1. Introduction

Turbulent flow over rough walls has piqued the interest of researchers and engineers for decades. From the earliest seminal works by Nikuradse (Reference Nikuradse1933) and Colebrook (Reference Colebrook1939), and the consolidated data interpretation by Moody (Reference Moody1944), the field of rough-wall bounded turbulence has continued to evolve, as is evident in subsequent works (Raupach, Antonia & Rajagopalan Reference Raupach, Antonia and Rajagopalan1991; Jiménez Reference Jiménez2004; Flack & Schultz Reference Flack and Schultz2010). In the recent review by Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021), the authors emphasize the importance of Townsend's outer-layer similarity hypothesis (Townsend Reference Townsend1976). This hypothesis assumes that under fully rough and sufficiently high boundary layer thickness to roughness height ratio (![]() $\delta /k$) conditions, the outer layer of a rough-wall boundary layer behaves similarly to that of a smooth wall. A logarithmic layer can therefore be expected between the roughness sublayer and the outer layer. This logarithmic layer, aside from a downward shift

$\delta /k$) conditions, the outer layer of a rough-wall boundary layer behaves similarly to that of a smooth wall. A logarithmic layer can therefore be expected between the roughness sublayer and the outer layer. This logarithmic layer, aside from a downward shift ![]() $\Delta U^+$ compared to the smooth-wall log law, remains unaffected by surface roughness. This downward shift

$\Delta U^+$ compared to the smooth-wall log law, remains unaffected by surface roughness. This downward shift ![]() $\Delta U^+$ constitutes the roughness function, enabling frictional drag comparisons across different rough surfaces. Besides

$\Delta U^+$ constitutes the roughness function, enabling frictional drag comparisons across different rough surfaces. Besides ![]() $\Delta U^+$, which characterizes the hydraulic properties, a rough wall is also characterized by the statistical moments of roughness height and the distribution of its topographical features. Establishing a functional mapping between the roughness function and the rough-wall topography is of significant practical utility and remains a challenging problem, given the variations in surface features and the costs of rough-wall boundary layer experiments (Schultz & Flack Reference Schultz and Flack2007) and scale-resolving computational studies (Choi & Moin Reference Choi and Moin2012; Yang & Griffin Reference Yang and Griffin2021).

$\Delta U^+$, which characterizes the hydraulic properties, a rough wall is also characterized by the statistical moments of roughness height and the distribution of its topographical features. Establishing a functional mapping between the roughness function and the rough-wall topography is of significant practical utility and remains a challenging problem, given the variations in surface features and the costs of rough-wall boundary layer experiments (Schultz & Flack Reference Schultz and Flack2007) and scale-resolving computational studies (Choi & Moin Reference Choi and Moin2012; Yang & Griffin Reference Yang and Griffin2021).

Several studies have aimed to develop roughness correlations for various surfaces. Flack & Schultz (Reference Flack and Schultz2010) proposed correlations utilizing skewness (![]() $Sk$) and root mean square roughness height (

$Sk$) and root mean square roughness height (![]() $k_{rms}$) to characterize equivalent sand-grain roughness (

$k_{rms}$) to characterize equivalent sand-grain roughness (![]() $k_s$) for irregular three-dimensional roughness. Yuan & Piomelli (Reference Yuan and Piomelli2014a) examined slope-based and moment-based correlations to study critical effective slope (

$k_s$) for irregular three-dimensional roughness. Yuan & Piomelli (Reference Yuan and Piomelli2014a) examined slope-based and moment-based correlations to study critical effective slope (![]() $ES$) associated with waviness regimes for realistic roughness from hydraulic turbine blades. Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) found that functional relations dependent on

$ES$) associated with waviness regimes for realistic roughness from hydraulic turbine blades. Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) found that functional relations dependent on ![]() $Sk$ and

$Sk$ and ![]() $ES$, which represent the shape and slope of the rough surface, respectively, produced satisfactory

$ES$, which represent the shape and slope of the rough surface, respectively, produced satisfactory ![]() $k_s$ predictions for randomly distributed roughness elements of random size and prescribed shape. In another study, Flack, Schultz & Barros (Reference Flack, Schultz and Barros2020) performed experiments on random rough surfaces by systematically varying

$k_s$ predictions for randomly distributed roughness elements of random size and prescribed shape. In another study, Flack, Schultz & Barros (Reference Flack, Schultz and Barros2020) performed experiments on random rough surfaces by systematically varying ![]() $k_{rms}$ and

$k_{rms}$ and ![]() $Sk$. They found predictive correlations of the form

$Sk$. They found predictive correlations of the form ![]() $k_s = Ak_{rms}(1+Sk)^B$, with

$k_s = Ak_{rms}(1+Sk)^B$, with ![]() $A$ and

$A$ and ![]() $B$ being constants. The authors also adapted the functional form according to groups of surfaces as being either positively, negatively or zero skewed for more accurate correlations. On the other hand, correlations can also take a data-driven form as developed by Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021), where deep neural networks incorporate information from diverse rough-wall geometries and their corresponding statistical moments. Irrespective of the models used, no single model has been able to generalize well across all rough surfaces (Yang et al. Reference Yang, Zhang, Yuan and Kunz2023).

$B$ being constants. The authors also adapted the functional form according to groups of surfaces as being either positively, negatively or zero skewed for more accurate correlations. On the other hand, correlations can also take a data-driven form as developed by Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021), where deep neural networks incorporate information from diverse rough-wall geometries and their corresponding statistical moments. Irrespective of the models used, no single model has been able to generalize well across all rough surfaces (Yang et al. Reference Yang, Zhang, Yuan and Kunz2023).

The difficulty is largely due to the complexity of rough surfaces and that each rough surface seems to have its unique behaviours. This calls for the categorization of rough surfaces. A possible categorization puts rough surfaces into regular roughness and irregular roughness. Regular surfaces have the same elements repeated in a predefined periodic arrangement, unlike irregular roughness where the features are random in shape and/or distribution. Categories based on the shape of the roughness features break down as being cubes (Castro, Cheng & Reynolds Reference Castro, Cheng and Reynolds2006), truncated cones (Womack et al. Reference Womack, Volino, Meneveau and Schultz2022), packed spheres (Schultz & Flack Reference Schultz and Flack2005), grit-blasted (Flack et al. Reference Flack, Schultz, Barros and Kim2016; Thakkar, Busse & Sandham Reference Thakkar, Busse and Sandham2018) and others. Rough surfaces may also be categorized by distribution, such as Gaussian (Flack et al. Reference Flack, Schultz and Barros2020; Ma, Alamé & Mahesh Reference Ma, Alamé and Mahesh2021; Altland et al. Reference Altland, Zhu, McClain, Kunz and Yang2022), random (randomly distributed regular roughness elements with Gaussian height distributions; Forooghi et al. Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017, Reference Forooghi, Stroh, Schlatter and Frohnapfel2018), pseudo-random (Yang et al. Reference Yang, Stroh, Chung and Forooghi2022), multiscale (Yang & Meneveau Reference Yang and Meneveau2017; Medjnoun et al. Reference Medjnoun, Rodriguez-Lopez, Ferreira, Griffiths, Meyers and Ganapathisubramani2021) and so on. The distinction between roughness types could also stem from its flow physics. For instance, the k-type and d-type roughness (Jiménez Reference Jiménez2004) exhibit different behaviours and correspond to sparse and densely packed roughness elements, respectively.

The more recent literature seems to favour more precise categorizations based on roughness’ statistics. Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021) identified several surface properties to be hydrodynamically important. These include measures of roughness height (such as root mean square ![]() $k_{rms}$, average

$k_{rms}$, average ![]() $k_a$, maximum peak to trough (

$k_a$, maximum peak to trough (![]() $k_t$), effective slope (

$k_t$), effective slope (![]() $ES$), frontal solidity (

$ES$), frontal solidity (![]() $\lambda _f$), planar packing density (

$\lambda _f$), planar packing density (![]() $\lambda _p$), skewness (

$\lambda _p$), skewness (![]() $Sk$), and solid volume fraction (

$Sk$), and solid volume fraction (![]() $\phi$), among others. A number of existing studies focus on the effects of variations in these individual parameters. Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015) studied the effects of varying

$\phi$), among others. A number of existing studies focus on the effects of variations in these individual parameters. Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015) studied the effects of varying ![]() $\lambda _p$ and

$\lambda _p$ and ![]() $\lambda _f$ with ‘LEGO’ brick type roughness in the fully rough regime. Unlike cubical roughness, they found roughness length to monotonically decrease with increasing

$\lambda _f$ with ‘LEGO’ brick type roughness in the fully rough regime. Unlike cubical roughness, they found roughness length to monotonically decrease with increasing ![]() $\lambda _p$, suggesting that the same geometrical parameter may behave differently based on roughness type. Thakkar, Busse & Sandham (Reference Thakkar, Busse and Sandham2017) found that the streamwise correlation length plays a role in determining the roughness function in addition to

$\lambda _p$, suggesting that the same geometrical parameter may behave differently based on roughness type. Thakkar, Busse & Sandham (Reference Thakkar, Busse and Sandham2017) found that the streamwise correlation length plays a role in determining the roughness function in addition to ![]() $k_{rms}$,

$k_{rms}$, ![]() $Sk$ and

$Sk$ and ![]() $\lambda _f$ for irregular rough surfaces including samples that are cast, composite, hand-filed, grit-blasted, ground, spark-eroded and from ship propellers. The effect of surface anisotropy was investigated systematically by Busse & Jelly (Reference Busse and Jelly2020) for irregular surfaces where another roughness parameter, the surface anisotropy ratio, defined as the ratio of the streamwise and spanwise correlation lengths, was varied and found to strongly influence the mean flow. Even spanwise parameters such as the spanwise spacing (Vanderwel & Ganapathisubramani Reference Vanderwel and Ganapathisubramani2015) and spanwise effective slope (

$\lambda _f$ for irregular rough surfaces including samples that are cast, composite, hand-filed, grit-blasted, ground, spark-eroded and from ship propellers. The effect of surface anisotropy was investigated systematically by Busse & Jelly (Reference Busse and Jelly2020) for irregular surfaces where another roughness parameter, the surface anisotropy ratio, defined as the ratio of the streamwise and spanwise correlation lengths, was varied and found to strongly influence the mean flow. Even spanwise parameters such as the spanwise spacing (Vanderwel & Ganapathisubramani Reference Vanderwel and Ganapathisubramani2015) and spanwise effective slope (![]() $ES_y$) (Jelly et al. Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022) are found to significantly affect mean flow statistics. It appears that whenever one varies a roughness parameter, that roughness parameter stands out and plays an important role in determining the equivalent sand-grain roughness height.

$ES_y$) (Jelly et al. Reference Jelly, Ramani, Nugroho, Hutchins and Busse2022) are found to significantly affect mean flow statistics. It appears that whenever one varies a roughness parameter, that roughness parameter stands out and plays an important role in determining the equivalent sand-grain roughness height.

In anticipation of the discussion in the following sections, here we review the previous studies of cubical roughness. Due to its simplicity, cubical roughness is one of the most extensively studied types of surface roughness. Early experimental investigations on cube patterns (O'Loughlin & Macdonald Reference O'Loughlin and Macdonald1964) studied the effect of ![]() $\lambda _p$ on equivalent roughness size (

$\lambda _p$ on equivalent roughness size (![]() $k_s/k$), establishing that the resistance to flow reaches a maximum at an intermediate

$k_s/k$), establishing that the resistance to flow reaches a maximum at an intermediate ![]() $\lambda _p$, approximately 0.2, then tends towards smooth-wall behaviour at increasing cube densities. Thanks to the rich physics that cube arrays can represent, several studies have enriched the cubical roughness literature with details about the roughness sublayer (Castro et al. Reference Castro, Cheng and Reynolds2006), aerodynamic characteristics (Cheng et al. Reference Cheng, Hayden, Robins and Castro2007) and associated flow structures (Volino, Schultz & Flack Reference Volino, Schultz and Flack2011). Computational studies implementing direct numerical simulations (DNS) have further prompted discussions on the mean velocity profile, equivalent roughness height (

$\lambda _p$, approximately 0.2, then tends towards smooth-wall behaviour at increasing cube densities. Thanks to the rich physics that cube arrays can represent, several studies have enriched the cubical roughness literature with details about the roughness sublayer (Castro et al. Reference Castro, Cheng and Reynolds2006), aerodynamic characteristics (Cheng et al. Reference Cheng, Hayden, Robins and Castro2007) and associated flow structures (Volino, Schultz & Flack Reference Volino, Schultz and Flack2011). Computational studies implementing direct numerical simulations (DNS) have further prompted discussions on the mean velocity profile, equivalent roughness height (![]() $z_0$), and zero-plane displacement height (

$z_0$), and zero-plane displacement height (![]() $d$). These include works by Leonardi & Castro (Reference Leonardi and Castro2010) and Lee, Sung & Krogstad (Reference Lee, Sung and Krogstad2011), which focused on turbulence statistics and coherent structures, respectively. The utility involved in studying cubical roughness arising from its ability to generate surface parametrizations, and the relevance to urban canopy studies, have also led to analytical roughness models by Yang & Meneveau (Reference Yang and Meneveau2016) and Yang et al. (Reference Yang, Sadique, Mittal and Meneveau2016).

$d$). These include works by Leonardi & Castro (Reference Leonardi and Castro2010) and Lee, Sung & Krogstad (Reference Lee, Sung and Krogstad2011), which focused on turbulence statistics and coherent structures, respectively. The utility involved in studying cubical roughness arising from its ability to generate surface parametrizations, and the relevance to urban canopy studies, have also led to analytical roughness models by Yang & Meneveau (Reference Yang and Meneveau2016) and Yang et al. (Reference Yang, Sadique, Mittal and Meneveau2016).

Based on the existing literature, it can be argued that surface features ![]() $Sk$ and

$Sk$ and ![]() $k_{rms}$ are two of the most important parameters, and that a parameter space involving these features would be significant to look at. Figure 1 highlights the context of this study with respect to the existing literature in the

$k_{rms}$ are two of the most important parameters, and that a parameter space involving these features would be significant to look at. Figure 1 highlights the context of this study with respect to the existing literature in the ![]() $Sk\unicode{x2013}k_{rms}/k_a$ space. It can be seen that most studies have focused on surfaces with either low

$Sk\unicode{x2013}k_{rms}/k_a$ space. It can be seen that most studies have focused on surfaces with either low ![]() $Sk$ and low

$Sk$ and low ![]() $k_{rms}/k_a$ or high

$k_{rms}/k_a$ or high ![]() $Sk$ and high

$Sk$ and high ![]() $k_{rms}/k_a$. In this study, we will expand the investigated parameter space by designing unique cubical surfaces that fall in a region of low

$k_{rms}/k_a$. In this study, we will expand the investigated parameter space by designing unique cubical surfaces that fall in a region of low ![]() $Sk$ and high

$Sk$ and high ![]() $k_{rms}/k_a$. This dataset will allow us to study the hydrodynamic properties of unconventional roughness and test the efficacy of the existing rough-wall modelling approaches. We will see that the valleys, or the pits, do not contribute significantly to any of the first- and second-order statistics reported here. We will also see that the accuracy of a rough-wall model depends largely on whether its input space distinguishes the rough walls under consideration.

$k_{rms}/k_a$. This dataset will allow us to study the hydrodynamic properties of unconventional roughness and test the efficacy of the existing rough-wall modelling approaches. We will see that the valleys, or the pits, do not contribute significantly to any of the first- and second-order statistics reported here. We will also see that the accuracy of a rough-wall model depends largely on whether its input space distinguishes the rough walls under consideration.

Figure 1. Parameter space describing the rough surfaces in the current study and certain existing works: Flack et al. (Reference Flack, Schultz and Barros2020), Yang et al. (Reference Yang, Stroh, Chung and Forooghi2022), Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017), Xu et al. (Reference Xu, Altland, Yang and Kunz2021), Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021), Medjnoun et al. (Reference Medjnoun, Rodriguez-Lopez, Ferreira, Griffiths, Meyers and Ganapathisubramani2021), Zhang et al. (Reference Zhang, Zhu, Yang and Wan2022) and Womack et al. (Reference Womack, Volino, Meneveau and Schultz2022). Each dataset is denoted by the initials of the authors’ last names.

The rest of the paper is organized as follows. We present the details of the computational set-up in § 2 along with the geometry of the rough surfaces. The DNS results, including the instantaneous flow field and the mean flow statistics, are presented in § 3. We will see that although the rough surfaces presented here are new, the resulting flow behaviour aligns with trends found in the existing literature. In § 4, we discuss the implications of the DNS results on roughness modelling. Finally, conclusions are given in § 5.

2. Computational details

2.1. Case set-up

Figure 2 depicts a half-channel set-up containing a wall with cube-like roughness elements. This is a representative domain over which flow is computed for the DNS runs. The bottom surface is a rough wall comprising pits (or valleys) and protrusions (or peaks) in the form of cube-like elements. The ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ represent streamwise, spanwise and wall-normal directions. Periodic conditions are applied to the lateral boundaries. A stress-free condition with no penetration (

$z$ represent streamwise, spanwise and wall-normal directions. Periodic conditions are applied to the lateral boundaries. A stress-free condition with no penetration (![]() ${\partial u}/{\partial z} = {\partial v}/{\partial z} = w = 0$) is imposed on the upper boundary. A streamwise pressure gradient acts as the forcing that drives the flow. A friction Reynolds number

${\partial u}/{\partial z} = {\partial v}/{\partial z} = w = 0$) is imposed on the upper boundary. A streamwise pressure gradient acts as the forcing that drives the flow. A friction Reynolds number ![]() $Re_\tau \approx 400$ is used for all cases in this study, where

$Re_\tau \approx 400$ is used for all cases in this study, where ![]() $Re_\tau$ is defined as

$Re_\tau$ is defined as

Note that the wall-normal length ![]() $L_z$ used in (2.1) includes the depth of the negatively skewed features or valleys

$L_z$ used in (2.1) includes the depth of the negatively skewed features or valleys ![]() $h_2$. This depth

$h_2$. This depth ![]() $h_2$ is subtracted from

$h_2$ is subtracted from ![]() $L_z$ to make a good estimate of the half-channel height. The friction velocity

$L_z$ to make a good estimate of the half-channel height. The friction velocity ![]() $u_\tau$ is obtained using

$u_\tau$ is obtained using

\begin{equation} u_\tau= \sqrt{\left|\frac{\text{d} \langle \bar{p}\rangle }{\text{d}\kern0.07em x}\right|\frac{V_f}{\rho A_p}} \approx \sqrt{\left|\frac{\text{d} \langle \bar{p}\rangle }{\text{d}\kern0.07em x}\right|\frac{(L_z-h_2)}{\rho}}, \end{equation}

\begin{equation} u_\tau= \sqrt{\left|\frac{\text{d} \langle \bar{p}\rangle }{\text{d}\kern0.07em x}\right|\frac{V_f}{\rho A_p}} \approx \sqrt{\left|\frac{\text{d} \langle \bar{p}\rangle }{\text{d}\kern0.07em x}\right|\frac{(L_z-h_2)}{\rho}}, \end{equation}

where ![]() ${\rm d}\langle \bar {p}\rangle /{\rm d}\kern0.07em x$ refers to the mean streamwise pressure gradient, and

${\rm d}\langle \bar {p}\rangle /{\rm d}\kern0.07em x$ refers to the mean streamwise pressure gradient, and ![]() $\rho$,

$\rho$, ![]() $V_f$ and

$V_f$ and ![]() $A_p$ refer to the fluid density, half-channel fluid volume and wall-parallel area, respectively. Here

$A_p$ refer to the fluid density, half-channel fluid volume and wall-parallel area, respectively. Here ![]() $\langle \cdot \rangle$ denotes the streamwise and spanwise averaging (or double-averaging) operation, and

$\langle \cdot \rangle$ denotes the streamwise and spanwise averaging (or double-averaging) operation, and ![]() $\overline {(\cdot )}$ denotes time averaging.

$\overline {(\cdot )}$ denotes time averaging.

Figure 2. A sketch illustrating a periodic half-channel flow set-up over cube-like peaks and valleys. Here, ![]() $h_1$ denotes peak height,

$h_1$ denotes peak height, ![]() $h_2$ denotes valley depth, and

$h_2$ denotes valley depth, and ![]() $b$ denotes the width of the cube-like element. The boundary layer thickness

$b$ denotes the width of the cube-like element. The boundary layer thickness ![]() $\delta$ here is at least 6 times the maximum of

$\delta$ here is at least 6 times the maximum of ![]() $h_1$ and

$h_1$ and ![]() $h_2$.

$h_2$.

Note that ![]() $V_f$ includes the fluid volume within valleys, and the approximation sign in (2.2) is used because the peak height is not always equal to the valley depth, causing minor differences in

$V_f$ includes the fluid volume within valleys, and the approximation sign in (2.2) is used because the peak height is not always equal to the valley depth, causing minor differences in ![]() $V_f$ in some cases.

$V_f$ in some cases.

The size of the computational domain is determined such that ![]() $L_x>6L_z$ and

$L_x>6L_z$ and ![]() $L_y>3L_z$. Lozano-Durán & Jiménez (Reference Lozano-Durán and Jiménez2014) have shown that such a domain would be sufficiently large to ensure the accuracy of first- and second-order statistics for plane channel flow. Note that

$L_y>3L_z$. Lozano-Durán & Jiménez (Reference Lozano-Durán and Jiménez2014) have shown that such a domain would be sufficiently large to ensure the accuracy of first- and second-order statistics for plane channel flow. Note that ![]() $L_x$ and

$L_x$ and ![]() $L_y$ represent the streamwise and spanwise domain lengths, respectively. For rough-wall flows, this domain size should be a conservative estimate since DNS studies in Coceal et al. (Reference Coceal, Thomas, Castro and Belcher2006) and Leonardi & Castro (Reference Leonardi and Castro2010) produce good mean flow statistics with smaller domains

$L_y$ represent the streamwise and spanwise domain lengths, respectively. For rough-wall flows, this domain size should be a conservative estimate since DNS studies in Coceal et al. (Reference Coceal, Thomas, Castro and Belcher2006) and Leonardi & Castro (Reference Leonardi and Castro2010) produce good mean flow statistics with smaller domains ![]() $L_x \times L_y \times L_z = 4h \times 4h \times 4h$ and

$L_x \times L_y \times L_z = 4h \times 4h \times 4h$ and ![]() $8h \times 6h \times 8h$, respectively (

$8h \times 6h \times 8h$, respectively (![]() $h$ being the height of the cube). Other studies, such as Chung et al. (Reference Chung, Chan, MacDonald, Hutchins and Ooi2015), have shown that even further reduction in computational domain is possible in the spanwise direction, and such minimal-span channels have been shown to capture accurate mean drag characteristics (at least for sinusoidal roughness) when

$h$ being the height of the cube). Other studies, such as Chung et al. (Reference Chung, Chan, MacDonald, Hutchins and Ooi2015), have shown that even further reduction in computational domain is possible in the spanwise direction, and such minimal-span channels have been shown to capture accurate mean drag characteristics (at least for sinusoidal roughness) when ![]() $L_y > k/0.4$ and

$L_y > k/0.4$ and ![]() $L_y^+>100$. Furthermore, since the roughness is regular,

$L_y^+>100$. Furthermore, since the roughness is regular, ![]() $L_x$ and

$L_x$ and ![]() $L_y$ are also integral multiples of the length of the repeating tile to ensure a periodic domain. Here, a repeating tile represents the smallest unit that when repeated in the streamwise and spanwise directions produces the entire surface.

$L_y$ are also integral multiples of the length of the repeating tile to ensure a periodic domain. Here, a repeating tile represents the smallest unit that when repeated in the streamwise and spanwise directions produces the entire surface.

A uniform grid has been utilized with grid resolution such that ![]() $\varDelta _x^+ = \varDelta _y^+<5$ and

$\varDelta _x^+ = \varDelta _y^+<5$ and ![]() $\varDelta _z^+<3$, where these represent streamwise, spanwise and wall-normal grid spacings, respectively, normalized by the viscous length scale (

$\varDelta _z^+<3$, where these represent streamwise, spanwise and wall-normal grid spacings, respectively, normalized by the viscous length scale (![]() $\delta _v = \nu /u_\tau$). It is important to note that while

$\delta _v = \nu /u_\tau$). It is important to note that while ![]() $\varDelta _z^+$ may appear to be large for DNS, this resolution is based on friction velocity

$\varDelta _z^+$ may appear to be large for DNS, this resolution is based on friction velocity ![]() $u_{\tau }$ obtained from (2.2). The

$u_{\tau }$ obtained from (2.2). The ![]() $\delta _v$ value computed based on this

$\delta _v$ value computed based on this ![]() $u_{\tau }$ includes the form drag component. If

$u_{\tau }$ includes the form drag component. If ![]() $\delta _v$ is computed from the local viscous stress at the mean surface comprising the bottom wall, then the grid resolution is at most 0.66 plus units. Note that the local viscous stress

$\delta _v$ is computed from the local viscous stress at the mean surface comprising the bottom wall, then the grid resolution is at most 0.66 plus units. Note that the local viscous stress ![]() $\mu \,\partial {u}/\partial {n}$ here does not pertain to the cube surfaces, where the corresponding value would spike at the leading edge due to the strong shear rate. A similar grid resolution

$\mu \,\partial {u}/\partial {n}$ here does not pertain to the cube surfaces, where the corresponding value would spike at the leading edge due to the strong shear rate. A similar grid resolution ![]() $\varDelta _x^+ = \varDelta _y^+<4.5$ and

$\varDelta _x^+ = \varDelta _y^+<4.5$ and ![]() $\varDelta _z^+\approx 2.5$ was used by Zhang et al. (Reference Zhang, Zhu, Yang and Wan2022) for deep canopy flows. The grid spacing is also comparable to that in previous studies of rough-wall DNS, where Coceal et al. (Reference Coceal, Thomas, Castro and Belcher2006) used

$\varDelta _z^+\approx 2.5$ was used by Zhang et al. (Reference Zhang, Zhu, Yang and Wan2022) for deep canopy flows. The grid spacing is also comparable to that in previous studies of rough-wall DNS, where Coceal et al. (Reference Coceal, Thomas, Castro and Belcher2006) used ![]() $\varDelta ^+_{x,y,z}$ in the range 7.8–15.6, and Leonardi & Castro (Reference Leonardi and Castro2010) used

$\varDelta ^+_{x,y,z}$ in the range 7.8–15.6, and Leonardi & Castro (Reference Leonardi and Castro2010) used ![]() $\varDelta ^+_{x,y} = 19$. For further reference, DNS studies by Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) have found

$\varDelta ^+_{x,y} = 19$. For further reference, DNS studies by Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) have found ![]() $\varDelta ^+_{x,y,z_{max}} = 3.5$ to be more than sufficient. Yuan & Piomelli (Reference Yuan and Piomelli2014b) utilize

$\varDelta ^+_{x,y,z_{max}} = 3.5$ to be more than sufficient. Yuan & Piomelli (Reference Yuan and Piomelli2014b) utilize ![]() $\varDelta ^+_{x} = 12$ and

$\varDelta ^+_{x} = 12$ and ![]() $\varDelta ^+_{y} = 6$, whereas Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021) employ

$\varDelta ^+_{y} = 6$, whereas Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021) employ ![]() $\varDelta ^+_{x} = 7.5$ and

$\varDelta ^+_{x} = 7.5$ and ![]() $\varDelta ^+_{y} = 6.3$ for obtaining accurate flow statistics in their rough-wall channels.

$\varDelta ^+_{y} = 6.3$ for obtaining accurate flow statistics in their rough-wall channels.

All simulations are performed using LESGO: a parallel pseudo-spectral large-eddy simulation code (see https://lesgo-jhu.github.io/lesgo), a solver of the filtered Navier–Stokes equations with pseudo-spectral discretization in the streamwise and spanwise directions, and a second-order finite difference in the wall-normal direction. Code LESGO and modified versions of the code have been used extensively for studies involving channel flows, including Bou-Zeid, Meneveau & Parlange (Reference Bou-Zeid, Meneveau and Parlange2005), Anderson & Meneveau (Reference Anderson and Meneveau2011), Abkar & Porté-Agel (Reference Abkar and Porté-Agel2012), Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017), Yang et al. (Reference Yang, Xu, Huang and Ge2019), and several others. Immersed boundary conditions (Anderson Reference Anderson2013) are used at the solid boundaries comprising the rough wall. A Courant–Friedrichs–Lewy number (![]() ${\rm CFL} = u\,\Delta t/\Delta x$) of 0.2 is employed to automatically adjust the time step, which is advanced via the second-order Adams–Bashforth scheme.

${\rm CFL} = u\,\Delta t/\Delta x$) of 0.2 is employed to automatically adjust the time step, which is advanced via the second-order Adams–Bashforth scheme.

2.2. Roughness generation

Roughness elements are distributed in various arrangements to generate different rough surfaces. We will vary one statistic at a time, but repeat the process and vary many roughness statistics. Figures 3(a), 3(c) and 3(d) depict these elements aligned in the spanwise (AY), streamwise (AX) and ![]() $45^\circ$ (AXY) directions, respectively. Their staggered equivalents (S and SXY) are shown in figures 3(b) and 3(e). Figure 3( f) shows another surface (NV) where the negatively skewed features (valleys) are removed. The rough surfaces also include variations in

$45^\circ$ (AXY) directions, respectively. Their staggered equivalents (S and SXY) are shown in figures 3(b) and 3(e). Figure 3( f) shows another surface (NV) where the negatively skewed features (valleys) are removed. The rough surfaces also include variations in ![]() $\lambda _p$, as indicated by figures 3(g) and 3(h), peak height to width ratio (

$\lambda _p$, as indicated by figures 3(g) and 3(h), peak height to width ratio (![]() $h_1/b$), and valley depth to width ratio (

$h_1/b$), and valley depth to width ratio (![]() $h_2/b$). Table 1 provides the naming convention used, and table 2 lists all 36 different surfaces considered for the DNS study. For each case, the nomenclature is as follows: [Arrangement][Packing density][Roughness height], where arrangement could be AX, AY, AXY, S, SXY, NV, packing density could be L1, L2, L3, and roughness height could be H1, H2, H3. For example, the L1, L2 and L3 in AYL1H1, AYL2H1 and AYL3H1 correspond to

$h_2/b$). Table 1 provides the naming convention used, and table 2 lists all 36 different surfaces considered for the DNS study. For each case, the nomenclature is as follows: [Arrangement][Packing density][Roughness height], where arrangement could be AX, AY, AXY, S, SXY, NV, packing density could be L1, L2, L3, and roughness height could be H1, H2, H3. For example, the L1, L2 and L3 in AYL1H1, AYL2H1 and AYL3H1 correspond to ![]() $\lambda _p$ magnitudes 6.25 %, 11.1 % and 25 %, respectively. Similarly, the H1, H2 and H3 in AYL1H1, AYL1H2 and AYL1H3 denote variations in the heights of the peaks as

$\lambda _p$ magnitudes 6.25 %, 11.1 % and 25 %, respectively. Similarly, the H1, H2 and H3 in AYL1H1, AYL1H2 and AYL1H3 denote variations in the heights of the peaks as ![]() $h_1 = b, 1.2b, 0.8b$. Note that in this context, the conditions

$h_1 = b, 1.2b, 0.8b$. Note that in this context, the conditions ![]() $h_1/h_2 = 1$,

$h_1/h_2 = 1$, ![]() $h_1/h_2 > 1$ and

$h_1/h_2 > 1$ and ![]() $h_1/h_2 < 1$ correspond to zero skewed, positively skewed and negatively skewed surfaces. The separation lengths between the roughness elements are listed as

$h_1/h_2 < 1$ correspond to zero skewed, positively skewed and negatively skewed surfaces. The separation lengths between the roughness elements are listed as ![]() $4b$,

$4b$, ![]() $3b$ and

$3b$ and ![]() $2b$ for L1, L2 and L3 configurations, with

$2b$ for L1, L2 and L3 configurations, with ![]() $b/L_z$ assuming values 0.1375, 0.1111 and 0.1429 for H1, H2 and H3 cases, respectively.

$b/L_z$ assuming values 0.1375, 0.1111 and 0.1429 for H1, H2 and H3 cases, respectively.

Figure 3. Top view of various rough-surface types considered for the DNS study: (a) AYL1H1, (b) SL1H1, (c) AXL1H1, (d) AXYL1H1, (e) SXYL1H1, ( f) NVL1H1, (g) AYL2H1 and (h) AYL3H1. Here, ![]() $k$ is the elevation of the surface. The peaks have positive

$k$ is the elevation of the surface. The peaks have positive ![]() $k$ (depicted as yellow), and the valleys have negative

$k$ (depicted as yellow), and the valleys have negative ![]() $k$ (depicted as blue).

$k$ (depicted as blue).

Table 1. Nomenclature for the 36 configurations of the parameter space studied.

Table 2. Details of the DNS case-set-up, where ![]() $\lambda _p$,

$\lambda _p$, ![]() $h_1/b$,

$h_1/b$, ![]() $h_2/b$ denote planar packing density, peak height to width, and valley depth to width ratios, respectively;

$h_2/b$ denote planar packing density, peak height to width, and valley depth to width ratios, respectively; ![]() $N_{x,y,z}$ denotes the number of grid cells in the streamwise (

$N_{x,y,z}$ denotes the number of grid cells in the streamwise (![]() $x$), spanwise (

$x$), spanwise (![]() $y$) and wall-normal (

$y$) and wall-normal (![]() $z$) directions;

$z$) directions; ![]() $N$ denotes the number of peaks plus valleys in the case. Note that the surface coverage densities of the NV cases are half the value of their AX (and AY) counterparts.

$N$ denotes the number of peaks plus valleys in the case. Note that the surface coverage densities of the NV cases are half the value of their AX (and AY) counterparts.

The definitions for a few roughness statistics ![]() $k_{rms}$,

$k_{rms}$, ![]() $k_a$,

$k_a$, ![]() $k_t$,

$k_t$, ![]() $Sk$,

$Sk$, ![]() $ES$,

$ES$, ![]() $Ku$ and

$Ku$ and ![]() $\lambda _p$ (which are discussed further in table 3) for the rough surfaces thus generated are listed as follows:

$\lambda _p$ (which are discussed further in table 3) for the rough surfaces thus generated are listed as follows:

$$\begin{gather}k_{rms}=\sqrt{\frac{1}{L_x L_y}\int_{L_x}\int_{L_y}|k(x,y) -\bar{k}|^2\,{\rm d}\kern0.07em{x}\,{\rm d}{y}}, \end{gather}$$

$$\begin{gather}k_{rms}=\sqrt{\frac{1}{L_x L_y}\int_{L_x}\int_{L_y}|k(x,y) -\bar{k}|^2\,{\rm d}\kern0.07em{x}\,{\rm d}{y}}, \end{gather}$$Table 3. Hydrodynamic properties of roughness. The geometric parameters listed include average and root mean square roughness height ![]() $k_a$ and

$k_a$ and ![]() $k_{rms}$, skewness

$k_{rms}$, skewness ![]() $Sk$, kurtosis

$Sk$, kurtosis ![]() $Ku$, maximum peak to trough height

$Ku$, maximum peak to trough height ![]() $k_t$, effective slope (along the

$k_t$, effective slope (along the ![]() $x$ direction)

$x$ direction) ![]() $ES$, streamwise and spanwise correlation lengths

$ES$, streamwise and spanwise correlation lengths ![]() $Rl_{x}$ and

$Rl_{x}$ and ![]() $Rl_y$ (defined in (4.6), (4.7)). Here,

$Rl_y$ (defined in (4.6), (4.7)). Here, ![]() $d$ denotes zero-plane displacement height, and

$d$ denotes zero-plane displacement height, and ![]() $z_0$ is the effective roughness height.

$z_0$ is the effective roughness height.

The packing density ![]() $\lambda _p$ in (2.10) is defined in the same way as plan solidity in Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021). Here,

$\lambda _p$ in (2.10) is defined in the same way as plan solidity in Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021). Here, ![]() $A_p$ comprises the plan area of roughness elements, which in this case includes the base area of peaks and valleys.

$A_p$ comprises the plan area of roughness elements, which in this case includes the base area of peaks and valleys.

Additional constraints have been placed to ensure that the grid surface matches the cube surface for accurate roughness representation in the simulations. This is done by enforcing ![]() $b/\varDelta _x$,

$b/\varDelta _x$, ![]() $b/\varDelta _y$,

$b/\varDelta _y$, ![]() $h_1/\varDelta _z$ and

$h_1/\varDelta _z$ and ![]() $h_2/\varDelta _z$ to be integers, where

$h_2/\varDelta _z$ to be integers, where ![]() $\varDelta _x$,

$\varDelta _x$, ![]() $\varDelta _y$ and

$\varDelta _y$ and ![]() $\varDelta _z$ stand for the grid spacing in the streamwise, spanwise and wall-normal directions. This has been implemented for all cases except the

$\varDelta _z$ stand for the grid spacing in the streamwise, spanwise and wall-normal directions. This has been implemented for all cases except the ![]() $45^\circ$ alignment rough surfaces.

$45^\circ$ alignment rough surfaces.

As can be seen from figure 4, the grid is in perfect alignment with the roughness element in AYL1H1 as opposed to AXYL1H1. As a result, there are minor variations in the average roughness height ![]() $k_a/b$, root mean square roughness height

$k_a/b$, root mean square roughness height ![]() $k_{rms}/k_a$, and kurtosis

$k_{rms}/k_a$, and kurtosis ![]() $Ku$ for AXYL

$Ku$ for AXYL![]() $i$H1 and SXYL

$i$H1 and SXYL![]() $i$H1 surfaces when compared with AYL

$i$H1 surfaces when compared with AYL![]() $i$H1 and SL

$i$H1 and SL![]() $i$H1, where

$i$H1, where ![]() $i=1, 2, 3$. This can be noticed in table 3. A finer resolution has been opted for in all such cases to minimize these variations. The streamwise and spanwise grid resolutions, in terms of number of cells per roughness element, are given by

$i=1, 2, 3$. This can be noticed in table 3. A finer resolution has been opted for in all such cases to minimize these variations. The streamwise and spanwise grid resolutions, in terms of number of cells per roughness element, are given by ![]() $b/\varDelta _x = b/\varDelta _y = 12\unicode{x2013}14$ for AX, AY, S and NV surfaces. These grid resolutions are approximately 16–18 for AXY and SXY surfaces. The wall-normal grid resolution is in the range

$b/\varDelta _x = b/\varDelta _y = 12\unicode{x2013}14$ for AX, AY, S and NV surfaces. These grid resolutions are approximately 16–18 for AXY and SXY surfaces. The wall-normal grid resolution is in the range ![]() $b/\varDelta _z = 20\unicode{x2013}25$ for all cases.

$b/\varDelta _z = 20\unicode{x2013}25$ for all cases.

Figure 4. Top and side views of DNS grids used for two cases: (a,c) AYL1H1 and (b,d) AXYL1H1. The side views are streamwise wall-normal (![]() $x$–

$x$–![]() $z$) planes cut at the middle of the cubes. The top views are wall-parallel (

$z$) planes cut at the middle of the cubes. The top views are wall-parallel (![]() $x$–

$x$–![]() $y$) planes cut near the roughness peak.

$y$) planes cut near the roughness peak.

3. DNS results

The rough walls that we study cover an underexplored region in roughness parameter space and therefore are a good addition to the rough-wall literature. In this section, we first discuss qualitative findings pertaining to the instantaneous flow field. Subsequently, the quality of our channel flow simulations is examined with the help of the mean momentum budget, followed by results of mean velocity profiles and quantitative estimates of effective roughness height (![]() $z_0$) and zero-plane displacement height (

$z_0$) and zero-plane displacement height (![]() $d$). The section concludes with Reynolds and dispersive stress results and comparisons for all 36 cases.

$d$). The section concludes with Reynolds and dispersive stress results and comparisons for all 36 cases.

3.1. Instantaneous flow field

We begin by presenting the instantaneous flow field as an introduction to the dataset. From the contours in figure 5, an overall decrease in instantaneous bulk velocity can be observed with increasing ![]() $\lambda _p$. A region of reduced streamwise velocity can be noted in the immediate wake of the protrusions. The flow in the pits can be observed to be less energetic, and their interactions with the outer layer are minimal.

$\lambda _p$. A region of reduced streamwise velocity can be noted in the immediate wake of the protrusions. The flow in the pits can be observed to be less energetic, and their interactions with the outer layer are minimal.

Figure 5. Streamwise instantaneous velocity contours at ![]() $y/L_y \approx 0.43$ for (a) AYL1H1, (b) AYL2H1 and (c) AYL3H1.

$y/L_y \approx 0.43$ for (a) AYL1H1, (b) AYL2H1 and (c) AYL3H1.

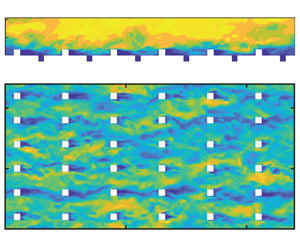

Figure 6 shows the velocity contours on a wall-parallel plane near the peak height for different roughness element arrangements at the same ![]() $\lambda _p$. By visual inspection, contours in figures 6(a) and 6(b) are observed to have similar and intermediate average streamwise velocities. Figure 6(c) contains the highest and figure 6(d) the lowest average streamwise velocities amongst these four cases. In all cases, streamwise streaks of high and low velocities can be observed near the roughness peak. These streaks are noticeably longer in certain cases, such as in figure 6(c), as the wakes overlap each other. These wake interactions become more pronounced at higher

$\lambda _p$. By visual inspection, contours in figures 6(a) and 6(b) are observed to have similar and intermediate average streamwise velocities. Figure 6(c) contains the highest and figure 6(d) the lowest average streamwise velocities amongst these four cases. In all cases, streamwise streaks of high and low velocities can be observed near the roughness peak. These streaks are noticeably longer in certain cases, such as in figure 6(c), as the wakes overlap each other. These wake interactions become more pronounced at higher ![]() $\lambda _p$ and result in a flow-sheltering effect as observed in densely packed surfaces such as in Xu et al. (Reference Xu, Altland, Yang and Kunz2021).

$\lambda _p$ and result in a flow-sheltering effect as observed in densely packed surfaces such as in Xu et al. (Reference Xu, Altland, Yang and Kunz2021).

Figure 6. Streamwise instantaneous velocity contours at ![]() $z/b \approx 1.0$ for (a) AYL1H1, (b) SL1H1, (c) AXL1H1 and (d) AXYL1H1.

$z/b \approx 1.0$ for (a) AYL1H1, (b) SL1H1, (c) AXL1H1 and (d) AXYL1H1.

Although we will pursue a quantitative analysis in the following subsections, here we may already conclude first that the valleys do not contribute significantly to the drag, and second that two-point rough-wall statistics are important to the characterization of the equivalent sand-grain roughness height ![]() $k_s$.

$k_s$.

3.2. Statistical convergence

Before presenting the flow statistics, we first check the statistical convergence of our data. The statistical convergence can be evaluated with the help of the mean momentum budget following Coceal et al. (Reference Coceal, Thomas, Castro and Belcher2006), Leonardi & Castro (Reference Leonardi and Castro2010), Xu et al. (Reference Xu, Altland, Yang and Kunz2021) and Zhang et al. (Reference Zhang, Zhu, Yang and Wan2022). The equation is comprised of viscous diffusion, turbulent transport, dispersive stress and pressure-gradient terms:

It is considered to be statistically converged when the sum of these stresses is a linear function of the wall-normal distance (![]() $z$), i.e. when the budget balances without the unsteady term. Note that (3.1) is obtained by integrating the

$z$), i.e. when the budget balances without the unsteady term. Note that (3.1) is obtained by integrating the ![]() $x$ component of the double-averaged momentum equation

$x$ component of the double-averaged momentum equation

found in (15) of Nikora et al. (Reference Nikora, Ballio, Coleman and Pokrajac2013), with static roughness in place of the mobile roughness assumed by the authors. Here, ![]() $f$ represents the drag force. As

$f$ represents the drag force. As ![]() $f$ is non-zero within the roughness-occupied region, (3.1) applies to the region outside the roughness only. The averaging procedure corresponds to the double-averaging method, common in the roughness literature, introduced by Raupach & Shaw (Reference Raupach and Shaw1982) for flows within vegetation canopies. The spatial averaging used in the context of (3.1) and (3.2) is superficial, as per the definition for superficial averaging in Schmid et al. (Reference Schmid, Lawrence, Parlange and Giometto2019).

$f$ is non-zero within the roughness-occupied region, (3.1) applies to the region outside the roughness only. The averaging procedure corresponds to the double-averaging method, common in the roughness literature, introduced by Raupach & Shaw (Reference Raupach and Shaw1982) for flows within vegetation canopies. The spatial averaging used in the context of (3.1) and (3.2) is superficial, as per the definition for superficial averaging in Schmid et al. (Reference Schmid, Lawrence, Parlange and Giometto2019).

Figure 7 shows these terms for a few cases. These cases have been selected so that they include different ![]() $\lambda _p$,

$\lambda _p$, ![]() $Sk$ and roughness arrangements while maintaining brevity. We see that the total stresses in all cases follow a linear function of

$Sk$ and roughness arrangements while maintaining brevity. We see that the total stresses in all cases follow a linear function of ![]() $z/b$, therefore our DNS are statistically converged. In addition, we make the following observations. The Reynolds stress

$z/b$, therefore our DNS are statistically converged. In addition, we make the following observations. The Reynolds stress ![]() $R_{13}$ can be observed to be the largest in magnitude as compared to the viscous stress

$R_{13}$ can be observed to be the largest in magnitude as compared to the viscous stress ![]() $\tau _v$ and dispersive stress

$\tau _v$ and dispersive stress ![]() $D_{13}$ outside the roughness-occupied layer. The roughness-occupied layer is marked by the vertical line in figure 7. In the roughness-occupied layer, i.e. below this marking,

$D_{13}$ outside the roughness-occupied layer. The roughness-occupied layer is marked by the vertical line in figure 7. In the roughness-occupied layer, i.e. below this marking, ![]() $\tau _v$ is observed to contain two maxima, one caused by the surface at

$\tau _v$ is observed to contain two maxima, one caused by the surface at ![]() $z=0$, and the other near the cube height

$z=0$, and the other near the cube height ![]() $z=h_1$. The latter is also observed in other DNS studies by Xu et al. (Reference Xu, Altland, Yang and Kunz2021) and Zhang et al. (Reference Zhang, Zhu, Yang and Wan2022). Meanwhile,

$z=h_1$. The latter is also observed in other DNS studies by Xu et al. (Reference Xu, Altland, Yang and Kunz2021) and Zhang et al. (Reference Zhang, Zhu, Yang and Wan2022). Meanwhile, ![]() $R_{13}$ attains a maximum just above the peak height, and declines to zero as

$R_{13}$ attains a maximum just above the peak height, and declines to zero as ![]() $z$ approaches the outer layer;

$z$ approaches the outer layer; ![]() $D_{13}$ is small and contained within the roughness region for most cases. For

$D_{13}$ is small and contained within the roughness region for most cases. For ![]() $z/b < 0$, i.e. below the surface in the region of valleys, all stresses are observed to be negligible. Note that figure 7(e) starts from

$z/b < 0$, i.e. below the surface in the region of valleys, all stresses are observed to be negligible. Note that figure 7(e) starts from ![]() $z/b = 0$ as the case NVL1H1 contains no valleys.

$z/b = 0$ as the case NVL1H1 contains no valleys.

Figure 7. The stress budget plot comprising Reynolds stress ![]() $R_{13}$, dispersive stress

$R_{13}$, dispersive stress ![]() $D_{13}$, viscous stress

$D_{13}$, viscous stress ![]() $\tau _v$ and total stress

$\tau _v$ and total stress ![]() $\tau _t$ for cases: (a) AYL3H1, (b) SL1H2, (c) SL2H3, (d) AXL2H3, (e) NVL1H1 and ( f) AXYL3H1. The black solid line corresponds to

$\tau _t$ for cases: (a) AYL3H1, (b) SL1H2, (c) SL2H3, (d) AXL2H3, (e) NVL1H1 and ( f) AXYL3H1. The black solid line corresponds to ![]() $1-z/\delta$.The vertical dashed line denotes the peak roughness height.

$1-z/\delta$.The vertical dashed line denotes the peak roughness height.

It might be worth noting certain differences in dispersive stress ![]() $D_{13}$ in figure 7. For instance, most noticeable would be the differences in cases AYL3H1 and NVL1H1:

$D_{13}$ in figure 7. For instance, most noticeable would be the differences in cases AYL3H1 and NVL1H1: ![]() $D_{13}$ is observed to be non-negligible within the roughness-occupied region for AYL3H1, whereas

$D_{13}$ is observed to be non-negligible within the roughness-occupied region for AYL3H1, whereas ![]() $D_{13}$ for NVL1H1 inside the sublayer is almost zero. Figure 8 aims to provide an intuitive explanation for this. Here, the dispersive streamwise and wall-normal fluctuating components,

$D_{13}$ for NVL1H1 inside the sublayer is almost zero. Figure 8 aims to provide an intuitive explanation for this. Here, the dispersive streamwise and wall-normal fluctuating components, ![]() $u^{\prime \prime }$ and

$u^{\prime \prime }$ and ![]() $w^{\prime \prime }$, are shown for averaged repeating tiles for cases NVL1H1 and AYL3H1. Three planes, one within and the others at and above the roughness crest, are chosen to display their scatter. When

$w^{\prime \prime }$, are shown for averaged repeating tiles for cases NVL1H1 and AYL3H1. Three planes, one within and the others at and above the roughness crest, are chosen to display their scatter. When ![]() $u^{\prime \prime }$ and

$u^{\prime \prime }$ and ![]() $w^{\prime \prime }$ predominantly lie in the second or fourth quadrant, the dispersive stress

$w^{\prime \prime }$ predominantly lie in the second or fourth quadrant, the dispersive stress ![]() $-\langle u^{\prime \prime }w^{\prime \prime }\rangle$ becomes positive. The negative slope of the linear fit is also indicative of this. This can be seen in figure 8(c), which corresponds to NVL1H1 just above the roughness, and figure 8(d), which corresponds to AYL3H1 within the roughness. These may indirectly imply mean flow inhomogeneity, which is due to the presence of surface roughness and/or secondary flows. On the other hand, when the points are more evenly spread across all quadrants, as is the case in figures 8(a), 8(b) and 8(e), or too close to the origin as in figure 8( f), this dispersive stress becomes negligible.

$-\langle u^{\prime \prime }w^{\prime \prime }\rangle$ becomes positive. The negative slope of the linear fit is also indicative of this. This can be seen in figure 8(c), which corresponds to NVL1H1 just above the roughness, and figure 8(d), which corresponds to AYL3H1 within the roughness. These may indirectly imply mean flow inhomogeneity, which is due to the presence of surface roughness and/or secondary flows. On the other hand, when the points are more evenly spread across all quadrants, as is the case in figures 8(a), 8(b) and 8(e), or too close to the origin as in figure 8( f), this dispersive stress becomes negligible.

Figure 8. Quadrant analysis for the dispersive stress components of ![]() $D_{13}$ for cases NVL1H1 at (a)

$D_{13}$ for cases NVL1H1 at (a) ![]() $z/b=0.5$, (b)

$z/b=0.5$, (b) ![]() $z/b=1$, (c)

$z/b=1$, (c) ![]() $z/b=2$ and AYL3H1 at (d)

$z/b=2$ and AYL3H1 at (d) ![]() $z/b=0.5$, (e)

$z/b=0.5$, (e) ![]() $z/b=1$ and ( f)

$z/b=1$ and ( f) ![]() $z/b=2$. The solid black line depicts a linear fit on the data points.

$z/b=2$. The solid black line depicts a linear fit on the data points.

3.3. Mean velocity profiles

The mean flow statistics are presented in this subsection. Additionally, the relevant rough surface parameters and the hydrodynamic properties determined from mean velocity profiles are also listed in table 3.

Figure 9(a) shows the inner scaled mean velocity profiles, comparing the spanwise-aligned and staggered cases, i.e. the AY cases and the S cases. The following observations can be duly noted. First, the higher ![]() $\lambda _p$ cases of surface coverage density 25 %, comprising AYL3H1, AYL3H2, AYL3H3 and their staggered counterparts SL3H1, SL3H2 and SL3H3, produce lower magnitudes of mean velocity. This is expected for roughness in the k-type regime. Second, the staggered arrangement produces similar velocity profiles to the spanwise-aligned arrangement. This is not unexpected, and similar observations were made in Yang et al. (Reference Yang, Sadique, Mittal and Meneveau2016). Due to a large spanwise distance between neighbouring roughness elements in the spanwise direction, staggering the roughness element in the streamwise direction has little effect on the mean flow. Finally, at constant

$\lambda _p$ cases of surface coverage density 25 %, comprising AYL3H1, AYL3H2, AYL3H3 and their staggered counterparts SL3H1, SL3H2 and SL3H3, produce lower magnitudes of mean velocity. This is expected for roughness in the k-type regime. Second, the staggered arrangement produces similar velocity profiles to the spanwise-aligned arrangement. This is not unexpected, and similar observations were made in Yang et al. (Reference Yang, Sadique, Mittal and Meneveau2016). Due to a large spanwise distance between neighbouring roughness elements in the spanwise direction, staggering the roughness element in the streamwise direction has little effect on the mean flow. Finally, at constant ![]() $\lambda _p$, cases with higher skewness (

$\lambda _p$, cases with higher skewness (![]() $Sk$) produce lower mean velocity profiles. This role of

$Sk$) produce lower mean velocity profiles. This role of ![]() $Sk$ is apparent as we notice increased drag with increased

$Sk$ is apparent as we notice increased drag with increased ![]() $Sk$ (consistent with systematic studies performed by Flack et al. Reference Flack, Schultz and Barros2020), and we observe this effect in all our cases, irrespective of arrangement. For example, comparing AYL1H1, AYL1H2 and AYL1H3 from figure 9(a) or AXL1H1, AXL1H2 and AXL1H3 from figure 9(b) at the same

$Sk$ (consistent with systematic studies performed by Flack et al. Reference Flack, Schultz and Barros2020), and we observe this effect in all our cases, irrespective of arrangement. For example, comparing AYL1H1, AYL1H2 and AYL1H3 from figure 9(a) or AXL1H1, AXL1H2 and AXL1H3 from figure 9(b) at the same ![]() $z^+$, one can notice that the mean velocities in the log layer are slightly lower for the surface with higher

$z^+$, one can notice that the mean velocities in the log layer are slightly lower for the surface with higher ![]() $Sk$ (H3 cases being lower than H2 and H1 cases). In the present dataset, variations in

$Sk$ (H3 cases being lower than H2 and H1 cases). In the present dataset, variations in ![]() $Sk$ are introduced by varying the height of the peaks, while maintaining the depth of the dips constant, therefore any changes due to

$Sk$ are introduced by varying the height of the peaks, while maintaining the depth of the dips constant, therefore any changes due to ![]() $Sk$ could also be viewed as due to the roughness height. Similarly, as variations in

$Sk$ could also be viewed as due to the roughness height. Similarly, as variations in ![]() $k_{rms}/k_a$ are introduced by varying the surface coverage density, any changes due to

$k_{rms}/k_a$ are introduced by varying the surface coverage density, any changes due to ![]() $k_{rms}/k_a$ could also be viewed as due to surface coverage density.

$k_{rms}/k_a$ could also be viewed as due to surface coverage density.

Figure 9. Mean streamwise velocity profile comparing (a) spanwise-aligned and staggered cases, and (b) spanwise-aligned and streamwise-aligned cases.

Similarly, figure 9(b) compares mean velocity profiles for roughness with streamwise and spanwise alignment, i.e. AX cases and AY cases. When the roughness features are aligned in the streamwise direction, higher mean velocities can be observed as compared to those aligned in the spanwise direction. An intuitive explanation for this is the unobstructed passage of fluid between two rows of roughness elements giving the fluid less drag when they are aligned in the streamwise direction. This is also evident from the instantaneous velocity contours in figure 6(c).

Figure 10 includes the mean velocity profiles from the ![]() $45^\circ$ arrangements (XY), with figure 10(a) comparing AY, AX, AXY, and figure 10(b) comparing S and SXY. For the same

$45^\circ$ arrangements (XY), with figure 10(a) comparing AY, AX, AXY, and figure 10(b) comparing S and SXY. For the same ![]() $\lambda _p$, the surfaces follow

$\lambda _p$, the surfaces follow ![]() ${\rm AX} > {\rm AY} >{\rm AXY}$ in figure (a), and

${\rm AX} > {\rm AY} >{\rm AXY}$ in figure (a), and ![]() ${\rm S} > {\rm SXY}$ in figure (b) for the order of mean velocity magnitudes in the log-law region. The orientation of the roughness element is found to be an important factor here. The AXY and SXY surfaces possess a higher frontal area (i.e. higher solidity) as compared to their counterparts AX, AY or S, which is the reason for the higher drag observed for these surfaces.

${\rm S} > {\rm SXY}$ in figure (b) for the order of mean velocity magnitudes in the log-law region. The orientation of the roughness element is found to be an important factor here. The AXY and SXY surfaces possess a higher frontal area (i.e. higher solidity) as compared to their counterparts AX, AY or S, which is the reason for the higher drag observed for these surfaces.

Figure 10. Mean streamwise velocity profile comparing (a) spanwise, streamwise and ![]() $45^\circ$ aligned cases, and (b) staggered and staggered

$45^\circ$ aligned cases, and (b) staggered and staggered ![]() $45^\circ$ cases.

$45^\circ$ cases.

Figure 11(a) shows the mean velocity profiles comparing three pairs of surfaces with and without valleys. It can be observed that the valleys do contribute to mean velocity reduction, but by only a small amount. This reduced mean velocity can be inferred to be caused by the additional pressure drag contributions from the valleys. In support of this claim, figures 11(b) and 11(c) are shown, which contain mean pressure contours that are averaged over repeating tiles in both ![]() $(x, y)$ directions in AYL1H1 and NVL1H1. In these pressure contours, which are normalized by

$(x, y)$ directions in AYL1H1 and NVL1H1. In these pressure contours, which are normalized by ![]() $\rho u_{\tau }^2$, the volume-averaged mean pressure is taken as the reference pressure. The additional pressure drop can be noticed clearly in valleys. Note that the observation here cannot be generalized to all dips. In particular, dips or valleys will play a significant role if they occupy a considerable part of the surface area, in which scenario a new bottom surface forms and the protrusions between the dips can be viewed as surface roughness.

$\rho u_{\tau }^2$, the volume-averaged mean pressure is taken as the reference pressure. The additional pressure drop can be noticed clearly in valleys. Note that the observation here cannot be generalized to all dips. In particular, dips or valleys will play a significant role if they occupy a considerable part of the surface area, in which scenario a new bottom surface forms and the protrusions between the dips can be viewed as surface roughness.

Figure 11. Details of the effects of valleys. (a) Mean streamwise velocity profile comparing cases with and without valleys. The solid and dotted lines depict spanwise-aligned and no-valleys cases, respectively. (b) Mean pressure contours for a repeating tile in NVL1H1. (c) Mean pressure contours for a repeating tile in AYL1H1.

Next, we measure the hydrodynamic properties of the roughness. The effective roughness height ![]() $z_0$ and zero-plane displacement height

$z_0$ and zero-plane displacement height ![]() $d$ for the rough surfaces are determined from the mean streamwise velocity profiles as

$d$ for the rough surfaces are determined from the mean streamwise velocity profiles as

where ![]() $\langle \bar {u} \rangle$ and

$\langle \bar {u} \rangle$ and ![]() $z$ are taken from the log-law region, which has been taken to be in the range

$z$ are taken from the log-law region, which has been taken to be in the range ![]() $(z-h_1)^+ \approx 30\unicode{x2013}100$. Further evidence of the existence of a log law in this range will be discussed later with the help of figure 13. Linear regression of (3.3) yields the resulting

$(z-h_1)^+ \approx 30\unicode{x2013}100$. Further evidence of the existence of a log law in this range will be discussed later with the help of figure 13. Linear regression of (3.3) yields the resulting ![]() $z_0$ and

$z_0$ and ![]() $d$ reported in table 3. Here, the von Kármán constant is set to

$d$ reported in table 3. Here, the von Kármán constant is set to ![]() $\kappa = 0.4$. There can be alternate approaches to calculate

$\kappa = 0.4$. There can be alternate approaches to calculate ![]() $d$ from the centroid of the total force distribution following Jackson (Reference Jackson1981) and Coceal et al. (Reference Coceal, Thomas, Castro and Belcher2006). However, it is also observed that the centre of the force could sometimes underestimate

$d$ from the centroid of the total force distribution following Jackson (Reference Jackson1981) and Coceal et al. (Reference Coceal, Thomas, Castro and Belcher2006). However, it is also observed that the centre of the force could sometimes underestimate ![]() $d$ when the flow primarily interacts with the top portion of the roughness, as seen in figure 7 of Xu et al. (Reference Xu, Altland, Yang and Kunz2021). Here, we prefer regression fitting over this approach for the aforementioned reason.

$d$ when the flow primarily interacts with the top portion of the roughness, as seen in figure 7 of Xu et al. (Reference Xu, Altland, Yang and Kunz2021). Here, we prefer regression fitting over this approach for the aforementioned reason.

Since we assume the value of the von Kármán constant ![]() $\kappa = 0.4$ for our regression procedure, checking the changes in measured

$\kappa = 0.4$ for our regression procedure, checking the changes in measured ![]() $z_0/b$ due to variations in

$z_0/b$ due to variations in ![]() $\kappa$ is important. Figure 12 shows the sensitivity of calculated

$\kappa$ is important. Figure 12 shows the sensitivity of calculated ![]() $z_0/b$ and

$z_0/b$ and ![]() $d/b$ with various values of

$d/b$ with various values of ![]() $\kappa$. It can be seen that

$\kappa$. It can be seen that ![]() $z_0/b$ decreases and

$z_0/b$ decreases and ![]() $d/b$ increases with

$d/b$ increases with ![]() $\kappa$. While we do see noticeable variations in these values, it is worth noting that these changes would not be significant on the log scale, which is the relevant scale for the drag produced by these surfaces. Also, for a given value of

$\kappa$. While we do see noticeable variations in these values, it is worth noting that these changes would not be significant on the log scale, which is the relevant scale for the drag produced by these surfaces. Also, for a given value of ![]() $\kappa$, the differences in

$\kappa$, the differences in ![]() $z_0/b$ and

$z_0/b$ and ![]() $d/b$ are almost the same, which means that it is reasonable to compare these values for the different surfaces.

$d/b$ are almost the same, which means that it is reasonable to compare these values for the different surfaces.

Figure 12. Plot showing the sensitivity to variations in von Kármán constant ![]() $\kappa$ for spanwise-aligned (AY) and staggered (S) cases for the calculated (a) effective roughness height

$\kappa$ for spanwise-aligned (AY) and staggered (S) cases for the calculated (a) effective roughness height ![]() $z_0/b$, and (b) zero-plane displacement height

$z_0/b$, and (b) zero-plane displacement height ![]() $d/b$.

$d/b$.

Further, we note that determining the roughness height ![]() $z_0$ or equivalent sand-grain roughness height

$z_0$ or equivalent sand-grain roughness height ![]() $k_s$ requires the flow to be in the fully rough regime. Based on Jiménez (Reference Jiménez2004), flow is considered fully rough when

$k_s$ requires the flow to be in the fully rough regime. Based on Jiménez (Reference Jiménez2004), flow is considered fully rough when ![]() $k_s^+ > 80$. In Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021), the authors have chosen

$k_s^+ > 80$. In Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021), the authors have chosen ![]() $k_s^+ > 50$ to be their definition for the fully rough regime. We have verified that all surfaces except AXL1H3 and AXL3H3 satisfy this latter condition, the

$k_s^+ > 50$ to be their definition for the fully rough regime. We have verified that all surfaces except AXL1H3 and AXL3H3 satisfy this latter condition, the ![]() $k_s^+$ values for which stand at 42.6 and 36 respectively. However, it is important to note that the exact value of

$k_s^+$ values for which stand at 42.6 and 36 respectively. However, it is important to note that the exact value of ![]() $k_s^+$ for which this transition to fully rough flow happens is unknown and also depends on the type of roughness being considered Flack & Schultz (Reference Flack and Schultz2010). Even so, we could still measure

$k_s^+$ for which this transition to fully rough flow happens is unknown and also depends on the type of roughness being considered Flack & Schultz (Reference Flack and Schultz2010). Even so, we could still measure ![]() $\Delta U^+$ and

$\Delta U^+$ and ![]() $z_0$, and discuss their variations with respect to the roughness as we are making these comparisons at a fixed Reynolds number (

$z_0$, and discuss their variations with respect to the roughness as we are making these comparisons at a fixed Reynolds number (![]() $Re_{\tau }=400$).

$Re_{\tau }=400$).

Figure 13 illustrates the quality of this log-law fit. The mean velocity plots can be observed to show a good collapse in the log layer region for all cases. The collapse is also a sign of mean flow universality, wherein such two-parameter forms of mean velocity profiles have been know to be adequate irrespective of the rough surface for ![]() $h/\delta \approx 0.03\unicode{x2013}0.5$. Figure 14 shows mean velocity profiles in defect form. This is being presented here as evidence for outer-layer similarity. Reasonably well collapsed regions can be observed farther away from the wall for the smooth- and rough-wall cases, underscoring a universality in mean flow behaviour in the outer layer irrespective of surface conditions for fully rough flow.

$h/\delta \approx 0.03\unicode{x2013}0.5$. Figure 14 shows mean velocity profiles in defect form. This is being presented here as evidence for outer-layer similarity. Reasonably well collapsed regions can be observed farther away from the wall for the smooth- and rough-wall cases, underscoring a universality in mean flow behaviour in the outer layer irrespective of surface conditions for fully rough flow.

Figure 13. Plot showing the log-law collapse for all cases: (a) AY, S cases; (b) AX, NV, AXY and SXY cases.

Figure 14. Velocity defect profiles for all surfaces: (a) AY, S cases; (b) AX, NV, AXY and SXY cases.

The mean velocity profile for the smooth wall in figures 14(a) and 14(b) was obtained from DNS of a half-channel with ![]() $Re_{\tau } = 400$. Similarly, figure 15 depicts outer-layer similarity in the streamwise Reynolds stress profiles.

$Re_{\tau } = 400$. Similarly, figure 15 depicts outer-layer similarity in the streamwise Reynolds stress profiles.

Figure 15. Normalized streamwise Reynolds stress profiles for all surfaces: (a) AY, S cases; (b) AX, NV, AXY and SXY cases.

Figure 16 summarizes the ![]() $z_0$ magnitudes for all cases, and the data are consistent with the various mean velocity profiles observed so far. Figure 16(a) compares the spanwise-aligned (AY) and staggered (S) cases. The

$z_0$ magnitudes for all cases, and the data are consistent with the various mean velocity profiles observed so far. Figure 16(a) compares the spanwise-aligned (AY) and staggered (S) cases. The ![]() $z_0/b$ magnitudes are observed to be similar between the AY and S cases when comparing cases with similar

$z_0/b$ magnitudes are observed to be similar between the AY and S cases when comparing cases with similar ![]() $\lambda _p$ and

$\lambda _p$ and ![]() $Sk$ magnitudes. When cases with similar packing densities

$Sk$ magnitudes. When cases with similar packing densities ![]() $\lambda _p$ and orientation but different

$\lambda _p$ and orientation but different ![]() $Sk$ are compared – for instance, AYL1H1, AYL1H2 and AYL1H3 –

$Sk$ are compared – for instance, AYL1H1, AYL1H2 and AYL1H3 – ![]() $z_0/b$ increases with

$z_0/b$ increases with ![]() $Sk$. This holds true for all cases listed in table 3. When cases with similar

$Sk$. This holds true for all cases listed in table 3. When cases with similar ![]() $Sk$ and orientation but different

$Sk$ and orientation but different ![]() $\lambda _p$ are compared – for instance, AYL1H1, AYL2H1 and AYL3H1 –

$\lambda _p$ are compared – for instance, AYL1H1, AYL2H1 and AYL3H1 – ![]() $z_0/b$ decreases with decreasing

$z_0/b$ decreases with decreasing ![]() $k_{rms}/k_a$. This is observed true for all cases except the AX surfaces, which will be discussed subsequently. It should be of interest to note that low

$k_{rms}/k_a$. This is observed true for all cases except the AX surfaces, which will be discussed subsequently. It should be of interest to note that low ![]() $k_{rms}/k_a$ magnitudes actually correspond to high

$k_{rms}/k_a$ magnitudes actually correspond to high ![]() $k_{rms}/b$ and

$k_{rms}/b$ and ![]() $\lambda _p$. The normalization with

$\lambda _p$. The normalization with ![]() $k_a$ causes this as an increment in

$k_a$ causes this as an increment in ![]() $\lambda _p$ increases both

$\lambda _p$ increases both ![]() $k_a$ and

$k_a$ and ![]() $k_{rms}$, but

$k_{rms}$, but ![]() $k_a$ increases at a rate faster than

$k_a$ increases at a rate faster than ![]() $k_{rms}$. Figure 16(b) compares the spanwise-aligned (AY) and streamwise-aligned (AX) cases. The effects due to changes in roughness element alignment are evident as the AX surfaces in figure 16(b) show notably lower

$k_{rms}$. Figure 16(b) compares the spanwise-aligned (AY) and streamwise-aligned (AX) cases. The effects due to changes in roughness element alignment are evident as the AX surfaces in figure 16(b) show notably lower ![]() $z_0/b$ magnitudes when compared to AY surfaces. For instance, even the densely packed surfaces AXL3H1, AXL3H2 and AXL3H3, which have higher solidities, are lower in

$z_0/b$ magnitudes when compared to AY surfaces. For instance, even the densely packed surfaces AXL3H1, AXL3H2 and AXL3H3, which have higher solidities, are lower in ![]() $z_0/b$ than the coarsely packed surfaces AYL1H1, AYL1H2 and AYL1H3. Moreover, it can be noticed that

$z_0/b$ than the coarsely packed surfaces AYL1H1, AYL1H2 and AYL1H3. Moreover, it can be noticed that ![]() $z_0/b$ first increases then decreases with decreasing

$z_0/b$ first increases then decreases with decreasing ![]() $k_{rms}/k_{a}$ (or increasing

$k_{rms}/k_{a}$ (or increasing ![]() $\lambda _p$) for H1 and H3 cases in AX surfaces. For higher

$\lambda _p$) for H1 and H3 cases in AX surfaces. For higher ![]() $\lambda _p$ surfaces AXL2H2 and AXL3H2, the increase in

$\lambda _p$ surfaces AXL2H2 and AXL3H2, the increase in ![]() $z_0/b$ is not as significant as it is for AYL2H2 and AYL3H3. These observations showcase a flow-sheltering effect in AX surfaces. Trends with changes in

$z_0/b$ is not as significant as it is for AYL2H2 and AYL3H3. These observations showcase a flow-sheltering effect in AX surfaces. Trends with changes in ![]() $Sk$ for AX surfaces are similar to those observed in AY ones, with

$Sk$ for AX surfaces are similar to those observed in AY ones, with ![]() $z_0/b$ increasing with increasing

$z_0/b$ increasing with increasing ![]() $Sk$. Figure 16(c) reports the effect of valleys on

$Sk$. Figure 16(c) reports the effect of valleys on ![]() $z_0/b$. The presence of valleys in the AY cases leads to higher

$z_0/b$. The presence of valleys in the AY cases leads to higher ![]() $k_{rms}/k_a$ compared to the NV cases, but the

$k_{rms}/k_a$ compared to the NV cases, but the ![]() $z_0/b$ magnitudes are very close between the AY and NV cases, with some noticeable difference at low

$z_0/b$ magnitudes are very close between the AY and NV cases, with some noticeable difference at low ![]() $k_{rms}/k_a$ magnitudes. Figure 16(d) presents spanwise-aligned (AY),

$k_{rms}/k_a$ magnitudes. Figure 16(d) presents spanwise-aligned (AY), ![]() $45^\circ$ alignment (AXY) and their respective staggered equivalents (S and SXY). A significant increase in

$45^\circ$ alignment (AXY) and their respective staggered equivalents (S and SXY). A significant increase in ![]() $z_0/b$ can be observed as alignment is changed to

$z_0/b$ can be observed as alignment is changed to ![]() $45^\circ$ when comparing AY and AXY. Also, SXY falls in the intermediate, with

$45^\circ$ when comparing AY and AXY. Also, SXY falls in the intermediate, with ![]() $z_0/b$ increasing due to a change in alignment when compared with S. However, this effect is less pronounced as

$z_0/b$ increasing due to a change in alignment when compared with S. However, this effect is less pronounced as ![]() $\lambda _p$ increases or

$\lambda _p$ increases or ![]() $k_{rms}/k_a$ decreases.

$k_{rms}/k_a$ decreases.

Figure 16. The effective roughness length to width ratio (![]() $z_0/b$) for the various cases: (a) spanwise-aligned versus staggered; (b) spanwise-aligned versus streamwise-aligned; (c) spanwise-aligned with and without valleys; (d) spanwise-aligned/staggered and their

$z_0/b$) for the various cases: (a) spanwise-aligned versus staggered; (b) spanwise-aligned versus streamwise-aligned; (c) spanwise-aligned with and without valleys; (d) spanwise-aligned/staggered and their ![]() $45^\circ$ rotated equivalents.

$45^\circ$ rotated equivalents.

3.4. Reynolds and dispersive stresses

We present the Reynolds stress and dispersive stress results. These results are usually not relevant to roughness modelling but are fundamental aspects of the flow, and we present them here for completeness.

Figure 17 shows the normal components of the horizontally averaged Reynolds and dispersive stresses for the five spanwise-aligned (AYL1H1, AYL2H1, AYL3H1, AYL1H2, AYL1H3) and staggered (SL1H1, SL2H1, SL3H1, SL1H2, SL1H3) cases. At first glance, all stresses are negligible in the valleys below the surface at ![]() $z=0$, and the spanwise and wall-normal components of the dispersive stresses are small throughout the channel. Second, it can be observed that the corresponding streamwise components of both stresses (

$z=0$, and the spanwise and wall-normal components of the dispersive stresses are small throughout the channel. Second, it can be observed that the corresponding streamwise components of both stresses (![]() $uu$) are higher than the respective spanwise (

$uu$) are higher than the respective spanwise (![]() $vv$) and wall-normal (