1. Introduction

The wetting phenomena of liquids sitting on top of solid substrates have attracted great scientific attention in past decades (De Gennes Reference De Gennes1985; Bonn Reference Bonn2001; Quéré Reference Quéré2008; Yuan & Lee Reference Yuan and Lee2013; Mitra et al. Reference Mitra, Nguyen, Doroodchi, Pareek, Joshi and Evans2016; Wang et al. Reference Wang, Orejon, Takata and Sefiane2022; Wang, Wu & Nestler Reference Wang, Wu and Nestler2023). The scientific significance of the wetting phenomenon lies in its natural importance, such as lotus effect (Marmur Reference Marmur2004) and coffee-ring pattern (Deegan et al. Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten1997), as well as the broad technical applications, e.g. inkjet printing in printed electronics (Määttänen et al. Reference Määttänen, Ihalainen, Bollström, Toivakka and Peltonen2010). It appears that in most previous studies (Cahn Reference Cahn1977; De Gennes Reference De Gennes1985; Puri & Binder Reference Puri and Binder1994; Jacqmin Reference Jacqmin2000; Tanaka Reference Tanaka2001; Sefiane, David & Shanahan Reference Sefiane, David and Shanahan2008; Badillo Reference Badillo2015; Zhang, Tang & Wu Reference Zhang, Tang and Wu2022b), one-component liquids or binary fluids have been focused on regarding the investigation of wetting phenomena, such as water on top of a solid substrate (Wenzel Reference Wenzel1936). However, in most realistic circumstances, the liquid droplet involved in the wetting effect contains more than one component. Typical examples are a water–coffee droplet and an inkjet printing droplet including several components of electrolytes (Turkoz et al. Reference Turkoz, Perazzo, Kim, Stone and Arnold2018; Cadilha Marques et al. Reference Cadilha Marques, Weller, Erozan, Feng, Tahoori and Aghassi-Hagmann2019). Moreover, in some cases (Attinger, Zhao & Poulikakos Reference Attinger, Zhao and Poulikakos2000; Govor et al. Reference Govor, Reiter, Bauer and Parisi2004), the components in the droplet are immiscible with each other, such as water–oil (Tan et al. Reference Tan, Diddens, Lv, Kuerten, Zhang and Lohse2016). These situations are within the scope of the wetting phenomenon of multicomponent and multiphase systems, which have not yet been fully addressed in the literature, although some recent efforts have been devoted to this direction (Wang et al. Reference Wang, Reiter, Kellner, Brillo, Selzer and Nestler2018; Bala et al. Reference Bala, Pepona, Karlin, Kusumaatmaja and Semprebon2019; Aland & Auerbach Reference Aland and Auerbach2021; Chen et al. Reference Chen, Shu, Liu and Zhang2021; Yuan et al. Reference Yuan, Shi, Zhan and Chai2022). In this work, we aim to develop a model for the wetting effect of fluids containing three components and discuss two scenarios in which the components are miscible and immiscible.

For the wetting phenomenon of one- and two-component fluids, distinct types of models have been developed in the literature, such as sharp interface model (Chamakos et al. Reference Chamakos, Kavousanakis, Boudouvis and Papathanasiou2016; Du et al. Reference Du, Chamakos, Papathanasiou and Min2021), phase-field model (Yue & Feng Reference Yue and Feng2012; Ben Said et al. Reference Ben Said, Selzer, Nestler, Braun, Greiner and Garcke2014; Cai et al. Reference Cai, Marschall, Wörner and Deutschmann2015; Wu et al. Reference Wu, Wang, Selzer and Nestler2019b, Reference Wu, Wang, Ma, Selzer and Nestler2020, Reference Wu, Wang, Huang, Selzer and Nestler2022; Zhu et al. Reference Zhu, Kou, Yao, Li and Sun2020), lattice Boltzmann (Attar & Körner Reference Attar and Körner2009; Bala et al. Reference Bala, Pepona, Karlin, Kusumaatmaja and Semprebon2019), volume of fluid (Hirt & Nichols Reference Hirt and Nichols1981; Malgarinos et al. Reference Malgarinos, Nikolopoulos, Marengo, Antonini and Gavaises2014), level-set methods (Zheng & Zhang Reference Zheng and Zhang2000; Buscaglia & Ausas Reference Buscaglia and Ausas2011) and thin-film models (Thiele Reference Thiele2018). The sharp interface method has mathematically a zero interfacial thickness. The advantage of the sharp interface model lies in the direct application of physical principles. For instance, Young's law

is applied to determine the macroscopic equilibrium contact angle ![]() $\theta$ at the triple junction of droplet–surrounding–substrate. Here,

$\theta$ at the triple junction of droplet–surrounding–substrate. Here, ![]() $\gamma _{\delta S}$,

$\gamma _{\delta S}$, ![]() $\gamma _{\alpha S }$ and

$\gamma _{\alpha S }$ and ![]() $\gamma _{\alpha \delta }$ are the interfacial tensions of surrounding–substrate, liquid–substrate and liquid–surrounding, respectively. Another example in the sharp interface approach is the application of Young–Laplace pressure

$\gamma _{\alpha \delta }$ are the interfacial tensions of surrounding–substrate, liquid–substrate and liquid–surrounding, respectively. Another example in the sharp interface approach is the application of Young–Laplace pressure

for the boundary condition at the droplet–surrounding interface, where the droplet is in equilibrium with the surrounding phase. The droplet radius is represented by ![]() $R$ and its reciprocal denotes the mean curvature. However, the sharp interface model becomes less efficient when the droplet spreads and evaporates, where the interface and the triple junction move with time. In these cases, one has to make a huge effort to track the position of the interface as well as the triple junction to apply the corresponding boundary conditions. The sharp interface model seems to be tricky when it comes to multi-droplet scenarios where numerous interfaces need to be considered. In a second approach, the diffuse interface method is proved to be not only more efficient, but also more physically correct, as the droplet–surrounding interface is assigned a finite width, typically of the order of nanometres. To distinguish the droplet from the surrounding phase, the composition or the so-called phase-field order parameter

$R$ and its reciprocal denotes the mean curvature. However, the sharp interface model becomes less efficient when the droplet spreads and evaporates, where the interface and the triple junction move with time. In these cases, one has to make a huge effort to track the position of the interface as well as the triple junction to apply the corresponding boundary conditions. The sharp interface model seems to be tricky when it comes to multi-droplet scenarios where numerous interfaces need to be considered. In a second approach, the diffuse interface method is proved to be not only more efficient, but also more physically correct, as the droplet–surrounding interface is assigned a finite width, typically of the order of nanometres. To distinguish the droplet from the surrounding phase, the composition or the so-called phase-field order parameter ![]() $\phi$ is introduced which varies continuously from the equilibrium value in the droplet to that in the surrounding. Benefiting from the establishment of the free energy functional

$\phi$ is introduced which varies continuously from the equilibrium value in the droplet to that in the surrounding. Benefiting from the establishment of the free energy functional ![]() $\mathcal {F} (\phi, \boldsymbol {\nabla }\phi )$ for the diffuse interface model by Cahn (Cahn & Hilliard Reference Cahn and Hilliard1958), the equilibrium states in the bulk and on the substrate both are depicted by the minimization of the free energy functional of the system, which is calculated by the variational approach via the Euler–Lagrange equation:

$\mathcal {F} (\phi, \boldsymbol {\nabla }\phi )$ for the diffuse interface model by Cahn (Cahn & Hilliard Reference Cahn and Hilliard1958), the equilibrium states in the bulk and on the substrate both are depicted by the minimization of the free energy functional of the system, which is calculated by the variational approach via the Euler–Lagrange equation:

For one-component phases within the diffuse interface model, this variational approach gives rise to the equilibrium wetting state which has been shown to be consistent with Young's law of the sharp interface model. Considering droplet kinetics before reaching equilibrium, two kinds of diffuse interface approaches, namely Allen–Cahn and Cahn–Hilliard models, have been successfully adopted in the literature to study the wetting effect of one-component phases (Ben Said et al. Reference Ben Said, Selzer, Nestler, Braun, Greiner and Garcke2014; Wu et al. Reference Wu, Wang, Selzer and Nestler2019b). In these methods for one-component phases or two-component systems, only one single phase-field variable ![]() $\phi$ is necessary to depict the free energy functional of the system.

$\phi$ is necessary to depict the free energy functional of the system.

For multicomponent and multiphase systems, the droplet and surrounding can be dissolved with other components, but there is a paucity of literature studying the corresponding wetting phenomenon in detail. In a previous multiphase-field approach by Ben Said et al. (Reference Ben Said, Selzer, Nestler, Braun, Greiner and Garcke2014), the wetting phenomenon of ![]() $\mathcal {N}$ immiscible phases (

$\mathcal {N}$ immiscible phases (![]() $\mathcal {N}\geq 3$) was studied. The outstanding strength of this model lies in the utilization of the Allen–Cahn type of phase-field model in combination with the obstacle potential, which significantly reduces the computational time, allowing one to perform large-scale three-dimensional (3-D) simulations. The static wetting angle at the substrate has been captured based on the natural boundary condition. However, neither diffusion mechanism nor fluid dynamics is considered. Moreover, in this model, the Young–Laplace pressure has been overlooked. A recent work by Bala et al. (Reference Bala, Pepona, Karlin, Kusumaatmaja and Semprebon2019) based on the lattice Boltzmann model addressed the wetting effect of three immiscible fluid phases on a solid substrate. The wetting contact angles on the solid substrate have been described by three distinct methods. The difficulty of the multiphase and multicomponent approach for the diffuse interface model lies in the replication of the interfacial energies, since the paths for the free energy minimization on the free energy landscape are challenging to obtain analytically, as pointed out in Bala et al. (Reference Bala, Pepona, Karlin, Kusumaatmaja and Semprebon2019). Moreover, this study is only restricted to the two-dimensional (2-D) case, while the 3-D simulation turns out to be more realistic for taking the curvature of the third dimension into account, but indeed is more computationally time-expensive. Notably, these studies exclusively cover the wetting phenomenon of immiscible fluids. The previously mentioned circumstances are still not fully understood where the components are miscible, such as water–coffee or water–alcohol droplets.

$\mathcal {N}\geq 3$) was studied. The outstanding strength of this model lies in the utilization of the Allen–Cahn type of phase-field model in combination with the obstacle potential, which significantly reduces the computational time, allowing one to perform large-scale three-dimensional (3-D) simulations. The static wetting angle at the substrate has been captured based on the natural boundary condition. However, neither diffusion mechanism nor fluid dynamics is considered. Moreover, in this model, the Young–Laplace pressure has been overlooked. A recent work by Bala et al. (Reference Bala, Pepona, Karlin, Kusumaatmaja and Semprebon2019) based on the lattice Boltzmann model addressed the wetting effect of three immiscible fluid phases on a solid substrate. The wetting contact angles on the solid substrate have been described by three distinct methods. The difficulty of the multiphase and multicomponent approach for the diffuse interface model lies in the replication of the interfacial energies, since the paths for the free energy minimization on the free energy landscape are challenging to obtain analytically, as pointed out in Bala et al. (Reference Bala, Pepona, Karlin, Kusumaatmaja and Semprebon2019). Moreover, this study is only restricted to the two-dimensional (2-D) case, while the 3-D simulation turns out to be more realistic for taking the curvature of the third dimension into account, but indeed is more computationally time-expensive. Notably, these studies exclusively cover the wetting phenomenon of immiscible fluids. The previously mentioned circumstances are still not fully understood where the components are miscible, such as water–coffee or water–alcohol droplets.

Different diffuse interface models in the literature have been developed for the wetting effect of ternary fluids. From the aspect of thermodynamics, careful attention should be paid when extending the wetting model of binary fluids to the ternary case. Kim (Reference Kim2007) and Boyer et al. (Reference Boyer, Lapuerta, Minjeaud, Piar and Quintard2010) proposed a ternary phase-field method based on the Cahn–Hilliard model. The Cahn–Hilliard type of phase-field model is a kind of diffusion equation based on the chemical potential gradient rather than the composition gradient in Fick's law. In this way, in the Cahn–Hilliard model, the mass is naturally conserved. For a fluid with ![]() $K$ components, the chemical potential has

$K$ components, the chemical potential has ![]() $K-1$ independent variables because of the constraint for the volume concentration

$K-1$ independent variables because of the constraint for the volume concentration ![]() $\sum _{j=1}^{K} \phi _{j}=1$ due to incompressibility. Most importantly, for multicomponent fluids, the chemical potentials are constrained by the Gibbs–Duhem relation (Alhasan & Tree Reference Alhasan and Tree2022), which leads to a thermodynamically consistent mobility consistent with the Onsager theorem (Balluffi, Allen & Carter Reference Balluffi, Allen and Carter2005), as is demonstrated in the current work. This is in contrast to the case of constant mobility (Kim Reference Kim2007; Boyer et al. Reference Boyer, Lapuerta, Minjeaud, Piar and Quintard2010). The thermodynamic consistency due to the Gibbs–Duhem relation is in contrast to the Lagrange multiplier approach for the chemical potentials adopted in Kim (Reference Kim2007) and Boyer et al. (Reference Boyer, Lapuerta, Minjeaud, Piar and Quintard2010). As demonstrated by Jacqmin (Reference Jacqmin1996) for binary fluids and shown in the following for ternary fluids, the chemical potential plays a key role in the thermodynamic pressure, which contributes to the capillary force together with the Kortweg stress in the Navier–Stokes equation. The occurrence of the Kortweg stress and the thermodynamic pressure for multicomponent and multiphase fluids is a key difference from the one-component and one-phase Navier–Stokes flow. Only if the thermodynamic pressure is validated is the subsequent fluid dynamics for multicomponent fluids physically justified. As pointed out by Jacqmin (Reference Jacqmin2000), the pressure of a two-phase flow is different from the so-called ‘true pressure’ of one-phase flow. However, the validation of the fluid statics for the thermodynamic pressure of ternary fluids is scarce in the literature. In addition, the solid–liquid interaction, namely the wetting effect of liquid on solid, is not considered in Kim (Reference Kim2007) and Boyer et al. (Reference Boyer, Lapuerta, Minjeaud, Piar and Quintard2010). By considering the wetting boundary condition, an Allen–Cahn type of phase-field model for ternary fluids has been developed by He et al. (Reference He, Li, Huang, Hu, Li and Wang2020) and Jain, Mani & Moin (Reference Jain, Mani and Moin2020). As aforementioned, the advantage of the second-order Allen–Cahn model is its computational efficiency compared with the fourth-order Cahn–Hilliard model. However, the mass is not conserved in the Allen–Cahn model because of the curvature effect. Different ways have been adopted to amend this deficiency (Jeong & Kim Reference Jeong and Kim2017; Aihara, Takaki & Takada Reference Aihara, Takaki and Takada2019; Wu et al. Reference Wu, Wang, Selzer and Nestler2019a; Yang & He Reference Yang and He2022). One way is, for example, to remove the mean curvature in the evolution equation (He et al. Reference He, Li, Huang, Hu, Li and Wang2020, Reference He, Huang, Xu, Hu and Li2023). In this way, the thermodynamic pressure and the chemical potential in terms of the mean curvature (consequently in the capillary force) are overlooked; the real dynamics of the Allen–Cahn model should be different from that of the Cahn–Hilliard model. Mathematically, the Allen–Cahn model follows the energy dissipation law for

$\sum _{j=1}^{K} \phi _{j}=1$ due to incompressibility. Most importantly, for multicomponent fluids, the chemical potentials are constrained by the Gibbs–Duhem relation (Alhasan & Tree Reference Alhasan and Tree2022), which leads to a thermodynamically consistent mobility consistent with the Onsager theorem (Balluffi, Allen & Carter Reference Balluffi, Allen and Carter2005), as is demonstrated in the current work. This is in contrast to the case of constant mobility (Kim Reference Kim2007; Boyer et al. Reference Boyer, Lapuerta, Minjeaud, Piar and Quintard2010). The thermodynamic consistency due to the Gibbs–Duhem relation is in contrast to the Lagrange multiplier approach for the chemical potentials adopted in Kim (Reference Kim2007) and Boyer et al. (Reference Boyer, Lapuerta, Minjeaud, Piar and Quintard2010). As demonstrated by Jacqmin (Reference Jacqmin1996) for binary fluids and shown in the following for ternary fluids, the chemical potential plays a key role in the thermodynamic pressure, which contributes to the capillary force together with the Kortweg stress in the Navier–Stokes equation. The occurrence of the Kortweg stress and the thermodynamic pressure for multicomponent and multiphase fluids is a key difference from the one-component and one-phase Navier–Stokes flow. Only if the thermodynamic pressure is validated is the subsequent fluid dynamics for multicomponent fluids physically justified. As pointed out by Jacqmin (Reference Jacqmin2000), the pressure of a two-phase flow is different from the so-called ‘true pressure’ of one-phase flow. However, the validation of the fluid statics for the thermodynamic pressure of ternary fluids is scarce in the literature. In addition, the solid–liquid interaction, namely the wetting effect of liquid on solid, is not considered in Kim (Reference Kim2007) and Boyer et al. (Reference Boyer, Lapuerta, Minjeaud, Piar and Quintard2010). By considering the wetting boundary condition, an Allen–Cahn type of phase-field model for ternary fluids has been developed by He et al. (Reference He, Li, Huang, Hu, Li and Wang2020) and Jain, Mani & Moin (Reference Jain, Mani and Moin2020). As aforementioned, the advantage of the second-order Allen–Cahn model is its computational efficiency compared with the fourth-order Cahn–Hilliard model. However, the mass is not conserved in the Allen–Cahn model because of the curvature effect. Different ways have been adopted to amend this deficiency (Jeong & Kim Reference Jeong and Kim2017; Aihara, Takaki & Takada Reference Aihara, Takaki and Takada2019; Wu et al. Reference Wu, Wang, Selzer and Nestler2019a; Yang & He Reference Yang and He2022). One way is, for example, to remove the mean curvature in the evolution equation (He et al. Reference He, Li, Huang, Hu, Li and Wang2020, Reference He, Huang, Xu, Hu and Li2023). In this way, the thermodynamic pressure and the chemical potential in terms of the mean curvature (consequently in the capillary force) are overlooked; the real dynamics of the Allen–Cahn model should be different from that of the Cahn–Hilliard model. Mathematically, the Allen–Cahn model follows the energy dissipation law for ![]() $L^{2}$ gradient flow and the Cahn–Hilliard model obeys the energy dissipation law for the

$L^{2}$ gradient flow and the Cahn–Hilliard model obeys the energy dissipation law for the ![]() $H^{-1}$ gradient flow.

$H^{-1}$ gradient flow.

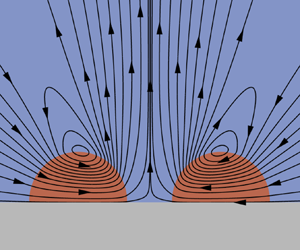

The dynamics of wetting has attracted great interest in the community of fluid dynamics. The diffuse interface model for the wetting dynamics of binary fluids dates back to the work of Jacqmin (Reference Jacqmin2000), Cahn (Reference Cahn1977) and De Gennes (Reference De Gennes1985). This diffuse interface model is based on the Cahn–Hilliard–Navier–Stokes equation. As demonstrated in Jacqmin (Reference Jacqmin2000), only numerical solution in two and three dimensions is possible even if this model is simplified to the Laplace equation for the chemical potential and the bi-harmonic equation for the stream function when the contact angle is 90![]() $^\circ$ and the viscosity ratio is 1. In the last 20 years, many other diffuse interface models (Ding & Spelt Reference Ding and Spelt2007; Carlson, Do-Quang & Amberg Reference Carlson, Do-Quang and Amberg2009; Yue, Zhou & Feng Reference Yue, Zhou and Feng2010; Sui, Ding & Spelt Reference Sui, Ding and Spelt2014; Prokopev, Vorobev & Lyubimova Reference Prokopev, Vorobev and Lyubimova2019; Huang, Lin & Ardekani Reference Huang, Lin and Ardekani2020; Gallo, Magaletti & Casciola Reference Gallo, Magaletti and Casciola2021) for the wetting effect are based on Jacqmin's approach. However, a significant difference of Jacqmin's approach from that of Cahn (Reference Cahn1977) and De Gennes (Reference De Gennes1985) is the surface composition. The surface composition is engendered by the joint equilibrium of bulk and surface and obtained somehow by the intersection of the wall free energy with the bulk free energy. In Jacqmin's approach, the minima of the wall free energy are always identical to that of the bulk free energy, which leads to the same surface and bulk compositions. However, in Cahn/de Gennes methods, the surface composition differs from the bulk composition. The surface composition gives rise to an additional contribution to the interface energies (De Gennes Reference De Gennes1985), making the situation more complex but indeed more generalized. Only a binary numerical model considers the effect of the surface composition on the wetting effect (Wang & Nestler Reference Wang and Nestler2021) and, to the best knowledge of the authors, no ternary model so far takes the surface composition into account. Moreover, it has been shown that the Marangoni flow plays a vital role in the dynamics of wetting (Wang et al. Reference Wang, Orejon, Takata and Sefiane2022). Because of the singularity at the triple junction (Huh & Scriven Reference Huh and Scriven1971), it seems to be difficult for the sharp interface model to address the Marangoni effect in the process of dynamic wetting. Using a diffuse interface model, we present distinct flow patterns of dynamic wetting in comparison with the analysis of Huh & Scriven (Reference Huh and Scriven1971) and cast light on the Marangoni effect for dynamic wetting.

$^\circ$ and the viscosity ratio is 1. In the last 20 years, many other diffuse interface models (Ding & Spelt Reference Ding and Spelt2007; Carlson, Do-Quang & Amberg Reference Carlson, Do-Quang and Amberg2009; Yue, Zhou & Feng Reference Yue, Zhou and Feng2010; Sui, Ding & Spelt Reference Sui, Ding and Spelt2014; Prokopev, Vorobev & Lyubimova Reference Prokopev, Vorobev and Lyubimova2019; Huang, Lin & Ardekani Reference Huang, Lin and Ardekani2020; Gallo, Magaletti & Casciola Reference Gallo, Magaletti and Casciola2021) for the wetting effect are based on Jacqmin's approach. However, a significant difference of Jacqmin's approach from that of Cahn (Reference Cahn1977) and De Gennes (Reference De Gennes1985) is the surface composition. The surface composition is engendered by the joint equilibrium of bulk and surface and obtained somehow by the intersection of the wall free energy with the bulk free energy. In Jacqmin's approach, the minima of the wall free energy are always identical to that of the bulk free energy, which leads to the same surface and bulk compositions. However, in Cahn/de Gennes methods, the surface composition differs from the bulk composition. The surface composition gives rise to an additional contribution to the interface energies (De Gennes Reference De Gennes1985), making the situation more complex but indeed more generalized. Only a binary numerical model considers the effect of the surface composition on the wetting effect (Wang & Nestler Reference Wang and Nestler2021) and, to the best knowledge of the authors, no ternary model so far takes the surface composition into account. Moreover, it has been shown that the Marangoni flow plays a vital role in the dynamics of wetting (Wang et al. Reference Wang, Orejon, Takata and Sefiane2022). Because of the singularity at the triple junction (Huh & Scriven Reference Huh and Scriven1971), it seems to be difficult for the sharp interface model to address the Marangoni effect in the process of dynamic wetting. Using a diffuse interface model, we present distinct flow patterns of dynamic wetting in comparison with the analysis of Huh & Scriven (Reference Huh and Scriven1971) and cast light on the Marangoni effect for dynamic wetting.

We develop a ternary phase-field model for the wetting phenomenon of droplets which contain either two miscible or three immiscible components. For the miscible case, we designate two kinds of phase diagrams, namely a symmetric and an asymmetric one, to emphasize the crucial impact of different thermodynamics for the sessile droplets. By varying the composition and the size of the droplet, we validate the present model by comparing the simulation results with Young's law in both two and three dimensions, as well as with the Young–Laplace relationship. Our present results show that the initial composition in combination with the phase diagram leads to different paths of free energy minimization, which engenders distinct wettabilities of the fluids on a solid substrate. Our model also allows one to scrutinize the surface composition, enabling one to relate the interfacial energies with the composition. In the case of miscible fluids, we further study the process of evaporation to be compared with the power law observed in experiments. Furthermore, we consider three immiscible fluids with different wettabilities on the substrate in both two and three dimensions. A similar consideration for the phase diagram of ternary fluids has been published by He et al. (Reference He, Li, Huang, Hu, Li and Wang2020). However, this work is based on the Allen–Cahn model via removing the mean curvature in the evolution equation, which is in contrast to the thermodynamically consistent Cahn–Hilliard model. The thermodynamic pressure as well as the dynamics which is important for the flow patterns of dynamic wetting should be intrinsically different although both models reduce the energy of the system.

The rest of the paper is structured as follows. In § 2, we review the Cahn/de Gennes wetting models for a two-component and two-phase system. In § 3, we present phase diagrams for miscible and immiscible fluids. In § 4, we derive the bulk and surface equilibrium conditions. Based on the results in § 4, we show the calculation of the interfacial energies in § 5. In § 6, we depict the kinetic equations based on the Cahn–Hilliard model and its coupling with the Navier–Stokes equations. In § 7, we present criteria for calculating the contact angles. In § 8, we present the effect of the droplet composition on the contact angle for different types of phase diagrams shown in § 3, and validate the surface composition. In § 9, we study the process of evaporation with different saturation rates. In §§ 10 and 11, we validate the present model for fluid statics and fluid dynamics. In § 12, we show the simulation results for three immiscible fluids. We conclude the paper in § 13.

2. Cahn/de Gennes model for two-component two-phase flow

For a system with two components and two immiscible phases, the free energy functional is written as (Cahn Reference Cahn1977; De Gennes Reference De Gennes1985)

where the bulk free energy density ![]() $f(\phi )$ as a function of the composition

$f(\phi )$ as a function of the composition ![]() $\phi$ has two local minima (equilibrium states) at

$\phi$ has two local minima (equilibrium states) at ![]() $\phi _{e}^{\delta }$ and

$\phi _{e}^{\delta }$ and ![]() $\phi _{e}^{\alpha }$ to model two immiscible fluids. The composition

$\phi _{e}^{\alpha }$ to model two immiscible fluids. The composition ![]() $\phi$ is space

$\phi$ is space ![]() $\boldsymbol x$ and time

$\boldsymbol x$ and time ![]() $t$ dependent defined on the bulk domain

$t$ dependent defined on the bulk domain ![]() $\varOmega$ and the solid substrate

$\varOmega$ and the solid substrate ![]() $S$. Typical examples for the free energy density are double-well potential (Jacqmin Reference Jacqmin2000), obstacle potential (Nestler, Garcke & Stinner Reference Nestler, Garcke and Stinner2005) or the regular solution model (Wang et al. Reference Wang, Choudhury, Selzer, Mukherjee and Nestler2012). The interface tension

$S$. Typical examples for the free energy density are double-well potential (Jacqmin Reference Jacqmin2000), obstacle potential (Nestler, Garcke & Stinner Reference Nestler, Garcke and Stinner2005) or the regular solution model (Wang et al. Reference Wang, Choudhury, Selzer, Mukherjee and Nestler2012). The interface tension ![]() $\gamma _{\alpha \delta }$ of the immiscible liquids is calculated by

$\gamma _{\alpha \delta }$ of the immiscible liquids is calculated by

where the excess energy density ![]() ${\rm \Delta} f$ is defined as

${\rm \Delta} f$ is defined as ![]() $f(\phi )-f(\phi _{e}^{\alpha })-\mu ^{e}(\phi -\phi _{e}^{\alpha })$,

$f(\phi )-f(\phi _{e}^{\alpha })-\mu ^{e}(\phi -\phi _{e}^{\alpha })$, ![]() $\mu ^{e}$ representing the chemical potential at equilibrium, and

$\mu ^{e}$ representing the chemical potential at equilibrium, and ![]() $X$ traces the integration path from the bulk of the droplet to the surrounding bulk region.

$X$ traces the integration path from the bulk of the droplet to the surrounding bulk region.

The second part of (2.1) describes the wall free energy whose density ![]() $\varGamma (\phi )$ is an interpolation over the individual interfacial tensions:

$\varGamma (\phi )$ is an interpolation over the individual interfacial tensions:

where the interpolation function ![]() $h(\phi )$ fulfils

$h(\phi )$ fulfils ![]() $h(\phi _{e}^{\alpha })=1$ and

$h(\phi _{e}^{\alpha })=1$ and ![]() $h(\phi _{e}^{\delta })=0$. By this interpolation, the liquid–substrate interfacial energy is

$h(\phi _{e}^{\delta })=0$. By this interpolation, the liquid–substrate interfacial energy is ![]() $\gamma _{\alpha S}$, when the liquid composition is

$\gamma _{\alpha S}$, when the liquid composition is ![]() $\phi =\phi _{e}^{\alpha }$; and the surrounding–substrate interfacial energy is

$\phi =\phi _{e}^{\alpha }$; and the surrounding–substrate interfacial energy is ![]() $\gamma _{\delta S}$, when the surrounding composition is

$\gamma _{\delta S}$, when the surrounding composition is ![]() $\phi =\phi _{e}^{\delta }$. Various formulations for

$\phi =\phi _{e}^{\delta }$. Various formulations for ![]() $h(\phi )$ have been used in previous literature (Carlson et al. Reference Carlson, Do-Quang and Amberg2009; Diewald et al. Reference Diewald, Kuhn, Blauwhoff, Heier, Becker, Werth, Horsch, Hasse and Müller2016; Xu Reference Xu2016; Wu et al. Reference Wu, Wang, Selzer and Nestler2019b). Apart from the interpolation concept over individual interfacial tensions, a second-order polynomial has been used (Cahn Reference Cahn1977; De Gennes Reference De Gennes1985):

$h(\phi )$ have been used in previous literature (Carlson et al. Reference Carlson, Do-Quang and Amberg2009; Diewald et al. Reference Diewald, Kuhn, Blauwhoff, Heier, Becker, Werth, Horsch, Hasse and Müller2016; Xu Reference Xu2016; Wu et al. Reference Wu, Wang, Selzer and Nestler2019b). Apart from the interpolation concept over individual interfacial tensions, a second-order polynomial has been used (Cahn Reference Cahn1977; De Gennes Reference De Gennes1985):

Here, ![]() $a_{0}$,

$a_{0}$, ![]() $a_{1}$ and

$a_{1}$ and ![]() $a_{2}$ depict the attractive and repulsive interactions between the liquid and the substrate. A significant difference between (2.3) and (2.4) is that in the former case, the effective interfacial energies

$a_{2}$ depict the attractive and repulsive interactions between the liquid and the substrate. A significant difference between (2.3) and (2.4) is that in the former case, the effective interfacial energies ![]() $\gamma _{\delta S}$ and

$\gamma _{\delta S}$ and ![]() $\gamma _{\alpha S}$ are independent of surface composition. While in the latter case,

$\gamma _{\alpha S}$ are independent of surface composition. While in the latter case, ![]() $\gamma _{\alpha S}$ and

$\gamma _{\alpha S}$ and ![]() $\gamma _{\delta S}$ depend on the surface composition

$\gamma _{\delta S}$ depend on the surface composition ![]() $\phi _{S}^{a}$ (

$\phi _{S}^{a}$ (![]() $a = \alpha$,

$a = \alpha$, ![]() $\delta$), which is determined by a series of partial differential equations resulting from the joint equilibrium of the bulk and the surface as

$\delta$), which is determined by a series of partial differential equations resulting from the joint equilibrium of the bulk and the surface as

where ![]() $\boldsymbol n$ is the normal vector of the solid substrate. After simplification, we obtain the following implicit equation for the surface composition

$\boldsymbol n$ is the normal vector of the solid substrate. After simplification, we obtain the following implicit equation for the surface composition ![]() $\phi _{S}^{a}$:

$\phi _{S}^{a}$:

where the left-hand side is typically a ‘W’-shaped curve (see supplementary figure S1 available at https://doi.org/10.1017/jfm.2023.561) and the right-hand side is a linear function of ![]() $\phi$ if (2.4) is applied. The intersection of the two curves

$\phi$ if (2.4) is applied. The intersection of the two curves ![]() $2\sqrt {\kappa {\rm \Delta} f}$ and

$2\sqrt {\kappa {\rm \Delta} f}$ and ![]() $\varGamma ^\prime (\phi )$ determines the surface composition

$\varGamma ^\prime (\phi )$ determines the surface composition ![]() $\phi _{S}^{\alpha }$ and

$\phi _{S}^{\alpha }$ and ![]() $\phi _{S}^{\delta }$ (see figure S1). In this way, the interfacial energies have two contributions: one is the wall free energy density

$\phi _{S}^{\delta }$ (see figure S1). In this way, the interfacial energies have two contributions: one is the wall free energy density ![]() $\varGamma (\phi _{S}^{a})$ (

$\varGamma (\phi _{S}^{a})$ (![]() $a=\alpha$,

$a=\alpha$, ![]() $\delta$) and the other one is the excess free energy which is calculated by an integration from the surface composition

$\delta$) and the other one is the excess free energy which is calculated by an integration from the surface composition ![]() $\phi _{S}^{a}$ to the bulk composition

$\phi _{S}^{a}$ to the bulk composition ![]() $\phi _{e}^{a}$. This result is in contrast to the independence of the interfacial energies on the surface composition if (2.3) is applied. The interfacial energies with the excess free energy at the solid–liquid interface represent a large difference of Cahn's approach from Jacqmin's wetting model (Jacqmin Reference Jacqmin2000). For fluids with three components, the variation of the wettabilities due to the occurrence of the surface composition is much more complex than the binary case and is examined in the following.

$\phi _{e}^{a}$. This result is in contrast to the independence of the interfacial energies on the surface composition if (2.3) is applied. The interfacial energies with the excess free energy at the solid–liquid interface represent a large difference of Cahn's approach from Jacqmin's wetting model (Jacqmin Reference Jacqmin2000). For fluids with three components, the variation of the wettabilities due to the occurrence of the surface composition is much more complex than the binary case and is examined in the following.

3. Model of ternary fluids

We consider a fluid mixture consisting of three components, of which the compositions are denoted by ![]() $\boldsymbol \phi = (\phi _{1}(\boldsymbol x, t), \phi _{2}(\boldsymbol x, t), \phi _{3}(\boldsymbol x, t))$. The compositions are space

$\boldsymbol \phi = (\phi _{1}(\boldsymbol x, t), \phi _{2}(\boldsymbol x, t), \phi _{3}(\boldsymbol x, t))$. The compositions are space ![]() $\boldsymbol x$ and time

$\boldsymbol x$ and time ![]() $t$ dependent and are restricted within the Gibbs simplex

$t$ dependent and are restricted within the Gibbs simplex ![]() $G=\{ \boldsymbol {\phi }\in \mathbb {R}^{3}:\sum _{j=1}^{3}\phi _{j}=1, \phi _{j}\geq 0 \}$ in accordance with the assumption of incompressible fluids. This constraint results from the definition of the volume concentration

$G=\{ \boldsymbol {\phi }\in \mathbb {R}^{3}:\sum _{j=1}^{3}\phi _{j}=1, \phi _{j}\geq 0 \}$ in accordance with the assumption of incompressible fluids. This constraint results from the definition of the volume concentration ![]() $\phi _{i}=v_{i}^{o}/v_{m}$, where

$\phi _{i}=v_{i}^{o}/v_{m}$, where ![]() $v_{i}^{o}$ and

$v_{i}^{o}$ and ![]() $v_{m}$ are the molar volumes of the

$v_{m}$ are the molar volumes of the ![]() $i$ component and the mixture, respectively. By the Flory–Huggins model (Flory Reference Flory1953), the free energy density of the system is formulated as a function of temperature

$i$ component and the mixture, respectively. By the Flory–Huggins model (Flory Reference Flory1953), the free energy density of the system is formulated as a function of temperature ![]() $T$ and composition

$T$ and composition ![]() $\boldsymbol \phi$ as

$\boldsymbol \phi$ as

\begin{equation} f(\boldsymbol\phi,T)= (R_{g}T/v_{m}) \left(\sum_{j=1}^{3} \frac{\phi_{j}\ln \phi_{j}}{N_{j}}+ \sum_{j< k}\chi_{jk} \phi_{j} \phi_{k}+\sum_{j< k< l}\chi_{jkl}\phi_{j}\phi_{k}\phi_{l}\right),\quad \forall\ \boldsymbol x \in \varOmega, \end{equation}

\begin{equation} f(\boldsymbol\phi,T)= (R_{g}T/v_{m}) \left(\sum_{j=1}^{3} \frac{\phi_{j}\ln \phi_{j}}{N_{j}}+ \sum_{j< k}\chi_{jk} \phi_{j} \phi_{k}+\sum_{j< k< l}\chi_{jkl}\phi_{j}\phi_{k}\phi_{l}\right),\quad \forall\ \boldsymbol x \in \varOmega, \end{equation}

where the first logarithm term denotes entropy contribution and the last two polynomial terms are related to the enthalpy of the mixture. The Flory–Huggins parameters ![]() $\chi _{jk}$ depict the double interaction between species

$\chi _{jk}$ depict the double interaction between species ![]() $j$ and

$j$ and ![]() $k$, while

$k$, while ![]() $\chi _{jkl}$ scales the more complex triple interaction between all three species

$\chi _{jkl}$ scales the more complex triple interaction between all three species ![]() $j$,

$j$, ![]() $k$ and

$k$ and ![]() $l$ (Zhang et al. Reference Zhang, Wu, Wang, Guo and Nestler2021). Especially for distinct polymer species, the entropy of the mixture can be altered by the degree of polymerization

$l$ (Zhang et al. Reference Zhang, Wu, Wang, Guo and Nestler2021). Especially for distinct polymer species, the entropy of the mixture can be altered by the degree of polymerization ![]() $N_{j}$ which, otherwise, is set to unity for very small molecular species, such as water or metal. In this work, the selection criteria for the interaction parameters

$N_{j}$ which, otherwise, is set to unity for very small molecular species, such as water or metal. In this work, the selection criteria for the interaction parameters ![]() $\chi _{jk}$ and

$\chi _{jk}$ and ![]() $\chi _{jkl}$, the temperature

$\chi _{jkl}$, the temperature ![]() $T$ as well as

$T$ as well as ![]() $N_{j}$ are made to model two different situations:

$N_{j}$ are made to model two different situations:

(S1) Two phases consisting of component 1 and component 2 are completely miscible, forming an

$\alpha$ phase droplet, like water–alcohol or water–coffee. Meanwhile, the

$\alpha$ phase droplet, like water–alcohol or water–coffee. Meanwhile, the  $\alpha$ phase is immiscible with the component-3-rich

$\alpha$ phase is immiscible with the component-3-rich  $\delta$ phase, like vapour. For two phases in equilibrium, as demonstrated in figures 1(I) and 1(II), there are two local minima in the free energy landscape. These two free energy minima states respectively represent the droplet of

$\delta$ phase, like vapour. For two phases in equilibrium, as demonstrated in figures 1(I) and 1(II), there are two local minima in the free energy landscape. These two free energy minima states respectively represent the droplet of  $\alpha$ phase and the

$\alpha$ phase and the  $\delta$ surrounding phase. The equilibrium compositions

$\delta$ surrounding phase. The equilibrium compositions  $\boldsymbol \phi _{{e}}^{\alpha }=( \phi _{1}^{\alpha }, \phi _{2}^{\alpha }, \phi _{3}^{\alpha })$,

$\boldsymbol \phi _{{e}}^{\alpha }=( \phi _{1}^{\alpha }, \phi _{2}^{\alpha }, \phi _{3}^{\alpha })$,  $\boldsymbol \phi _{e}^{\delta }=(\phi _{1}^{\delta }, \phi _{2}^{\delta }, \phi _{3}^{\delta })$ between the immiscible

$\boldsymbol \phi _{e}^{\delta }=(\phi _{1}^{\delta }, \phi _{2}^{\delta }, \phi _{3}^{\delta })$ between the immiscible  $\alpha$ and

$\alpha$ and  $\delta$ phases are defined by the common tangent construction as

(3.2)

$\delta$ phases are defined by the common tangent construction as

(3.2) \begin{gather} \boldsymbol\mu^{e}\equiv(\mu_{1}^{e},\mu_{2}^{e},\mu_{3}^{e}) = \left.\frac{\partial f}{\partial \boldsymbol\phi}\right\rvert_{\boldsymbol\phi=\boldsymbol \phi_{e}^{\alpha}} =\left.\frac{\partial f}{\partial \boldsymbol\phi}\right\rvert_{\boldsymbol\phi=\boldsymbol \phi_{e}^{\delta}}; \end{gather}(3.3)Here,

\begin{gather} \boldsymbol\mu^{e}\equiv(\mu_{1}^{e},\mu_{2}^{e},\mu_{3}^{e}) = \left.\frac{\partial f}{\partial \boldsymbol\phi}\right\rvert_{\boldsymbol\phi=\boldsymbol \phi_{e}^{\alpha}} =\left.\frac{\partial f}{\partial \boldsymbol\phi}\right\rvert_{\boldsymbol\phi=\boldsymbol \phi_{e}^{\delta}}; \end{gather}(3.3)Here, \begin{gather}f(\boldsymbol \phi_{e}^{\alpha})-f(\boldsymbol \phi_{e}^{\delta})= \langle \boldsymbol\mu^{e}, \boldsymbol \phi_{e}^{\alpha}-\boldsymbol \phi_{e}^{\delta} \rangle, \quad \forall\ \boldsymbol x \in \varOmega. \end{gather}

\begin{gather}f(\boldsymbol \phi_{e}^{\alpha})-f(\boldsymbol \phi_{e}^{\delta})= \langle \boldsymbol\mu^{e}, \boldsymbol \phi_{e}^{\alpha}-\boldsymbol \phi_{e}^{\delta} \rangle, \quad \forall\ \boldsymbol x \in \varOmega. \end{gather} $\mu _{i}^{e}$,

$\mu _{i}^{e}$,  $i=1, 2, 3$, denotes the equilibrium chemical potential of component

$i=1, 2, 3$, denotes the equilibrium chemical potential of component  $i$ and

$i$ and  $\langle \ \rangle$ is the dot product operator. Equations (3.2) and (3.3) are solved by the Newton iteration method and the equilibrium compositions are illustrated by the black solid lines in figure 1. The difference of figure 1(I) from figure 1(II) is that the miscibility of components 1 and 2 is symmetric with respect to the composition of

$\langle \ \rangle$ is the dot product operator. Equations (3.2) and (3.3) are solved by the Newton iteration method and the equilibrium compositions are illustrated by the black solid lines in figure 1. The difference of figure 1(I) from figure 1(II) is that the miscibility of components 1 and 2 is symmetric with respect to the composition of  $\phi _{2}=0.5$. In this case, the component 1 and 2 molecules have high similarity and their interaction with component 3 is identical. Figure 1(II) represents another case, where components 1 and 2 have different interaction parameters or degrees of polymerization (

$\phi _{2}=0.5$. In this case, the component 1 and 2 molecules have high similarity and their interaction with component 3 is identical. Figure 1(II) represents another case, where components 1 and 2 have different interaction parameters or degrees of polymerization ( $N_{i}$). Consequently, the miscibility shifts to the side of the component-2-rich phase in figure 1(II).

$N_{i}$). Consequently, the miscibility shifts to the side of the component-2-rich phase in figure 1(II).(S2) Three phases consisting of the three components 1, 2 and 3 are immiscible with each other (Zhang, Wang & Nestler Reference Zhang, Wang and Nestler2022a), for instance, a water–oil–vapour system. In this case, three local minima on the free energy landscape manifest the equilibrium compositions in each immiscible phase, as depicted by the black dots in the phase diagram of figure 1(III). For convenience, component 1-, 2- and 3-rich phases are called

$\alpha$,

$\alpha$,  $\beta$ and

$\beta$ and  $\delta$ phases, respectively.

$\delta$ phases, respectively.

Figure 1. Free energy density landscapes and phase diagram. (I,II) Miscible ternary system. The parameters for (I) are ![]() $(N_{1}, N_{2}, N_{3}) = (2, 2, 1)$,

$(N_{1}, N_{2}, N_{3}) = (2, 2, 1)$, ![]() $(\chi _{1},\chi _{2},\chi _{3}, \chi _{123})=(0.5, 3.5, 3.5, 1.5)$ and

$(\chi _{1},\chi _{2},\chi _{3}, \chi _{123})=(0.5, 3.5, 3.5, 1.5)$ and ![]() $T=2$. The parameters for (II) are

$T=2$. The parameters for (II) are ![]() $(N_{1}, N_{2}, N_{3}) = (5, 1, 1)$,

$(N_{1}, N_{2}, N_{3}) = (5, 1, 1)$, ![]() $(\chi _{1},\chi _{2},\chi _{3}, \chi _{123})=(0.5, 6.0, 4.5, 1.5)$ and

$(\chi _{1},\chi _{2},\chi _{3}, \chi _{123})=(0.5, 6.0, 4.5, 1.5)$ and ![]() $T=2$. The black solid lines depict the binodal composition in the phase consisting of components 1 and 2 (

$T=2$. The black solid lines depict the binodal composition in the phase consisting of components 1 and 2 (![]() $\alpha$ phase) and in the component-3-rich phase (

$\alpha$ phase) and in the component-3-rich phase (![]() $\delta$ phase). The dashed lines show the spinodal curves. (III) Immiscible ternary system with the simulation parameters

$\delta$ phase). The dashed lines show the spinodal curves. (III) Immiscible ternary system with the simulation parameters ![]() $(N_{1}, N_{2}, N_{3}) = (1, 1, 1)$,

$(N_{1}, N_{2}, N_{3}) = (1, 1, 1)$, ![]() $(\chi _{1},\chi _{2},\chi _{3}, \chi _{123})=(2.5, 2.5, 2.5, 4.0)$ and

$(\chi _{1},\chi _{2},\chi _{3}, \chi _{123})=(2.5, 2.5, 2.5, 4.0)$ and ![]() $T=2$. The equilibrium compositions in

$T=2$. The equilibrium compositions in ![]() $\alpha$ (component-1-rich),

$\alpha$ (component-1-rich), ![]() $\beta$ (component-2-rich) and

$\beta$ (component-2-rich) and ![]() $\delta$ (component-3-rich) phases are illustrated by the black circles at the left, right and top positions, respectively. Colour legend: red for high free energy density values and blue for low values.

$\delta$ (component-3-rich) phases are illustrated by the black circles at the left, right and top positions, respectively. Colour legend: red for high free energy density values and blue for low values.

4. Bulk and surface thermodynamics

The free energy functional of the system reads

\begin{equation} \mathcal{F}(\boldsymbol\phi, \boldsymbol{\nabla} \boldsymbol\phi) =\int_\varOmega \left[f(\boldsymbol\phi, T) + \sum_{j=1}^{3} \kappa_{j} (\nabla \phi_{j})^{2} \right] {\rm d}\varOmega + \int_{S} \varGamma(\boldsymbol\phi)\,{\rm d} S,\quad \forall\ \boldsymbol x \in \varOmega \cup S. \end{equation}

\begin{equation} \mathcal{F}(\boldsymbol\phi, \boldsymbol{\nabla} \boldsymbol\phi) =\int_\varOmega \left[f(\boldsymbol\phi, T) + \sum_{j=1}^{3} \kappa_{j} (\nabla \phi_{j})^{2} \right] {\rm d}\varOmega + \int_{S} \varGamma(\boldsymbol\phi)\,{\rm d} S,\quad \forall\ \boldsymbol x \in \varOmega \cup S. \end{equation}

Here, ![]() $\kappa _{i}$ stands for the gradient energy coefficient. Considering an

$\kappa _{i}$ stands for the gradient energy coefficient. Considering an ![]() $a$–

$a$–![]() $b$ interface (

$b$ interface (![]() $a=\alpha$,

$a=\alpha$, ![]() $\beta$,

$\beta$, ![]() $\delta$,

$\delta$, ![]() $b=\alpha$,

$b=\alpha$, ![]() $\beta$,

$\beta$, ![]() $\delta$,

$\delta$, ![]() $a\neq b$),

$a\neq b$),

Substituting (4.1) into (4.2) yields the following coupled ordinary differential equations:

An integration of (4.3) with the condition that the composition gradient vanishes at the boundary leads to

\begin{equation} \sum_{j=1}^{K}\kappa_{j} \left(\nabla\phi_{j}\right)^{2}={\rm \Delta} f,\quad \forall\ \boldsymbol x \in \varOmega, \end{equation}

\begin{equation} \sum_{j=1}^{K}\kappa_{j} \left(\nabla\phi_{j}\right)^{2}={\rm \Delta} f,\quad \forall\ \boldsymbol x \in \varOmega, \end{equation}

where the excess energy density ![]() ${\rm \Delta} f=f(\boldsymbol \phi )-f(\boldsymbol \phi _{e}^{a})- \boldsymbol \mu ^{{e}}\boldsymbol {\cdot }(\boldsymbol \phi - \boldsymbol \phi _{e}^{a})=f(\boldsymbol \phi )-f(\boldsymbol \phi _{e}^{b})- \boldsymbol \mu ^{{e}}\boldsymbol {\cdot }(\boldsymbol \phi - \boldsymbol \phi _{e}^{b})$ and

${\rm \Delta} f=f(\boldsymbol \phi )-f(\boldsymbol \phi _{e}^{a})- \boldsymbol \mu ^{{e}}\boldsymbol {\cdot }(\boldsymbol \phi - \boldsymbol \phi _{e}^{a})=f(\boldsymbol \phi )-f(\boldsymbol \phi _{e}^{b})- \boldsymbol \mu ^{{e}}\boldsymbol {\cdot }(\boldsymbol \phi - \boldsymbol \phi _{e}^{b})$ and ![]() $K$ is the total number of components in the system. Note that the equilibrium chemical potentials are generally not zero, as shown in the phase diagram. This is in contrast to the conventional way of a double-well potential for two-phase flow (Jacqmin Reference Jacqmin2000) and a multi-well potential (He et al. Reference He, Li, Huang, Hu, Li and Wang2020) for multiphase flow, where the chemical potential is zero at equilibrium. The integration of the equilibrium equation leads to a new potential in the form of

$K$ is the total number of components in the system. Note that the equilibrium chemical potentials are generally not zero, as shown in the phase diagram. This is in contrast to the conventional way of a double-well potential for two-phase flow (Jacqmin Reference Jacqmin2000) and a multi-well potential (He et al. Reference He, Li, Huang, Hu, Li and Wang2020) for multiphase flow, where the chemical potential is zero at equilibrium. The integration of the equilibrium equation leads to a new potential in the form of ![]() $f(\boldsymbol \phi )-\sum _{j=1}^{K}\mu _ {j}^{e}\phi _{j}$. Based on the Euler formulation for one-component phase (Sundman, Lukas & Fries Reference Sundman, Lukas and Fries2007), we write its generalization for a system with

$f(\boldsymbol \phi )-\sum _{j=1}^{K}\mu _ {j}^{e}\phi _{j}$. Based on the Euler formulation for one-component phase (Sundman, Lukas & Fries Reference Sundman, Lukas and Fries2007), we write its generalization for a system with ![]() $\varLambda$ phase and

$\varLambda$ phase and ![]() $K$ component as

$K$ component as ![]() $\sum _{\nu =1}^{\varLambda }(f-\sum _{j=1}^{K}\mu _{j}^{e} \phi _{j})v^{\nu }=0$ due to the additive property of extensive variables, where

$\sum _{\nu =1}^{\varLambda }(f-\sum _{j=1}^{K}\mu _{j}^{e} \phi _{j})v^{\nu }=0$ due to the additive property of extensive variables, where ![]() $v^{\nu }$ is the molar volume of the respective phase

$v^{\nu }$ is the molar volume of the respective phase ![]() $\nu$. Because of incompressibility, the summation of the molar volume is constant,

$\nu$. Because of incompressibility, the summation of the molar volume is constant, ![]() $\sum _{\nu =1}^{\varLambda } v^{\nu }=\text {constant}$. This leads to a necessary condition for the phase equilibrium

$\sum _{\nu =1}^{\varLambda } v^{\nu }=\text {constant}$. This leads to a necessary condition for the phase equilibrium ![]() $f-\sum _{j=1}^{K}\mu _{j}^{e} \phi _{j}=\text {constant}$. This result motivates us to define a thermodynamic potential

$f-\sum _{j=1}^{K}\mu _{j}^{e} \phi _{j}=\text {constant}$. This result motivates us to define a thermodynamic potential ![]() $P\equiv f-\sum _{j=1}^{K}\mu _{j} \phi _{j}$, which is the Legendre transformation of the chemical potential. Here, the chemical potential for the

$P\equiv f-\sum _{j=1}^{K}\mu _{j} \phi _{j}$, which is the Legendre transformation of the chemical potential. Here, the chemical potential for the ![]() $j$th component

$j$th component ![]() $\mu _{j}$ is not necessary to be

$\mu _{j}$ is not necessary to be ![]() $\mu _{j}^{e}$. The thermodynamic potential characterizes the phase state away from the equilibrium. The significance of the thermodynamic potential is its contribution to the capillary force together with the Kortweg stress.

$\mu _{j}^{e}$. The thermodynamic potential characterizes the phase state away from the equilibrium. The significance of the thermodynamic potential is its contribution to the capillary force together with the Kortweg stress.

The minimization of the free energy functional at the substrate ![]() $S$ requires that

$S$ requires that

With the expression for the free energy functional, the equilibrium condition at the substrate is rewritten as (see supplementary section S.II.3)

The joint equilibrium of bulk and substrate, as a result of (4.4) and (4.6), determines the surface composition ![]() $\boldsymbol \phi _{S}^{a}$ (

$\boldsymbol \phi _{S}^{a}$ (![]() $a = \alpha$,

$a = \alpha$, ![]() $\beta$,

$\beta$, ![]() $\delta$), which is analogous to (2.6) for the binary system. The details for the surface composition of the ternary system are discussed in the following section for the validation of the model.

$\delta$), which is analogous to (2.6) for the binary system. The details for the surface composition of the ternary system are discussed in the following section for the validation of the model.

5. Interfacial tension and wall free energy density

The interfacial tension of an ![]() $a$–

$a$–![]() $b$ interface (

$b$ interface (![]() $a=\alpha$,

$a=\alpha$, ![]() $\beta$,

$\beta$, ![]() $\delta$,

$\delta$, ![]() $b=\alpha$,

$b=\alpha$, ![]() $\beta$,

$\beta$, ![]() $\delta$,

$\delta$, ![]() $a\neq b$) is the excess free energy across the interface, which is expressed as

$a\neq b$) is the excess free energy across the interface, which is expressed as

\begin{equation} \gamma_{ab} = \int_{X}\left[f(\boldsymbol\phi)-f(\boldsymbol\phi_{e}^{a})- \boldsymbol\mu^{e}\boldsymbol{\cdot}(\boldsymbol \phi-\boldsymbol \phi_{e}^{a}) + \sum_{{j=1}}^{K} \kappa_{j}\left( \nabla\phi_{j}\right)^{2}\right] {\rm d} X. \end{equation}

\begin{equation} \gamma_{ab} = \int_{X}\left[f(\boldsymbol\phi)-f(\boldsymbol\phi_{e}^{a})- \boldsymbol\mu^{e}\boldsymbol{\cdot}(\boldsymbol \phi-\boldsymbol \phi_{e}^{a}) + \sum_{{j=1}}^{K} \kappa_{j}\left( \nabla\phi_{j}\right)^{2}\right] {\rm d} X. \end{equation}

The integral path ![]() $X$ is achieved by minimizing the interfacial tension

$X$ is achieved by minimizing the interfacial tension ![]() $\gamma _{ab}$. With the bulk equilibrium condition, the surface tension is rewritten as

$\gamma _{ab}$. With the bulk equilibrium condition, the surface tension is rewritten as

\begin{equation} \gamma_{ab}=\int_{\boldsymbol\phi_{e}^{a}}^{\boldsymbol\phi_{e}^{b}} 2\sqrt{{\rm \Delta} f}\,{\rm d} s,\end{equation}

\begin{equation} \gamma_{ab}=\int_{\boldsymbol\phi_{e}^{a}}^{\boldsymbol\phi_{e}^{b}} 2\sqrt{{\rm \Delta} f}\,{\rm d} s,\end{equation}

where ![]() ${\rm d} s=\sqrt {\sum _{j=1}^{K}\kappa _{j} ({\rm d}\phi _{j})^{2}}$. The path integral starts from one equilibrium composition

${\rm d} s=\sqrt {\sum _{j=1}^{K}\kappa _{j} ({\rm d}\phi _{j})^{2}}$. The path integral starts from one equilibrium composition ![]() ${\boldsymbol \phi _{e}^{a}}=(\phi _{1}^{a},\phi _{2}^{a}, \phi _{3}^{a})$ to the other one

${\boldsymbol \phi _{e}^{a}}=(\phi _{1}^{a},\phi _{2}^{a}, \phi _{3}^{a})$ to the other one ![]() ${\boldsymbol \phi _{e}^{b}}=(\phi _{1}^{b},\phi _{2}^{b},\phi _{3}^{b})$ by minimizing the interfacial tension.

${\boldsymbol \phi _{e}^{b}}=(\phi _{1}^{b},\phi _{2}^{b},\phi _{3}^{b})$ by minimizing the interfacial tension.

The interfacial tension between an ![]() $a$ phase (

$a$ phase (![]() $a=\alpha$,

$a=\alpha$, ![]() $\beta$,

$\beta$, ![]() $\delta$) and the substrate

$\delta$) and the substrate ![]() $S$ has two contributions. One is the excess free energy due to the presence of the surface composition, which leads to a non-uniform composition from

$S$ has two contributions. One is the excess free energy due to the presence of the surface composition, which leads to a non-uniform composition from ![]() $\boldsymbol \phi _{S}^{a}$ to

$\boldsymbol \phi _{S}^{a}$ to ![]() $\boldsymbol \phi _{e}^{a}$. The second part is the wall free energy

$\boldsymbol \phi _{e}^{a}$. The second part is the wall free energy ![]() $\varGamma (\boldsymbol \phi _{S}^{a})$, which depends on the composition on the substrate. Thus, the interfacial tension is expressed as

$\varGamma (\boldsymbol \phi _{S}^{a})$, which depends on the composition on the substrate. Thus, the interfacial tension is expressed as

\begin{equation} \gamma_{aS } =\varGamma(\boldsymbol \phi_{S}^{a}) + \int^{\boldsymbol\phi_{e}^{a}}_{{\boldsymbol\phi_{S}^{a} }} 2\sqrt{{\rm \Delta} f}\,{\rm d} s . \end{equation}

\begin{equation} \gamma_{aS } =\varGamma(\boldsymbol \phi_{S}^{a}) + \int^{\boldsymbol\phi_{e}^{a}}_{{\boldsymbol\phi_{S}^{a} }} 2\sqrt{{\rm \Delta} f}\,{\rm d} s . \end{equation}

The wall free energy density is assumed to be described by a second-order polynomial function with coefficients ![]() $g_{ij}$ as

$g_{ij}$ as

\begin{equation} \varGamma (\boldsymbol \phi) = \sum_{i=1}^{K} \sum_{j=1}^{K} g_{ij} \phi_{i}^{j-1},\quad \forall\ \boldsymbol x \in S.\end{equation}

\begin{equation} \varGamma (\boldsymbol \phi) = \sum_{i=1}^{K} \sum_{j=1}^{K} g_{ij} \phi_{i}^{j-1},\quad \forall\ \boldsymbol x \in S.\end{equation}

Here, the parameters ![]() $g_{i2}$ represent an attraction of the liquid by the solid; the parameters

$g_{i2}$ represent an attraction of the liquid by the solid; the parameters ![]() $g_{i3}$ depict a certain reduction of the liquid–liquid attractive interactions near the surface (De Gennes Reference De Gennes1985). The constants

$g_{i3}$ depict a certain reduction of the liquid–liquid attractive interactions near the surface (De Gennes Reference De Gennes1985). The constants ![]() $g_{i1}$ are reference values for the wall free energy and make no contribution to the contact angle.

$g_{i1}$ are reference values for the wall free energy and make no contribution to the contact angle.

6. Kinetics equation

The compositions in the domain ![]() $\varOmega$ and at the substrate

$\varOmega$ and at the substrate ![]() $S$ both evolve with time to minimize the free energy functional. There are different types of kinetics equations, such as Cahn–Hilliard and Allen–Cahn. In this work, we adopt the Cahn–Hilliard model for the time evolution of the composition

$S$ both evolve with time to minimize the free energy functional. There are different types of kinetics equations, such as Cahn–Hilliard and Allen–Cahn. In this work, we adopt the Cahn–Hilliard model for the time evolution of the composition ![]() $\boldsymbol \phi$ in

$\boldsymbol \phi$ in ![]() $\varOmega$ until the time

$\varOmega$ until the time ![]() $T{t}$. In § 9, we consider the droplet wetting coupling with evaporation. The diffusion mechanism in the evaporation process can be more conveniently described by the Cahn–Hilliard model, in comparison with the Allen–Cahn approach. The diffusion equation for the composition

$T{t}$. In § 9, we consider the droplet wetting coupling with evaporation. The diffusion mechanism in the evaporation process can be more conveniently described by the Cahn–Hilliard model, in comparison with the Allen–Cahn approach. The diffusion equation for the composition ![]() $\phi _{i}$ reads

$\phi _{i}$ reads

The contribution of ![]() $\boldsymbol {\nabla }\mu _{j}$ to the time evolution of

$\boldsymbol {\nabla }\mu _{j}$ to the time evolution of ![]() $\phi _{i}$ (

$\phi _{i}$ (![]() $j\neq i$) will be introduced by considering the Gibbs–Duhem relation. In comparison with the diffusion flux in terms of the composition gradient

$j\neq i$) will be introduced by considering the Gibbs–Duhem relation. In comparison with the diffusion flux in terms of the composition gradient ![]() $\boldsymbol j_ {i}=- D_{i}\boldsymbol {\nabla } \phi _{i}$, the mobility

$\boldsymbol j_ {i}=- D_{i}\boldsymbol {\nabla } \phi _{i}$, the mobility ![]() $L_{i}$ is expressed as

$L_{i}$ is expressed as ![]() $L_{i}=D_{i} \phi _{i} v_{m}/(R_{g}T)$. The parameter

$L_{i}=D_{i} \phi _{i} v_{m}/(R_{g}T)$. The parameter ![]() $D_{i}$ denotes the diffusivity of component

$D_{i}$ denotes the diffusivity of component ![]() $i$. From the Gibbs–Duhem relation

$i$. From the Gibbs–Duhem relation ![]() $\sum _{j=1}^{K}\phi _{j} \boldsymbol {\nabla } \mu _{j}=0$, we derive the chemical potential gradient for the multicomponent system as

$\sum _{j=1}^{K}\phi _{j} \boldsymbol {\nabla } \mu _{j}=0$, we derive the chemical potential gradient for the multicomponent system as

\begin{equation} \boldsymbol{\nabla} \mu_{i}=\sum_{j=1}^{K}(\delta_{ij}-\phi_{j})\boldsymbol{\nabla}\mu_{j}, \end{equation}

\begin{equation} \boldsymbol{\nabla} \mu_{i}=\sum_{j=1}^{K}(\delta_{ij}-\phi_{j})\boldsymbol{\nabla}\mu_{j}, \end{equation}

where ![]() $\delta _{ij}$ stands for the Kronecker delta. Thus, we have the generalized diffusion equation for a multicomponent system:

$\delta _{ij}$ stands for the Kronecker delta. Thus, we have the generalized diffusion equation for a multicomponent system:

\begin{equation} \partial{t}\phi_{i} = \boldsymbol{\nabla} \boldsymbol{\cdot} \left[\sum_{j=1}^{K} {\mathsf{M}}_{ij} \boldsymbol{\nabla}\left(\partial f/\partial \phi_{j}- 2 \kappa_{j} \nabla^{2}\phi_{j} \right)\right],\quad \forall\ (\boldsymbol x,t)\in \varOmega \times [0, T{t}], \end{equation}

\begin{equation} \partial{t}\phi_{i} = \boldsymbol{\nabla} \boldsymbol{\cdot} \left[\sum_{j=1}^{K} {\mathsf{M}}_{ij} \boldsymbol{\nabla}\left(\partial f/\partial \phi_{j}- 2 \kappa_{j} \nabla^{2}\phi_{j} \right)\right],\quad \forall\ (\boldsymbol x,t)\in \varOmega \times [0, T{t}], \end{equation}where the mobility is expressed as

Note that the mobility is composition-dependent, which is in contrast to the constant mobility (Kim Reference Kim2007; Boyer et al. Reference Boyer, Lapuerta, Minjeaud, Piar and Quintard2010). This dependency results from the diffusion equation plus the Gibbs–Duhem relation. A constant mobility and composition-dependent mobility can lead to different physical mechanisms for the time evolution of the equation as well as distinct energy dissipation laws (Cahn, Elliott & Novick-Cohen Reference Cahn, Elliott and Novick-Cohen1996; Abels, Garcke & Grün Reference Abels, Garcke and Grün2012). From the aspect of thermodynamic consistency, the mobility ![]() $\boldsymbol{\mathsf{M}}=({\mathsf{M}}_{ij})\in \mathbb {R}^{K\times K}$ must be positive semi-definite to fulfil the energy dissipation law (supplementary material, S.7).

$\boldsymbol{\mathsf{M}}=({\mathsf{M}}_{ij})\in \mathbb {R}^{K\times K}$ must be positive semi-definite to fulfil the energy dissipation law (supplementary material, S.7).

On the substrate ![]() $S$, we introduce the following evolution equation based on the surface equilibrium condition (4.6):

$S$, we introduce the following evolution equation based on the surface equilibrium condition (4.6):

where ![]() $\tau _{i}$ is a relaxation parameter. When the time

$\tau _{i}$ is a relaxation parameter. When the time ![]() $t\rightarrow \infty$, the surface equilibrium condition (4.6) is reached. To ensure the constraint

$t\rightarrow \infty$, the surface equilibrium condition (4.6) is reached. To ensure the constraint ![]() $\sum _{j=1}^{K}\phi _{j}=1$, a Lagrange multiplier

$\sum _{j=1}^{K}\phi _{j}=1$, a Lagrange multiplier ![]() $\lambda =-(1/K)\sum _{j=1}^{K} (\delta \mathcal {F}/\delta \phi _{j})$ has been added to the kinetic evolution for the surface composition.

$\lambda =-(1/K)\sum _{j=1}^{K} (\delta \mathcal {F}/\delta \phi _{j})$ has been added to the kinetic evolution for the surface composition.

Depending on the Péclet number, the convection may play a non-negligible role in the mass transfer. In this case, the Cahn–Hilliard model is modified as

\begin{equation} \partial{t}\phi_{i} + \boldsymbol{\nabla} \boldsymbol{\cdot}(\boldsymbol{u}\phi_{i})= \boldsymbol{\nabla} \boldsymbol{\cdot} \left[\sum_{j=1}^{K} {\mathsf{M}}_{ij} \boldsymbol{\nabla}\left(\partial f/\partial \phi_{j}- 2 \kappa_{j} \nabla^{2}\phi_{j} \right)\right],\quad \forall\ (\boldsymbol x,t)\in \varOmega \times [0, T{t}], \end{equation}

\begin{equation} \partial{t}\phi_{i} + \boldsymbol{\nabla} \boldsymbol{\cdot}(\boldsymbol{u}\phi_{i})= \boldsymbol{\nabla} \boldsymbol{\cdot} \left[\sum_{j=1}^{K} {\mathsf{M}}_{ij} \boldsymbol{\nabla}\left(\partial f/\partial \phi_{j}- 2 \kappa_{j} \nabla^{2}\phi_{j} \right)\right],\quad \forall\ (\boldsymbol x,t)\in \varOmega \times [0, T{t}], \end{equation}

where ![]() $\boldsymbol {u}$ is the convection velocity of the fluid. No-slip boundary condition is assumed for the fluid velocity on the solid substrate

$\boldsymbol {u}$ is the convection velocity of the fluid. No-slip boundary condition is assumed for the fluid velocity on the solid substrate ![]() $S$. Hence, the evolution equation for the composition on the substrate

$S$. Hence, the evolution equation for the composition on the substrate ![]() $S$, equation (6.5), is not altered. However, it should be noted that a slip boundary condition on the substrate may be considered when the slip length is known. We refer to Huang & Wang (Reference Huang and Wang2018) for a discussion on the effect of the slip boundary condition on the solid substrate.

$S$, equation (6.5), is not altered. However, it should be noted that a slip boundary condition on the substrate may be considered when the slip length is known. We refer to Huang & Wang (Reference Huang and Wang2018) for a discussion on the effect of the slip boundary condition on the solid substrate.

We focus on the fluid flow induced by the surface tension force which is formulated as (S.II.4)

\begin{equation} \boldsymbol f_{s}={-}\sum_{j=1}^{K-1} \phi_{j} \boldsymbol{\nabla} (\mu_{j}-\mu_{K}),\quad \forall\ (\boldsymbol x,t)\in \varOmega \times [0, T{t}], \end{equation}

\begin{equation} \boldsymbol f_{s}={-}\sum_{j=1}^{K-1} \phi_{j} \boldsymbol{\nabla} (\mu_{j}-\mu_{K}),\quad \forall\ (\boldsymbol x,t)\in \varOmega \times [0, T{t}], \end{equation}

where the chemical potential is defined by the variational approach as ![]() $\mu _{j}\equiv \partial f/\partial \phi _{j}-2\kappa _{j} \nabla ^{2}\phi _{j}$.

$\mu _{j}\equiv \partial f/\partial \phi _{j}-2\kappa _{j} \nabla ^{2}\phi _{j}$.

With the surface tension force, the incompressible Navier–Stokes equation for the convection velocity ![]() $\boldsymbol {u}$ reads

$\boldsymbol {u}$ reads

The parameters ![]() $\rho$,

$\rho$, ![]() $\eta$ and

$\eta$ and ![]() $p$ denote the fluid density, viscosity and pressure, respectively. The evolution equations (6.6), (6.8) and (6.9) effect a decrease of the total energy of the system (S.II.5). By selecting the reference values

$p$ denote the fluid density, viscosity and pressure, respectively. The evolution equations (6.6), (6.8) and (6.9) effect a decrease of the total energy of the system (S.II.5). By selecting the reference values ![]() $x^*$,

$x^*$, ![]() $\sigma ^*$ and

$\sigma ^*$ and ![]() $D^*$ for the length, surface tension and diffusivity, respectively, we have the following dimensionless quantities:

$D^*$ for the length, surface tension and diffusivity, respectively, we have the following dimensionless quantities: ![]() $Re$,

$Re$, ![]() $We$ and

$We$ and ![]() $P\acute {e}$ (Appendix A).

$P\acute {e}$ (Appendix A).

We present some remarks for the divergence free of the velocity when diffusion is considered. At atmospheric pressure and at room temperature, the density of a fluid mixture is almost constant, as supported by many experimental data and theories. For instance, at room temperature and 1 atm, the density of air with 100 % relative humidity is 1.1 times that of dry air with 0 % relative humidity (Picard et al. Reference Picard, Davis, Gläser and Fujii2008). In view of this fact, it is reasonable to assume ![]() ${\rm d}\rho /{\rm d} t\approx 0$ for a liquid–gas system at room temperature and 1 atm. By using the materials derivative with a frame moving with the direction of the fluid velocity

${\rm d}\rho /{\rm d} t\approx 0$ for a liquid–gas system at room temperature and 1 atm. By using the materials derivative with a frame moving with the direction of the fluid velocity ![]() $\boldsymbol u$, we have the following expression for the total derivative:

$\boldsymbol u$, we have the following expression for the total derivative: ![]() ${\rm d}\rho /{\rm d} t=\partial \rho /\partial t+\boldsymbol {u}\boldsymbol {\cdot }\boldsymbol {\nabla } \rho$. In comparison with the continuity equation (Landau & Lifshitz Reference Landau and Lifshitz2013),

${\rm d}\rho /{\rm d} t=\partial \rho /\partial t+\boldsymbol {u}\boldsymbol {\cdot }\boldsymbol {\nabla } \rho$. In comparison with the continuity equation (Landau & Lifshitz Reference Landau and Lifshitz2013), ![]() $\partial \rho /\partial t+\boldsymbol {\nabla }\boldsymbol {\cdot } (\rho \boldsymbol {u})=0$, we have

$\partial \rho /\partial t+\boldsymbol {\nabla }\boldsymbol {\cdot } (\rho \boldsymbol {u})=0$, we have ![]() $\rho \boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol u=-{\rm d}\rho /{\rm d} t$. Since

$\rho \boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol u=-{\rm d}\rho /{\rm d} t$. Since ![]() ${\rm d}\rho /{\rm d} t\approx 0$, the divergence free of the velocity is obtained. Note that the diffusion equation is normally written in terms of the volume composition

${\rm d}\rho /{\rm d} t\approx 0$, the divergence free of the velocity is obtained. Note that the diffusion equation is normally written in terms of the volume composition ![]() $\boldsymbol {\phi }$ rather than the density

$\boldsymbol {\phi }$ rather than the density ![]() $\rho$ (Landau & Lifshitz Reference Landau and Lifshitz2013). When diffusion takes place, we generally have

$\rho$ (Landau & Lifshitz Reference Landau and Lifshitz2013). When diffusion takes place, we generally have ![]() ${\rm d}\phi _{ i}/{\rm d} t\neq 0$, which seems to contradict with

${\rm d}\phi _{ i}/{\rm d} t\neq 0$, which seems to contradict with ![]() ${\rm d}\rho /{\rm d} t=0$. This contradicting point is realized by using

${\rm d}\rho /{\rm d} t=0$. This contradicting point is realized by using ![]() $\phi _{2}=1-\phi _{ 1}$ and

$\phi _{2}=1-\phi _{ 1}$ and ![]() ${\rm d}\rho /{\rm d} t=(\rho _{1}^{o}-\rho _{2}^{o})\,{\rm d}\phi _{1}/{\rm d} t$, if

${\rm d}\rho /{\rm d} t=(\rho _{1}^{o}-\rho _{2}^{o})\,{\rm d}\phi _{1}/{\rm d} t$, if ![]() $\rho =\rho _{1}^{o}\phi _{1} +\rho _{2}^{o}\phi _{2}$ for a binary mixture with

$\rho =\rho _{1}^{o}\phi _{1} +\rho _{2}^{o}\phi _{2}$ for a binary mixture with ![]() $\rho _{1}^{o}\neq \rho _{2}^{o}$. Here, we prefer to interpret

$\rho _{1}^{o}\neq \rho _{2}^{o}$. Here, we prefer to interpret ![]() $\rho _{1}^{o}$ and

$\rho _{1}^{o}$ and ![]() $\rho _{2}^{o}$ as partial densities, rather than the densities of pure fluids before mixing. We think that one possible reason is that

$\rho _{2}^{o}$ as partial densities, rather than the densities of pure fluids before mixing. We think that one possible reason is that ![]() $\rho _{1}^{o}$ and

$\rho _{1}^{o}$ and ![]() $\rho _{2}^{o}$ are no longer constant in a mixture but depend on the local volume fraction. The fact is that one cannot measure the local density

$\rho _{2}^{o}$ are no longer constant in a mixture but depend on the local volume fraction. The fact is that one cannot measure the local density ![]() $\rho _{i}^{o}$,

$\rho _{i}^{o}$, ![]() $i=1, 2$, after mixing, while the density of the mixture

$i=1, 2$, after mixing, while the density of the mixture ![]() $\rho$ and the density of the pure phase before the mixing can be measured. When the local volume concentration varies with time in the diffusion process, the partial density

$\rho$ and the density of the pure phase before the mixing can be measured. When the local volume concentration varies with time in the diffusion process, the partial density ![]() $\rho _{i}^{o}$ should change accordingly via the equation of state relating to the partial pressure; but the density of the mixture

$\rho _{i}^{o}$ should change accordingly via the equation of state relating to the partial pressure; but the density of the mixture ![]() $\rho$ does not vary.

$\rho$ does not vary.

7. Criterion of the contact angle measurement

For the two-phase wetting problem based on the phase diagrams in figures 1(I) and 1(II), the components ![]() $1$ and

$1$ and ![]() $2$ are miscible with each other. The two immiscible phases separate themselves by composition

$2$ are miscible with each other. The two immiscible phases separate themselves by composition ![]() $3$. Thus, we select the average composition

$3$. Thus, we select the average composition ![]() $3$ in the droplet and in the matrix

$3$ in the droplet and in the matrix ![]() $\phi _{{int}} = (\phi _{3}^{\alpha } + \phi _{3}^{\delta })/2$ as the criterion for the interface between the immiscible phases, as shown by the blue solid line in figure 2. This interface position almost corresponds to the extreme value between the two immiscible phases along the tie line in the free energy landscape. Specifically, the contact line radius

$\phi _{{int}} = (\phi _{3}^{\alpha } + \phi _{3}^{\delta })/2$ as the criterion for the interface between the immiscible phases, as shown by the blue solid line in figure 2. This interface position almost corresponds to the extreme value between the two immiscible phases along the tie line in the free energy landscape. Specifically, the contact line radius ![]() $r_{c}$ and the droplet height

$r_{c}$ and the droplet height ![]() $h$ are used to calculate the macroscopic contact angle as

$h$ are used to calculate the macroscopic contact angle as ![]() $\theta = 2\arctan (h/r_{c}) \times 180^\circ /{\rm \pi}$.

$\theta = 2\arctan (h/r_{c}) \times 180^\circ /{\rm \pi}$.

Figure 2. Sketch for the contact angle.

For the three-phase wetting problem based on the phase diagram in figure 1(III), the interface for the ![]() $\alpha$ phase is marked by the locations where

$\alpha$ phase is marked by the locations where ![]() $\phi _{{int}} = (\phi _{1}^{\alpha } + \phi _{1}^{\delta })/2$ (blue line), corresponding to the extreme value in the free energy landscape. Here,

$\phi _{{int}} = (\phi _{1}^{\alpha } + \phi _{1}^{\delta })/2$ (blue line), corresponding to the extreme value in the free energy landscape. Here, ![]() $\phi _{1}^{\alpha }$ and

$\phi _{1}^{\alpha }$ and ![]() $\phi _{1}^{\delta }$ are the equilibrium values of

$\phi _{1}^{\delta }$ are the equilibrium values of ![]() $\phi _{1}$ in the

$\phi _{1}$ in the ![]() $\alpha$ droplet and in the

$\alpha$ droplet and in the ![]() $\delta$ matrix, respectively. Similarly, we obtain the

$\delta$ matrix, respectively. Similarly, we obtain the ![]() $\beta$–

$\beta$–![]() $\delta$ interface with the criterion of

$\delta$ interface with the criterion of ![]() $\phi _{{int}} = (\phi _{2}^{\beta } + \phi _{2}^{\delta })/2$ (red line) as well as the

$\phi _{{int}} = (\phi _{2}^{\beta } + \phi _{2}^{\delta })/2$ (red line) as well as the ![]() $\alpha$–

$\alpha$–![]() $\beta$ interface (violet line). By fitting the three interfaces with circular arcs, we denote their intersection point as the triple junction, where three dot-dashed tangent lines for each interface define the contact angles

$\beta$ interface (violet line). By fitting the three interfaces with circular arcs, we denote their intersection point as the triple junction, where three dot-dashed tangent lines for each interface define the contact angles ![]() $\theta _{ij}^{\prime }$. At the other triple junctions where the two immiscible phases meet the substrate, the dot-dashed tangent lines are plotted at the contact line position and the contact angle

$\theta _{ij}^{\prime }$. At the other triple junctions where the two immiscible phases meet the substrate, the dot-dashed tangent lines are plotted at the contact line position and the contact angle ![]() $\theta _{ij}$ is estimated by the same method with the help of tangent lines, as shown in figure 2.

$\theta _{ij}$ is estimated by the same method with the help of tangent lines, as shown in figure 2.

8. Results and discussion

8.1. Symmetric phase diagram

The simulation results for the wetting phenomenon of the symmetric phase diagram are shown in figure 3. Two different initial droplet compositions are considered, (a) ![]() $\boldsymbol \phi =(0.63, 0.15, 0.22)$ and (b)

$\boldsymbol \phi =(0.63, 0.15, 0.22)$ and (b) ![]() $\boldsymbol \phi =(0.24, 0.55, 0.21)$, which fall on the black solid binodal line in figure 3(I). The compositions in the surrounding matrix are set to be the corresponding equilibrium values according to the coloured tie lines. In this case, we assume that components 1 and 2 have similar physical properties. Thus, we apply identical parameters

$\boldsymbol \phi =(0.24, 0.55, 0.21)$, which fall on the black solid binodal line in figure 3(I). The compositions in the surrounding matrix are set to be the corresponding equilibrium values according to the coloured tie lines. In this case, we assume that components 1 and 2 have similar physical properties. Thus, we apply identical parameters ![]() $\chi _{13}=\chi _{23}>0>\chi _{12}$ and