 104 surfaces considered here, and including the arbitrary truncation mentioned above, the correlation coefficients between measured and modelled sandgrain-roughness lengths are 36 % and 34 %, respectively, for these two models. The mean logarithmic errors are

$k_t={\max }(h)-{\min }(h)$. (This definition differs slightly from that used by Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) – the latter included subdivision of the surface into parts whose extent is specified based on additional parameters – but for present comparative purposes the effects on qualitative trends are relatively small.) Over the 104 surfaces considered here, and including the arbitrary truncation mentioned above, the correlation coefficients between measured and modelled sandgrain-roughness lengths are 36 % and 34 %, respectively, for these two models. The mean logarithmic errors are ![]() $e=0.28$ and

$e=0.28$ and ![]() $e=0.24$, respectively. We have verified that, as expected, when restricting to data for which these correlations were originally developed and fitted by their authors, the correlation is significantly higher and the error lower (see solid symbols in figure 7a).

$e=0.24$, respectively. We have verified that, as expected, when restricting to data for which these correlations were originally developed and fitted by their authors, the correlation is significantly higher and the error lower (see solid symbols in figure 7a).

Figure 7. (a) Sandgrain roughness predicted by the empirical fits of Flack et al. (Reference Flack, Schultz and Barros2020) with truncated skewness (in green), and Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) (in blue) vs measured values for all 104 surface cases considered in this work. Values used from the respective authors to fit the models are shown as solid symbols. (b) Sandgrain roughness predicted by the model without local pressure term, with ![]() $\theta =10^\circ$ and

$\theta =10^\circ$ and ![]() $a_p=7.5$ vs measured values for all 104 surfaces. Data and symbols same as in figure 6.

$a_p=7.5$ vs measured values for all 104 surfaces. Data and symbols same as in figure 6.

Many other correlation and data-based models have been proposed (see review and summary in Flack & Chung Reference Flack and Chung2022) but performing an exhaustive comparison with all of them is beyond the scope of this paper. In addition, the various data-driven and machine learning approaches that have been proposed, while promising in principle, are more challenging to reproduce by others compared with simple function evaluations looped over the surface (as is required in the present approach to compute the wind-shade factor). The main contention of the present work is that our results show that a single geometric parameter ![]() ${\mathcal {W}}_{L}$ can be developed, and that inclusion of such a parameter (e.g. in any other correlations-based or machine-learning-based models) is beneficial, since by itself, with only two adjustable parameters (

${\mathcal {W}}_{L}$ can be developed, and that inclusion of such a parameter (e.g. in any other correlations-based or machine-learning-based models) is beneficial, since by itself, with only two adjustable parameters (![]() $a_p$ and

$a_p$ and ![]() $\theta$), it already provides strong predictive power.

$\theta$), it already provides strong predictive power.

5. Analysis of model terms

In this section, we explore the effects of various included physical effects and model parameters. The effect of selecting ![]() $a_p=3$ is immediately obvious since it only serves as a multiplying factor, leaving the correlation coefficient intact. However, selecting larger or lower

$a_p=3$ is immediately obvious since it only serves as a multiplying factor, leaving the correlation coefficient intact. However, selecting larger or lower ![]() $a_p$ (e.g.

$a_p$ (e.g. ![]() $a_p=3.5$ or

$a_p=3.5$ or ![]() $a_p=2.5$) leads to a cloud falling further above (or below) the line in figure 6 and slightly increases the error parameter

$a_p=2.5$) leads to a cloud falling further above (or below) the line in figure 6 and slightly increases the error parameter ![]() $e$. An error fitting procedure shows that the minimum error is indeed obtained for

$e$. An error fitting procedure shows that the minimum error is indeed obtained for ![]() $a_p=3.06$ but the error is almost unchanged. We conclude that selecting

$a_p=3.06$ but the error is almost unchanged. We conclude that selecting ![]() $a_p=3$ appears to be a good choice.

$a_p=3$ appears to be a good choice.

Other model ingredients included the potential flow pressure distribution, i.e. selecting a local value of ![]() $\alpha (x,y)/[{\rm \pi} +\alpha {(x,y)}]$ inside the integral, using the projection of the square velocity via the term

$\alpha (x,y)/[{\rm \pi} +\alpha {(x,y)}]$ inside the integral, using the projection of the square velocity via the term ![]() $\hat {n}_x^2(x,y)$, and including the shading factor

$\hat {n}_x^2(x,y)$, and including the shading factor ![]() $F^{sh}(x,y;\theta)$. The effect of viscous contributions can also be ascertained. Finally, a specified angle

$F^{sh}(x,y;\theta)$. The effect of viscous contributions can also be ascertained. Finally, a specified angle ![]() $\theta$ was chosen for the model. The effect of each of these choices is analysed next and a summary of the resulting correlation and error coefficients are provided in tabular form (see table 1).

$\theta$ was chosen for the model. The effect of each of these choices is analysed next and a summary of the resulting correlation and error coefficients are provided in tabular form (see table 1).

Table 1. Summary of correlation coefficients and mean logarithmic error between model predicted and measured sandgrain roughness for various versions of the model.

5.1. Potential flow pressure distribution

To quantify the effect of the pressure distribution term, we here define a wind-shade factor using the overall mean pressure as prefactor instead of the local one and do not include the projection normal to the surface (i.e. we also omit the ![]() $\hat {n}_x^2$ term). We define

$\hat {n}_x^2$ term). We define

Everything else is left unchanged and the sandgrain roughness is computed using (2.14) but using ![]() ${\mathcal {W}}^{no \, p}_{L}$ instead of

${\mathcal {W}}^{no \, p}_{L}$ instead of ![]() ${\mathcal {W}}_{L}$. The ‘best’ value of