1. Introduction

Bounding surfaces in a fluid flow create frictional resistance, leading to energy expenditure required to maintain the flow. This resistance causes an increase in pressure gradient when a fixed mass flow rate is desired and a reduction of the flow rate when a fixed pressure gradient is available. In general, friction occurs due to fluid viscosity, and its magnitude is proportional to the wall-normal velocity gradient. The only possibility for resistance reduction for a given fluid is altering the fluid flow character near the wall. Several techniques have been developed to induce near-wall flow modifications. Examples of passive means include proper surface topography and replacing liquid–solid contact with a liquid–gas interface. An active means introduces a physical quantity, such as piezoelectric actuators (Fukunishi & Ebina Reference Fukunishi and Ebina2001), sound (Kato, Fukunishi & Kobayashi Reference Kato, Fukunishi and Kobayashi1997), plasma (Inasawa, Ninomiya & Asai Reference Inasawa, Ninomiya and Asai2013), surface transpiration (Bewley & Alamo Reference Bewley and Alamo2004; Min et al. Reference Min, Kang, Speyer and Kim2006; Bewley Reference Bewley2009; Hoepffner & Fukagata Reference Hoepffner and Fukagata2009; Mamori, Iwamoto & Marata Reference Mamori, Iwamoto and Marata2014; Jiao & Floryan Reference Jiao and Floryan2021a,Reference Jiao and Floryanb) and surface vibrations (Floryan & Haq Reference Floryan and Haq2022; Floryan & Zandi Reference Floryan and Zandi2022; Haq & Floryan Reference Haq and Floryan2022; Floryan & Haq Reference Floryan and Haq2023). While none of the methods produced net energy savings, recent results showed that a combination of different techniques might achieve that (Floryan Reference Floryan2023). Active systems may not be suitable for specific applications like the flow of delicate constituents, e.g. bacteria and DNA samples, which are prone to contamination and mechanical breakage.

One can reduce frictional losses by replacing liquid–solid contact with liquid–gas contact by placing micropores on the surface and then filling the pores with gas-forming bubbles (Ou, Perot & Rothstein Reference Ou, Perot and Rothstein2004; Ou & Rothstein Reference Ou and Rothstein2005; Rothstein Reference Rothstein2010; Park, Park & Kim Reference Park, Park and Kim2013; Srinivasan et al. Reference Srinivasan, Choi, Park, Chatre, Cohen and Mckinley2013; Park, Sun & Kim Reference Park, Sun and Kim2014). The shear acting at the solid surface is replaced by shear at the gas interface, which is much lower due to lower gas viscosity. This technique requires two phases and works only with the liquid phase as the main working fluid. An alternate version of this technique considers the liquid infusion into the pores to avoid a potential gas bubble collapse (Solomon, Khalil & Varanasi Reference Solomon, Khalil and Varanasi2014, Reference Solomon, Khalil and Varanasi2016; Rosenberg et al. Reference Rosenberg, Van Buren, Fu and Smits2016). Although substantial drag reduction has been reported recently (Van Buren & Smits Reference Van Buren and Smits2017), the effectiveness of this technique diminishes when migration of the infusing liquid occurs due to the variations of pressure along the surface.

One can create special surface topography, such as riblets (short wavelength longitudinal grooves), which can reduce drag by forcing the flow stream to lift above the grooves (Walsh Reference Walsh1983; Garcia-Mayoral & Jimenez Reference Garcia-Mayoral and Jimenez2011). Long-wavelength longitudinal grooves can also contribute to a reduction of the solid–fluid interface friction through changes in the distribution of the bulk flow and are effective on both laminar (Szumbarski, Blonski & Kowalewshi Reference Szumbarski, Blonski and Kowalewshi2011; Mohammadi & Floryan Reference Mohammadi and Floryan2013; Moradi & Floryan Reference Moradi and Floryan2013; Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017; Yadav, Gepner & Szumbarski Reference Yadav, Gepner and Szumbarski2018) and turbulent (Chen et al. Reference Chen, Floryan, Chew and Khoo2016; DeGroot, Wang & Floryan Reference DeGroot, Wang and Floryan2016) flows. Grooves increase the wetted area compared with a smooth surface; thus, the reduction of the wall shear must be large enough to overcome the increase of the shear caused by the increased area.

In addition to the above techniques, one can consider applying spatially distributed heating patterns on the bounding surface. This heating provides a horizontal density gradient, which creates rotary convection rolls. These rolls prevent direct contact between the stream and the bounding surfaces, reducing the shear experienced by the stream. The effectiveness of this method is increased by adding a uniform heating (Floryan & Floryan Reference Floryan and Floryan2015), and heating both walls with a proper phase difference between both heating patterns (Hossain & Floryan Reference Hossain and Floryan2016). The method remains effective for low Reynolds numbers (Hossain, Floryan & Floryan Reference Hossain, Floryan and Floryan2012) as stronger flows eliminate the convection bubbles. Drag reduction can be enhanced by properly combining the heating and groove patterns (Hossain & Floryan Reference Hossain and Floryan2020) by activating the thermal streaming mechanism (Abtahi & Floryan Reference Abtahi and Floryan2017; Floryan, Panday & Aman Reference Floryan, Panday and Aman2023a). These mechanisms have been confirmed experimentally (Inasawa, Taneda & Floryan Reference Inasawa, Taneda and Floryan2019; Floryan & Inasawa Reference Floryan and Inasawa2021; Inasawa, Hara & Floryan Reference Inasawa, Hara and Floryan2021). The same concept works in vertical and inclined channels (Floryan et al. Reference Floryan, Baayoun, Panday and Bassom2022; Floryan, Wang & Bassom Reference Floryan, Wang and Bassom2023b).

It was demonstrated recently (Hossain & Floryan Reference Hossain and Floryan2023) that thermal waves propagating along the fluid–solid boundary produce a propulsive effect, generating a net horizontal flow. The waves are characterized by a wave speed, a wavelength, an amplitude and a wave shape. The use of thermal waves, so far, was limited to generating fluid motion (Davey Reference Davey1967; Hinch & Schubert Reference Hinch and Schubert1971; Mao, Oron & Alexeev Reference Mao, Oron and Alexeev2013; Reiter et al. Reference Reiter, Zhang, Stepanov and Shishkina2021). These analyses used the long-wavelength approximation (Davey Reference Davey1967; Hinch & Schubert Reference Hinch and Schubert1971), considered slow to moderate wave velocities and high Rayleigh number (Reiter et al. Reference Reiter, Zhang, Stepanov and Shishkina2021). Mao et al. (Reference Mao, Oron and Alexeev2013) considered waves activating the thermocapillary effect rather than the buoyancy effect, with analysis limited to long waves. The question posed in this study is whether thermal waves can reduce resistance in an externally driven flow. Such waves can create convection rolls near the bounding surface (Hossain & Floryan Reference Hossain and Floryan2023), which were essential for resistance reduction in channels exposed to pattern heating. Thermal waves can be viewed as generating spatially distributed propulsion instead of concentrated propulsion, which could be advantageous in some applications such as where excess local stresses are detrimental to the surface. Reduction of frictional losses is quantified in terms of the flow rate change compared with the flow rate in an isothermal channel driven by the same pressure gradient. We examine the linear stability of the flow to ascertain that no instability occurs under the conditions used in this study, as formation of secondary states would invalidate our predictions. The paper is organized as follows. Section 2 introduces the model problem, and § 3 discusses its numerical solution. Section 4 presents and discusses the solution of the linear stability problem. Section 5 discusses the flow properties starting with § 5.1, describing waves’ pumping effect, and continuing with § 5.2, presenting wave-induced flow modification. The mechanisms governing the flow responses are discussed in § 6, with § 6.1 providing details of flow modifications caused by small amplitude waves, § 6.2 presenting modifications of weak flows, § 6.3 devoted to discussion of long waves and § 6.4 focusing on short waves. Section 7 discusses the results of linear stability analysis, § 8 shows the equivalence between flow response to waves applied at the upper and lower walls and, finally, § 9 provides a summary of the conclusions.

2. Problem formulation

Consider the two-dimensional flow of a fluid confined in a channel bounded by two parallel walls placed at a distance of ![]() $2h$ apart from each other, as shown in figure 1. A pressure gradient in the positive

$2h$ apart from each other, as shown in figure 1. A pressure gradient in the positive ![]() $X$-direction drives the flow and the resulting velocity, pressure and flow rate have the form

$X$-direction drives the flow and the resulting velocity, pressure and flow rate have the form

where ![]() $\boldsymbol {u_0} =(u_0,v_0)$ is the velocity vector scaled with the maximum

$\boldsymbol {u_0} =(u_0,v_0)$ is the velocity vector scaled with the maximum ![]() $X$-velocity

$X$-velocity ![]() $u _{max}$ as the velocity scale,

$u _{max}$ as the velocity scale, ![]() $p_0$ denotes the pressure scaled with

$p_0$ denotes the pressure scaled with ![]() $\rho u_{max} ^2$ as the pressure scale with

$\rho u_{max} ^2$ as the pressure scale with ![]() $\rho$ being the density of the fluid,

$\rho$ being the density of the fluid, ![]() $Q_0$ denotes the flow rate, and the Reynolds number is defined as

$Q_0$ denotes the flow rate, and the Reynolds number is defined as ![]() $Re=u_{max} h/\nu$ where

$Re=u_{max} h/\nu$ where ![]() $\nu$ stands for the kinematic viscosity and

$\nu$ stands for the kinematic viscosity and ![]() $h$ is the length scale.

$h$ is the length scale.

Figure 1. Sketch of the flow configuration.

The flow is modified by imposing a thermal wave in the lower wall while the upper wall is kept isothermal. The wave travelling in the positive ![]() $X$-direction with the phase speed

$X$-direction with the phase speed ![]() $c$ and wavenumber

$c$ and wavenumber ![]() $\alpha$ with a known wave profile results in the wall temperatures in the form

$\alpha$ with a known wave profile results in the wall temperatures in the form

where ![]() $\theta = (T-T_R)/T_\kappa$ denotes the relative temperature scaled with the temperature scale

$\theta = (T-T_R)/T_\kappa$ denotes the relative temperature scaled with the temperature scale ![]() $T_\kappa = \kappa \nu /(g \gamma h ^{3})$ where

$T_\kappa = \kappa \nu /(g \gamma h ^{3})$ where ![]() $\kappa$ is the thermal diffusivity,

$\kappa$ is the thermal diffusivity, ![]() $g$ is the gravitational acceleration acting in the negative

$g$ is the gravitational acceleration acting in the negative ![]() $Y$-direction,

$Y$-direction, ![]() $\gamma$ is the thermal expansion coefficient,

$\gamma$ is the thermal expansion coefficient, ![]() $T$ is the absolute temperature and

$T$ is the absolute temperature and ![]() $T_{R}$ is the reference temperature denoting the upper wall temperature. In the above,

$T_{R}$ is the reference temperature denoting the upper wall temperature. In the above, ![]() $t$ denotes time, and the subscripts

$t$ denotes time, and the subscripts ![]() $L$ and

$L$ and ![]() $U$ refer to the lower and the upper wall, respectively. Here

$U$ refer to the lower and the upper wall, respectively. Here ![]() $Ra_{P,L}=g \gamma h^{3} \theta _{P,L}/(\kappa \nu )$ is the wave Rayleigh number with

$Ra_{P,L}=g \gamma h^{3} \theta _{P,L}/(\kappa \nu )$ is the wave Rayleigh number with ![]() $\theta _{P,L}$ is the wave amplitude. The wavelength of the thermal wave

$\theta _{P,L}$ is the wave amplitude. The wavelength of the thermal wave ![]() $\lambda = 2{\rm \pi} /\alpha$.

$\lambda = 2{\rm \pi} /\alpha$.

Introduction of the thermal wave modifies the flow fields (2.1a–c), which can be represented as a superposition of the pressure-gradient-driven and the buoyancy-driven motions. The complete flow quantities have the form

\begin{equation} \left.\begin{gathered} u_1(X,Y) = Re ~ u_0(Y) + u(X,Y), \quad v_1=v(X,Y),\\ \theta_1 = \theta(X,Y), \quad p_1(X,Y)=Re^2\,p_0(X,Y)+p(X,Y), \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} u_1(X,Y) = Re ~ u_0(Y) + u(X,Y), \quad v_1=v(X,Y),\\ \theta_1 = \theta(X,Y), \quad p_1(X,Y)=Re^2\,p_0(X,Y)+p(X,Y), \end{gathered}\right\} \end{equation}

where ![]() $(u_1,v_1)$ represent the complete velocity vector with

$(u_1,v_1)$ represent the complete velocity vector with ![]() $(X,Y)$ components,

$(X,Y)$ components, ![]() $p_1$ and

$p_1$ and ![]() $\theta _1$ denote the complete pressure and temperature fields, respectively. Here

$\theta _1$ denote the complete pressure and temperature fields, respectively. Here ![]() $(u, v)$ represent the modification velocity vector with components in the

$(u, v)$ represent the modification velocity vector with components in the ![]() $(X,Y)$ directions,

$(X,Y)$ directions, ![]() $p$ and

$p$ and ![]() $\theta$ denote the pressure and temperature modifications, respectively. The complete velocity vector and the velocity modifications have been scaled using the convective velocity scale

$\theta$ denote the pressure and temperature modifications, respectively. The complete velocity vector and the velocity modifications have been scaled using the convective velocity scale ![]() $u_{\nu } = \nu /h$ where

$u_{\nu } = \nu /h$ where ![]() $u_{max}/u_{\nu } = Re$, the complete pressure and the pressure modifications have been scaled using the pressure scale

$u_{max}/u_{\nu } = Re$, the complete pressure and the pressure modifications have been scaled using the pressure scale ![]() $\rho u_{\nu }^2$.

$\rho u_{\nu }^2$.

Considering the Boussinesq approximation, the resulting two-dimensional flow is described by the unsteady Navier–Stokes, energy and continuity equations of the form

where ![]() $\nabla ^2$ denotes the Laplace operator and

$\nabla ^2$ denotes the Laplace operator and ![]() $Pr = \nu /\kappa$ is the Prandtl number. The relevant boundary conditions at the walls are

$Pr = \nu /\kappa$ is the Prandtl number. The relevant boundary conditions at the walls are

Conditions required for the use of this approximation are discussed in Tritton (Reference Tritton1977). Results of experiments for thermal conditions similar to those used in this analysis (Inasawa et al. Reference Inasawa, Taneda and Floryan2019, Reference Inasawa, Hara and Floryan2021; Floryan & Inasawa Reference Floryan and Inasawa2021) demonstrate that the Boussinesq approximation well captures the fluid response.

This analysis intends to determine the effectiveness of thermal waves in reducing flow losses and to quantify their effectiveness. The problem is posed as the determination of change in the flow rate driven through the heated and isothermal channels by the same pressure gradient. This requires imposition of the pressure gradient constraint of the form

where the subscript ![]() $m$ denotes the mean value.

$m$ denotes the mean value.

The total mean flow rate in the channel is decomposed into two parts: the reference isothermal flow rate and the flow rate correction ![]() $Q_c$ induced by the wave, i.e.

$Q_c$ induced by the wave, i.e.

Positive values of the correction ![]() $Q_c$ identify conditions leading to resistance reduction. The flow rate increase (decrease) is better illustrated using the correction factor

$Q_c$ identify conditions leading to resistance reduction. The flow rate increase (decrease) is better illustrated using the correction factor ![]() $\varGamma _{cor}$ defined as

$\varGamma _{cor}$ defined as

\begin{equation} \varGamma_{cor} = \frac{Q_c}{\dfrac {4}{3}Re}, \end{equation}

\begin{equation} \varGamma_{cor} = \frac{Q_c}{\dfrac {4}{3}Re}, \end{equation}which expresses the flow rate correction as a fraction of the reference flow rate.

Determination of surface forces acting on the fluid contributes to the understanding of the flow mechanics. The wall shear stress at the lower wall (![]() $\sigma _{X,L}$) can be calculated as

$\sigma _{X,L}$) can be calculated as

where ![]() $\sigma _{X,L,mod}$ is the shear stress modification due to interaction of the thermal wave, and the corresponding

$\sigma _{X,L,mod}$ is the shear stress modification due to interaction of the thermal wave, and the corresponding ![]() $X$-component of the shear force modification

$X$-component of the shear force modification ![]() $(\tau _{X,L,mod})$ per its unit length can easily be determined as

$(\tau _{X,L,mod})$ per its unit length can easily be determined as

where ![]() $X_0$ is a convenient reference point. Similar quantities, i.e.

$X_0$ is a convenient reference point. Similar quantities, i.e. ![]() $\sigma _{X,U}$ and

$\sigma _{X,U}$ and ![]() $\tau _{X,U,mod}$, can be defined for the upper wall.

$\tau _{X,U,mod}$, can be defined for the upper wall.

3. Method of solution

Introduction of a frame of reference moving with the wave phase speed and use of the relevant Galileo transformation of the form ![]() $y=Y, x=X-ct$ leads to a steady problem of the form

$y=Y, x=X-ct$ leads to a steady problem of the form

with the boundary conditions taking the following form:

\begin{equation} \left.\begin{gathered} u(y=\pm1)=v(y=\pm1)=0, \quad \theta(y={-}1)=\theta_L (x) = \frac{1}{2} Ra_{p,L} \cos(\alpha x),\\ \theta(y=1)= \theta_U (x) =0, \quad \left.\frac{\partial p}{\partial x} \right|_{m}= 0. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} u(y=\pm1)=v(y=\pm1)=0, \quad \theta(y={-}1)=\theta_L (x) = \frac{1}{2} Ra_{p,L} \cos(\alpha x),\\ \theta(y=1)= \theta_U (x) =0, \quad \left.\frac{\partial p}{\partial x} \right|_{m}= 0. \end{gathered}\right\} \end{equation} Introduction of stream function ![]() $\psi$ defined as

$\psi$ defined as ![]() $u=\partial \psi / \partial y$,

$u=\partial \psi / \partial y$, ![]() $v=-\partial \psi /\partial x$, and elimination of pressure provide the following form of the field equations:

$v=-\partial \psi /\partial x$, and elimination of pressure provide the following form of the field equations:

\begin{align} \nabla ^4 \psi + c \frac{\partial }{\partial x} (\nabla ^2 \psi) - Pr ^{{-}1} \frac{\partial \theta }{\partial x} &= Re\,u_0\frac{\partial }{\partial x} (\nabla ^2 \psi) -Re\,\frac{{\rm d}^2 u_0 }{{{\rm d}y}^2} \frac{\partial \psi }{\partial x}+ \frac{\partial \psi }{\partial y} \frac{\partial }{\partial x}(\nabla ^2 \psi) \nonumber\\ &\quad -\frac{\partial \psi }{\partial x} \frac{\partial }{\partial y}(\nabla ^2 \psi), \end{align}

\begin{align} \nabla ^4 \psi + c \frac{\partial }{\partial x} (\nabla ^2 \psi) - Pr ^{{-}1} \frac{\partial \theta }{\partial x} &= Re\,u_0\frac{\partial }{\partial x} (\nabla ^2 \psi) -Re\,\frac{{\rm d}^2 u_0 }{{{\rm d}y}^2} \frac{\partial \psi }{\partial x}+ \frac{\partial \psi }{\partial y} \frac{\partial }{\partial x}(\nabla ^2 \psi) \nonumber\\ &\quad -\frac{\partial \psi }{\partial x} \frac{\partial }{\partial y}(\nabla ^2 \psi), \end{align}subject to

where ![]() $\nabla ^4$ stands for the biharmonic operator.

$\nabla ^4$ stands for the biharmonic operator.

The system of (3.2a–f) is solved by representing the unknowns in terms of Fourier expansions in the streamwise direction as

\begin{equation} \psi (x,y) = \sum_{n={-}\infty} ^{n={+}\infty} \psi ^{(n)} (y) {\rm e}^{{\rm i}n\alpha x }, \quad \theta (x,y) = \sum_{n={-}\infty} ^{n={+}\infty} \theta ^{(n)} (y) {\rm e}^{{\rm i}n\alpha x } \end{equation}

\begin{equation} \psi (x,y) = \sum_{n={-}\infty} ^{n={+}\infty} \psi ^{(n)} (y) {\rm e}^{{\rm i}n\alpha x }, \quad \theta (x,y) = \sum_{n={-}\infty} ^{n={+}\infty} \theta ^{(n)} (y) {\rm e}^{{\rm i}n\alpha x } \end{equation}

where the modal functions ![]() $\psi ^{(n)} (y)$ and

$\psi ^{(n)} (y)$ and ![]() $\theta ^{(n)} (y)$ are to be determined. The pressure gradient constraint (3.2f) can be expressed in terms of modal functions as

$\theta ^{(n)} (y)$ are to be determined. The pressure gradient constraint (3.2f) can be expressed in terms of modal functions as

\begin{equation} \frac{{\rm d}^2 \psi }{{{\rm d}y}^2} ^{(0)} (1) - \frac{{\rm d}^2 \psi }{{{\rm d}y}^2} ^{(0)} ({-}1)= 0. \end{equation}

\begin{equation} \frac{{\rm d}^2 \psi }{{{\rm d}y}^2} ^{(0)} (1) - \frac{{\rm d}^2 \psi }{{{\rm d}y}^2} ^{(0)} ({-}1)= 0. \end{equation} For the purpose of numerical solution, expansions (3.3a,b) are truncated after a finite number of terms ![]() $N_M$ resulting in a system of

$N_M$ resulting in a system of ![]() $2(N_M+1)$ equations which are solved using a Chebyshev collocation technique based on

$2(N_M+1)$ equations which are solved using a Chebyshev collocation technique based on ![]() $N_P$ collocation points (Canuto et al. Reference Canuto, Hussaini, Quarteroni and Zang1996). An under-relaxation-based iterative technique is used to control solution accuracy within the specified tolerance limit. The number of collocation points and the Fourier modes used in the solution have been selected through numerical experiments to guarantee at least six digits accuracy.

$N_P$ collocation points (Canuto et al. Reference Canuto, Hussaini, Quarteroni and Zang1996). An under-relaxation-based iterative technique is used to control solution accuracy within the specified tolerance limit. The number of collocation points and the Fourier modes used in the solution have been selected through numerical experiments to guarantee at least six digits accuracy.

Using the Fourier modal functions, the flow rate correction is simply evaluated as

and the expressions for the shear force modifications reduce to much simpler form as

4. Linear stability analysis

In order to have a reliable prediction of the flow rate, we determine whether the flow discussed above undergoes any bifurcations which, if they occur, would invalidate predictions.

We shall use linear stability theory in order to determine the onset conditions (Floryan Reference Floryan1997; Hossain & Floryan Reference Hossain and Floryan2013). The analysis begins with the three-dimensional forms of the momentum, energy and continuity equations expressed in the moving frame of reference, shown in (3.1). We superimpose unsteady, three-dimensional infinitesimal disturbances into the wave-modified flow and represent the flow field as

In the above, the subscripts 1 and 2 refer to the wave-modified flow and the disturbance fields, respectively, with ![]() $\boldsymbol {v_1}=(u_1,v_1,0)$ standing for the modified flow velocity vector,

$\boldsymbol {v_1}=(u_1,v_1,0)$ standing for the modified flow velocity vector, ![]() $\boldsymbol {v_2}=(u_2,v_2,w_2)$ standing for the disturbance velocity vector,

$\boldsymbol {v_2}=(u_2,v_2,w_2)$ standing for the disturbance velocity vector, ![]() $\theta _1$ denoting the modified temperature,

$\theta _1$ denoting the modified temperature, ![]() $\theta _2$ denoting the temperature disturbance,

$\theta _2$ denoting the temperature disturbance, ![]() $p_1$ standing for the modified pressure field and

$p_1$ standing for the modified pressure field and ![]() $p_2$ standing for the disturbance pressure field. Substitution of the flow quantities (4.1) into the field equations, subtraction of the wave-modified part (3.1) and linearization of the resulting equations provide the following disturbance equations in vector form:

$p_2$ standing for the disturbance pressure field. Substitution of the flow quantities (4.1) into the field equations, subtraction of the wave-modified part (3.1) and linearization of the resulting equations provide the following disturbance equations in vector form:

where ![]() $\boldsymbol {j}$ is the unit vector along vertical

$\boldsymbol {j}$ is the unit vector along vertical ![]() $y$-direction. The above system is subject to the homogeneous boundary conditions

$y$-direction. The above system is subject to the homogeneous boundary conditions

System (4.2) represents a linear stability system for a thermal-wave spatially modulated flow with its spatial distribution of modulations characterized by the wavenumber ![]() $\alpha$. Spatial distribution of disturbances is characterized by the spanwise (

$\alpha$. Spatial distribution of disturbances is characterized by the spanwise (![]() $\beta )$ and streamwise (

$\beta )$ and streamwise (![]() $\delta$) wavenumbers. The overall system periodicity in the spanwise direction is characterized by

$\delta$) wavenumbers. The overall system periodicity in the spanwise direction is characterized by ![]() $\beta$ while the character of this system in the

$\beta$ while the character of this system in the ![]() $x$-direction depends on the ratio of

$x$-direction depends on the ratio of ![]() $\alpha$ and

$\alpha$ and ![]() $\delta$. The system can be aperiodic in this direction for an irrational ratio of

$\delta$. The system can be aperiodic in this direction for an irrational ratio of ![]() $\alpha$ and

$\alpha$ and ![]() $\delta$ (non-commensurate system), and could be periodic but with wavelengths varying by several orders of magnitude (commensurate systems). Wavenumber

$\delta$ (non-commensurate system), and could be periodic but with wavelengths varying by several orders of magnitude (commensurate systems). Wavenumber ![]() $\alpha$ can be viewed as a control parameter as its value characterizes the thermal wave of interest. The stability analysis requires determination of the amplification rate for

$\alpha$ can be viewed as a control parameter as its value characterizes the thermal wave of interest. The stability analysis requires determination of the amplification rate for ![]() $\beta \in (0,\infty )$ and

$\beta \in (0,\infty )$ and ![]() $\delta \in (0,\infty )$ which, in the case of direct-numerical-simulation-type solutions, necessitates use of very large solution domains which makes such solutions impractical, if not impossible (Panday & Floryan Reference Panday and Floryan2023). Here we follow the formulation proposed by Floryan (Reference Floryan1997).

$\delta \in (0,\infty )$ which, in the case of direct-numerical-simulation-type solutions, necessitates use of very large solution domains which makes such solutions impractical, if not impossible (Panday & Floryan Reference Panday and Floryan2023). Here we follow the formulation proposed by Floryan (Reference Floryan1997).

The disturbance quantities are represented as

where (![]() $\delta, \beta$) are the disturbance wavenumber in the (

$\delta, \beta$) are the disturbance wavenumber in the (![]() $x, z$) directions, the real and imaginary parts of the complex exponent

$x, z$) directions, the real and imaginary parts of the complex exponent ![]() $\sigma = \sigma _r + \textrm {i} \sigma _i$ describe the rate of growth and the frequency of disturbances with positive

$\sigma = \sigma _r + \textrm {i} \sigma _i$ describe the rate of growth and the frequency of disturbances with positive ![]() $\sigma _i$ identifying instability and c.c. stands for the complex conjugate. Here

$\sigma _i$ identifying instability and c.c. stands for the complex conjugate. Here ![]() $\boldsymbol {V_2} (x,y)$,

$\boldsymbol {V_2} (x,y)$, ![]() $\varTheta _2 (x,y)$, and

$\varTheta _2 (x,y)$, and ![]() $P_2(x,y)$ are the

$P_2(x,y)$ are the ![]() $x$-periodic amplitudes functions. Substitution of (4.3a) into (4.2) leads to an eigenvalue problem for the partial differential equations for the amplitude functions. These functions are represented as Fourier expansions in the

$x$-periodic amplitudes functions. Substitution of (4.3a) into (4.2) leads to an eigenvalue problem for the partial differential equations for the amplitude functions. These functions are represented as Fourier expansions in the ![]() $x$-direction

$x$-direction

\begin{equation} \left [ \boldsymbol{V_2}, \varTheta_2, P_2 \right ] (x,y) = \sum_{m={-}\infty} ^{m={+}\infty} \left [ \left ( f_u ^{(m)},f_v ^{(m)}, f_w ^{(m)} \right), f_\theta ^{(m)}, f_p^{(m)} \right ] (y) {\rm e} ^{{\rm i} m \alpha x }. \end{equation}

\begin{equation} \left [ \boldsymbol{V_2}, \varTheta_2, P_2 \right ] (x,y) = \sum_{m={-}\infty} ^{m={+}\infty} \left [ \left ( f_u ^{(m)},f_v ^{(m)}, f_w ^{(m)} \right), f_\theta ^{(m)}, f_p^{(m)} \right ] (y) {\rm e} ^{{\rm i} m \alpha x }. \end{equation} We transform the system (4.2a,b) into wall-normal vorticity ![]() $(\zeta = {\partial u_2}/{\partial z} - {\partial w_2}/{\partial x})$ and wall-normal velocity (

$(\zeta = {\partial u_2}/{\partial z} - {\partial w_2}/{\partial x})$ and wall-normal velocity (![]() $v$) form, substitute (4.3a,b) and separate the Fourier components, after some rather lengthy algebra, to arrive at a system of linear homogeneous ordinary differential equations of the form

$v$) form, substitute (4.3a,b) and separate the Fourier components, after some rather lengthy algebra, to arrive at a system of linear homogeneous ordinary differential equations of the form

$$\begin{gather} A^{(m)} \zeta ^{(m)} +Re D u_0 \beta f_v^{(m)} = \sum_{n={-}\infty} ^{n={+}\infty} [ H_\zeta ^{(m-n)} \zeta ^{(m-n)}+H_v ^{(m-n)} f_v ^{(m-n)}], \end{gather}$$

$$\begin{gather} A^{(m)} \zeta ^{(m)} +Re D u_0 \beta f_v^{(m)} = \sum_{n={-}\infty} ^{n={+}\infty} [ H_\zeta ^{(m-n)} \zeta ^{(m-n)}+H_v ^{(m-n)} f_v ^{(m-n)}], \end{gather}$$ $$\begin{gather}B^{(m)} f_v ^{(m)} - Pr ^{{-}1} k_m ^2 \,f_\theta^{(m)} ={-}\sum_{n={-}\infty} ^{n={+}\infty} [ L_\zeta ^{(m-n)} \zeta ^{(m-n)}+L_v ^{(m-n)} f_v ^{(m-n)}], \end{gather}$$

$$\begin{gather}B^{(m)} f_v ^{(m)} - Pr ^{{-}1} k_m ^2 \,f_\theta^{(m)} ={-}\sum_{n={-}\infty} ^{n={+}\infty} [ L_\zeta ^{(m-n)} \zeta ^{(m-n)}+L_v ^{(m-n)} f_v ^{(m-n)}], \end{gather}$$ $$\begin{gather}C^{(m)} f_\theta^{(m)} = Pr \sum_{n={-}\infty} ^{n={+}\infty} [ J_\zeta ^{(m-n)} \zeta ^{(m-n)}+J_v ^{(m-n)} f_v ^{(m-n)} +J_\theta ^{(m-n)} f_\theta ^{(m-n)}] , \end{gather}$$

$$\begin{gather}C^{(m)} f_\theta^{(m)} = Pr \sum_{n={-}\infty} ^{n={+}\infty} [ J_\zeta ^{(m-n)} \zeta ^{(m-n)}+J_v ^{(m-n)} f_v ^{(m-n)} +J_\theta ^{(m-n)} f_\theta ^{(m-n)}] , \end{gather}$$and the boundary conditions take the form

\begin{equation} \left.\begin{gathered}\zeta

^{(m)}({\pm} 1)=0, \quad f_v ^{(m)}({\pm} 1)=0, \quad D

f_v ^{(m)}({\pm} 1)=0, \\ f_\theta ^{(m)}({\pm} 1)=0\quad

{\rm for}\ {-}\infty < m<{+}\infty,\end{gathered} \right\}

\end{equation}

\begin{equation} \left.\begin{gathered}\zeta

^{(m)}({\pm} 1)=0, \quad f_v ^{(m)}({\pm} 1)=0, \quad D

f_v ^{(m)}({\pm} 1)=0, \\ f_\theta ^{(m)}({\pm} 1)=0\quad

{\rm for}\ {-}\infty < m<{+}\infty,\end{gathered} \right\}

\end{equation}

with the coefficients ![]() $A, B, C, H, L, J$ being given in Appendix A.

$A, B, C, H, L, J$ being given in Appendix A.

The linear disturbance equations (4.4) represent an eigenvalue problem and are discretized with spectral accuracy using the Chebyshev collocation method with ![]() $N_P$ collocation points (Canuto et al. Reference Canuto, Hussaini, Quarteroni and Zang1996) and truncating after

$N_P$ collocation points (Canuto et al. Reference Canuto, Hussaini, Quarteroni and Zang1996) and truncating after ![]() $N_M$ modes. For the purposes of calculations, the problem is posed as an eigenvalue problem for

$N_M$ modes. For the purposes of calculations, the problem is posed as an eigenvalue problem for ![]() $\sigma$. The resulting matrix system is solved by the ‘inverse iteration’ technique as described in Saad (Reference Saad2011).

$\sigma$. The resulting matrix system is solved by the ‘inverse iteration’ technique as described in Saad (Reference Saad2011).

5. Flow characteristics

It is convenient to start with a short outline of the reference case of ![]() $Re=0$, which has been studied previously by Hossain & Floryan (Reference Hossain and Floryan2023).

$Re=0$, which has been studied previously by Hossain & Floryan (Reference Hossain and Floryan2023).

5.1. Thermal waves’ pumping effect

When there is no flow in the channel, a thermal wave acting on the lower wall can pump fluid horizontally at a rate ![]() $Q$ in the direction opposite to wave propagation. The flow response for a wave travelling to the right is a mirror image of the response for a wave travelling to the left;

$Q$ in the direction opposite to wave propagation. The flow response for a wave travelling to the right is a mirror image of the response for a wave travelling to the left; ![]() $Q$ is positive for the leftward wave, whereas it is negative for the rightward wave. Figure 2(a) shows that an increase in wave velocity

$Q$ is positive for the leftward wave, whereas it is negative for the rightward wave. Figure 2(a) shows that an increase in wave velocity ![]() $|c|$ increases

$|c|$ increases ![]() $|Q|$ at the rate proportional to

$|Q|$ at the rate proportional to ![]() ${\sim }|c|$, but after reaching a maximum, its further increase reduces

${\sim }|c|$, but after reaching a maximum, its further increase reduces ![]() $|Q|$ proportionally to

$|Q|$ proportionally to ![]() ${\sim }|c|^{-4}$. Figure 2(b) demonstrates that an excessive increase in the wave wavelength reduces

${\sim }|c|^{-4}$. Figure 2(b) demonstrates that an excessive increase in the wave wavelength reduces ![]() $|Q|$ proportionally to

$|Q|$ proportionally to ![]() $\sim \alpha ^4$, whereas an excessive reduction reduces

$\sim \alpha ^4$, whereas an excessive reduction reduces ![]() $|Q|$ proportionally to

$|Q|$ proportionally to ![]() $\sim \alpha ^{-6}$. The largest

$\sim \alpha ^{-6}$. The largest ![]() $|Q|$ occurs for waves with the wavenumbers

$|Q|$ occurs for waves with the wavenumbers ![]() $\alpha \in [1,4]$ and phase speed

$\alpha \in [1,4]$ and phase speed ![]() $|c| \in [1,5]$. An increase in the wave amplitude

$|c| \in [1,5]$. An increase in the wave amplitude ![]() $Ra_{p,L}$ increases the flow rate proportionally to

$Ra_{p,L}$ increases the flow rate proportionally to ![]() $\sim Ra_{p,L} ^2$, as shown in figure 2(c), but an excessively large amplitude slows down the increase due to various saturation effects. The pumping effect is known to be associated with the propulsion provided by the convection rollers (see figure 3) formed due to wave diffusion into the channel interior. At large

$\sim Ra_{p,L} ^2$, as shown in figure 2(c), but an excessively large amplitude slows down the increase due to various saturation effects. The pumping effect is known to be associated with the propulsion provided by the convection rollers (see figure 3) formed due to wave diffusion into the channel interior. At large ![]() $|c|$ and

$|c|$ and ![]() $\alpha$, these rollers appear very near to the lower wall, forming a boundary layer and reducing

$\alpha$, these rollers appear very near to the lower wall, forming a boundary layer and reducing ![]() $|Q|$ drastically.

$|Q|$ drastically.

Figure 2. (a) Variation of the flow rate correction ![]() $Q_c$ as a function of the wave speed

$Q_c$ as a function of the wave speed ![]() $c$, (b) wave wavenumber

$c$, (b) wave wavenumber ![]() $\alpha$ and (c) wave amplitude

$\alpha$ and (c) wave amplitude ![]() $Ra_{p.L}$ for

$Ra_{p.L}$ for ![]() $Re =0$,

$Re =0$, ![]() $Pr=0.71$. Asymptotes are depicted by dashed lines. In (a,c)

$Pr=0.71$. Asymptotes are depicted by dashed lines. In (a,c) ![]() $\alpha =2$, and in (b)

$\alpha =2$, and in (b) ![]() $Ra_{p.L}=1000$.

$Ra_{p.L}=1000$.

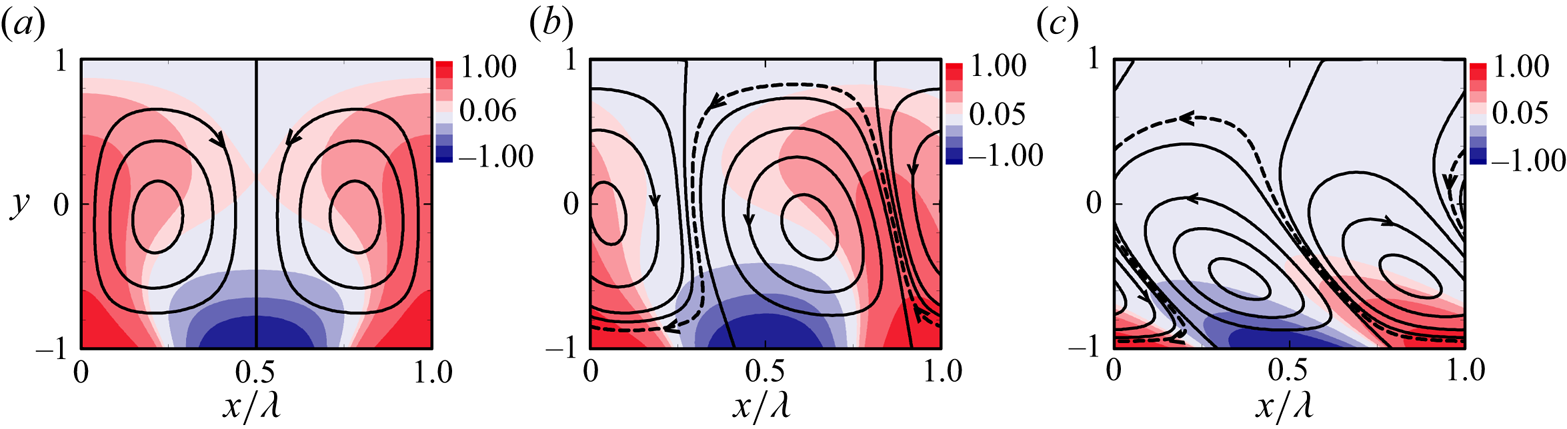

Figure 3. Flow topology (line) and temperature (filled colour) field at ![]() $Re =0$ with (a)

$Re =0$ with (a) ![]() $c=0$, (b)

$c=0$, (b) ![]() $c=2$ and (c)

$c=2$ and (c) ![]() $c=20$ for

$c=20$ for ![]() $Ra_{p,L}=1000$,

$Ra_{p,L}=1000$, ![]() $\alpha =2$,

$\alpha =2$, ![]() $Pr=0.71$. The dashed lines show the meandering flow stream. Arrows show the stream flow direction.

$Pr=0.71$. The dashed lines show the meandering flow stream. Arrows show the stream flow direction.

Variations of flow topology associated with variation of ![]() $c$ are illustrated in figure 3. As the waves diffuse into the channel interior, they are delayed by the fluid thermal inertia, with their positions falling farther behind the surface waves as the distance from the lower wall increases. This process results in bubbles tilting. We refer to this effect as the lagging thermal penetration. The bubble tilting occurs leftward when the wave travels rightward (

$c$ are illustrated in figure 3. As the waves diffuse into the channel interior, they are delayed by the fluid thermal inertia, with their positions falling farther behind the surface waves as the distance from the lower wall increases. This process results in bubbles tilting. We refer to this effect as the lagging thermal penetration. The bubble tilting occurs leftward when the wave travels rightward (![]() $c> 0$), and rightward when the wave travels leftward (

$c> 0$), and rightward when the wave travels leftward (![]() $c < 0$).

$c < 0$).

5.2. Flow modifications generated by thermal waves

There is an established isothermal flow from left to right characterized by ![]() $Re$. This flow is modified by a thermal wave with wave velocity

$Re$. This flow is modified by a thermal wave with wave velocity ![]() $c$ applied at the lower wall. Its response depends on

$c$ applied at the lower wall. Its response depends on ![]() $Re$ and

$Re$ and ![]() $c$. A stationary wave (

$c$. A stationary wave (![]() $c=0$) represents the reference configuration with flow topology displayed in figure 4. The topology for

$c=0$) represents the reference configuration with flow topology displayed in figure 4. The topology for ![]() $Re=0$ consists of pairs of counter-rotating rolls and has vertical mushroom-shaped isotherms (figure 4a). Introduction of a weak flow, e.g.

$Re=0$ consists of pairs of counter-rotating rolls and has vertical mushroom-shaped isotherms (figure 4a). Introduction of a weak flow, e.g. ![]() $Re=1$, causes these rolls to separate, creating a narrow meandering stream between them (figure 4b). The rolls morph into upper and lower wall separation bubbles, with the upper bubbles rotating anticlockwise and the lower bubbles rotating clockwise. The bubbles and isotherms are slightly tilted rightward. Further, an increase in

$Re=1$, causes these rolls to separate, creating a narrow meandering stream between them (figure 4b). The rolls morph into upper and lower wall separation bubbles, with the upper bubbles rotating anticlockwise and the lower bubbles rotating clockwise. The bubbles and isotherms are slightly tilted rightward. Further, an increase in ![]() $Re$ eliminates the upper bubbles (figure 4c), reduces the size of the lower bubbles and increases the rightward tilt of the bubbles and isotherms. A fast enough flow (e.g.

$Re$ eliminates the upper bubbles (figure 4c), reduces the size of the lower bubbles and increases the rightward tilt of the bubbles and isotherms. A fast enough flow (e.g. ![]() $Re>20$) washes away even the lower bubbles, bringing the flow to a parallel form (figure 4d), with the titled isotherms concentrated only near the lower wall. The flow advects a portion of the applied wall heat horizontally, and the rest diffuses into the interior of the channel. We refer to this as leading thermal penetration, resulting in the bubbles and isotherms tilting along the flow direction.

$Re>20$) washes away even the lower bubbles, bringing the flow to a parallel form (figure 4d), with the titled isotherms concentrated only near the lower wall. The flow advects a portion of the applied wall heat horizontally, and the rest diffuses into the interior of the channel. We refer to this as leading thermal penetration, resulting in the bubbles and isotherms tilting along the flow direction.

Figure 4. Flow topology (line) and temperature (filled colour) field at ![]() $c=0$ with (a)

$c=0$ with (a) ![]() $Re=0$, (b)

$Re=0$, (b) ![]() $Re=1$, (c)

$Re=1$, (c) ![]() $Re=10$, (d)

$Re=10$, (d) ![]() $Re=20$ for

$Re=20$ for ![]() $Ra_{p,L}=1000$,

$Ra_{p,L}=1000$, ![]() $\alpha =2$,

$\alpha =2$, ![]() $Pr=0.71$. The grey dashed lines show the meandering flow stream. Arrows show the stream flow direction.

$Pr=0.71$. The grey dashed lines show the meandering flow stream. Arrows show the stream flow direction.

Response to the moving wave is illustrated in figure 5 for ![]() $Re=1$ flow. The flow topology remains qualitatively similar for larger

$Re=1$ flow. The flow topology remains qualitatively similar for larger ![]() $Re$ (not shown), with the bubbles decreasing in size. The use of low-velocity waves (

$Re$ (not shown), with the bubbles decreasing in size. The use of low-velocity waves (![]() $c=1$) directed along the flow direction results in an appearance of a rightward (i.e. towards flow direction) shift of the position of the bubbles (figure 5a), which is mainly due to the formation of a thicker stream tube carrying fluid to the right. The upper bubbles shift to the left and exhibit right tilting (figure 5b). Further increase of

$c=1$) directed along the flow direction results in an appearance of a rightward (i.e. towards flow direction) shift of the position of the bubbles (figure 5a), which is mainly due to the formation of a thicker stream tube carrying fluid to the right. The upper bubbles shift to the left and exhibit right tilting (figure 5b). Further increase of ![]() $c$ eventually eliminates the bubbles (figure 5c,d). The tilting is caused by delay associated with heat diffusion into the flow interior (the rightward wave movement is faster than the heat diffusion across the stream), i.e. thermal lagging. Reversing the wave's direction to opposite the flow (see figure 5e–h) has qualitatively similar effects on the bubbles’ sizes and their eventual elimination but causes rightward tilt, which increases with the wave velocity. One can note that thermal lagging causes tilting along flow direction when the wave travels leftward (

$c$ eventually eliminates the bubbles (figure 5c,d). The tilting is caused by delay associated with heat diffusion into the flow interior (the rightward wave movement is faster than the heat diffusion across the stream), i.e. thermal lagging. Reversing the wave's direction to opposite the flow (see figure 5e–h) has qualitatively similar effects on the bubbles’ sizes and their eventual elimination but causes rightward tilt, which increases with the wave velocity. One can note that thermal lagging causes tilting along flow direction when the wave travels leftward (![]() $c<0$). The rightward wave (

$c<0$). The rightward wave (![]() $c>0$) produces tilting in the direction opposite to the flow.

$c>0$) produces tilting in the direction opposite to the flow.

Figure 5. Flow topology (line) and temperature (filled colour) field at ![]() $Re=1$ with (a)

$Re=1$ with (a) ![]() $c=1$, (b)

$c=1$, (b) ![]() $c=10$, (c)

$c=10$, (c) ![]() $c=20$, (d)

$c=20$, (d) ![]() $c=70$, (e)

$c=70$, (e) ![]() $c=-1$, ( f)

$c=-1$, ( f) ![]() $c=-10$, (g)

$c=-10$, (g) ![]() $c=-20$ and (h)

$c=-20$ and (h) ![]() $c=-70$ for

$c=-70$ for ![]() $Ra_{p,L}=1000$,

$Ra_{p,L}=1000$, ![]() $\alpha =2$,

$\alpha =2$, ![]() $Pr=0.71$. The grey dashed lines show the meandering flow stream. Arrows show the stream flow direction.

$Pr=0.71$. The grey dashed lines show the meandering flow stream. Arrows show the stream flow direction.

The effects of ![]() $Re$ and

$Re$ and ![]() $c$ can be gleaned from figure 6, displaying variations of the correction factor

$c$ can be gleaned from figure 6, displaying variations of the correction factor ![]() $\varGamma _{cor}=Q_c/(\frac {4}{3}Re)$ defined in (2.8), as a function of

$\varGamma _{cor}=Q_c/(\frac {4}{3}Re)$ defined in (2.8), as a function of ![]() $Re$ and

$Re$ and ![]() $c$. Conditions leading to the reduction of flow losses are marked using grey colour. A characteristic, nearly straight line separates the resistance-reducing from the resistance-increasing waves. Conditions along this line identify the critical wave speed

$c$. Conditions leading to the reduction of flow losses are marked using grey colour. A characteristic, nearly straight line separates the resistance-reducing from the resistance-increasing waves. Conditions along this line identify the critical wave speed ![]() $c_n$ and the critical Reynolds number

$c_n$ and the critical Reynolds number ![]() $Re_n$, with

$Re_n$, with ![]() $c_n = 0.77 Re_n$, which results in zero flow rate correction

$c_n = 0.77 Re_n$, which results in zero flow rate correction ![]() $Q_c=0$. The countercurrent waves always reduce flow resistance. Their effectiveness is largest for small

$Q_c=0$. The countercurrent waves always reduce flow resistance. Their effectiveness is largest for small ![]() $Re$ where they can increase flow rate up to

$Re$ where they can increase flow rate up to ![]() ${\sim }20$ times compared with the reference isothermal flow. The cocurrent waves also reduce resistance, but such waves cannot be too fast as fast enough waves increase resistance. Such waves are less effective than countercurrent waves, providing only up to 20 % flow rate increase. These results demonstrate a potential for significantly reducing flow losses by waves with proper characteristics.

${\sim }20$ times compared with the reference isothermal flow. The cocurrent waves also reduce resistance, but such waves cannot be too fast as fast enough waves increase resistance. Such waves are less effective than countercurrent waves, providing only up to 20 % flow rate increase. These results demonstrate a potential for significantly reducing flow losses by waves with proper characteristics.

Figure 6. Variation of the correction factor ![]() $\varGamma _{cor}$ as a function of Reynolds number

$\varGamma _{cor}$ as a function of Reynolds number ![]() $Re$ and wave speed

$Re$ and wave speed ![]() $c$ for

$c$ for ![]() $\alpha =2$,

$\alpha =2$, ![]() $Ra_{p,L} =1000$,

$Ra_{p,L} =1000$, ![]() $Pr=0.71$. Grey shaded zone identifies conditions leading to flow rate increase with respect to the reference isothermal flow. The thick line illustrates variation of the critical Reynolds number

$Pr=0.71$. Grey shaded zone identifies conditions leading to flow rate increase with respect to the reference isothermal flow. The thick line illustrates variation of the critical Reynolds number ![]() $Re_n$ as a function of the critical wave velocity

$Re_n$ as a function of the critical wave velocity ![]() $c_n$, which can be approximated as

$c_n$, which can be approximated as ![]() $c_n = 0.77 Re_n$. Vertical (purple) and horizontal (blue) dotted lines identify conditions used in figures 9 and 10, respectively.

$c_n = 0.77 Re_n$. Vertical (purple) and horizontal (blue) dotted lines identify conditions used in figures 9 and 10, respectively.

We shall now discuss how waves affect flow structures. The introduction of waves activate three effects. The first one is the reduction of direct contact between the stream and the bounding walls, which reduces friction experienced by the stream. The second one involves additional propulsion generated by the bubbles’ rotation as the bubbles rotate in the stream direction, which is favourable to the flow. The third one is flow blockage by the bubbles (reduction of flow cross-sectional area), which increases flow losses. As ![]() $Re$ increases, bubbles are eventually washed away, eliminating the resistance-reducing effect. The net effect of waves on the flow rate can be determined by integrating the modal function

$Re$ increases, bubbles are eventually washed away, eliminating the resistance-reducing effect. The net effect of waves on the flow rate can be determined by integrating the modal function ![]() $u^{(0)}$ across the channel. Figure 7 illustrates the distribution of this function for a variety of conditions. A wave with critical velocity

$u^{(0)}$ across the channel. Figure 7 illustrates the distribution of this function for a variety of conditions. A wave with critical velocity ![]() $c_n=0.77$ produces modal function

$c_n=0.77$ produces modal function ![]() $u^{(0)}=0$ across the channel, thus no change in the flow rate. Other waves generally produce large flow rate changes in the upper portion of the channel and relatively smaller changes in the lower portion, so the upper portion determines the overall flow rate correction. Waves with

$u^{(0)}=0$ across the channel, thus no change in the flow rate. Other waves generally produce large flow rate changes in the upper portion of the channel and relatively smaller changes in the lower portion, so the upper portion determines the overall flow rate correction. Waves with ![]() $c< c_n$ (countercurrent waves and sufficiently slow cocurrent waves) produce a large flow rate increase in the upper portion of the channel and the overall flow rate increase, while sufficiently fast cocurrent waves produce large flow rate decrease in the upper portion and the overall flow rate decrease.

$c< c_n$ (countercurrent waves and sufficiently slow cocurrent waves) produce a large flow rate increase in the upper portion of the channel and the overall flow rate increase, while sufficiently fast cocurrent waves produce large flow rate decrease in the upper portion and the overall flow rate decrease.

Figure 7. Distribution of the modal function ![]() $u^{(0)}$ for selected values of

$u^{(0)}$ for selected values of ![]() $c$ at

$c$ at ![]() $Re = 1$,

$Re = 1$, ![]() $Ra_{p,L} = 1000$,

$Ra_{p,L} = 1000$, ![]() $\alpha = 2$,

$\alpha = 2$, ![]() $Pr = 0.71$.

$Pr = 0.71$.

Wave action changes wall shear, which may increase or decrease depending on the flow conditions and wave characteristics. Change in the shear is responsible for the change in the flow rate. Distributions of shear modifications for different wave velocities, propagation directions and flow Reynolds numbers are displayed in figures 8(a) and 8(b). The shear distribution is symmetric for waves with velocity ![]() $c_n$, producing a zero mean value. Waves with

$c_n$, producing a zero mean value. Waves with ![]() $c \ne c_n$ break this symmetry, producing a net shear force with the modifications equal and opposite in the lower and upper walls. Waves travelling opposite to the flow (

$c \ne c_n$ break this symmetry, producing a net shear force with the modifications equal and opposite in the lower and upper walls. Waves travelling opposite to the flow (![]() $c<0$) and sufficiently slow waves travelling in the flow direction (

$c<0$) and sufficiently slow waves travelling in the flow direction (![]() $c< c_n$) produce positive modification at the lower wall, whereas sufficiently fast waves travelling in the flow direction (

$c< c_n$) produce positive modification at the lower wall, whereas sufficiently fast waves travelling in the flow direction (![]() $c>c_n$) produce negative modifications. When mean shear at

$c>c_n$) produce negative modifications. When mean shear at ![]() $c=c_n$ is used as a reference point, an increase of

$c=c_n$ is used as a reference point, an increase of ![]() $|c-c_n|$ causes the magnitude of the average shear modification to initially increases, attains a maximum and then decrease with a further increase of

$|c-c_n|$ causes the magnitude of the average shear modification to initially increases, attains a maximum and then decrease with a further increase of ![]() $|c-c_n|$ (figure 8c). The decrease at large

$|c-c_n|$ (figure 8c). The decrease at large ![]() $|c|$ is proportionally to

$|c|$ is proportionally to ![]() $|c|^{-4}$ (see Appendix B for discussion on the asymptote).

$|c|^{-4}$ (see Appendix B for discussion on the asymptote).

Figure 8. Wall shear force modification ![]() $\tau _{mod}$ profiles and mean shear modifications

$\tau _{mod}$ profiles and mean shear modifications ![]() $\tau _{av}$ at the (a) lower and (b) upper wall for selected values of

$\tau _{av}$ at the (a) lower and (b) upper wall for selected values of ![]() $c$ at

$c$ at ![]() $Re = 1$,

$Re = 1$, ![]() $Ra_{p,L} = 1000$,

$Ra_{p,L} = 1000$, ![]() $\alpha = 2$,

$\alpha = 2$, ![]() $Pr = 0.71$. Subscripts

$Pr = 0.71$. Subscripts ![]() $L$ and

$L$ and ![]() $U$ denote the lower and upper wall, respectively. The dotted line shows shear for

$U$ denote the lower and upper wall, respectively. The dotted line shows shear for ![]() $c_n=0.77$. Panel (c) displays the average wall shear force modification at the lower wall and in this figure, solid and dashed lines show positive and negative values, respectively. Large

$c_n=0.77$. Panel (c) displays the average wall shear force modification at the lower wall and in this figure, solid and dashed lines show positive and negative values, respectively. Large ![]() $c$ asymptotes are shown by dotted lines.

$c$ asymptotes are shown by dotted lines.

Variations of the flow rate correction ![]() $Q_c$ as a function of

$Q_c$ as a function of ![]() $c$ are illustrated in detail in figure 9 for

$c$ are illustrated in detail in figure 9 for ![]() $Re=1$, 10, 20. The critical wave velocity for each

$Re=1$, 10, 20. The critical wave velocity for each ![]() $Re$ is

$Re$ is ![]() $c_n=0.77$, 7.7, 15.4, respectively;

$c_n=0.77$, 7.7, 15.4, respectively; ![]() $c< c_n$ provides positive flow rate correction, causing an overall decrease of flow resistance, but

$c< c_n$ provides positive flow rate correction, causing an overall decrease of flow resistance, but ![]() $c>c_n$ provides negative flow rate correction, causing the overall increase in flow resistance. When

$c>c_n$ provides negative flow rate correction, causing the overall increase in flow resistance. When ![]() $c$ either increases or decreases away from

$c$ either increases or decreases away from ![]() $c_n$, the flow rate correction exhibits a qualitatively similar response – its magnitude initially increases, attains a maximum and then gradually decreases, eventually becoming proportionally to

$c_n$, the flow rate correction exhibits a qualitatively similar response – its magnitude initially increases, attains a maximum and then gradually decreases, eventually becoming proportionally to ![]() $|c|^{-4}$.

$|c|^{-4}$.

Figure 9. Variation of the flow rate correction ![]() $Q_c$ as a function of wave speed

$Q_c$ as a function of wave speed ![]() $c$ for selected values of

$c$ for selected values of ![]() $Re$. Solid and dashed lines show positive and negative values, respectively. Large

$Re$. Solid and dashed lines show positive and negative values, respectively. Large ![]() $c$ asymptotes are shown by dotted lines. Flow conditions used in this figure are identified by purple dotted lines in figure 6.

$c$ asymptotes are shown by dotted lines. Flow conditions used in this figure are identified by purple dotted lines in figure 6.

Figure 10 illustrates in more detail how an increase of ![]() $Re$ affects

$Re$ affects ![]() $Q_c$. The selected curves corresponding to

$Q_c$. The selected curves corresponding to ![]() $c=0, \pm 0.1, \pm 2$ and

$c=0, \pm 0.1, \pm 2$ and ![]() $\pm 10$ illustrate how the flow response changes with the wave direction change and clearly identify the change from an increase of the flow rate to its decrease as

$\pm 10$ illustrate how the flow response changes with the wave direction change and clearly identify the change from an increase of the flow rate to its decrease as ![]() $Re$ increases. There are well-defined limits of

$Re$ increases. There are well-defined limits of ![]() $Q_c$ for

$Q_c$ for ![]() $Re\rightarrow 0$, which are positive for negative

$Re\rightarrow 0$, which are positive for negative ![]() $c$ and negative for positive

$c$ and negative for positive ![]() $c$, with

$c$, with ![]() $c=0$ representing the boundary between them characterized by

$c=0$ representing the boundary between them characterized by ![]() $Q_c \rightarrow 0$ with

$Q_c \rightarrow 0$ with ![]() $Re \rightarrow 0$. The case of

$Re \rightarrow 0$. The case of ![]() $Re=0$ corresponds to the pumping problem studied in Hossain & Floryan (Reference Hossain and Floryan2023) and briefly reviewed in § 5.1. It is interesting to note that in the case of

$Re=0$ corresponds to the pumping problem studied in Hossain & Floryan (Reference Hossain and Floryan2023) and briefly reviewed in § 5.1. It is interesting to note that in the case of ![]() $c=0$,

$c=0$, ![]() $Q_c$ initially increases proportionally to

$Q_c$ initially increases proportionally to ![]() $Re$, attains a maximum and then decreases with the further increase of

$Re$, attains a maximum and then decreases with the further increase of ![]() $Re$ proportionally to

$Re$ proportionally to ![]() $Re ^ {-2.5}$. Countercurrent waves produce

$Re ^ {-2.5}$. Countercurrent waves produce ![]() $Q_c$ changing marginally with

$Q_c$ changing marginally with ![]() $Re$ until

$Re$ until ![]() $Re$ becomes large enough to cause a decrease proportional to

$Re$ becomes large enough to cause a decrease proportional to ![]() $Re ^ { -2.5}$. The behaviour of cocurrent waves is qualitatively similar if one considers

$Re ^ { -2.5}$. The behaviour of cocurrent waves is qualitatively similar if one considers ![]() $|Q_c|$, i.e. there is a well-defined limit for small

$|Q_c|$, i.e. there is a well-defined limit for small ![]() $Re$ and well-defined behaviour for large

$Re$ and well-defined behaviour for large ![]() $Re$, except in the neighbourhood of

$Re$, except in the neighbourhood of ![]() $Re=Re_n$ where

$Re=Re_n$ where ![]() $Q_c$ passes through zero. A countercurrent wave, a wave travelling opposite the flow (

$Q_c$ passes through zero. A countercurrent wave, a wave travelling opposite the flow (![]() $c < 0$), always provides

$c < 0$), always provides ![]() $Q_c > 0$. The cocurrent wave, a wave travelling along the flow (

$Q_c > 0$. The cocurrent wave, a wave travelling along the flow (![]() $c > 0$), increases flow losses if

$c > 0$), increases flow losses if ![]() $Re< Re_n$ and decreases flow losses when

$Re< Re_n$ and decreases flow losses when ![]() $Re>Re_n$. One, of course, needs to remember that a flow that is too fast (

$Re>Re_n$. One, of course, needs to remember that a flow that is too fast (![]() $Re$ too big) washes away bubbles, and the flow resistance loses any dependence on the thermal waves.

$Re$ too big) washes away bubbles, and the flow resistance loses any dependence on the thermal waves.

Figure 10. Variation of the flow rate correction ![]() $Q_c$ as a function of Reynolds number

$Q_c$ as a function of Reynolds number ![]() $Re$ for selected values of

$Re$ for selected values of ![]() $c$. Solid and dashed lines show positive and negative values, respectively. Small and large

$c$. Solid and dashed lines show positive and negative values, respectively. Small and large ![]() $Re$ asymptotes are shown by dotted lines. Flow conditions used in this figure are identified by blue dotted lines in figure 6.

$Re$ asymptotes are shown by dotted lines. Flow conditions used in this figure are identified by blue dotted lines in figure 6.

Effects of a wave's wavelength are illustrated in figure 11. As the wavenumber increases, the countercurrent waves reduce resistance (![]() $Q_c >0$) proportionally to

$Q_c >0$) proportionally to ![]() ${\sim }\alpha ^4$, the resistance reduction attains a maximum and then decreases proportionally to

${\sim }\alpha ^4$, the resistance reduction attains a maximum and then decreases proportionally to ![]() ${\sim }\alpha ^{-6}$ (details of the analysis are given in § 6). Cocurrent waves exhibit a similar trend but with a notable difference. They reduce resistance (

${\sim }\alpha ^{-6}$ (details of the analysis are given in § 6). Cocurrent waves exhibit a similar trend but with a notable difference. They reduce resistance (![]() $Q_c>0$) if they are sufficiently slow and increase resistance if they are fast enough. An estimate of the critical velocity

$Q_c>0$) if they are sufficiently slow and increase resistance if they are fast enough. An estimate of the critical velocity ![]() $c_n$ can be obtained from analytical solutions for large and small

$c_n$ can be obtained from analytical solutions for large and small ![]() $\alpha$, i.e.

$\alpha$, i.e.

Figure 11. Variation of the flow rate correction ![]() $Q_c$ as a function of wave wavenumber

$Q_c$ as a function of wave wavenumber ![]() $\alpha$ for selected values of

$\alpha$ for selected values of ![]() $c$ at

$c$ at ![]() $Ra_{p,L}$ =1000,

$Ra_{p,L}$ =1000, ![]() $Re=1$,

$Re=1$, ![]() $Pr=0.71$. Solid and dashed lines show positive and negative, respectively. Large and small

$Pr=0.71$. Solid and dashed lines show positive and negative, respectively. Large and small ![]() $\alpha$ asymptotes are shown by dotted lines.

$\alpha$ asymptotes are shown by dotted lines.

Variations of ![]() $\varGamma _{cor}$ as a function of

$\varGamma _{cor}$ as a function of ![]() $c$ and

$c$ and ![]() $\alpha$ displayed in figure 12 permit a quick identification of the most effective waves. Waves with

$\alpha$ displayed in figure 12 permit a quick identification of the most effective waves. Waves with ![]() $\alpha \approx 2$ and

$\alpha \approx 2$ and ![]() $c \in [-2, -3]$ produce the largest resistance reduction, and waves with

$c \in [-2, -3]$ produce the largest resistance reduction, and waves with ![]() $\alpha \approx 2$ and

$\alpha \approx 2$ and ![]() $c \in [3, 5]$ produce the largest resistance increase. The maximum resistance reduction occurs for

$c \in [3, 5]$ produce the largest resistance increase. The maximum resistance reduction occurs for ![]() $\alpha = \alpha _{max} \approx 2$ with

$\alpha = \alpha _{max} \approx 2$ with ![]() $\alpha _{max}$ decreases marginally with

$\alpha _{max}$ decreases marginally with ![]() $c$. The reader may note that the critical wave velocity

$c$. The reader may note that the critical wave velocity ![]() $c_n$ varies marginally as a function of

$c_n$ varies marginally as a function of ![]() $\alpha$.

$\alpha$.

Figure 12. Variation of the correction factor ![]() $\varGamma _{cor}$ as functions of wave wavenumber

$\varGamma _{cor}$ as functions of wave wavenumber ![]() $\alpha$ and wave speed

$\alpha$ and wave speed ![]() $c$ for

$c$ for ![]() $Re=1$,

$Re=1$, ![]() $Ra_{p,L}=1000$,

$Ra_{p,L}=1000$, ![]() $Pr=0.71$. Grey shaded zone identifies conditions leading to an increase of the flow rate above the flow rate in the reference isothermal channel.

$Pr=0.71$. Grey shaded zone identifies conditions leading to an increase of the flow rate above the flow rate in the reference isothermal channel.

Results displayed in figure 13 demonstrate that the magnitude of change of resistance initially increases proportionally to ![]() ${\sim }Ra_{p,L}^2$ . This growth slows down for

${\sim }Ra_{p,L}^2$ . This growth slows down for ![]() $Ra_{p,L}> \sim 2000$ due to saturation effects, which suggests that excessively large heating is not beneficial. Also, the results of stability analysis discussed in § 7 suggest a possible transition to secondary states for excessively large wave amplitudes.

$Ra_{p,L}> \sim 2000$ due to saturation effects, which suggests that excessively large heating is not beneficial. Also, the results of stability analysis discussed in § 7 suggest a possible transition to secondary states for excessively large wave amplitudes.

Figure 13. Variation of the flow rate correction ![]() $Q_c$ as a function of wave intensity

$Q_c$ as a function of wave intensity ![]() $Ra_{p,L}$ for selected values of

$Ra_{p,L}$ for selected values of ![]() $c$ at

$c$ at ![]() $\alpha =2$,

$\alpha =2$, ![]() $Re=1$,

$Re=1$, ![]() $Pr=0.71$. Solid and dashed lines show positive and negative values, respectively. Small

$Pr=0.71$. Solid and dashed lines show positive and negative values, respectively. Small ![]() $Ra_{p,L}$ asymptote is shown by dotted lines.

$Ra_{p,L}$ asymptote is shown by dotted lines.

One may wish to ascertain the effectiveness of a moving thermal wave over a stationary heating pattern. Figure 14 displays variations of the stationary gain factor ![]() $\varGamma _s$, defined as

$\varGamma _s$, defined as

with ![]() $Q_c|_{c=0}$ denoting the flow rate correction when

$Q_c|_{c=0}$ denoting the flow rate correction when ![]() $c=0$. Positive values of

$c=0$. Positive values of ![]() $\varGamma _s$ correspond to the moving wave being more effective. Variation of the critical wave velocity

$\varGamma _s$ correspond to the moving wave being more effective. Variation of the critical wave velocity ![]() $c_n=0.77Re$ in figure 14(a,c) corresponds to

$c_n=0.77Re$ in figure 14(a,c) corresponds to ![]() $\varGamma _s=-1$, with

$\varGamma _s=-1$, with ![]() $c_n$ varying marginally with

$c_n$ varying marginally with ![]() $\alpha$ shown in figure 14(b,d). In general, countercurrent waves are more effective (as high as

$\alpha$ shown in figure 14(b,d). In general, countercurrent waves are more effective (as high as ![]() ${\sim }100$ fold) for small

${\sim }100$ fold) for small ![]() $Re$ while cocurrent waves are more effective for larger

$Re$ while cocurrent waves are more effective for larger ![]() $Re$ (figure 14a,c). Use of

$Re$ (figure 14a,c). Use of ![]() $\alpha = 4$–

$\alpha = 4$–![]() $5$ provides the best improvement achieve by the waves (figure 14b,d).

$5$ provides the best improvement achieve by the waves (figure 14b,d).

Figure 14. Variation of the stationary gain factor ![]() $\varGamma _{s}$ as functions of (a,c)

$\varGamma _{s}$ as functions of (a,c) ![]() $Re$ and

$Re$ and ![]() $c$ at

$c$ at ![]() $\alpha =2$ (b,d)

$\alpha =2$ (b,d) ![]() $\alpha$ and

$\alpha$ and ![]() $c$ at

$c$ at ![]() $Re=1$, for

$Re=1$, for ![]() $Ra_{p,L}=1000$,

$Ra_{p,L}=1000$, ![]() $Pr=0.71$. Grey shaded zone denotes flow rate increase over the stationary heating pattern. In (a,c), the line

$Pr=0.71$. Grey shaded zone denotes flow rate increase over the stationary heating pattern. In (a,c), the line ![]() $\varGamma _{s}=-1$ represents

$\varGamma _{s}=-1$ represents ![]() $c_n = 0.77 Re$. In (b,d), the line

$c_n = 0.77 Re$. In (b,d), the line ![]() $\varGamma _{s}=-1$ represents

$\varGamma _{s}=-1$ represents ![]() $c_n$.

$c_n$.

In the next section, we analyse the mechanisms driving the flow response.

6. Mechanism governing the flow response

The mechanisms governing flow response are discussed with the help of analytic solutions, which can be obtained in special limits. We start with the small amplitude waves.

6.1. Small amplitude wave

We introduce a small parameter ![]() $\epsilon \ll 1$ which measures the wave amplitude. The flow quantities are assumed to be asymptotic power series of

$\epsilon \ll 1$ which measures the wave amplitude. The flow quantities are assumed to be asymptotic power series of ![]() $\epsilon$ as

$\epsilon$ as

Substitution of (6.1) into (3.1) leads to a system of ![]() $O(\epsilon )$ in the form

$O(\epsilon )$ in the form

and a system of ![]() $O(\epsilon ^2)$ in the form

$O(\epsilon ^2)$ in the form

which is subject to homogeneous boundary conditions and a constraint associated with constant mean-pressure-gradient.

We start with the solution of (6.2c) for the temperature ![]() $\varTheta _1$ which is subject to the forcing (6.2f–g) leading to assume a solution in the form

$\varTheta _1$ which is subject to the forcing (6.2f–g) leading to assume a solution in the form

and energy equation (6.2c) takes the form

Equations (6.2a,b) are reduced to a single equation of the form

where ![]() $\varPsi _1$ denotes the stream function with

$\varPsi _1$ denotes the stream function with ![]() $U_1 = {\partial \varPsi _1 }/{\partial y}$ and

$U_1 = {\partial \varPsi _1 }/{\partial y}$ and ![]() $V_1 = -{\partial \varPsi _1 }/{\partial x}$. The character of the forcing on the right-hand side of (6.6) suggests a solution in the form

$V_1 = -{\partial \varPsi _1 }/{\partial x}$. The character of the forcing on the right-hand side of (6.6) suggests a solution in the form

Substitution of (6.4) and (6.7) into (6.6) leads to

\begin{align} &D ^4 \varPsi_1 ^{(1)} - ({\rm i} \alpha Re u_0-{\rm i} \alpha c +2 \alpha ^2) D^2 \varPsi_1 ^{(1)} +({\rm i} \alpha ^3 Re u_0 + {\rm i} \alpha Re D^2 u_0 -{\rm i} \alpha ^3 c+\alpha ^4 ) \varPsi_1 ^{(1)}\nonumber\\ &\quad ={\rm i} \alpha Pr^{{-}1}\varTheta_1 ^{(1)}, \end{align}

\begin{align} &D ^4 \varPsi_1 ^{(1)} - ({\rm i} \alpha Re u_0-{\rm i} \alpha c +2 \alpha ^2) D^2 \varPsi_1 ^{(1)} +({\rm i} \alpha ^3 Re u_0 + {\rm i} \alpha Re D^2 u_0 -{\rm i} \alpha ^3 c+\alpha ^4 ) \varPsi_1 ^{(1)}\nonumber\\ &\quad ={\rm i} \alpha Pr^{{-}1}\varTheta_1 ^{(1)}, \end{align}

In the above, we assume the right-hand side as ![]() $F_1 =\textrm {i}\alpha Pr^{-1} \varTheta _1 ^{(1)}$ which is the

$F_1 =\textrm {i}\alpha Pr^{-1} \varTheta _1 ^{(1)}$ which is the ![]() $x$-component of the gradient of buoyancy force and acts as a flow forcing. The velocity components have the form

$x$-component of the gradient of buoyancy force and acts as a flow forcing. The velocity components have the form

with ![]() $U_1 ^{(1)} = D \varPsi _1 ^{(1)}$ and

$U_1 ^{(1)} = D \varPsi _1 ^{(1)}$ and ![]() $V_1 ^{(1)} = -\textrm {i} \alpha \varPsi _1 ^{(1)}$. Analysis of

$V_1 ^{(1)} = -\textrm {i} \alpha \varPsi _1 ^{(1)}$. Analysis of ![]() $O(\epsilon ^2)$ equations shows that the unknowns can be represented as

$O(\epsilon ^2)$ equations shows that the unknowns can be represented as

It is easy to show that ![]() $V_2 ^{(0)}=0$. Substitution of (6.9) and (6.10) into (6.3a) and extraction of the zero modal function combined with the enforcement of the mean-pressure gradient constraint lead to the following flow problem:

$V_2 ^{(0)}=0$. Substitution of (6.9) and (6.10) into (6.3a) and extraction of the zero modal function combined with the enforcement of the mean-pressure gradient constraint lead to the following flow problem:

Double integration of (6.11a,b) yields

where

and leads to evaluate the flow rate correction ![]() $Q_c$ as

$Q_c$ as

In the above, ![]() $g(y)$ represents the Reynolds stress created by the buoyancy-induced motion resulting from effect of the thermal wave, and its sign dictates whether

$g(y)$ represents the Reynolds stress created by the buoyancy-induced motion resulting from effect of the thermal wave, and its sign dictates whether ![]() $Q_c$ is positive or negative. Numerical solution of (6.5) and (6.8) have been carried out using the collocation method as described in § 3, and integrations present in (6.12) and (6.13) have been performed with an accuracy of fourth-order.

$Q_c$ is positive or negative. Numerical solution of (6.5) and (6.8) have been carried out using the collocation method as described in § 3, and integrations present in (6.12) and (6.13) have been performed with an accuracy of fourth-order.

Solution of ![]() $\varTheta _1 ^{(1)}$ reveals that the modal functions are purely real in the absence of wave motion or the external flow, but the presence of wave movement or external flow causes this modal function to become complex. Hence the imaginary part, shown in figure 15(a), has two components: wave-induced correction and flow-induced correction. Both corrections contribute to the driving force

$\varTheta _1 ^{(1)}$ reveals that the modal functions are purely real in the absence of wave motion or the external flow, but the presence of wave movement or external flow causes this modal function to become complex. Hence the imaginary part, shown in figure 15(a), has two components: wave-induced correction and flow-induced correction. Both corrections contribute to the driving force ![]() $F_1$ (see (6.8)) with the flow-induced correction always assisting the bulk flow whereas the wave-induced correction assists for the wave moving opposite to the flow direction (countercurrent wave) and opposes for the wave moving in the flow direction(cocurrent wave) if the wave velocity exceeds certain threshold. The complex modal function

$F_1$ (see (6.8)) with the flow-induced correction always assisting the bulk flow whereas the wave-induced correction assists for the wave moving opposite to the flow direction (countercurrent wave) and opposes for the wave moving in the flow direction(cocurrent wave) if the wave velocity exceeds certain threshold. The complex modal function ![]() $\varTheta _1 ^{(1)}$ produces a phase shift

$\varTheta _1 ^{(1)}$ produces a phase shift ![]() $\varPhi$ with respect to the wave imposed at the lower plate and is shown in figure 15(b). The interplay of wave-induced and flow-induced corrections creates either a negative phase shift causing the net horizontal flow rate to increase (overall resistance reduction in the channel) or a positive phase shift causing the net flow rate to decrease (overall resistance increase in the channel). The phase shift

$\varPhi$ with respect to the wave imposed at the lower plate and is shown in figure 15(b). The interplay of wave-induced and flow-induced corrections creates either a negative phase shift causing the net horizontal flow rate to increase (overall resistance reduction in the channel) or a positive phase shift causing the net flow rate to decrease (overall resistance increase in the channel). The phase shift ![]() $\varPhi =0$ produces

$\varPhi =0$ produces ![]() $Q_c =0$.

$Q_c =0$.

Figure 15. (a) Distributions of the imaginary ![]() $\varTheta _i ^{(1)}$ parts of the temperature modal function

$\varTheta _i ^{(1)}$ parts of the temperature modal function ![]() $\varTheta _1 ^{(1)}$, (b) the phase shift

$\varTheta _1 ^{(1)}$, (b) the phase shift ![]() $\varPhi$ of

$\varPhi$ of ![]() $\varTheta _1 ^{(1)}$ with respect to the wave at the lower plate and (c) distribution of the Reynolds stress

$\varTheta _1 ^{(1)}$ with respect to the wave at the lower plate and (c) distribution of the Reynolds stress ![]() $g(y)$ for

$g(y)$ for ![]() $\alpha =2$,

$\alpha =2$, ![]() $Ra_{p,L}=200$,

$Ra_{p,L}=200$, ![]() $Pr=0.71$. In (c), solid, dashed and dotted lines represent

$Pr=0.71$. In (c), solid, dashed and dotted lines represent ![]() $Re=1$ with wave velocity (

$Re=1$ with wave velocity (![]() $c\ne 0$),

$c\ne 0$), ![]() $Re=1$ with stationary wave (

$Re=1$ with stationary wave (![]() $c=0$), and

$c=0$), and ![]() $Re=0$ with wave velocity (

$Re=0$ with wave velocity (![]() $c\ne 0$), respectively, and the grey shaded zone denotes flow rate increase over the stationary wave limit.

$c\ne 0$), respectively, and the grey shaded zone denotes flow rate increase over the stationary wave limit.

Next, we look into the Reynolds stress developed due to the interaction of the convective flow modifications generated from the thermal waves acting on the lower wall (see figure 15c). A stationary wave as well as a countercurrent wave generate positive Reynolds stress causing the resistance reduction in the channel, but a cocurrent wave (higher than the threshold) creates negative Reynolds stress causing the resistance increase in the channel. Increase or decrease of resistance reduction over the stationary wave limit is dictated by the increase or decrease of the Reynolds stress compared with the Reynolds stress developed by the stationary wave, as depicted by the grey colour in figure 15(c).

Furthermore, small amplitude waves, i.e. ![]() $\epsilon = Ra_{p,L} \rightarrow 0$, reveal that the velocity components

$\epsilon = Ra_{p,L} \rightarrow 0$, reveal that the velocity components ![]() $U_1 ^{(1)}$ and

$U_1 ^{(1)}$ and ![]() $V_1 ^{(1)}$ present in the Reynolds stress

$V_1 ^{(1)}$ present in the Reynolds stress ![]() $g(y)$ are proportional to

$g(y)$ are proportional to ![]() $Ra_{p,L}$. Hence, the flow rate correction

$Ra_{p,L}$. Hence, the flow rate correction ![]() $Q_c$ varies proportionally to

$Q_c$ varies proportionally to ![]() $Ra ^2_{p,L}$, as shown in figure 13.

$Ra ^2_{p,L}$, as shown in figure 13.

Next, we focus our attention to a weak flow with ![]() $Re \rightarrow 0$.

$Re \rightarrow 0$.

6.2. Weak flow

We assume ![]() $Re$ is small but finite, and represent the solutions of (3.1) as

$Re$ is small but finite, and represent the solutions of (3.1) as

Substitution of (6.14) into (3.1) results in the following leading-order systems: for ![]() $O(1)$ we have

$O(1)$ we have

which describes the system that produces a pumping effect by thermal waves with a net horizontal flow rate ![]() $Q_{00} = \int _{-1} ^{+1} U_0 \,{\textrm {d}y}$ (Hossain & Floryan Reference Hossain and Floryan2023); for

$Q_{00} = \int _{-1} ^{+1} U_0 \,{\textrm {d}y}$ (Hossain & Floryan Reference Hossain and Floryan2023); for ![]() $O(Re)$ we have

$O(Re)$ we have

where ![]() $u_0=1-y^2$ is the reference isothermal flow whose effects are evident in the right-hand side of (6.16a–c) and acts as a forcing function which certainly provides a non-zero