1. Introduction

Pathogenic bacteria are a persistent threat to human health incurring a heavy cost on the healthcare system (Jean et al. Reference Jean, Tanya, Lin and MacDonald1996). The motility of bacteria is an essential mechanism with which pathogens reach the membranes of susceptible cells or form harmful biofilms on tissues and implants (Ottemann & Miller Reference Ottemann and Miller1997; Jarrell & McBride Reference Jarrell and McBride2008; Kearns Reference Kearns2010). The majority of the cells and tissues prone to pathogenic infections in the human body are lined with a multi-scale complex biological fluid. For instance, the mucosal surfaces in the body including the epithelial cells in the respiratory tract, the human intestines, the urinary tract, the eyes etc. are lined with a slimy hydro-gel known as mucus (McShane et al. Reference McShane, Bath, Jaramilo, Ridley, Walsh, Evans, Thornton and Ribbeck2021). These are complex fluids, meaning that they possess a microstructure (a porous, mesh-like polymer network resulting from entanglement) and often exhibit non-Newtonian rheology, which is a function of length scale. Therefore, a fundamental understanding of how the rheology and microstructure of biological fluids affect the motion of a swimming bacterium has applications ranging from designing therapeutic techniques by changing the properties of the biological fluids (Werlang, Carcarmo-Oyarce & Ribbeck Reference Werlang, Carcarmo-Oyarce and Ribbeck2019) to designing synthetic swimmers for targeted drug delivery (Huang et al. Reference Huang, Uslu, Katsamba, Lauga, Sakar and Nelson2019; Xiea et al. Reference Xiea, Xiab, Lia, Moa, Chena and Lia2020; Ghosh & Ghosh Reference Ghosh and Ghosh2021), and developing gene regulatory programs for bacteria to name a few.

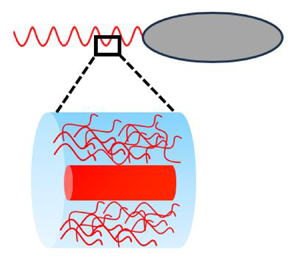

In this work, we develop a two-fluid model, where the complex fluid is modelled as a coupled, interpenetrating medium of two Newtonian fluids, and we analyse the motion of a flagellated bacterium (like Escherichia coli) in it. This Newtonian model captures the effect of the microstructure present in these complex biological fluids by allowing for a relative motion between the solvent and polymer. This differential motion is relevant because the length scale of the the entangled polymer network in such fluids is comparable to the diameter of the flagellar bundle of the bacterium. This results in the bundle forcing the solvent and the polymer differently, leading to differential response of the two fluids. The model can be easily extended to a complex fluid with non-Newtonian rheology, using which, the combined effects of microstructure and non-Newtonian rheology of the complex biological fluid on the swimming bacterium can be analysed by numerical simulations.

The motion of swimming microorganisms in Newtonian fluids has been a well-studied problem for decades (Berg & Anderson Reference Berg and Anderson1973; Purcell Reference Purcell1977; Lauga & Powers Reference Lauga and Powers2009; Subramanian & Nott Reference Subramanian and Nott2011). Microorganisms, owing to their small size, essentially swim in a low-Reynolds-number (![]() $Re$) environment, where viscous effects dominate inertial effects. In this Stokesian regime, the fluid flow is quasi-steady and linear making the flow (kinematically) reversible. Therefore, the usual macroscopic swimming strategies, like periodic paddling motion, are ineffective and will result in no net motion (Ludwig Reference Ludwig1930). To overcome this, microorganisms have evolved several successful propulsion strategies. There are many variations of these strategies among swimming microorganisms and several types of organisms exist that swim in low-Reynolds-number environments using different means (Lauga & Powers Reference Lauga and Powers2009; Subramanian & Nott Reference Subramanian and Nott2011). In this work, we restrict our attention to the motion of flagellated bacteria, like Escherichia coli (E. coli).

$Re$) environment, where viscous effects dominate inertial effects. In this Stokesian regime, the fluid flow is quasi-steady and linear making the flow (kinematically) reversible. Therefore, the usual macroscopic swimming strategies, like periodic paddling motion, are ineffective and will result in no net motion (Ludwig Reference Ludwig1930). To overcome this, microorganisms have evolved several successful propulsion strategies. There are many variations of these strategies among swimming microorganisms and several types of organisms exist that swim in low-Reynolds-number environments using different means (Lauga & Powers Reference Lauga and Powers2009; Subramanian & Nott Reference Subramanian and Nott2011). In this work, we restrict our attention to the motion of flagellated bacteria, like Escherichia coli (E. coli).

Berg & Anderson (Reference Berg and Anderson1973) showed that bacteria like E. coli break the Stokesian symmetry by means of a rotating appendage – the flagellar bundle, made up of multiple individual flagellar filaments. The flagellum is a slender filament attached to the head of the bacterium by a hook and rotated by a molecular motor (Berg Reference Berg2003). E. coli have prolate spheroidal heads of typical length 2–3 ![]() $\mathrm {\mu }$m and width 1–2

$\mathrm {\mu }$m and width 1–2 ![]() $\mathrm {\mu }$m. The flagellar filament of E. coli has a diameter of

$\mathrm {\mu }$m. The flagellar filament of E. coli has a diameter of ![]() $\approx$20 nm and traces out a helix with contour length

$\approx$20 nm and traces out a helix with contour length ![]() $\approx$10

$\approx$10 ![]() $\mathrm {\mu }$m. In the absence of external forces and moments, the helix is typically left-handed with a pitch

$\mathrm {\mu }$m. In the absence of external forces and moments, the helix is typically left-handed with a pitch ![]() $\approx$2.5

$\approx$2.5 ![]() $\mathrm {\mu }$m and a helical diameter

$\mathrm {\mu }$m and a helical diameter ![]() $\approx$0.5

$\approx$0.5 ![]() $\mathrm {\mu }$m (Turner, Ryu & Berg Reference Turner, Ryu and Berg2000). There are typically

$\mathrm {\mu }$m (Turner, Ryu & Berg Reference Turner, Ryu and Berg2000). There are typically ![]() $\sim$5–8 flagellar filaments per cell of E. coli. When all the motors rotate in the same direction, all the filaments wrap into a helical bundle of diameter

$\sim$5–8 flagellar filaments per cell of E. coli. When all the motors rotate in the same direction, all the filaments wrap into a helical bundle of diameter ![]() $\approx$60–80 nm and rotate in unison. This generates thrust due to an anisotropy in the drag experienced by the flagellar bundle (Lauga & Powers Reference Lauga and Powers2009), propelling the bacterium forward – the motion being called a run. When one or more of the motors reverse, the corresponding filaments leave the bundle and undergo ‘polymorphic’ transformations which change the swimming direction of the cell – this process being called tumbling. Thus, bacteria exhibit run and tumble motions in a fluid medium. This motion of bacteria in Newtonian fluids has been successfully modelled by resistive force theory (RFT) (Gray & Hancock Reference Gray and Hancock1955; Chwang & Wu Reference Chwang and Wu1971) and slender body theory (SBT) (Batchelor Reference Batchelor1970; Cox Reference Cox1970; Johnson Reference Johnson1980), which treat the helical flagellar bundle as a slender fibre moving through a viscous fluid. Recently, these theories for slender objects have been experimentally verified by Rodenborn et al. (Reference Rodenborn, Chen, Swinney, Liu and Zhang2013), by comparing experimentally measured values of thrust, drag and torque on a slender helical fibre that was rotated and translated in a viscous fluid with those values predicted by the theories.

$\approx$60–80 nm and rotate in unison. This generates thrust due to an anisotropy in the drag experienced by the flagellar bundle (Lauga & Powers Reference Lauga and Powers2009), propelling the bacterium forward – the motion being called a run. When one or more of the motors reverse, the corresponding filaments leave the bundle and undergo ‘polymorphic’ transformations which change the swimming direction of the cell – this process being called tumbling. Thus, bacteria exhibit run and tumble motions in a fluid medium. This motion of bacteria in Newtonian fluids has been successfully modelled by resistive force theory (RFT) (Gray & Hancock Reference Gray and Hancock1955; Chwang & Wu Reference Chwang and Wu1971) and slender body theory (SBT) (Batchelor Reference Batchelor1970; Cox Reference Cox1970; Johnson Reference Johnson1980), which treat the helical flagellar bundle as a slender fibre moving through a viscous fluid. Recently, these theories for slender objects have been experimentally verified by Rodenborn et al. (Reference Rodenborn, Chen, Swinney, Liu and Zhang2013), by comparing experimentally measured values of thrust, drag and torque on a slender helical fibre that was rotated and translated in a viscous fluid with those values predicted by the theories.

While the preceding discussion addressed bacterial motion in Newtonian fluids, bacterial motility in complex fluids is still an open question in many ways. There are several interesting characteristics exhibited by swimming bacteria in complex fluids (Spagnolie & Underhill Reference Spagnolie and Underhill2023). While the class of complex fluids is enormous, most of the attention so far has been centred on one type of complex fluid, namely, polymer solutions. The major motivation for this is that several biological fluids, which these organisms typically encounter, are polymer solutions (Lauga & Powers Reference Lauga and Powers2009). In these fluids, for instance, bacteria are known to swim in straighter trajectories (Patteson et al. Reference Patteson, Gopinath, Goulian and Araatia2015), exhibit less frequent tumbling (Qu & Breuer Reference Qu and Breuer2020) and form a flagellar bundle more rapidly (Qu et al. Reference Qu, Temel, Henderikx and Breuer2018).

A fundamental understanding of the aforementioned phenomena necessitates a thorough understanding of the swimming motion of bacteria in polymer solutions. Polymer solutions are non-Newtonian fluids possessing three primary characteristics, namely: (i) viscoelasticity; (ii) shear-dependent viscosity; and (iii) a microstructure, and several studies have tried to understand the relative importance of these factors on the swimming motion of bacteria. Earlier theoretical studies on simple geometries, like waving sheets (Lauga Reference Lauga2007) and waving filaments (Fu, Powers & Wolgemuth Reference Fu, Powers and Wolgemuth2007a; Fu, Wolgemuth & Powers Reference Fu, Wolgemuth and Powers2009) in viscoelastic polymer solutions with shear-independent viscosities (Boger fluids) as the swimming media, showed that the propulsive velocities of the sheets and fibres are smaller in viscoelastic fluids than in Newtonian solvents since the polymer solutions always have a larger viscosity than the Newtonian solvents (even with shear thinning). However, later theoretical studies (Teran, Fauci & Shelley Reference Teran, Fauci and Shelley2010; Spagnolie, Liu & Powers Reference Spagnolie, Liu and Powers2013; Riley & Lauga Reference Riley and Lauga2014; Thomases & Guy Reference Thomases and Guy2014) on undulating sheets and helices, and experimental studies (Liu, Powers & Breuer Reference Liu, Powers and Breuer2011; Espinosa-Garcia, Lauga & Zenir Reference Espinosa-Garcia, Lauga and Zenir2013) on artificial swimmers, extended the results of the earlier ones to show that swimming enhancement can result in a viscoelastic (Boger) media due to several factors like large amplitude oscillations (Liu et al. Reference Liu, Powers and Breuer2011; Spagnolie et al. Reference Spagnolie, Liu and Powers2013), stress-singularities at filament/sheet ends (Teran et al. Reference Teran, Fauci and Shelley2010), dynamic balance of stresses (Riley & Lauga Reference Riley and Lauga2014), flexibility (Espinosa-Garcia et al. Reference Espinosa-Garcia, Lauga and Zenir2013) and (elastic) stress-asymmetry (Thomases & Guy Reference Thomases and Guy2014). These results suggested that in viscoelastic media, the motion of microswimmers is highly dependent on the geometry of the swimmer, the generated waveform and the relaxation time of the medium, owing to its nonlinearity.

Experiments with actual bacteria, such as E. coli, in shear-thinning, viscoelastic polymer solutions reported specifically that they swim at higher speeds than in Newtonian liquids having the same shear viscosity (Berg & Turner Reference Berg and Turner1979; Patteson et al. Reference Patteson, Gopinath, Goulian and Araatia2015; Qu et al. Reference Qu, Temel, Henderikx and Breuer2018). These studies proposed that shear-thinning of the polymer near the flagellar bundle, owing to its fast rotation, contributes most to the observed swimming enhancement of bacteria for polymers with small relaxation times (low ![]() $De$;

$De$; ![]() $De$ being the Deborah number defined as the ratio of the polymer relaxation time to the flow time scale), while viscoelastic effects like normal stress differences and elastic stresses contribute significantly to enhancement with high relaxation time polymers (high

$De$ being the Deborah number defined as the ratio of the polymer relaxation time to the flow time scale), while viscoelastic effects like normal stress differences and elastic stresses contribute significantly to enhancement with high relaxation time polymers (high ![]() $De$) (Qu & Breuer Reference Qu and Breuer2020). This has motivated theoretical models (Man & Lauga Reference Man and Lauga2015) that use a two-layer approximation of the polymer solutions at low

$De$) (Qu & Breuer Reference Qu and Breuer2020). This has motivated theoretical models (Man & Lauga Reference Man and Lauga2015) that use a two-layer approximation of the polymer solutions at low ![]() $De$ – with a layer of lower viscosity near the flagellar bundle and a layer of larger viscosity on the scale of the cell – and explain the observed experimental results. The experiments and the theoretical model mentioned above correspond to viscoelastic polymer solutions, with small polymer concentrations (

$De$ – with a layer of lower viscosity near the flagellar bundle and a layer of larger viscosity on the scale of the cell – and explain the observed experimental results. The experiments and the theoretical model mentioned above correspond to viscoelastic polymer solutions, with small polymer concentrations (![]() $c < c^*$;

$c < c^*$; ![]() $c$ is polymer concentration and

$c$ is polymer concentration and ![]() $c^*$ is overlap concentration) as the swimming media, but biological fluids are usually concentrated polymer solutions (

$c^*$ is overlap concentration) as the swimming media, but biological fluids are usually concentrated polymer solutions (![]() $c \geq c^*$).

$c \geq c^*$).

There are not many experimental or theoretical studies that address the fluid mechanics of bacterial motion in concentrated polymer solutions. Berg & Turner (Reference Berg and Turner1979) first showed that bacteria can swim with higher velocities in concentrated polymer solutions, compared with polymer solutions of short chained polymers having the same viscosity, but they wrongly attributed this enhancement to the presence of bacteria-sized pores in the polymer network, which do not exist. Magariyama & Kudo (Reference Magariyama and Kudo2002) used this idea to develop a theory, which used different viscosities (resistances) for translation and rotation of both the head and flagellar bundle in a fluid medium modelling the entangled polymer solution, and predicted qualitatively similar trends for swimming velocity, but their model also resulted in a non-physical trend, wherein the angular velocity of the bacterial head was found to increase with viscosity.

More recently, an experimental study by Martinez et al. (Reference Martinez, Schwarz-Link, Reufer, Wilson, Morozov and Poon2014) also showed that an enhancement in swimming speed is observed in a concentrated polymer solution (![]() $c \sim c^*$), and the explanation offered was a combination of shear thinning and depletion of polymers from the vicinity of the flagellar bundle, essentially making the flagellar bundle swim through a fluid of small viscosity. However, this explanation is not consistent with the fact that for the polymer solution used in the experiment (Martinez et al. Reference Martinez, Schwarz-Link, Reufer, Wilson, Morozov and Poon2014), rheological measurements do not show significant shear thinning at the shear rates assumed near the flagellar bundle. Moreover, the authors do not provide any explanation for depletion of polymers near the flagellar bundle. A computational work by Zottl & Yeomans (Reference Zottl and Yeomans2019) on a bacterium swimming through a concentrated polymer solution showed an enhancement due to depletion of polymers near the flagellar bundle. The authors used coarse-grained molecular dynamics (MD) simulations, where the polymer was modelled as a chain of spherical (monomer) beads which were large, resulting in a few degrees of freedom for the chain, and the observed depletion near the bundle may therefore be an overestimate that does not correspond to the actual scenario.

$c \sim c^*$), and the explanation offered was a combination of shear thinning and depletion of polymers from the vicinity of the flagellar bundle, essentially making the flagellar bundle swim through a fluid of small viscosity. However, this explanation is not consistent with the fact that for the polymer solution used in the experiment (Martinez et al. Reference Martinez, Schwarz-Link, Reufer, Wilson, Morozov and Poon2014), rheological measurements do not show significant shear thinning at the shear rates assumed near the flagellar bundle. Moreover, the authors do not provide any explanation for depletion of polymers near the flagellar bundle. A computational work by Zottl & Yeomans (Reference Zottl and Yeomans2019) on a bacterium swimming through a concentrated polymer solution showed an enhancement due to depletion of polymers near the flagellar bundle. The authors used coarse-grained molecular dynamics (MD) simulations, where the polymer was modelled as a chain of spherical (monomer) beads which were large, resulting in a few degrees of freedom for the chain, and the observed depletion near the bundle may therefore be an overestimate that does not correspond to the actual scenario.

Recently, the work of Kamdar et al. (Reference Kamdar, Shin, Leishangthem, Francis, Xu and Cheng2022) has shown that, in the dilute and semi-dilute regimes, ![]() $c \lesssim c^*$, the colloidal nature of the polymer solutions quantitatively explain the observed swimming enhancement in the aforementioned experiments, where the enhancement scales with the radius of gyration of the polymer chains, and polymer dynamics may not be essential for capturing the phenomena. This suggests that the length scale of the polymer chains (microstructure) may be more relevant in this regime. Notably, the results of Kamdar et al. (Reference Kamdar, Shin, Leishangthem, Francis, Xu and Cheng2022) with colloidal suspensions also quantitatively explain other features, namely, straighter trajectories of bacteria, reduced tumbling frequency etc., which were observed in the earlier experiments with dilute polymer solutions. Their findings seem to imply that the length scale of the polymer chains (microstructure) could be the most relevant parameter affecting the swimming velocity directly in dilute and semi-dilute polymer solutions, while viscoelasticity leads to other consequences like straight trajectories, reduced tumbling etc., which affect velocity indirectly.

$c \lesssim c^*$, the colloidal nature of the polymer solutions quantitatively explain the observed swimming enhancement in the aforementioned experiments, where the enhancement scales with the radius of gyration of the polymer chains, and polymer dynamics may not be essential for capturing the phenomena. This suggests that the length scale of the polymer chains (microstructure) may be more relevant in this regime. Notably, the results of Kamdar et al. (Reference Kamdar, Shin, Leishangthem, Francis, Xu and Cheng2022) with colloidal suspensions also quantitatively explain other features, namely, straighter trajectories of bacteria, reduced tumbling frequency etc., which were observed in the earlier experiments with dilute polymer solutions. Their findings seem to imply that the length scale of the polymer chains (microstructure) could be the most relevant parameter affecting the swimming velocity directly in dilute and semi-dilute polymer solutions, while viscoelasticity leads to other consequences like straight trajectories, reduced tumbling etc., which affect velocity indirectly.

In concentrated polymer solutions, the question of relative importance of these characteristics on swimming motion is yet to be answered satisfactorily. Concentrated polymer solutions also exhibit shear-dependent viscosity and viscoelastic stresses, and crucially, they are entangled and possess a porous microstructure, where in some cases, the pore sizes may be comparable to the thickness of the flagellar bundle, but not the head of the bacterium. For instance, it is known that mucus has a microstructure that resembles a mesh, where the mucin filaments form a complicated network of entangled polymer fibres with pores (![]() $\sim$100 nm (in humans)–400 nm (in horses), see Kirch et al. Reference Kirch, Schneider, Abou, Hopf, Schaefer, Schneider, Schall, Wagner and Lehr2012), which are larger than the flagellar bundle diameter (

$\sim$100 nm (in humans)–400 nm (in horses), see Kirch et al. Reference Kirch, Schneider, Abou, Hopf, Schaefer, Schneider, Schall, Wagner and Lehr2012), which are larger than the flagellar bundle diameter (![]() $\sim$60–80 nm, see Turner et al. Reference Turner, Ryu and Berg2000) and are filled with the Newtonian solvent (Cone Reference Cone2009; Lai et al. Reference Lai, Wang, Hida, Cone and Hanes2011). Notably, unlike dilute solutions, their viscoelastic response and shear-dependent viscosity cannot be explained by analogy to colloidal suspensions, and therefore the model of Kamdar et al. (Reference Kamdar, Shin, Leishangthem, Francis, Xu and Cheng2022) cannot be applied. Also, the theoretical models mentioned earlier (Magariyama & Kudo Reference Magariyama and Kudo2002; Martinez et al. Reference Martinez, Schwarz-Link, Reufer, Wilson, Morozov and Poon2014; Man & Lauga Reference Man and Lauga2015; Zottl & Yeomans Reference Zottl and Yeomans2019) assume bacteria-sized pores, significant shear thinning or depletion near the flagellar bundle, and these assumptions are inappropriate for an entangled polymer solution like mucus. In such a medium, rather than a physical depletion of polymers or shear thinning, one has the flagellar bundle interacting differently with the solvent and polymer, exerting different forces on them, owing to the porous polymer network with pores having nearly the same size as the bundle diameter. This differential response results in a relative motion between the solvent and polymer near the bundle. Some earlier studies of waving sheets in entangled networks (Fu, Shenoy & Powers Reference Fu, Shenoy and Powers2010; Wada Reference Wada2010; Du et al. Reference Du, Keener, Guy and Fogelson2012) have used this idea, with the polymer being treated as a purely elastic medium. A similar idea was used in the computational study by Wrobel et al. (Reference Wrobel, Lynch, Barrett, Fauci and Cortez2016), where the polymer was modelled as an elastic network constructed out of a collection of cross-linked regularised Stokeslets, with the links between them being linearly viscoelastic. The theoretical studies have not considered helical geometries, like the flagellar bundle of a bacterium, which requires a slender body treatment, and the polymer network in biological fluids like mucus are not perfectly elastic, as these studies assume.

$\sim$60–80 nm, see Turner et al. Reference Turner, Ryu and Berg2000) and are filled with the Newtonian solvent (Cone Reference Cone2009; Lai et al. Reference Lai, Wang, Hida, Cone and Hanes2011). Notably, unlike dilute solutions, their viscoelastic response and shear-dependent viscosity cannot be explained by analogy to colloidal suspensions, and therefore the model of Kamdar et al. (Reference Kamdar, Shin, Leishangthem, Francis, Xu and Cheng2022) cannot be applied. Also, the theoretical models mentioned earlier (Magariyama & Kudo Reference Magariyama and Kudo2002; Martinez et al. Reference Martinez, Schwarz-Link, Reufer, Wilson, Morozov and Poon2014; Man & Lauga Reference Man and Lauga2015; Zottl & Yeomans Reference Zottl and Yeomans2019) assume bacteria-sized pores, significant shear thinning or depletion near the flagellar bundle, and these assumptions are inappropriate for an entangled polymer solution like mucus. In such a medium, rather than a physical depletion of polymers or shear thinning, one has the flagellar bundle interacting differently with the solvent and polymer, exerting different forces on them, owing to the porous polymer network with pores having nearly the same size as the bundle diameter. This differential response results in a relative motion between the solvent and polymer near the bundle. Some earlier studies of waving sheets in entangled networks (Fu, Shenoy & Powers Reference Fu, Shenoy and Powers2010; Wada Reference Wada2010; Du et al. Reference Du, Keener, Guy and Fogelson2012) have used this idea, with the polymer being treated as a purely elastic medium. A similar idea was used in the computational study by Wrobel et al. (Reference Wrobel, Lynch, Barrett, Fauci and Cortez2016), where the polymer was modelled as an elastic network constructed out of a collection of cross-linked regularised Stokeslets, with the links between them being linearly viscoelastic. The theoretical studies have not considered helical geometries, like the flagellar bundle of a bacterium, which requires a slender body treatment, and the polymer network in biological fluids like mucus are not perfectly elastic, as these studies assume.

In this work, we propose a two-fluid model to accurately capture this differential response of solvent and polymer, caused by the microstructure in an entangled polymer solution like mucus. In our model, the polymer and solvent are both treated as Newtonian fluids with different viscosities ![]() $\mu _p$ and

$\mu _p$ and ![]() $\mu _s$;

$\mu _s$; ![]() $\lambda = \mu _p/\mu _s$ being the viscosity ratio. This Newtonian approximation for the polymer is valid if the polymer has small non-Newtonian effects, with

$\lambda = \mu _p/\mu _s$ being the viscosity ratio. This Newtonian approximation for the polymer is valid if the polymer has small non-Newtonian effects, with ![]() $De \ll 1$, an assumption that is fairly representative of the polymer solutions used in the experiments of Martinez et al. (Reference Martinez, Schwarz-Link, Reufer, Wilson, Morozov and Poon2014) and Qu & Breuer (Reference Qu and Breuer2020). In such a scenario, the flagellar bundle directly forces the solvent present in the pores, which then transmits the stresses to the polymer. These two fluids therefore move relative to each other leading to a Darcy drag term in the governing equations and hence a screening length

$De \ll 1$, an assumption that is fairly representative of the polymer solutions used in the experiments of Martinez et al. (Reference Martinez, Schwarz-Link, Reufer, Wilson, Morozov and Poon2014) and Qu & Breuer (Reference Qu and Breuer2020). In such a scenario, the flagellar bundle directly forces the solvent present in the pores, which then transmits the stresses to the polymer. These two fluids therefore move relative to each other leading to a Darcy drag term in the governing equations and hence a screening length ![]() $L_B$, within which the relative velocity of the two fluids decays. The resulting equations for the relative velocity of the solvent and polymer are similar to the Brinkman equations for flow through porous media (Brinkman Reference Brinkman1947). Some earlier studies have studied the motion of a slender body (Howells Reference Howells1998; Leshansky Reference Leshansky2009) and a bacterium (Chen et al. Reference Chen, Lordi, Taylor and Pak2021) in a Brinkman medium using RFT. There have also been a slender body treatment of helical fibres (Ho, Leiderman & Olsen Reference Ho, Leiderman and Olsen2019) and a study of squirmers in Brinkman medium (Nganguia & Pak Reference Nganguia and Pak2018). In these studies, the pores result from a sparse random distribution of rigid bodies, whereas in this study, the porous structure results from polymers, which are also subject to motion.

$L_B$, within which the relative velocity of the two fluids decays. The resulting equations for the relative velocity of the solvent and polymer are similar to the Brinkman equations for flow through porous media (Brinkman Reference Brinkman1947). Some earlier studies have studied the motion of a slender body (Howells Reference Howells1998; Leshansky Reference Leshansky2009) and a bacterium (Chen et al. Reference Chen, Lordi, Taylor and Pak2021) in a Brinkman medium using RFT. There have also been a slender body treatment of helical fibres (Ho, Leiderman & Olsen Reference Ho, Leiderman and Olsen2019) and a study of squirmers in Brinkman medium (Nganguia & Pak Reference Nganguia and Pak2018). In these studies, the pores result from a sparse random distribution of rigid bodies, whereas in this study, the porous structure results from polymers, which are also subject to motion.

We first analyse the motion of a slender helical fibre in such a medium using SBT and then use RFT to analyse the motion of a bacterium with a helical flagellar bundle in this medium. Our analysis indicates that bacterial motion is sensitive to the nature of the interaction between the flagellar bundle and the polymer, and predicts an increased drag anisotropy. This, in turn, leads to an enhancement in the swimming speed, compared with the case where the polymer solution is treated as a continuum mixture – a Newtonian medium with viscosity ![]() $\mu _s(1 + \lambda )$. We model two physical scenarios, corresponding to two possible polymer–flagellar bundle interactions: (i) a case where the polymer slips past the bundle and (ii) a case where the polymer is not subject to any direct continuum forcing by the bundle (no interaction).

$\mu _s(1 + \lambda )$. We model two physical scenarios, corresponding to two possible polymer–flagellar bundle interactions: (i) a case where the polymer slips past the bundle and (ii) a case where the polymer is not subject to any direct continuum forcing by the bundle (no interaction).

2. Two-fluid model of the polymer solution

In this section, we describe the two-fluid model of a polymer solution and analyse the motion of a sphere through it to explain its features. Two-fluid models for polymer solutions were first introduced by Doi (Reference Doi1990). While typical mixture models of polymer solutions assume that the polymers and solvent move with a common velocity, Doi's two-fluid model allows for relative motion between the polymer and the solvent, owing to the fact that under certain conditions, inhomogeneous fluid flow can create polymer concentration gradients and lead to diffusion of polymers relative to the solvent flow. The model describes a polymer solution composed of a Newtonian solvent phase with viscosity ![]() $\mu _s$ and a polymer phase with the two phases coexisting as interpenetrating continua. In general, the model permits a non-uniform concentration for the polymer, while treating the polymer as a non-Newtonian medium. Such models have been successfully used in other phenomena involving entangled polymer solutions, where such a differential response in solvent and polymer may arise (e.g. electroconvection of electrolytes with polymer additives Tikekar et al. Reference Tikekar, Li, Archer and Koch2018, shear banding phenomenon in concentrated polymer solutions Cromer et al. Reference Cromer, Villet, Frederickson and Leal2013 and swelling of polymeric gels Wang, Li & Hu Reference Wang, Li and Hu1997). In all these cases, a non-equilibrium forcing results in the polymer having a different velocity than the solvent. The predictions of these models have also been shown to match with experimental observations (Doi Reference Doi2009; Burroughs et al. Reference Burroughs, Zhang, Shetty, Bates, Leal and Helgeson2021).

$\mu _s$ and a polymer phase with the two phases coexisting as interpenetrating continua. In general, the model permits a non-uniform concentration for the polymer, while treating the polymer as a non-Newtonian medium. Such models have been successfully used in other phenomena involving entangled polymer solutions, where such a differential response in solvent and polymer may arise (e.g. electroconvection of electrolytes with polymer additives Tikekar et al. Reference Tikekar, Li, Archer and Koch2018, shear banding phenomenon in concentrated polymer solutions Cromer et al. Reference Cromer, Villet, Frederickson and Leal2013 and swelling of polymeric gels Wang, Li & Hu Reference Wang, Li and Hu1997). In all these cases, a non-equilibrium forcing results in the polymer having a different velocity than the solvent. The predictions of these models have also been shown to match with experimental observations (Doi Reference Doi2009; Burroughs et al. Reference Burroughs, Zhang, Shetty, Bates, Leal and Helgeson2021).

In this work, the polymer is modelled as a Newtonian fluid with uniform concentration (as this fairly represents the conditions found in earlier experiments by Martinez et al. Reference Martinez, Schwarz-Link, Reufer, Wilson, Morozov and Poon2014; Qu & Breuer Reference Qu and Breuer2020), having a different viscosity ![]() $\mu _p$, where the viscosity is equivalent to the polymer's contribution to the zero-shear viscosity of the polymer solution. The polymer and the solvent are allowed to move relative to each other and the inertial effects in both fluids are considered to be negligible, with the Reynolds number (

$\mu _p$, where the viscosity is equivalent to the polymer's contribution to the zero-shear viscosity of the polymer solution. The polymer and the solvent are allowed to move relative to each other and the inertial effects in both fluids are considered to be negligible, with the Reynolds number (![]() $Re$) based on both

$Re$) based on both ![]() $\mu _s$ and

$\mu _s$ and ![]() $\mu _p$ being small;

$\mu _p$ being small; ![]() $Re \ll 1$. Here, the non-equilibrium condition between the polymer and solvent is created by the different forces they experience at the boundary of the rotating flagellar bundle, because of the microstructure ‘seen’ by the flagellar bundle. Unlike Doi (Reference Doi1990), we consider the polymer to have a constant concentration and an incompressible mass conservation equation. This condition can be approximated in the model of Doi (Reference Doi1990) if the osmotic susceptibility of the polymer is small, so that the osmotic pressure (termed

$Re \ll 1$. Here, the non-equilibrium condition between the polymer and solvent is created by the different forces they experience at the boundary of the rotating flagellar bundle, because of the microstructure ‘seen’ by the flagellar bundle. Unlike Doi (Reference Doi1990), we consider the polymer to have a constant concentration and an incompressible mass conservation equation. This condition can be approximated in the model of Doi (Reference Doi1990) if the osmotic susceptibility of the polymer is small, so that the osmotic pressure (termed ![]() $p_p$ here) takes on whatever values are needed to impose the incompressibility of the polymer phase. The governing equations of our two-fluid model are given by

$p_p$ here) takes on whatever values are needed to impose the incompressibility of the polymer phase. The governing equations of our two-fluid model are given by

where ![]() $\boldsymbol {u}_s$,

$\boldsymbol {u}_s$, ![]() $\boldsymbol {u}_p$,

$\boldsymbol {u}_p$, ![]() $p_s$ and

$p_s$ and ![]() $p_p$ correspond to the solvent and polymer phase velocities and pressures, respectively, and

$p_p$ correspond to the solvent and polymer phase velocities and pressures, respectively, and ![]() $\xi$ is the Darcy resistance coefficient defined as

$\xi$ is the Darcy resistance coefficient defined as ![]() $\xi = \mu _s/L_B^2$, where

$\xi = \mu _s/L_B^2$, where ![]() $L_B$ is the screening length of the two-fluid medium. As noted earlier, the form of the equations is similar to Brinkman's equations in a porous medium (Brinkman Reference Brinkman1947), except that here, the polymers forming the porous network are capable of flowing. Thus,

$L_B$ is the screening length of the two-fluid medium. As noted earlier, the form of the equations is similar to Brinkman's equations in a porous medium (Brinkman Reference Brinkman1947), except that here, the polymers forming the porous network are capable of flowing. Thus, ![]() $L_B$ can be considered to be the length scale of hydrodynamic coupling in the polymer solution, which is

$L_B$ can be considered to be the length scale of hydrodynamic coupling in the polymer solution, which is ![]() $O(\phi ^{-1/2} \log \phi ^{1/2})$,

$O(\phi ^{-1/2} \log \phi ^{1/2})$, ![]() $\phi$ being the polymer volume fraction, if the polymers are assumed to be fibres of finite length randomly oriented in space (Howells Reference Howells1998). The above equations can be written in dimensionless form as

$\phi$ being the polymer volume fraction, if the polymers are assumed to be fibres of finite length randomly oriented in space (Howells Reference Howells1998). The above equations can be written in dimensionless form as

where we have non-dimensionalised the lengths with a characteristic length scale ![]() $l$, the velocity with characteristic velocity scale

$l$, the velocity with characteristic velocity scale ![]() $U$, and the solvent and polymer pressures with

$U$, and the solvent and polymer pressures with ![]() $\mu _s U / l$ and

$\mu _s U / l$ and ![]() $\mu _p U/l$. Note that

$\mu _p U/l$. Note that ![]() $L_B$ in (2.5), (2.6) is dimensionless (equal to

$L_B$ in (2.5), (2.6) is dimensionless (equal to ![]() $L_B/l$) and should be considered as such in the sections that follow, unless otherwise stated.

$L_B/l$) and should be considered as such in the sections that follow, unless otherwise stated.

2.1. A translating and rotating sphere in the two-fluid medium

Before embarking on the more challenging problems of studying the motion of a helix and then a bacterium in the two-fluid medium, we first study a sphere of radius ‘![]() $a$’ moving with a velocity

$a$’ moving with a velocity ![]() $\boldsymbol {U}$ and rotating with an angular velocity

$\boldsymbol {U}$ and rotating with an angular velocity ![]() $\boldsymbol {\omega }$ through the quiescent two-fluid medium to gain insights into the response of the medium. A similar problem has been solved by Fu, Shenoy & Powers (Reference Fu, Shenoy and Powers2007b) for a sphere translating in a a purely elastic polymer, and by Moradi, Shi & Nazockdast (Reference Moradi, Shi and Nazockdast2022) for a sphere moving in a linearly viscoelastic polymer. Our model considers a Newtonian polymer phase. As mentioned in the introduction, our calculations consider two sets of boundary conditions corresponding to two physical scenarios: (i) the polymer slipping past the solid body and (ii) the polymer not interacting with the solid body. The first case is relevant when the body moves through an entangled polymer solution with pore sizes comparable to the characteristic length scale of the body (in this example, this is the sphere diameter

$\boldsymbol {\omega }$ through the quiescent two-fluid medium to gain insights into the response of the medium. A similar problem has been solved by Fu, Shenoy & Powers (Reference Fu, Shenoy and Powers2007b) for a sphere translating in a a purely elastic polymer, and by Moradi, Shi & Nazockdast (Reference Moradi, Shi and Nazockdast2022) for a sphere moving in a linearly viscoelastic polymer. Our model considers a Newtonian polymer phase. As mentioned in the introduction, our calculations consider two sets of boundary conditions corresponding to two physical scenarios: (i) the polymer slipping past the solid body and (ii) the polymer not interacting with the solid body. The first case is relevant when the body moves through an entangled polymer solution with pore sizes comparable to the characteristic length scale of the body (in this example, this is the sphere diameter ![]() $2a$) and the second case is relevant when the pore size is much larger than the characteristic length scale of the body, so that the polymer is not directly forced by the moving body, but is forced indirectly by the solvent which is affected by the motion. The solvent satisfies no-slip in both cases. Thus, the boundary conditions for the first case are

$2a$) and the second case is relevant when the pore size is much larger than the characteristic length scale of the body, so that the polymer is not directly forced by the moving body, but is forced indirectly by the solvent which is affected by the motion. The solvent satisfies no-slip in both cases. Thus, the boundary conditions for the first case are

which are respectively the far-field conditions, no slip condition for the solvent, no penetration condition for the polymer and zero tangential polymer stress on the sphere surface (a completely slipping polymer). Here, ![]() $r = |\boldsymbol {r}|$ is the radial distance and

$r = |\boldsymbol {r}|$ is the radial distance and ![]() $\boldsymbol {n} = \boldsymbol {r}/r$ is the unit normal. Therefore, the polymer will not resist tangential motion (shearing) but will resist normal motion (pressure).

$\boldsymbol {n} = \boldsymbol {r}/r$ is the unit normal. Therefore, the polymer will not resist tangential motion (shearing) but will resist normal motion (pressure).

The solution procedure and the exact expressions for the velocities and pressures for both fluids are given in supplementary Appendix A available at https://doi.org/10.1017/jfm.2024.1069, and the procedure involves solving the above set of coupled partial differential equations by defining two new fields ![]() $\boldsymbol {u}_m = \boldsymbol {u}_s + \lambda \boldsymbol {u}_p$ and

$\boldsymbol {u}_m = \boldsymbol {u}_s + \lambda \boldsymbol {u}_p$ and ![]() $\boldsymbol {u}_d = \boldsymbol {u}_p - \boldsymbol {u}_s$ (similarly for

$\boldsymbol {u}_d = \boldsymbol {u}_p - \boldsymbol {u}_s$ (similarly for ![]() $p_m$,

$p_m$, ![]() $p_d$ and other variables). These two fields define a mixture field satisfying Stokes equations and a difference field satisfying Brinkman equations, for which solutions are easily derived. Figure 1 shows the normalised drag force on a translating sphere and the torque on a rotating sphere as functions of the screening length

$p_d$ and other variables). These two fields define a mixture field satisfying Stokes equations and a difference field satisfying Brinkman equations, for which solutions are easily derived. Figure 1 shows the normalised drag force on a translating sphere and the torque on a rotating sphere as functions of the screening length ![]() $L_B/a$ for different values of

$L_B/a$ for different values of ![]() $\lambda$, where the normalisation is with respect to drag and torque in the solvent (of viscosity

$\lambda$, where the normalisation is with respect to drag and torque in the solvent (of viscosity ![]() $\mu _s$). From the figure, we see that as the screening length approaches zero, the dimensional drag on the sphere approaches

$\mu _s$). From the figure, we see that as the screening length approaches zero, the dimensional drag on the sphere approaches ![]() $6 {\rm \pi} \mu _s |\boldsymbol {U}| (1 + \lambda ) a$ for translation and the torque approaches

$6 {\rm \pi} \mu _s |\boldsymbol {U}| (1 + \lambda ) a$ for translation and the torque approaches ![]() $8 {\rm \pi} \mu _s a^3 (1+\lambda ) |\boldsymbol {\omega }|$ for the case of rotation. These are the corresponding values for drag and torque, in a medium that is a mixture of the two fluids (same as a single-fluid medium with viscosity

$8 {\rm \pi} \mu _s a^3 (1+\lambda ) |\boldsymbol {\omega }|$ for the case of rotation. These are the corresponding values for drag and torque, in a medium that is a mixture of the two fluids (same as a single-fluid medium with viscosity ![]() $\mu _s(1 + \lambda )$; hereby just referred to as the mixture). This suggests that for

$\mu _s(1 + \lambda )$; hereby just referred to as the mixture). This suggests that for ![]() $L_B/a \rightarrow 0$, the medium behaves like a mixture implying that there is no relative motion between the two fluids, even if one of them is allowed to slip past the solid boundary, i.e. taking this limit is the same as using a no-slip boundary condition for both fluids. The other limit of

$L_B/a \rightarrow 0$, the medium behaves like a mixture implying that there is no relative motion between the two fluids, even if one of them is allowed to slip past the solid boundary, i.e. taking this limit is the same as using a no-slip boundary condition for both fluids. The other limit of ![]() $L_B/a \rightarrow \infty$ corresponds to the decoupled solvent and polymer acting independently of each other, which results in a dimensional drag and torque of

$L_B/a \rightarrow \infty$ corresponds to the decoupled solvent and polymer acting independently of each other, which results in a dimensional drag and torque of ![]() $6 {\rm \pi} \mu _s |\boldsymbol {U}| (1 + {2 \lambda }/{3}) a$ and

$6 {\rm \pi} \mu _s |\boldsymbol {U}| (1 + {2 \lambda }/{3}) a$ and ![]() $8 {\rm \pi} \mu _s a^3 (1+{2\lambda }/{3}) |\boldsymbol {\omega }|$, respectively. The factor

$8 {\rm \pi} \mu _s a^3 (1+{2\lambda }/{3}) |\boldsymbol {\omega }|$, respectively. The factor ![]() $2/3$ arises because, in this limit, the sphere acts like a bubble moving through the polymer on account of the zero tangential stress condition on the polymer. This calculation shows that one can go from a mixture-like behaviour to a completely decoupled behaviour of the two fluids using the two-fluid model.

$2/3$ arises because, in this limit, the sphere acts like a bubble moving through the polymer on account of the zero tangential stress condition on the polymer. This calculation shows that one can go from a mixture-like behaviour to a completely decoupled behaviour of the two fluids using the two-fluid model.

Figure 1. Plots of (a) drag force normalised by ![]() $F_N = 6 {\rm \pi} U \mu _s a$ on a sphere of radius

$F_N = 6 {\rm \pi} U \mu _s a$ on a sphere of radius ![]() $a$ translating with velocity

$a$ translating with velocity ![]() $U$ and (b) torque normalised by

$U$ and (b) torque normalised by ![]() $T_N = 8 {\rm \pi} \mu _s a^3 \omega$ on a sphere rotating with angular velocity

$T_N = 8 {\rm \pi} \mu _s a^3 \omega$ on a sphere rotating with angular velocity ![]() $\omega$ in a two-fluid medium with a slipping polymer, as a function of

$\omega$ in a two-fluid medium with a slipping polymer, as a function of ![]() $L_B/a$.

$L_B/a$.

A similar calculation can be done for the second case, where there is no polymer–sphere interaction with the boundary conditions now given by

For this case, the plots of normalised drag and torque are given in figure 2, which are similar to those in figure 1 (the torque on the sphere being exactly the same). The primary difference between this scenario and the previous one arises in the drag force acting on the sphere in the limit of ![]() $L_B/a \rightarrow \infty$, for which the drag on the sphere is

$L_B/a \rightarrow \infty$, for which the drag on the sphere is ![]() $6 {\rm \pi} \mu _s |\boldsymbol {U}| a$. This is consistent with the fact that the polymer is not forced by the sphere and in the limit of large screening length, where the fluids act independently, only the solvent contributes to the drag.

$6 {\rm \pi} \mu _s |\boldsymbol {U}| a$. This is consistent with the fact that the polymer is not forced by the sphere and in the limit of large screening length, where the fluids act independently, only the solvent contributes to the drag.

Figure 2. Plots of (a) drag force normalised by ![]() $F_N = 6 {\rm \pi} U \mu _s a$ on a sphere of radius

$F_N = 6 {\rm \pi} U \mu _s a$ on a sphere of radius ![]() $a$ translating with velocity

$a$ translating with velocity ![]() $U$ and (b) torque normalised by

$U$ and (b) torque normalised by ![]() $T_N = 8 {\rm \pi} \mu _s a^3 \omega$ on a sphere rotating with angular velocity

$T_N = 8 {\rm \pi} \mu _s a^3 \omega$ on a sphere rotating with angular velocity ![]() $\omega$ in a two-fluid medium with no polymer–sphere interaction, as a function of

$\omega$ in a two-fluid medium with no polymer–sphere interaction, as a function of ![]() $L_B/a$.

$L_B/a$.

The takeaway from this sample calculation is that, using the two-fluid model, one can go from mixture-like behaviour (a single fluid with viscosity ![]() $\mu _s + \mu _p$ – similar to the canonical treatment of polymer solutions) to completely decoupled behaviour of the two fluids by varying

$\mu _s + \mu _p$ – similar to the canonical treatment of polymer solutions) to completely decoupled behaviour of the two fluids by varying ![]() $L_B$. Thus, the screening length

$L_B$. Thus, the screening length ![]() $L_B$ is equivalent to the characteristic length scale of the microstructure in the polymer solution. In the next section, we derive solutions for a slender helical fibre moving through the two-fluid medium, satisfying the same two sets of boundary conditions as the sphere, and analyse the effect of microstructure on its motion.

$L_B$ is equivalent to the characteristic length scale of the microstructure in the polymer solution. In the next section, we derive solutions for a slender helical fibre moving through the two-fluid medium, satisfying the same two sets of boundary conditions as the sphere, and analyse the effect of microstructure on its motion.

2.2. Fundamental solutions of the two-fluid equations

To derive the SBT in the two-fluid medium, we need the fundamental solutions for the two-fluid equations, which are derived here. The dimensionless governing equations are now given by

with arbitrary forcing on both the solvent (![]() $\boldsymbol {F}_s$) and the polymer (

$\boldsymbol {F}_s$) and the polymer (![]() $\boldsymbol {F}_p$). The solution can be found by writing the above equation in terms of a mixture flow and difference flow, given by

$\boldsymbol {F}_p$). The solution can be found by writing the above equation in terms of a mixture flow and difference flow, given by

where ![]() $\boldsymbol {u}_m = \boldsymbol {u}_s + \lambda \boldsymbol {u}_p$ and likewise for

$\boldsymbol {u}_m = \boldsymbol {u}_s + \lambda \boldsymbol {u}_p$ and likewise for ![]() $p_m$ and

$p_m$ and ![]() $\boldsymbol {F}_m$, and

$\boldsymbol {F}_m$, and ![]() $\boldsymbol {u}_d = \boldsymbol {u}_p - \boldsymbol {u}_s$ and similar definitions follow for

$\boldsymbol {u}_d = \boldsymbol {u}_p - \boldsymbol {u}_s$ and similar definitions follow for ![]() $p_d$ and

$p_d$ and ![]() $\boldsymbol {F}_d$. Since the mixture flow and difference flow equations are the well-known Stokes and Brinkman equations, one can find the Green's function for the two-fluid medium using the Green's functions of the Stokes (

$\boldsymbol {F}_d$. Since the mixture flow and difference flow equations are the well-known Stokes and Brinkman equations, one can find the Green's function for the two-fluid medium using the Green's functions of the Stokes (![]() $\boldsymbol {G}_{St}$) and Brinkman (

$\boldsymbol {G}_{St}$) and Brinkman (![]() $\boldsymbol {G}_{Br}$) media. Thus, this Green's function is a tensor

$\boldsymbol {G}_{Br}$) media. Thus, this Green's function is a tensor ![]() $\boldsymbol {G}$ consisting of four elements namely

$\boldsymbol {G}$ consisting of four elements namely ![]() $\boldsymbol {G}_{SS}$,

$\boldsymbol {G}_{SS}$, ![]() $\boldsymbol {G}_{SP}$,

$\boldsymbol {G}_{SP}$, ![]() $\boldsymbol {G}_{PS}$ and

$\boldsymbol {G}_{PS}$ and ![]() $\boldsymbol {G}_{PP}$, i.e.

$\boldsymbol {G}_{PP}$, i.e.

where ![]() $\boldsymbol {G}_{ij}$ gives the velocity of fluid

$\boldsymbol {G}_{ij}$ gives the velocity of fluid ![]() $i$ due to a force acting on fluid

$i$ due to a force acting on fluid ![]() $j$. To find these functions, one can write the equation for

$j$. To find these functions, one can write the equation for ![]() $\boldsymbol {u}_m$ and

$\boldsymbol {u}_m$ and ![]() $\boldsymbol {u}_d$ in terms of these functions and equate it to the known Stokesian (

$\boldsymbol {u}_d$ in terms of these functions and equate it to the known Stokesian (![]() $\boldsymbol {G}_{St}$) and Brinkman (

$\boldsymbol {G}_{St}$) and Brinkman (![]() $\boldsymbol {G}_{Br}$) Green's functions. This is given by

$\boldsymbol {G}_{Br}$) Green's functions. This is given by

Solving (2.19)–(2.20) for the four elements of ![]() $\boldsymbol {G}$, we get

$\boldsymbol {G}$, we get

Here, the Stokes and Brinkman Green's functions (Howells Reference Howells1974) are given by

$$\begin{gather}\boldsymbol{G}_{Br} = (\boldsymbol{\nabla} \boldsymbol{\nabla} - \boldsymbol{I}\nabla^2) \left(\frac{2 \lambda L^2_B \left(1- {\rm e}^{-{(\sqrt{{(\lambda +1)}/{\lambda}}\,r})/{L_B}}\right)}{(\lambda +1) r}\right), \end{gather}$$

$$\begin{gather}\boldsymbol{G}_{Br} = (\boldsymbol{\nabla} \boldsymbol{\nabla} - \boldsymbol{I}\nabla^2) \left(\frac{2 \lambda L^2_B \left(1- {\rm e}^{-{(\sqrt{{(\lambda +1)}/{\lambda}}\,r})/{L_B}}\right)}{(\lambda +1) r}\right), \end{gather}$$

where ![]() $\boldsymbol {n}=\boldsymbol {r}/r$.

$\boldsymbol {n}=\boldsymbol {r}/r$.

3. Slender body theory for the two-fluid medium

Herein, the velocity disturbance created by a slender fibre with a circular cross-section, when placed in the two-fluid medium, is described using SBT. SBT allows for an approximate solution of the flow produced by bodies which are long and thin in the Stokesian regime (Batchelor Reference Batchelor1970; Cox Reference Cox1970; Keller & Rubinow Reference Keller and Rubinow1976; Johnson Reference Johnson1980; Borker & Koch Reference Borker and Koch2019). The basic idea in SBT is to obtain the strength of a line of singularities placed along the centreline of the slender filament that approximates the field of interest around the filament far away from the cross-sectional surface, termed as the outer region, i.e. ![]() $a \ll \rho$. Here,

$a \ll \rho$. Here, ![]() $\rho$ is the radial distance from the centreline of the slender filament and ‘

$\rho$ is the radial distance from the centreline of the slender filament and ‘![]() $a$’ is a measure of the cross-sectional size of the particle at a certain location along the centreline of the slender body as shown in figure 3. The singularity for a Stokes flow problem is a point force. The strength of the singularities is found by matching the field approximated in the outer region, termed as the outer solution, to a field obtained from the inner region (

$a$’ is a measure of the cross-sectional size of the particle at a certain location along the centreline of the slender body as shown in figure 3. The singularity for a Stokes flow problem is a point force. The strength of the singularities is found by matching the field approximated in the outer region, termed as the outer solution, to a field obtained from the inner region (![]() $\rho \ll l$, where

$\rho \ll l$, where ![]() $l$ is the length of the slender filament). In the inner region, any curved slender body with

$l$ is the length of the slender filament). In the inner region, any curved slender body with ![]() $O(1)$ curvature appears locally as a straight infinite cylinder to a first approximation. The velocity field in the inner region is therefore obtained by assuming flow over an infinite cylinder, which is two-dimensional. Thus, the flow along and transverse to the cylinder is solved separately. Any coupling between these flows arises due to the curvature and finite aspect ratio of the particle, and leads to algebraic

$O(1)$ curvature appears locally as a straight infinite cylinder to a first approximation. The velocity field in the inner region is therefore obtained by assuming flow over an infinite cylinder, which is two-dimensional. Thus, the flow along and transverse to the cylinder is solved separately. Any coupling between these flows arises due to the curvature and finite aspect ratio of the particle, and leads to algebraic ![]() $O(\gamma ^{-2})$ corrections (

$O(\gamma ^{-2})$ corrections (![]() $\gamma = l/(2a)$ being the aspect ratio of the fibre) to the velocity disturbance (Cox Reference Cox1970; Johnson Reference Johnson1980) which are not considered here. Placing higher order singularities along the centreline of the slender filament gives a better estimate of the field of interest. In Stokes flow, these singularities would include doublets, rotlets, sources, stresslets and quadrupoles (Cox Reference Cox1970; Keller & Rubinow Reference Keller and Rubinow1976; Johnson Reference Johnson1980). These higher order singularities are also not considered in this work, as the dimensions of the flagellar bundle of E. coli that we model in this work (see table 1) imply that the shear and rotational resistances of the bundle are negligible in most circumstances (Lauga & Powers Reference Lauga and Powers2009).

$\gamma = l/(2a)$ being the aspect ratio of the fibre) to the velocity disturbance (Cox Reference Cox1970; Johnson Reference Johnson1980) which are not considered here. Placing higher order singularities along the centreline of the slender filament gives a better estimate of the field of interest. In Stokes flow, these singularities would include doublets, rotlets, sources, stresslets and quadrupoles (Cox Reference Cox1970; Keller & Rubinow Reference Keller and Rubinow1976; Johnson Reference Johnson1980). These higher order singularities are also not considered in this work, as the dimensions of the flagellar bundle of E. coli that we model in this work (see table 1) imply that the shear and rotational resistances of the bundle are negligible in most circumstances (Lauga & Powers Reference Lauga and Powers2009).

Figure 3. Local coordinate system for a general curved body; ![]() $\boldsymbol{e}_{\boldsymbol{z}}$ is along the tangent to the filament axis,

$\boldsymbol{e}_{\boldsymbol{z}}$ is along the tangent to the filament axis, ![]() $\boldsymbol{e}_{\boldsymbol{x}}$ is along the normal and

$\boldsymbol{e}_{\boldsymbol{x}}$ is along the normal and ![]() $\boldsymbol{e}_{\boldsymbol{y}}$ is pointed along the binormal to the centreline of the slender body (

$\boldsymbol{e}_{\boldsymbol{y}}$ is pointed along the binormal to the centreline of the slender body (![]() $\boldsymbol{r}_{\boldsymbol{c}}$).

$\boldsymbol{r}_{\boldsymbol{c}}$).

Table 1. Values of the various parameters corresponding to E. coli used in RFT calculation.

In this work, we consider a slender fibre with circular cross-section, and a curved centreline, having a characteristic length ![]() $l$, radius

$l$, radius ![]() $a(s) = a_0 \times \bar {a}(s)$, which varies along the centreline coordinate

$a(s) = a_0 \times \bar {a}(s)$, which varies along the centreline coordinate ![]() $s$, and aspect ratio

$s$, and aspect ratio ![]() $\gamma = l/(2a_0) \gg 1$. Here,

$\gamma = l/(2a_0) \gg 1$. Here, ![]() $a_0$ is the cross-section radius at the mid-point of the curved centreline, and the centreline coordinate

$a_0$ is the cross-section radius at the mid-point of the curved centreline, and the centreline coordinate ![]() $s \in [0,1]$, with the arc length given by

$s \in [0,1]$, with the arc length given by ![]() $l * s$. The body is assumed to have a curvature (

$l * s$. The body is assumed to have a curvature (![]() $\kappa$) that is much smaller than the slenderness parameter, i.e.

$\kappa$) that is much smaller than the slenderness parameter, i.e. ![]() $\kappa \ll \gamma$. The position vector is denoted by

$\kappa \ll \gamma$. The position vector is denoted by ![]() $\boldsymbol {r}$ and

$\boldsymbol {r}$ and ![]() $\boldsymbol {r}_{\boldsymbol {c}}(s)$ denotes a point on the centreline of the slender body. A local coordinate system (

$\boldsymbol {r}_{\boldsymbol {c}}(s)$ denotes a point on the centreline of the slender body. A local coordinate system (![]() $\boldsymbol {e}_{\boldsymbol {x}}, \boldsymbol {e}_{\boldsymbol {y}}, \boldsymbol {e}_{\boldsymbol {z}}$) is chosen based on the tangent (

$\boldsymbol {e}_{\boldsymbol {x}}, \boldsymbol {e}_{\boldsymbol {y}}, \boldsymbol {e}_{\boldsymbol {z}}$) is chosen based on the tangent (![]() $\boldsymbol {e}_{\boldsymbol {z}}$), normal (

$\boldsymbol {e}_{\boldsymbol {z}}$), normal (![]() $\boldsymbol {e}_{\boldsymbol {x}}$) and binormal (

$\boldsymbol {e}_{\boldsymbol {x}}$) and binormal (![]() $\boldsymbol {e}_{\boldsymbol {y}}$) to the centreline of the slender body, as shown in figure 3, and is mathematically given by

$\boldsymbol {e}_{\boldsymbol {y}}$) to the centreline of the slender body, as shown in figure 3, and is mathematically given by

where ![]() $\kappa$ is the local curvature of the body centreline (

$\kappa$ is the local curvature of the body centreline (![]() $\kappa = | {\partial ^2 \boldsymbol {r}_{\boldsymbol {c}}}/{\partial s^2}|$). The velocity on the particle surface (

$\kappa = | {\partial ^2 \boldsymbol {r}_{\boldsymbol {c}}}/{\partial s^2}|$). The velocity on the particle surface (![]() $\boldsymbol {r} = \boldsymbol {r}_{\boldsymbol {s}}$) is given by

$\boldsymbol {r} = \boldsymbol {r}_{\boldsymbol {s}}$) is given by

In canonical SBT for Stokes flow, the only relevant length scale in the inner region is ![]() $a$ and all other length scales are assumed to be in the outer region. For the case of a two-fluid medium, we have one other length scale, the screening length

$a$ and all other length scales are assumed to be in the outer region. For the case of a two-fluid medium, we have one other length scale, the screening length ![]() $L_B$, which can either be considered part of the inner or outer region, resulting in two different formulations of SBT for a slender fibre. However, these two formulations overlap when

$L_B$, which can either be considered part of the inner or outer region, resulting in two different formulations of SBT for a slender fibre. However, these two formulations overlap when ![]() $L_B$ is of the same order as the length scale of the matching region. Additionally, one can have different versions of SBT corresponding to different polymer–fibre interactions, which affect the solutions in the inner region. In our study, we consider two types of polymer–fibre interactions: (i) polymer slipping over the fibre and (ii) polymer not interacting with the fibre. For the first case, we consider

$L_B$ is of the same order as the length scale of the matching region. Additionally, one can have different versions of SBT corresponding to different polymer–fibre interactions, which affect the solutions in the inner region. In our study, we consider two types of polymer–fibre interactions: (i) polymer slipping over the fibre and (ii) polymer not interacting with the fibre. For the first case, we consider ![]() $L_B$ to be in the inner, outer and matching region, and for the second case,

$L_B$ to be in the inner, outer and matching region, and for the second case, ![]() $L_B$ is in the outer region, owing to the fact that the no-interaction boundary condition is only applicable if the microstructure length scale is larger than the characteristic length scale of the moving body (here, the fibre cross-sectional diameter

$L_B$ is in the outer region, owing to the fact that the no-interaction boundary condition is only applicable if the microstructure length scale is larger than the characteristic length scale of the moving body (here, the fibre cross-sectional diameter ![]() $2a$).

$2a$).

3.1. Slender body theory for polymer slip condition with  $L_B$ in the inner region

$L_B$ in the inner region

For a slipping polymer, when the screening length is in the inner region (![]() $L_B/a \sim O(1)$), the inner solution corresponds to the disturbance field due to the motion of a circular cylinder in the two-fluid medium. In the outer region, the screening length satisfies the limit

$L_B/a \sim O(1)$), the inner solution corresponds to the disturbance field due to the motion of a circular cylinder in the two-fluid medium. In the outer region, the screening length satisfies the limit ![]() $L_B/l \ll 1$. From § 2.2, we recall that this limit corresponds to the mixture-like behaviour of the two-fluid medium, which is essentially a single-fluid medium with viscosity

$L_B/l \ll 1$. From § 2.2, we recall that this limit corresponds to the mixture-like behaviour of the two-fluid medium, which is essentially a single-fluid medium with viscosity ![]() $\mu _s(1+\lambda )$. Thus, the outer solution is the velocity disturbance due to the distribution of Stokeslets along the centreline (

$\mu _s(1+\lambda )$. Thus, the outer solution is the velocity disturbance due to the distribution of Stokeslets along the centreline (![]() $\boldsymbol {r}_{\boldsymbol {c}}$) of the fibre in a medium of viscosity

$\boldsymbol {r}_{\boldsymbol {c}}$) of the fibre in a medium of viscosity ![]() $\mu _s(1+\lambda )$. The inner and outer solutions given below for this case are then matched to obtain a governing equation for the singularity strength. Note that in all the cases presented hereafter, the velocities in the inner and outer region are presented in dimensionless form. The inner solution is made dimensionless by choosing

$\mu _s(1+\lambda )$. The inner and outer solutions given below for this case are then matched to obtain a governing equation for the singularity strength. Note that in all the cases presented hereafter, the velocities in the inner and outer region are presented in dimensionless form. The inner solution is made dimensionless by choosing ![]() $a$,

$a$, ![]() $U$, and

$U$, and ![]() $\mu _sU/a$ and

$\mu _sU/a$ and ![]() $\mu _pU/a$ as the length, velocity, and solvent and polymer stress scales. For the outer solution, we choose

$\mu _pU/a$ as the length, velocity, and solvent and polymer stress scales. For the outer solution, we choose ![]() $l$,

$l$, ![]() $U$, and

$U$, and ![]() $\mu _sU/l$ and

$\mu _sU/l$ and ![]() $\mu _pU/l$ as the length, velocity, and solvent and polymer stress scales. Also, all the equations are derived for a translating fibre for simplicity, and the rotation of the fibre can be included by simply adding the surface velocity due to rotation to the translation velocity.

$\mu _pU/l$ as the length, velocity, and solvent and polymer stress scales. Also, all the equations are derived for a translating fibre for simplicity, and the rotation of the fibre can be included by simply adding the surface velocity due to rotation to the translation velocity.

3.1.1. Inner solution ( $\rho \ll l$)

$\rho \ll l$)

The velocity field around a cylinder of radius ![]() $a$ in the two-fluid medium can be derived by solving the governing equations (2.1)–(2.3) following a procedure similar to that given for a sphere in supplementary Appendix A, subject to the boundary conditions,

$a$ in the two-fluid medium can be derived by solving the governing equations (2.1)–(2.3) following a procedure similar to that given for a sphere in supplementary Appendix A, subject to the boundary conditions,

where the last boundary condition is the (unknown) drag force per unit length acting on the cylinder surface (denoted by ![]() $\boldsymbol {r}_{\boldsymbol {s}}$) and is the same as the Stokeslet strength of the outer solution. Here,

$\boldsymbol {r}_{\boldsymbol {s}}$) and is the same as the Stokeslet strength of the outer solution. Here, ![]() $\boldsymbol {r} = s \boldsymbol {e}_{\boldsymbol {z}} + \boldsymbol {\rho }$ written in terms of a polar coordinate system, where

$\boldsymbol {r} = s \boldsymbol {e}_{\boldsymbol {z}} + \boldsymbol {\rho }$ written in terms of a polar coordinate system, where ![]() $\boldsymbol {\rho } = \boldsymbol {e}_{\boldsymbol {x}} + \boldsymbol {e}_{\boldsymbol {y}}$, with

$\boldsymbol {\rho } = \boldsymbol {e}_{\boldsymbol {x}} + \boldsymbol {e}_{\boldsymbol {y}}$, with ![]() $|\boldsymbol {\rho }| = \rho$, which are defined in (3.1), is normal to the axis of the cylinder and

$|\boldsymbol {\rho }| = \rho$, which are defined in (3.1), is normal to the axis of the cylinder and ![]() $\boldsymbol {e}_{\boldsymbol {z}}$ is along the axis of the cylinder with

$\boldsymbol {e}_{\boldsymbol {z}}$ is along the axis of the cylinder with ![]() $\boldsymbol {n} = {\boldsymbol {\rho }}/{\rho }$ and

$\boldsymbol {n} = {\boldsymbol {\rho }}/{\rho }$ and ![]() $\boldsymbol {r}_{\boldsymbol {s}} = a \boldsymbol {n}$. In the matching region, the velocity fields are subject to the limit

$\boldsymbol {r}_{\boldsymbol {s}} = a \boldsymbol {n}$. In the matching region, the velocity fields are subject to the limit ![]() $\rho \gg a$. Since the outer solution for this case is the velocity field in the mixture of two fluids, the inner velocity field is also written for the mixture of solvent and polymer (

$\rho \gg a$. Since the outer solution for this case is the velocity field in the mixture of two fluids, the inner velocity field is also written for the mixture of solvent and polymer (![]() $\boldsymbol {u}_s + \lambda \boldsymbol {u}_p$), so as to match it to the outer solution. Therefore, the outer limit (

$\boldsymbol {u}_s + \lambda \boldsymbol {u}_p$), so as to match it to the outer solution. Therefore, the outer limit (![]() $\rho /a \gg 1$) of the inner mixture velocity field (dimensionless) for transverse and longitudinal motions of the cylinder is written as

$\rho /a \gg 1$) of the inner mixture velocity field (dimensionless) for transverse and longitudinal motions of the cylinder is written as

\begin{align} \boldsymbol{u}^{in} &= \boldsymbol{U}(1+\lambda) - \left[\frac{\boldsymbol{f} \boldsymbol{\cdot} (\boldsymbol{I} + \boldsymbol{e_z e_z})}{4{\rm \pi} } \log (\rho ) - \frac{(\boldsymbol{f} \boldsymbol{\cdot} \boldsymbol{n})\boldsymbol{n}}{4 {\rm \pi}} + \frac{\boldsymbol{f}}{4 {\rm \pi}} \left(\frac{1}{2} + g(\lambda,L_B)\right) \right.\nonumber\\ &\quad \left. + \frac{(\boldsymbol{f} \boldsymbol{\cdot} \boldsymbol{e}_{\boldsymbol{z}})\boldsymbol{e}_{\boldsymbol{z}}}{4 {\rm \pi}} \left[h(\lambda,L_B) - g(\lambda,L_B) -\frac{1}{2} \right] + O\left(\frac{1}{\rho^2}\right) \right]. \end{align}

\begin{align} \boldsymbol{u}^{in} &= \boldsymbol{U}(1+\lambda) - \left[\frac{\boldsymbol{f} \boldsymbol{\cdot} (\boldsymbol{I} + \boldsymbol{e_z e_z})}{4{\rm \pi} } \log (\rho ) - \frac{(\boldsymbol{f} \boldsymbol{\cdot} \boldsymbol{n})\boldsymbol{n}}{4 {\rm \pi}} + \frac{\boldsymbol{f}}{4 {\rm \pi}} \left(\frac{1}{2} + g(\lambda,L_B)\right) \right.\nonumber\\ &\quad \left. + \frac{(\boldsymbol{f} \boldsymbol{\cdot} \boldsymbol{e}_{\boldsymbol{z}})\boldsymbol{e}_{\boldsymbol{z}}}{4 {\rm \pi}} \left[h(\lambda,L_B) - g(\lambda,L_B) -\frac{1}{2} \right] + O\left(\frac{1}{\rho^2}\right) \right]. \end{align}

Note that the ![]() $\rho$ and

$\rho$ and ![]() $L_B$ that appear inside the logarithm and

$L_B$ that appear inside the logarithm and ![]() $g,h$ are dimensionless. The functions

$g,h$ are dimensionless. The functions ![]() $g(\lambda,L_B)$ and

$g(\lambda,L_B)$ and ![]() $h(\lambda,L_B)$ are given by

$h(\lambda,L_B)$ are given by

$$\begin{gather} g = \frac{\lambda }{ \left(\dfrac{\dfrac{1}{L_B} \sqrt{\dfrac{1+\lambda }{\lambda}} K_1\left(\sqrt{\dfrac{1+\lambda}{\lambda} \dfrac{1}{L_B}} \right)}{K_0\left(\sqrt{\dfrac{1+\lambda}{\lambda} \dfrac{1}{L_B}} \right)}+2 \lambda +2\right)}, \end{gather}$$

$$\begin{gather} g = \frac{\lambda }{ \left(\dfrac{\dfrac{1}{L_B} \sqrt{\dfrac{1+\lambda }{\lambda}} K_1\left(\sqrt{\dfrac{1+\lambda}{\lambda} \dfrac{1}{L_B}} \right)}{K_0\left(\sqrt{\dfrac{1+\lambda}{\lambda} \dfrac{1}{L_B}} \right)}+2 \lambda +2\right)}, \end{gather}$$ $$\begin{gather}h = \frac{2 \lambda K_0\left(\sqrt{\dfrac{1+\lambda}{\lambda} \dfrac{1}{L_B}} \right)}{\dfrac{1}{L_B} \sqrt{\dfrac{\lambda +1}{\lambda}} K_1\left(\sqrt{\dfrac{1+\lambda}{\lambda} \dfrac{1}{L_B}} \right)}, \end{gather}$$

$$\begin{gather}h = \frac{2 \lambda K_0\left(\sqrt{\dfrac{1+\lambda}{\lambda} \dfrac{1}{L_B}} \right)}{\dfrac{1}{L_B} \sqrt{\dfrac{\lambda +1}{\lambda}} K_1\left(\sqrt{\dfrac{1+\lambda}{\lambda} \dfrac{1}{L_B}} \right)}, \end{gather}$$

where ![]() $K_0$,

$K_0$, ![]() $K_1$ are modified Bessel functions. Note that

$K_1$ are modified Bessel functions. Note that ![]() $g \rightarrow 0$ and

$g \rightarrow 0$ and ![]() $h \rightarrow 0$ for

$h \rightarrow 0$ for ![]() $L_B \rightarrow 0$, and (3.7) reduces to the solution in a single fluid medium (Keller & Rubinow Reference Keller and Rubinow1976).

$L_B \rightarrow 0$, and (3.7) reduces to the solution in a single fluid medium (Keller & Rubinow Reference Keller and Rubinow1976).

3.1.2. Outer solution ( $\rho \gg a$)

$\rho \gg a$)

The outer solution for this case is the velocity disturbance produced by a distribution of Stokeslets along the centreline of the fibre in a fluid with viscosity ![]() $\mu _s(1+\lambda )$, since

$\mu _s(1+\lambda )$, since ![]() $L_B$ is in the inner region. Thus, one has

$L_B$ is in the inner region. Thus, one has

\begin{align} \boldsymbol{u}^{out}(\boldsymbol{r}) & = \boldsymbol{U}_{\infty}(\boldsymbol{r}) + \frac{1}{8 {\rm \pi}} \int_{\boldsymbol{r}_{\boldsymbol{c}}(s')} \boldsymbol{f}(\boldsymbol{r}_{\boldsymbol{c}}(s')) \nonumber\\ &\quad \boldsymbol{\cdot} \left[\frac{\boldsymbol{I}}{|\boldsymbol{r}-\boldsymbol{r}_{\boldsymbol{c}}(s')|} + \frac{(\boldsymbol{r}-\boldsymbol{r}_{\boldsymbol{c}}(s'))(\boldsymbol{r}-\boldsymbol{r}_{\boldsymbol{c}}(s'))} {|\boldsymbol{r}-\boldsymbol{r}_{\boldsymbol{c}}(s')|^3} \right]\,{\rm d}\boldsymbol{s}', \end{align}

\begin{align} \boldsymbol{u}^{out}(\boldsymbol{r}) & = \boldsymbol{U}_{\infty}(\boldsymbol{r}) + \frac{1}{8 {\rm \pi}} \int_{\boldsymbol{r}_{\boldsymbol{c}}(s')} \boldsymbol{f}(\boldsymbol{r}_{\boldsymbol{c}}(s')) \nonumber\\ &\quad \boldsymbol{\cdot} \left[\frac{\boldsymbol{I}}{|\boldsymbol{r}-\boldsymbol{r}_{\boldsymbol{c}}(s')|} + \frac{(\boldsymbol{r}-\boldsymbol{r}_{\boldsymbol{c}}(s'))(\boldsymbol{r}-\boldsymbol{r}_{\boldsymbol{c}}(s'))} {|\boldsymbol{r}-\boldsymbol{r}_{\boldsymbol{c}}(s')|^3} \right]\,{\rm d}\boldsymbol{s}', \end{align}

where ![]() $\boldsymbol {r}$ is the point at which the velocity is evaluated,

$\boldsymbol {r}$ is the point at which the velocity is evaluated, ![]() $\boldsymbol {r}_{\boldsymbol {c}}(s')$ takes all values along the centreline and

$\boldsymbol {r}_{\boldsymbol {c}}(s')$ takes all values along the centreline and ![]() $ds'$ is the elemental length along the centreline of the slender body. As

$ds'$ is the elemental length along the centreline of the slender body. As ![]() $\boldsymbol {r}_{\boldsymbol {c}}(s') \rightarrow \boldsymbol {r}$, the integral diverges as

$\boldsymbol {r}_{\boldsymbol {c}}(s') \rightarrow \boldsymbol {r}$, the integral diverges as ![]() $\log \rho$. One can add and subtract an analytically integrable term that captures the diverging part of the integral, as shown by Keller & Rubinow (Reference Keller and Rubinow1976). Using

$\log \rho$. One can add and subtract an analytically integrable term that captures the diverging part of the integral, as shown by Keller & Rubinow (Reference Keller and Rubinow1976). Using ![]() $|\boldsymbol {r}_{\boldsymbol {c}}(s)-\boldsymbol {r}_{\boldsymbol {c}}(s')| = \sqrt {(s-s')^2 + \rho ^2}$ (where

$|\boldsymbol {r}_{\boldsymbol {c}}(s)-\boldsymbol {r}_{\boldsymbol {c}}(s')| = \sqrt {(s-s')^2 + \rho ^2}$ (where ![]() $\boldsymbol {r}_{\boldsymbol {c}}(s) = s\,\boldsymbol {e}_{\boldsymbol {z}} + \boldsymbol {\rho }$) in terms of the local polar coordinate system, where we have used

$\boldsymbol {r}_{\boldsymbol {c}}(s) = s\,\boldsymbol {e}_{\boldsymbol {z}} + \boldsymbol {\rho }$) in terms of the local polar coordinate system, where we have used ![]() $\boldsymbol {r} = \boldsymbol {r}_{\boldsymbol {c}}(s)$ (as we are interested in the velocity at the centreline), the resulting expression for the inner limit (

$\boldsymbol {r} = \boldsymbol {r}_{\boldsymbol {c}}(s)$ (as we are interested in the velocity at the centreline), the resulting expression for the inner limit (![]() $\rho \ll l$) of the outer solution is given by

$\rho \ll l$) of the outer solution is given by

\begin{align} \boldsymbol{u}(\boldsymbol{r}_{\boldsymbol{c}}(s)) &\approx \boldsymbol{U}_{\infty}(\boldsymbol{r}_{\boldsymbol{c}}(s)) + \frac{\boldsymbol{f} \boldsymbol{\cdot} (\boldsymbol{I + e_z e_z})}{4 {\rm \pi}} \left(\log \left(\frac{2(\sqrt{s(1-s)})}{\rho} \right) \right) - \frac{\boldsymbol{f} \boldsymbol{\cdot} \boldsymbol{e_z e_z}}{4 {\rm \pi}} + \frac{\boldsymbol{f} \boldsymbol{\cdot} \boldsymbol{nn}}{4 {\rm \pi}} \nonumber\\ &\quad +\frac{1}{8{\rm \pi} } \int \left[\left( \frac{\boldsymbol{I}}{|\boldsymbol{r}_{\boldsymbol{c}}(s) - \boldsymbol{r}_{\boldsymbol{c}}(s')|} + \frac{(\boldsymbol{r}_{\boldsymbol{c}}(s) - \boldsymbol{r}_{\boldsymbol{c}}(s'))(\boldsymbol{r}_{\boldsymbol{c}}(s) - \boldsymbol{r}_{\boldsymbol{c}}(s'))}{|\boldsymbol{r}_{\boldsymbol{c}}(s) - \boldsymbol{r}_{\boldsymbol{c}}(s')|^3} \right) \boldsymbol{\cdot} \boldsymbol{f}(\boldsymbol{r}_{\boldsymbol{c}}(s')) \right.\nonumber\\ &\quad \left.- \left(\frac{(\boldsymbol{I} + \boldsymbol{e_z e_z})}{|s - s'|} \right) \boldsymbol{\cdot} \boldsymbol{f}(\boldsymbol{r}_{\boldsymbol{c}}(s)) \right]\,{\rm d}s', \end{align}