1 Introduction

The various approaches for cavitation modelling differ mainly in the treatment of the vapour phase. While Euler–Euler methods assume that liquid and vapour phases are continua, Euler–Lagrange methods consider the vapour phase to be an accumulation of discrete individual bubbles, where only the liquid phase is a continuum. For the continuous phase approach (Euler–Euler), we distinguish between density-based and projection methods. Capturing the phase transition in Euler–Euler methods requires special techniques. Most researchers use a volume of fluid method, where a volume fraction describes the percentage of a phase volume in one control volume. Projection methods solve an additional transport equation for the volume fraction and model vaporisation and condensation using source terms. Simplified cavitation models based on single-bubble dynamics (Rayleigh–Plesset equation) compute these source terms, where vaporisation and condensation depend on the ambient pressure in a control volume. The most common models follow Merkle, Feng & Buelow (Reference Merkle, Feng and Buelow1998), Kunz et al. (Reference Kunz, Boger, Stinebring, Chyczewski, Lindau, Gibeling, Venkateswaran and Govindan2000), Sauer & Schnerr (Reference Sauer and Schnerr2000), Singhal et al. (Reference Singhal, Athavale, Li and Jiang2002) and Zwart, Gerber & Belamri (Reference Zwart, Gerber and Belamri2004).

Euler–Lagrange methods employ a Lagrangian coordinate system to describe the motion of individual cavitation bubbles, which are transported by a continuous liquid background flow. Contrary to Euler–Euler methods, Euler–Lagrange methods consider external forces on the bubble, e.g. forces owing to drag, pressure gradient, volume variation, shear, lift and buoyancy. This leads to relative velocities between the bubbles and the liquid phase and may, therein, cause bubble trajectories to deviate from streamlines of the flow. Equations of bubble dynamics model growth and collapse of every single bubble, see Rayleigh (Reference Rayleigh1917), Plesset (Reference Plesset1949), Tomita & Shima (Reference Tomita and Shima1977) and Hsiao, Chahine & Liu (Reference Hsiao, Chahine and Liu2000). The multiple forces depend on pressure, bubble wall acceleration, surface tension, viscosity and relative velocity between a bubble and the carrier fluid.

Hsiao et al. (Reference Hsiao, Chahine and Liu2000) and Hsiao, Chahine & Liu (Reference Hsiao, Chahine and Liu2003) utilised Lagrangian methods to treat the vapour phase of cavitating flows. Abdel-Maksoud, Hänel & Lantermann (Reference Abdel-Maksoud, Hänel and Lantermann2010) developed a coupled Euler–Lagrange method to calculate cavitating flows. For the flow around a hydrofoil, they compared bubble trajectories and carrier flow streamlines. Their Lagrangian treatment allowed determining of the motion of bubbles relative to the carrier fluid flow. At the outer edge of the foil they examined, these motions deviated significantly from the carrier fluid flow. Yakubov et al. (Reference Yakubov, Cankurt, Maquil, Schiller, Abdel-Maksoud and Rung2011) compared numerical simulations of cavitating flows around a hydrofoil and a propeller using Euler–Euler and Euler–Lagrange approaches. They found a strong dependence of the Euler–Euler simulation on model constants. Using a measured distribution of nuclei, their Euler–Lagrange simulation allowed accounting for water quality effects. Yakubov et al. (Reference Yakubov, Cankurt, Abdel-Maksoud and Rung2013) extended this approach for parallel computing. Ma, Hsiao & Chahine (Reference Ma, Hsiao and Chahine2015a) used an Euler–Lagrange approach to simulate the dynamics of a cavitation cloud consisting of single spherical bubbles. They considered the influence of the liquid phase on the bubbles using a two-way coupled approach. Ma, Hsiao & Chahine (Reference Ma, Hsiao and Chahine2015b) enhanced this approach for parallel simulations.

Pure Euler–Euler approaches to simulate cavitating flows have shown to be efficient and accurate for a wide range of technical flow problems. Disadvantages lie in the prediction of the microscopic cavitation processes of single bubbles. Specifically, to obtain quantitative assessments of cavitation erosion (incubation period, erosion pitting rates, mass loss rates) it is necessary to incorporate the behaviour of single bubbles as they collapse. With Euler–Euler methods the growth and collapse of multiple single bubbles and their motions can only be captured using an extremely fine spatial discretisation. However, the required computational effort is high and, therefore, the microscopic bubble behaviour is usually neglected.

Abdel-Maksoud et al. (Reference Abdel-Maksoud, Hänel and Lantermann2010) showed that, for technical applications, bubble traces may differ significantly from streamlines of the carrier fluid. This is especially true when high pressure and velocity gradients or vortex-induced flows are present. In addition, the predicted cavitation with an Euler–Euler method may show a diffusive behaviour. In the computational domain, this prevents the transport of small amounts of vapour volume fractions and leads to unrealistic results. In this regard, the Euler–Lagrange approach is more accurate because the single bubbles do not vanish owing to an initial non-condensable gas content. However, the computational effort needed to conduct Euler–Lagrange simulations is substantially higher than for Euler–Euler simulations.

To benefit from the efficiency of the Eulerian treatment for the vapour phase and to increase the accuracy of simulating the behaviour of individual single bubbles using a Lagrangian approach, both methods have recently been combined using hybrid multi-scale methods. Depending on the absolute size of a vapour volume and its size relative to the numerical grid, these methods switch between Eulerian and Lagrangian approaches. Accordingly, the dynamics and motions of spherical single bubbles are simulated for small vapour structures, such as collapsing bubbles. Vallier (Reference Vallier2013) developed a multi-scale approach to transform vapour volumes between Eulerian and Lagrangian frames. Using this approach, the author simulated the break up of a cavitation sheet and the cavitation structures on a hydrofoil. Hsiao, Ma & Chahine (Reference Hsiao, Ma and Chahine2017) developed a similar approach to capture the formation of sheet cavitation and shedding of cloud cavitation on a hydrofoil. They used a wall nucleation approach to enable the unsteady shedding of cloud cavitation. Their results agreed favourably with published experimental measurements of sheet cavitation lengths and shedding frequencies. Hsiao, Ma & Chahine (Reference Hsiao, Ma and Chahine2015) used a similar multi-phase approach to simulate sheet and tip vortex cavitation on a three-bladed propeller for three different advance coefficients. They showed that a reduction of the advance coefficient resulted in the extension of sheet cavitation towards the leading edge and the development of tip vortex cavitation caused by single cavitation bubbles merging into a macroscopic cavity. Following their work, Ma, Hsiao & Chahine (Reference Ma, Hsiao and Chahine2017) presented a multi-scale approach to simulate cavitating flow in a waterjet propulsion nozzle, bubbly flow in a line vortex, unsteady sheet cavitation on a hydrofoil and cavitation behind a blunt body. Lidtke (Reference Lidtke2017) used a fully parallel, multi-scale approach to simulate the flow around a hydrofoil to investigate cavitation noise. In contrast to a purely Eulerian approach, the simulation of Lagrangian bubble dynamics enabled the calculation of medium to high frequency pressure fluctuations induced by cavitation. Ghahramani, Arabnejad & Bensow (Reference Ghahramani, Arabnejad and Bensow2018) developed a multi-scale model similar to Vallier (Reference Vallier2013), wherein larger cavities are considered in the Eulerian framework while smaller cavities are treated as Lagrangian bubbles. Although, in contrast to other approaches discussed above (Vallier Reference Vallier2013; Lidtke Reference Lidtke2017; Ma et al. Reference Ma, Hsiao and Chahine2017) their approach transforms small vapour clouds into multiple Lagrangian bubbles and, based on the Eulerian vapour volume fraction, a Lagrangian bubble is introduced into each control volume of a small cavity.

Near-wall collapsing macroscopic cavitation structures, which are accumulations of single cavitation bubbles, cause cavitation-induced erosion. Potentially, these near-wall bubble collapses generate high wall pressures and may cause surface damage, which has been extensively studied both experimentally and numerically. Specifically, collapses of single laser-induced bubbles in undisturbed fields, acoustic fields and near solid boundaries were experimentally studied by Lauterborn & Bolle (Reference Lauterborn and Bolle1975), Vogel & Lauterborn (Reference Vogel and Lauterborn1988), Noack & Vogel (Reference Noack and Vogel1998), Philipp & Lauterborn (Reference Philipp and Lauterborn1998), Brujan et al. (Reference Brujan, Keen, Vogel and Blake2002), Lauterborn & Kurz (Reference Lauterborn and Kurz2010), Lauterborn & Vogel (Reference Lauterborn and Vogel2013), Reuter & Mettin (Reference Reuter and Mettin2016), Reuter, Cairós & Mettin (Reference Reuter, Cairós and Mettin2016), Supponen et al. (Reference Supponen, Obreschkow, Tinguely, Kobel, Dorsaz and Farhat2016), Dular et al. (Reference Dular, Požar, Zevnik and Petkovšek2019), Sagar et al. (Reference Sagar, Hanke, Underberg, Feng, el Moctar and Kaiser2018), Sagar (Reference Sagar2018) and Sagar & el Moctar (Reference Sagar and el Moctar2020). Numerical simulations of near-wall single bubble collapses were conducted by Johnsen & Colonius (Reference Johnsen and Colonius2008, Reference Johnsen and Colonius2009), Osterman, Dular & Širok (Reference Osterman, Dular and Širok2009), Hawker & Ventikos (Reference Hawker and Ventikos2012), Lauer et al. (Reference Lauer, Hu, Hickel and Adams2012), Chahine & Hsiao (Reference Chahine and Hsiao2015), Pöhl et al. (Reference Pöhl, Mottyll, Skoda and Huth2015), Koch et al. (Reference Koch, Lechner, Reuter, Köhler, Mettin and Lauterborn2016), Goncalves et al. (Reference Goncalves, Zeidan, Goncalves and Zeidan2017) and Hadlabdaoui et al. (Reference Hadlabdaoui, Parnaudeau, Goncalves and Zeidan2019).

Over the past years, several researchers have developed numerical approaches to assess cavitation erosion. These approaches rely on different assumptions of the physical processes involved and use various numerical techniques to simulate cavitation behaviour. Assuming that the collapse of cloud cavitation is the main cause of cavitation erosion, Li (Reference Li2012) developed a numerical model using the time derivative of pressure on a surface to indicate erosion risk. When a threshold of the time derivative of pressure is exceeded on a given surface, this region is identified with a high risk of erosion. However, the threshold value must be calibrated for each flow problem. Furthermore, the Euler–Euler method does not allow accurate predictions of the bubble behaviour and collapse-induced pressures in a cloud of bubbles or in regions close to a solid surface. Krumenacker, Fortes-Patella & Archer (Reference Krumenacker, Fortes-Patella and Archer2014) developed a numerical method that determines the cavitation intensity as an indicator for erosion risk when cloud-like cavitation areas collapse. In their method, the flow is simulated using an Euler–Euler approach and a Reynolds-averaged Navier–Stokes (RANS) method coupled with a solver to compute the acoustic energy of single bubbles from a bubble dynamics equation. Accumulation of the acoustic energy of all collapsing single bubbles then yields the cavitation intensity on a given surface. Accounting for bubble dynamics in the erosion model improves the assessment of erosion. Mottyll (Reference Mottyll2017) used a density-based solver to simulate cavitation and evaluated erosion using a collapse detection approach. The author assumes that aggressive types of cavitation are related to collapsing cavitation volumes in the vicinity of solid walls. The model was applied to an axisymmetric nozzle and an ultrasonic horn and obtained qualitatively favourable agreement. When a single cavitation bubble collapses near a solid surface, the collapse is asymmetric causing a high-speed waterjet to flow through the vapour-filled bubble. Dular, Stoffel & Širok (Reference Dular, Stoffel and Širok2006) and Dular & Coutier-Delgosha (Reference Dular and Coutier-Delgosha2009) developed a numerical erosion model by assuming that this microjet is the main cause of erosion leading to circular pits. For a foil in two-dimensional flow the quality of their erosion assessments compared favourably to experiments. Peters, Lantermann & el Moctar (Reference Peters, Lantermann and el Moctar2015a), Peters et al. (Reference Peters, Sagar, Lantermann and el Moctar2015b) expanded the models of Dular et al. (Reference Dular, Stoffel and Širok2006) and Dular & Coutier-Delgosha (Reference Dular and Coutier-Delgosha2009) and validated their results against experiments for a three-dimensional flow case. The qualitative assessment of erosion considered both number and intensity of microjet impacts on an area. Peters, Lantermann & el Moctar (Reference Peters, Lantermann and el Moctar2018) used a similar erosion model to estimate cavitation erosion for a model propeller. Although their erosion assessments agreed with experimental erosion predictions for different flow problems, we found that an Euler–Euler approach provides only a qualitative estimation of erosion. For a more accurate assessment of erosion caused by collapsing cavitation bubbles near a solid surface, detailed insight into the transport and the dynamics of bubbles is needed.

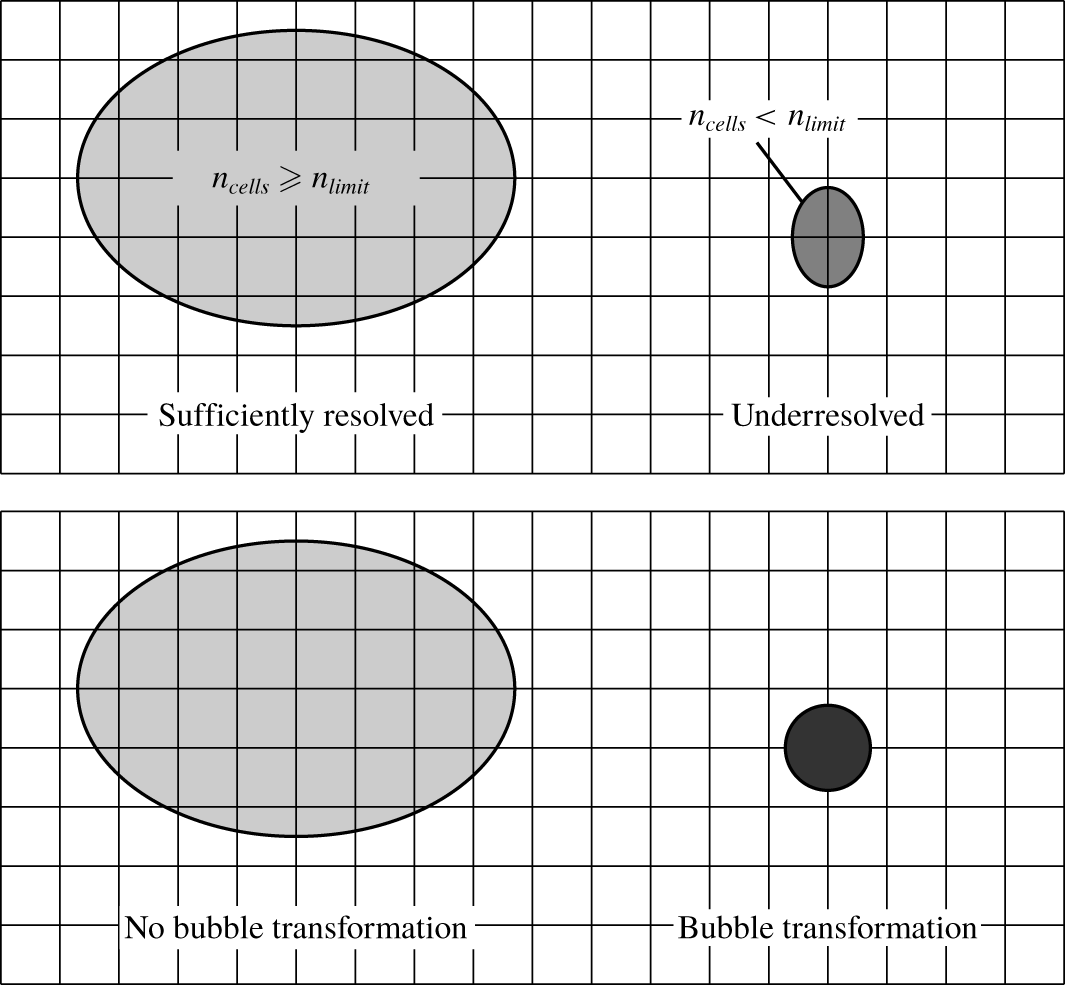

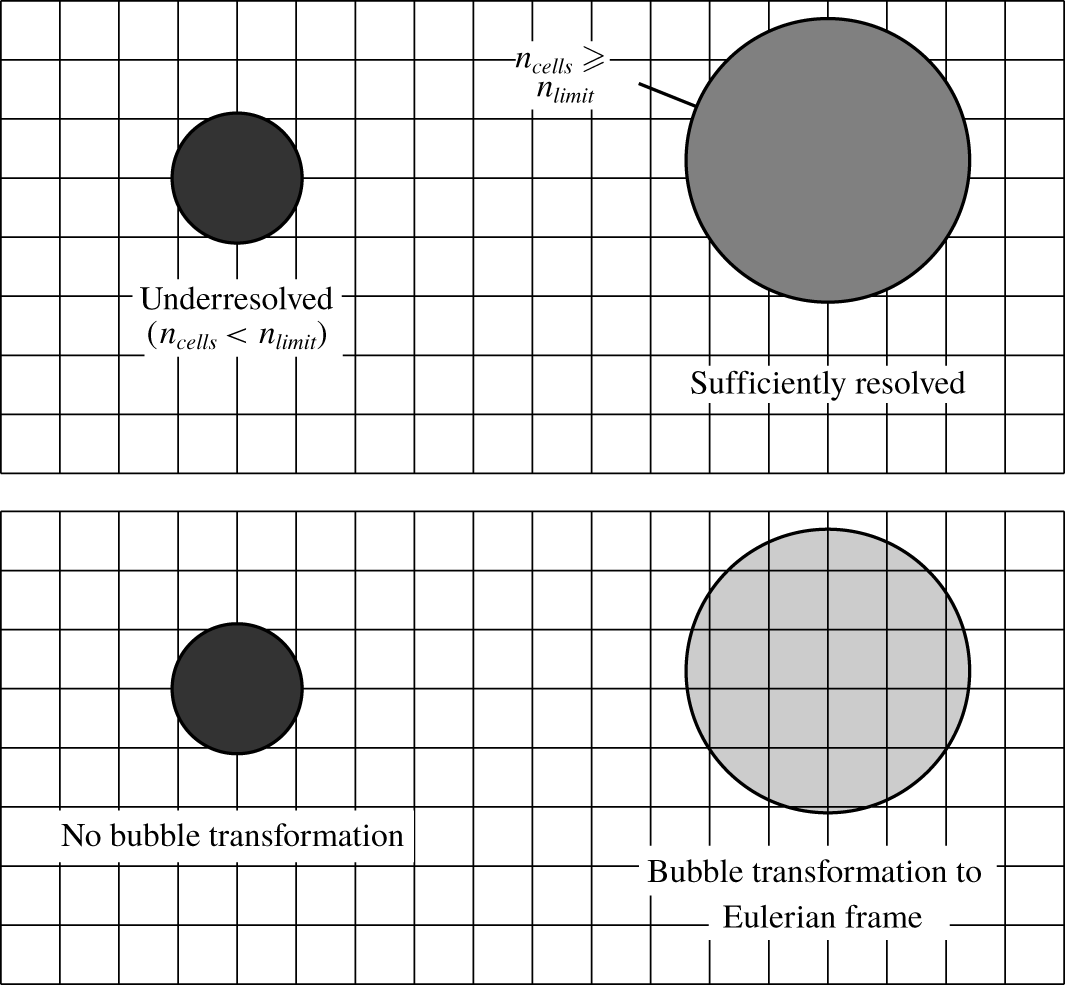

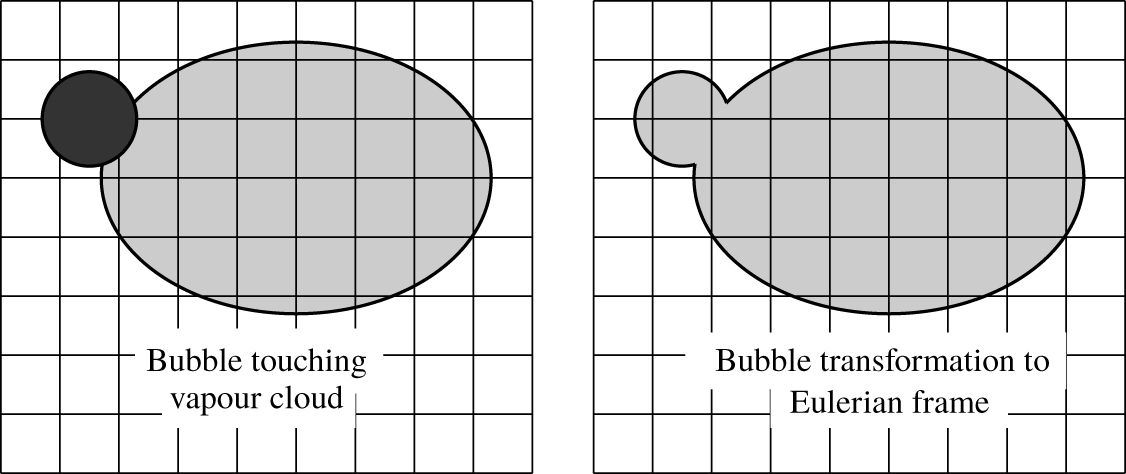

The existing approaches and models to simulate cavitating flows and to assess erosion led us to develop a method that couples an Euler–Euler method with an Euler–Lagrange method. Based on existing libraries, we implemented the new method into the open source computational fluid dynamics (CFD) software package OpenFOAM (OpenFOAM Foundation 2018) that combines the Lagrangian tracking of bubbles with a finite volume method flow solver. Our approach enabled a more accurate assessment of erosion and the potential to assess damage rates. The computation of transport and dynamics of spherical single bubbles provided greater insight into bubble behaviour. Depending on their absolute size and spatial resolution relative to the numerical grid, our multi-scale approach switched between an Eulerian and a Lagrangian treatment of vapour structures. Accordingly, Eulerian vapour volumes were transformed into Lagrangian bubbles when the vapour volumes were isolated and sufficiently small. Motions and dynamics of spherical Lagrangian bubbles were solved individually. Lagrangian bubbles that increased above a certain size or that were sufficiently resolved by the numerical grid were transformed into Eulerian vapour volumes. The assessment of cavitation erosion was based on the information about collapses of Lagrangian bubbles near a solid surface. A comparison of spherical bubble collapses and pit erosion presented here provided insights for a quantitative estimate of erosion by correlating spherical bubble collapses with experimentally measured erosion pits.

Our numerical methods for continuous flows and for Lagrangian bubbles include a procedure to transform vapour volumes between the Eulerian and the Lagrangian frames. Based on nuclei measurements, a distribution of the initial gas content in Lagrangian bubbles is derived. An erosion model based on an Eulerian treatment of the vapour phase is described, and a new erosion model based on Lagrangian bubble collapses is developed. Our multi-scale approach links the macroscopic Eulerian treatment of large vapour structures to the microscopic Lagrangian treatment of single cavitation bubbles and uses the bubble collapses to assess cavitation-induced erosion. After verifying and validating our bubble dynamics model for different cases, we performed verification and sensitivity studies related to the procedures to transform vapour volumes between these frames. The cavitating flow through an axisymmetric nozzle was simulated, and numerically evaluated cavitation-induced erosion was compared to measured erosion depths.

2 Multi-scale approach to assess cavitation erosion

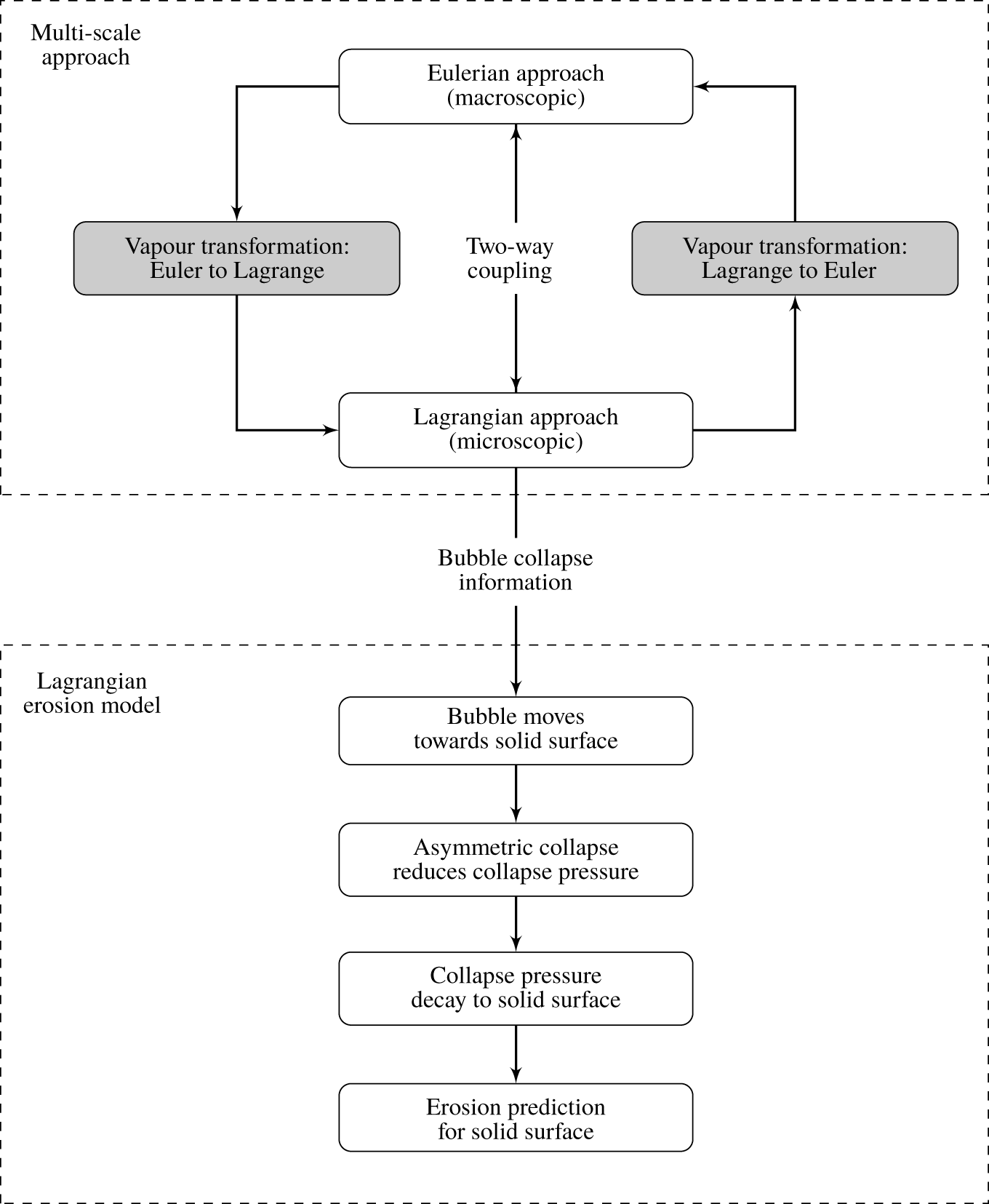

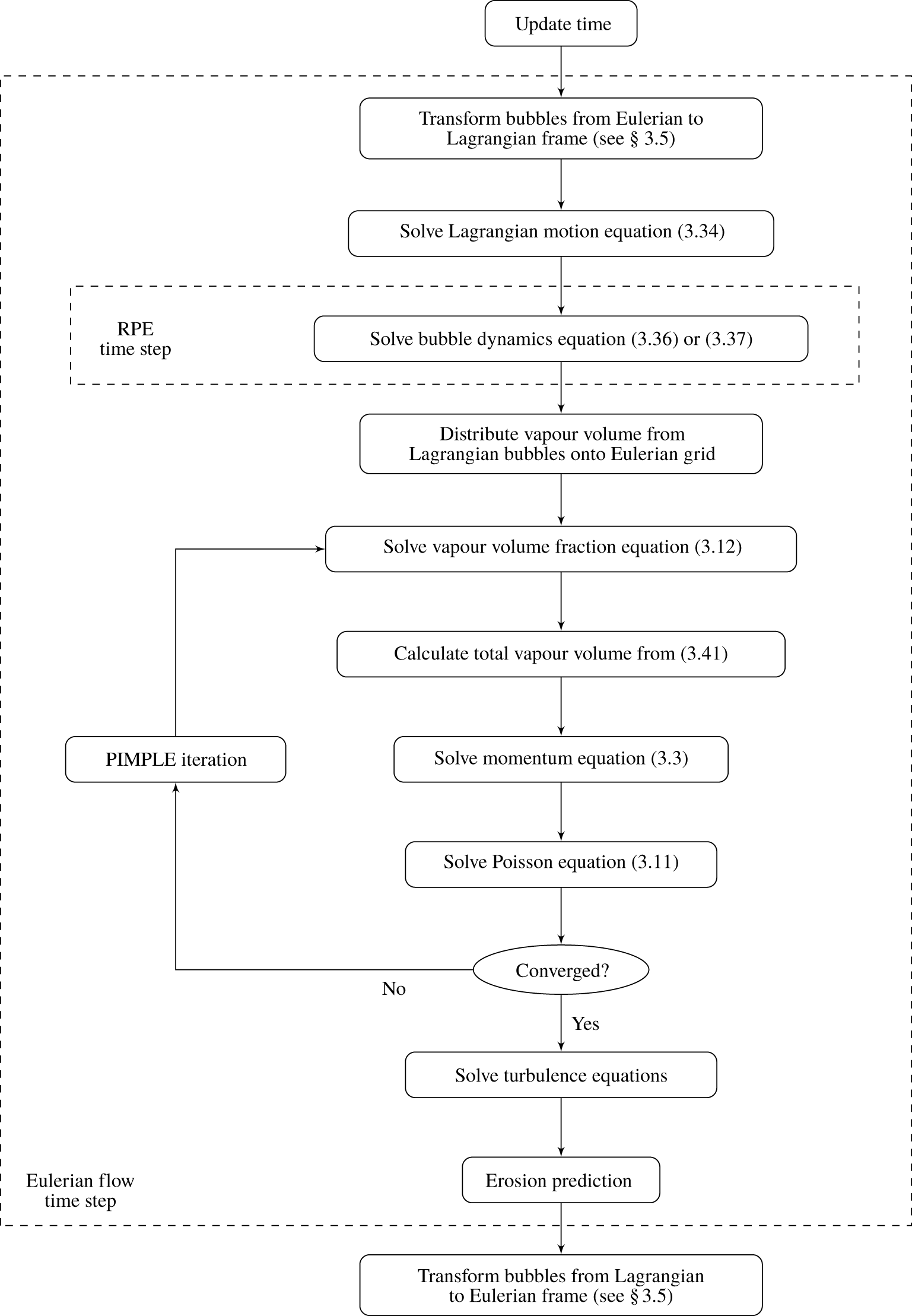

Figure 1. Schematic of the coupling of the multi-scale method with the Lagrangian erosion model.

This section summarises our approach based on a multi-scale treatment of cavitation structures and a model to assess erosion from Lagrangian bubble collapses. Figure 1 schematically depicts the multi-scale method to simulate cavitation and its coupling with the Lagrangian erosion model. The multi-scale method treats the liquid phase as a continuum in the Eulerian frame, but uses different approaches for vapour volumes. Large vapour structures are treated also in the Eulerian frame, while small vapour volumes are considered as spherical Lagrangian bubbles, whose motions and associated bubble dynamics are calculated on a local coordinate system. While fully conserving the volume of vapour, vapour structures are transformed between the Eulerian and the Lagrangian frame and vice versa when they fall below or exceed a defined absolute size or the size relative to the numerical grid. Lagrangian bubbles interact with the continuous liquid phase via a two-way coupling scheme that accounts for influences of the liquid phase on the Lagrangian bubbles and contrariwise. Information from Lagrangian bubble collapses near solid surfaces (e.g. pressures, positions, radii) serve to estimate erosion. Resolving shock wave radiation for asymmetric bubble collapses in a macroscopic flow simulation was almost impossible because, at this moment, the computational effort would have been too high. Therefore, we chose to model the physics involved in an asymmetric near-wall bubble collapse based on well-recognised fundamental experiments and theoretical considerations. The erosion model accounts for various phenomena during an asymmetric bubble collapse, such as (i) the motion of the bubble’s centre towards the solid surface, (ii) the reduced collapse pressure attributed to the non-spherical collapse and (iii) the pressure decay of the shock wave that travels towards the solid surface.

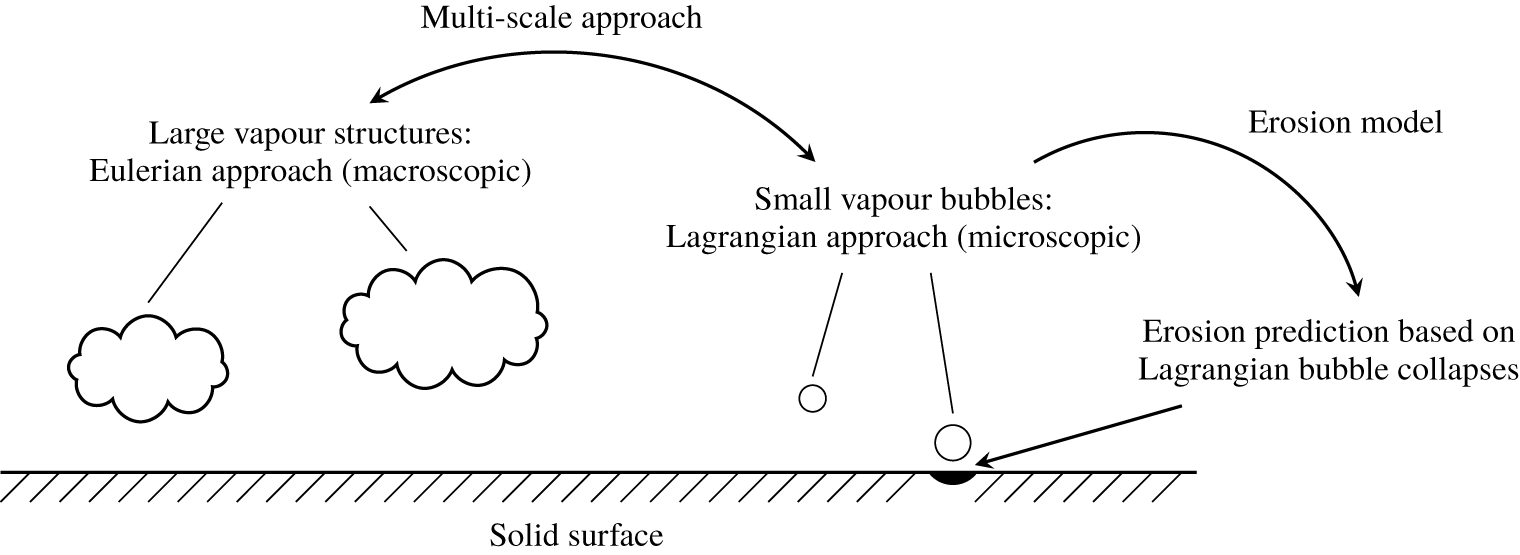

Figure 2 sketches the approaches used for the different physical phenomena involved in the process of cavitation erosion. The multi-scale method creates a link between large vapour structures that are treated in the Eulerian frame and small Lagrangian vapour bubbles. The erosion model links the dynamics of single Lagrangian bubbles near a solid surface to the assessment of erosion and accounts for various phenomena involved in an asymmetric near-wall bubble collapse.

Figure 2. Sketch of approaches used for various cavitation regimes and for erosion evaluation.

3 Numerical method

Cavitation of macroscopic vapour structures is simulated using an Euler–Euler approach that considers the liquid and vapour phases as continua. Microscopic vapour structures are treated as single Lagrangian bubbles transported by the continuous carrier fluid flow. Numerical approaches for Eulerian and Lagrangian approaches are given in the following.

3.1 Continuous Eulerian phases

A homogeneous mixture approach simulates the macroscopic cavitating flow on an Eulerian grid. Substance properties of liquid and vapour phases vary according to the volume fraction of each phase in the mixture. The vapour volume fraction is defined as  $\unicode[STIX]{x1D6FC}_{v}=V_{v}/V$ with the volume of vapour,

$\unicode[STIX]{x1D6FC}_{v}=V_{v}/V$ with the volume of vapour,  $V_{v}$, in a certain control volume,

$V_{v}$, in a certain control volume,  $V$. For a two phase flow, the liquid volume fraction is defined as

$V$. For a two phase flow, the liquid volume fraction is defined as  $\unicode[STIX]{x1D6FC}_{l}=1-\unicode[STIX]{x1D6FC}_{v}$. Using the volume fraction variables, the density,

$\unicode[STIX]{x1D6FC}_{l}=1-\unicode[STIX]{x1D6FC}_{v}$. Using the volume fraction variables, the density,  $\unicode[STIX]{x1D70C}$, and viscosity,

$\unicode[STIX]{x1D70C}$, and viscosity,  $\unicode[STIX]{x1D707}$, of the mixture can be calculated

$\unicode[STIX]{x1D707}$, of the mixture can be calculated

$$\begin{eqnarray}\unicode[STIX]{x1D70C}=\unicode[STIX]{x1D6FC}_{v}\unicode[STIX]{x1D70C}_{v}+(1-\unicode[STIX]{x1D6FC}_{v})\unicode[STIX]{x1D70C}_{l},\quad \unicode[STIX]{x1D707}=\unicode[STIX]{x1D6FC}_{v}\unicode[STIX]{x1D707}_{v}+(1-\unicode[STIX]{x1D6FC}_{v})\unicode[STIX]{x1D707}_{l}.\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D70C}=\unicode[STIX]{x1D6FC}_{v}\unicode[STIX]{x1D70C}_{v}+(1-\unicode[STIX]{x1D6FC}_{v})\unicode[STIX]{x1D70C}_{l},\quad \unicode[STIX]{x1D707}=\unicode[STIX]{x1D6FC}_{v}\unicode[STIX]{x1D707}_{v}+(1-\unicode[STIX]{x1D6FC}_{v})\unicode[STIX]{x1D707}_{l}.\end{eqnarray}$$ Indices ‘ $v$’ denote properties of the vapour phase; indices ‘

$v$’ denote properties of the vapour phase; indices ‘ $l$’, properties of the liquid phase. Properties of the mixture are then used to calculate the flow properties for the mixture fluid.

$l$’, properties of the liquid phase. Properties of the mixture are then used to calculate the flow properties for the mixture fluid.

The continuous flow of the homogeneous mixture is calculated based on the mass conservation equation and the Navier–Stokes equations for an isothermal fluid consisting of the equations of conservation of momentum. The equations for the present finite volume method are written in integral form. The mass conservation equation yields

$$\begin{eqnarray}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}t}\int _{V}\unicode[STIX]{x1D70C}\,\text{d}V+\int _{S}\unicode[STIX]{x1D70C}\boldsymbol{u}\boldsymbol{\cdot }\text{d}\boldsymbol{S}=0,\end{eqnarray}$$

$$\begin{eqnarray}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}t}\int _{V}\unicode[STIX]{x1D70C}\,\text{d}V+\int _{S}\unicode[STIX]{x1D70C}\boldsymbol{u}\boldsymbol{\cdot }\text{d}\boldsymbol{S}=0,\end{eqnarray}$$ where  $t$ is time,

$t$ is time,  $V$ is the volume of a control volume,

$V$ is the volume of a control volume,  $\boldsymbol{S}$ is the surface area vector of a control volume’s surface and

$\boldsymbol{S}$ is the surface area vector of a control volume’s surface and  $\boldsymbol{u}$ is the flow velocity of the mixture. The velocity is calculated from the momentum equation

$\boldsymbol{u}$ is the flow velocity of the mixture. The velocity is calculated from the momentum equation

$$\begin{eqnarray}\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}t}\int _{V}\unicode[STIX]{x1D70C}\boldsymbol{u}\,\text{d}V+\int _{S}\unicode[STIX]{x1D70C}\boldsymbol{u}\boldsymbol{u}\boldsymbol{\cdot }\text{d}\boldsymbol{S} & = & \displaystyle \int _{S}\unicode[STIX]{x1D707}(\unicode[STIX]{x1D735}\boldsymbol{u}+(\unicode[STIX]{x1D735}\boldsymbol{u})^{\text{T}})\boldsymbol{\cdot }\text{d}\boldsymbol{S}-\int _{S}\left(p-\frac{2}{3}\unicode[STIX]{x1D735}\boldsymbol{\cdot }\unicode[STIX]{x1D707}\right)\unicode[STIX]{x1D644}\boldsymbol{\cdot }\text{d}\boldsymbol{S}\nonumber\\ \displaystyle & & \displaystyle +\,\int _{V}\unicode[STIX]{x1D70C}\boldsymbol{b}\,\text{d}V+\int _{V}\unicode[STIX]{x1D70E}\unicode[STIX]{x1D705}\unicode[STIX]{x1D735}\unicode[STIX]{x1D6FC}\,\text{d}V+\int _{V}\boldsymbol{s}_{b}\,\text{d}V,\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}t}\int _{V}\unicode[STIX]{x1D70C}\boldsymbol{u}\,\text{d}V+\int _{S}\unicode[STIX]{x1D70C}\boldsymbol{u}\boldsymbol{u}\boldsymbol{\cdot }\text{d}\boldsymbol{S} & = & \displaystyle \int _{S}\unicode[STIX]{x1D707}(\unicode[STIX]{x1D735}\boldsymbol{u}+(\unicode[STIX]{x1D735}\boldsymbol{u})^{\text{T}})\boldsymbol{\cdot }\text{d}\boldsymbol{S}-\int _{S}\left(p-\frac{2}{3}\unicode[STIX]{x1D735}\boldsymbol{\cdot }\unicode[STIX]{x1D707}\right)\unicode[STIX]{x1D644}\boldsymbol{\cdot }\text{d}\boldsymbol{S}\nonumber\\ \displaystyle & & \displaystyle +\,\int _{V}\unicode[STIX]{x1D70C}\boldsymbol{b}\,\text{d}V+\int _{V}\unicode[STIX]{x1D70E}\unicode[STIX]{x1D705}\unicode[STIX]{x1D735}\unicode[STIX]{x1D6FC}\,\text{d}V+\int _{V}\boldsymbol{s}_{b}\,\text{d}V,\end{eqnarray}$$ where  $\unicode[STIX]{x1D707}$ is viscosity of the mixture,

$\unicode[STIX]{x1D707}$ is viscosity of the mixture,  $p$ is pressure and

$p$ is pressure and  $\unicode[STIX]{x1D644}$ is the identity matrix. The left-hand side comprises the time derivative of momentum and the convection term. The first two terms on the right-hand side represent diffusion and pressure, respectively. Symbol

$\unicode[STIX]{x1D644}$ is the identity matrix. The left-hand side comprises the time derivative of momentum and the convection term. The first two terms on the right-hand side represent diffusion and pressure, respectively. Symbol  $\boldsymbol{b}$ stands for sources of volume forces caused by gravity or Coriolis effects. The last term on the right-hand side contains the source term originating from Lagrangian bubbles entering a control volume,

$\boldsymbol{b}$ stands for sources of volume forces caused by gravity or Coriolis effects. The last term on the right-hand side contains the source term originating from Lagrangian bubbles entering a control volume,  $\boldsymbol{s}_{b}$. The second to last term on the right-hand side accounts for forces owing to surface tension,

$\boldsymbol{s}_{b}$. The second to last term on the right-hand side accounts for forces owing to surface tension,  $\unicode[STIX]{x1D70E}$, between liquid and vapour phases treated in the Eulerian framework, where

$\unicode[STIX]{x1D70E}$, between liquid and vapour phases treated in the Eulerian framework, where  $\unicode[STIX]{x1D705}$ is the curvature of the interface. As surface tension acts directly at the interface between the two phases, it cannot explicitly be applied in interface capturing methods, where the interface is smeared over multiple control volumes. We used the continuum surface model, introduced by Brackbill, Kothe & Zemach (Reference Brackbill, Kothe and Zemach1992), to calculate the surface tension force as a volume force acting on the control volume. The curvature of the interface is defined as follows:

$\unicode[STIX]{x1D705}$ is the curvature of the interface. As surface tension acts directly at the interface between the two phases, it cannot explicitly be applied in interface capturing methods, where the interface is smeared over multiple control volumes. We used the continuum surface model, introduced by Brackbill, Kothe & Zemach (Reference Brackbill, Kothe and Zemach1992), to calculate the surface tension force as a volume force acting on the control volume. The curvature of the interface is defined as follows:

$$\begin{eqnarray}\unicode[STIX]{x1D705}=-\unicode[STIX]{x1D735}\boldsymbol{\cdot }\frac{\unicode[STIX]{x1D735}\unicode[STIX]{x1D6FC}}{|\unicode[STIX]{x1D735}\unicode[STIX]{x1D6FC}|},\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D705}=-\unicode[STIX]{x1D735}\boldsymbol{\cdot }\frac{\unicode[STIX]{x1D735}\unicode[STIX]{x1D6FC}}{|\unicode[STIX]{x1D735}\unicode[STIX]{x1D6FC}|},\end{eqnarray}$$ where the gradient of the volume fraction,  $\unicode[STIX]{x1D735}\unicode[STIX]{x1D6FC}$, points into the normal direction of the interface. Surface tension vanishes in control volumes occupying only one phase (

$\unicode[STIX]{x1D735}\unicode[STIX]{x1D6FC}$, points into the normal direction of the interface. Surface tension vanishes in control volumes occupying only one phase ( $\unicode[STIX]{x1D735}\unicode[STIX]{x1D6FC}=0$).

$\unicode[STIX]{x1D735}\unicode[STIX]{x1D6FC}=0$).

The system of equations contains the momentum equation to calculate velocities. The continuity equation does not serve for the calculation of pressure because it does not contain the pressure. To close this system of equations, an additional equation for the pressure is derived. First, the mass conservation equation is rearranged. Using Gauss’ theorem to convert a surface integral into a volume integral and letting the arbitrary volume become zero, equation (3.2) is written in differential form. Following Shams, Finn & Apte (Reference Shams, Finn and Apte2010) and rearranging terms leads to the following expression:

$$\begin{eqnarray}\unicode[STIX]{x1D735}\boldsymbol{\cdot }\boldsymbol{u}=-\frac{1}{\unicode[STIX]{x1D70C}}\frac{\text{d}\unicode[STIX]{x1D70C}}{\text{d}t}.\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D735}\boldsymbol{\cdot }\boldsymbol{u}=-\frac{1}{\unicode[STIX]{x1D70C}}\frac{\text{d}\unicode[STIX]{x1D70C}}{\text{d}t}.\end{eqnarray}$$For an incompressible isothermal single phase flow, the density along the path of a fluid particle does not change. This leads to a divergence free velocity field, causing the term on the right-hand side of (3.5) to vanish. However, for cavitating flows, the changing density of the moving free surface and the vaporisation and condensation processes must be considered. The density varies and, therefore, the velocity field diverges. Integrating over a control volume and applying Gauss’ theorem yields the following integral equation:

$$\begin{eqnarray}\int _{S}\boldsymbol{u}\boldsymbol{\cdot }\text{d}\boldsymbol{S}=-\int _{V}\frac{1}{\unicode[STIX]{x1D70C}}\frac{\text{d}\unicode[STIX]{x1D70C}}{\text{d}t}\,\text{d}V.\end{eqnarray}$$

$$\begin{eqnarray}\int _{S}\boldsymbol{u}\boldsymbol{\cdot }\text{d}\boldsymbol{S}=-\int _{V}\frac{1}{\unicode[STIX]{x1D70C}}\frac{\text{d}\unicode[STIX]{x1D70C}}{\text{d}t}\,\text{d}V.\end{eqnarray}$$The partially discretised form of the momentum equation according to Jasak (Reference Jasak1996) is used to obtain the equation containing the pressure

$$\begin{eqnarray}a_{P}\boldsymbol{u}_{P}=-\mathop{\sum }_{N}a_{N}\boldsymbol{u}_{N}+\boldsymbol{S}_{u}(\boldsymbol{x},t)+\unicode[STIX]{x1D735}p=\boldsymbol{H}(\boldsymbol{u})-\unicode[STIX]{x1D735}p,\end{eqnarray}$$

$$\begin{eqnarray}a_{P}\boldsymbol{u}_{P}=-\mathop{\sum }_{N}a_{N}\boldsymbol{u}_{N}+\boldsymbol{S}_{u}(\boldsymbol{x},t)+\unicode[STIX]{x1D735}p=\boldsymbol{H}(\boldsymbol{u})-\unicode[STIX]{x1D735}p,\end{eqnarray}$$ where  $a$ are matrix coefficients for the linear system of equations. Indices

$a$ are matrix coefficients for the linear system of equations. Indices  $P$ and

$P$ and  $N$ identify the considered control volume (cell) and the neighbouring control volumes, respectively, and

$N$ identify the considered control volume (cell) and the neighbouring control volumes, respectively, and  $\boldsymbol{S}_{u}$ is a known source vector for all cells. Accordingly,

$\boldsymbol{S}_{u}$ is a known source vector for all cells. Accordingly,  $\boldsymbol{H}(\boldsymbol{u})$ contains the velocity terms from neighbouring cells,

$\boldsymbol{H}(\boldsymbol{u})$ contains the velocity terms from neighbouring cells,  $(-\sum _{N}a_{N}\boldsymbol{u}_{N})$, including all source terms which do not depend on pressure,

$(-\sum _{N}a_{N}\boldsymbol{u}_{N})$, including all source terms which do not depend on pressure,  $\boldsymbol{S}_{u}$. Dividing (3.7) by

$\boldsymbol{S}_{u}$. Dividing (3.7) by  $a_{P}$ yields the following relationship:

$a_{P}$ yields the following relationship:

$$\begin{eqnarray}\boldsymbol{u}_{P}=\frac{\boldsymbol{H}(\boldsymbol{u})}{a_{P}}-\frac{\unicode[STIX]{x1D735}p}{a_{P}}.\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{u}_{P}=\frac{\boldsymbol{H}(\boldsymbol{u})}{a_{P}}-\frac{\unicode[STIX]{x1D735}p}{a_{P}}.\end{eqnarray}$$ Substituting (3.8) into (3.5) for cell index  $P$ we obtain the Poisson equation

$P$ we obtain the Poisson equation

$$\begin{eqnarray}\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\boldsymbol{H}(\boldsymbol{u})}{a_{P}}\right)-\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\unicode[STIX]{x1D735}p}{a_{P}}\right)=-\frac{1}{\unicode[STIX]{x1D70C}}\frac{\text{d}\unicode[STIX]{x1D70C}}{\text{d}t}.\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\boldsymbol{H}(\boldsymbol{u})}{a_{P}}\right)-\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\unicode[STIX]{x1D735}p}{a_{P}}\right)=-\frac{1}{\unicode[STIX]{x1D70C}}\frac{\text{d}\unicode[STIX]{x1D70C}}{\text{d}t}.\end{eqnarray}$$ The term on the right-hand side vanishes only in regions where no vaporisation and condensation or transport of a free surface take place. According to Sauer (Reference Sauer2000), the right-hand side can be expressed using source terms from the cavitation model for vaporisation,  $S_{pv}$, and condensation,

$S_{pv}$, and condensation,  $S_{pc}$, multiplied by the pressure difference between local fluid pressure,

$S_{pc}$, multiplied by the pressure difference between local fluid pressure,  $p$, and vapour pressure,

$p$, and vapour pressure,  $p_{v}$, as follows:

$p_{v}$, as follows:

$$\begin{eqnarray}\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\boldsymbol{H}(\boldsymbol{u})}{a_{P}}\right)-\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\unicode[STIX]{x1D735}p}{a_{P}}\right)=(S_{p,c}-S_{p,v})(p-p_{v}).\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\boldsymbol{H}(\boldsymbol{u})}{a_{P}}\right)-\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\unicode[STIX]{x1D735}p}{a_{P}}\right)=(S_{p,c}-S_{p,v})(p-p_{v}).\end{eqnarray}$$ We separate the hydrostatic part from the absolute pressure, where  $p_{rgh}=p-\unicode[STIX]{x1D70C}g_{z}h$.

$p_{rgh}=p-\unicode[STIX]{x1D70C}g_{z}h$.  $g_{z}$ is the vertical component of the vector of gravitational acceleration, and

$g_{z}$ is the vertical component of the vector of gravitational acceleration, and  $h$ is the height of the water column. Separating the hydrostatic part from the absolute pressure enables us to treat implicitly all terms proportional to

$h$ is the height of the water column. Separating the hydrostatic part from the absolute pressure enables us to treat implicitly all terms proportional to  $p_{rgh}$. After rearranging terms in (3.10) and separating the pressures, the pressure equation is written as follows:

$p_{rgh}$. After rearranging terms in (3.10) and separating the pressures, the pressure equation is written as follows:

$$\begin{eqnarray}\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\unicode[STIX]{x1D735}p_{rgh}}{a_{P}}\right)+(S_{p,c}-S_{p,v})p_{rgh}=\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\boldsymbol{H}(\boldsymbol{u})}{a_{P}}\right)+(S_{p,c}-S_{p,v})(p_{v}-\unicode[STIX]{x1D70C}g_{z}h).\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\unicode[STIX]{x1D735}p_{rgh}}{a_{P}}\right)+(S_{p,c}-S_{p,v})p_{rgh}=\unicode[STIX]{x1D735}\boldsymbol{\cdot }\left(\frac{\boldsymbol{H}(\boldsymbol{u})}{a_{P}}\right)+(S_{p,c}-S_{p,v})(p_{v}-\unicode[STIX]{x1D70C}g_{z}h).\end{eqnarray}$$ Terms on the left-hand side are treated implicitly; terms on the right-hand side, explicitly. Substituting the temporal derivative of density in (3.9) by terms proportional to  $p_{rgh}$ increases the stability of the equation. The source terms on the right-hand side are treated explicitly and have to be calculated in advance. These source terms depend on space and time and are obtained from a cavitation model representing the processes of vaporisation (‘

$p_{rgh}$ increases the stability of the equation. The source terms on the right-hand side are treated explicitly and have to be calculated in advance. These source terms depend on space and time and are obtained from a cavitation model representing the processes of vaporisation (‘ $v$’) and condensation (‘

$v$’) and condensation (‘ $c$’). Applying the cavitation model of Sauer & Schnerr (Reference Sauer and Schnerr2000) that assumes both continuous phases to be incompressible we obtain the volume of vapour in a considered control volume via the solution of a scalar transport equation

$c$’). Applying the cavitation model of Sauer & Schnerr (Reference Sauer and Schnerr2000) that assumes both continuous phases to be incompressible we obtain the volume of vapour in a considered control volume via the solution of a scalar transport equation

$$\begin{eqnarray}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}t}\int _{V}\unicode[STIX]{x1D6FC}_{v}\,\text{d}V+\int _{S}\unicode[STIX]{x1D6FC}_{v}\boldsymbol{u}\boldsymbol{\cdot }\text{d}\boldsymbol{S}=\int _{V}(S_{v}-S_{c})\,\text{d}V.\end{eqnarray}$$

$$\begin{eqnarray}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}t}\int _{V}\unicode[STIX]{x1D6FC}_{v}\,\text{d}V+\int _{S}\unicode[STIX]{x1D6FC}_{v}\boldsymbol{u}\boldsymbol{\cdot }\text{d}\boldsymbol{S}=\int _{V}(S_{v}-S_{c})\,\text{d}V.\end{eqnarray}$$ Derivation of the cavitation source terms,  $S_{v}$ and

$S_{v}$ and  $S_{c}$, on the right-hand side is based on a simplified Rayleigh–Plesset equation, which defines the velocity of the bubble wall,

$S_{c}$, on the right-hand side is based on a simplified Rayleigh–Plesset equation, which defines the velocity of the bubble wall,  $\text{d}R/\text{d}t$, for a bubble of radius

$\text{d}R/\text{d}t$, for a bubble of radius  $R$. For a positive velocity of the bubble wall, we speak of the bubble growth rate that is calculated from a simplified Rayleigh–Plesset equation as follows:

$R$. For a positive velocity of the bubble wall, we speak of the bubble growth rate that is calculated from a simplified Rayleigh–Plesset equation as follows:

$$\begin{eqnarray}\frac{\text{d}R}{\text{d}t}=\sqrt{\frac{2(p_{v}-p)}{3\unicode[STIX]{x1D70C}_{l}}},\quad \text{if }p<p_{v}.\end{eqnarray}$$

$$\begin{eqnarray}\frac{\text{d}R}{\text{d}t}=\sqrt{\frac{2(p_{v}-p)}{3\unicode[STIX]{x1D70C}_{l}}},\quad \text{if }p<p_{v}.\end{eqnarray}$$On the other hand, the negative velocity of the bubble wall, referred to as bubble collapse rate, is calculated as follows:

$$\begin{eqnarray}\frac{\text{d}R}{\text{d}t}=\sqrt{\frac{2(p-p_{v})}{3\unicode[STIX]{x1D70C}_{l}}},\quad \text{if }p\geqslant p_{v}.\end{eqnarray}$$

$$\begin{eqnarray}\frac{\text{d}R}{\text{d}t}=\sqrt{\frac{2(p-p_{v})}{3\unicode[STIX]{x1D70C}_{l}}},\quad \text{if }p\geqslant p_{v}.\end{eqnarray}$$This assumption is rough because it neglects influences attributable to bubble radius acceleration, non-condensable gas, viscosity and surface tension in the Rayleigh–Plesset equation (3.36). Moreover, the change of sign under the root from (3.13) to (3.14) cannot be accounted for by the pressure term in the Rayleigh–Plesset equation. In the cavitation model of Sauer & Schnerr (Reference Sauer and Schnerr2000), the source terms are derived from the continuity equation using the homogeneous mixture expressions of density and assuming a homogeneous distribution of cavitation nuclei per volume of liquid. The source terms depend on the aforementioned simplified calculations of the bubble growth rate as follows:

$$\begin{eqnarray}\displaystyle \left.\begin{array}{@{}c@{}}\!\!\displaystyle S_{v}=\left\{\begin{array}{@{}l@{}}\displaystyle (-C_{v})\frac{1}{R(\unicode[STIX]{x1D6FC}_{l})}\left[\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\unicode[STIX]{x1D6FC}_{l}\left(\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\frac{1}{\unicode[STIX]{x1D70C}_{v}}\right)\right]\frac{3\unicode[STIX]{x1D70C}_{v}\unicode[STIX]{x1D70C}_{l}}{\unicode[STIX]{x1D70C}}(1+\unicode[STIX]{x1D6FC}_{nuc}-\unicode[STIX]{x1D6FC}_{l})\sqrt{\frac{2}{3}\frac{p_{v}-p}{\unicode[STIX]{x1D70C}_{l}}},\quad \text{if }p<p_{v}\quad \\ 0\quad \text{else},\quad \end{array}\right.\\ \displaystyle S_{c}=\left\{\begin{array}{@{}l@{}}\displaystyle C_{c}\frac{1}{R(\unicode[STIX]{x1D6FC}_{l})}\left[\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\unicode[STIX]{x1D6FC}_{l}\left(\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\frac{1}{\unicode[STIX]{x1D70C}_{v}}\right)\right]\frac{3\unicode[STIX]{x1D70C}_{v}\unicode[STIX]{x1D70C}_{l}}{\unicode[STIX]{x1D70C}}\unicode[STIX]{x1D6FC}_{l}\sqrt{\frac{2}{3}\frac{p-p_{v}}{\unicode[STIX]{x1D70C}_{l}}},\quad \text{if }p\geqslant p_{v}\quad \\ 0\quad \text{else},\quad \end{array}\right.\end{array}\!\!\!\!\!\!\right\} & & \displaystyle \nonumber\\ \displaystyle & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \left.\begin{array}{@{}c@{}}\!\!\displaystyle S_{v}=\left\{\begin{array}{@{}l@{}}\displaystyle (-C_{v})\frac{1}{R(\unicode[STIX]{x1D6FC}_{l})}\left[\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\unicode[STIX]{x1D6FC}_{l}\left(\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\frac{1}{\unicode[STIX]{x1D70C}_{v}}\right)\right]\frac{3\unicode[STIX]{x1D70C}_{v}\unicode[STIX]{x1D70C}_{l}}{\unicode[STIX]{x1D70C}}(1+\unicode[STIX]{x1D6FC}_{nuc}-\unicode[STIX]{x1D6FC}_{l})\sqrt{\frac{2}{3}\frac{p_{v}-p}{\unicode[STIX]{x1D70C}_{l}}},\quad \text{if }p<p_{v}\quad \\ 0\quad \text{else},\quad \end{array}\right.\\ \displaystyle S_{c}=\left\{\begin{array}{@{}l@{}}\displaystyle C_{c}\frac{1}{R(\unicode[STIX]{x1D6FC}_{l})}\left[\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\unicode[STIX]{x1D6FC}_{l}\left(\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\frac{1}{\unicode[STIX]{x1D70C}_{v}}\right)\right]\frac{3\unicode[STIX]{x1D70C}_{v}\unicode[STIX]{x1D70C}_{l}}{\unicode[STIX]{x1D70C}}\unicode[STIX]{x1D6FC}_{l}\sqrt{\frac{2}{3}\frac{p-p_{v}}{\unicode[STIX]{x1D70C}_{l}}},\quad \text{if }p\geqslant p_{v}\quad \\ 0\quad \text{else},\quad \end{array}\right.\end{array}\!\!\!\!\!\!\right\} & & \displaystyle \nonumber\\ \displaystyle & & \displaystyle\end{eqnarray}$$ where  $\unicode[STIX]{x1D6FC}_{l}$ is the liquid volume fraction,

$\unicode[STIX]{x1D6FC}_{l}$ is the liquid volume fraction,  $\unicode[STIX]{x1D6FC}_{nuc}$ is the volume fraction owing to the presence of initial gas nuclei and

$\unicode[STIX]{x1D6FC}_{nuc}$ is the volume fraction owing to the presence of initial gas nuclei and  $R(\unicode[STIX]{x1D6FC}_{l})$ is the bubble radius as a function of

$R(\unicode[STIX]{x1D6FC}_{l})$ is the bubble radius as a function of  $\unicode[STIX]{x1D6FC}_{l}$. The constants of vaporisation,

$\unicode[STIX]{x1D6FC}_{l}$. The constants of vaporisation,  $C_{v}$, and of condensation,

$C_{v}$, and of condensation,  $C_{c}$, are set to unity. The bubble radius is calculated as follows:

$C_{c}$, are set to unity. The bubble radius is calculated as follows:

$$\begin{eqnarray}R(\unicode[STIX]{x1D6FC}_{l})=\sqrt[3]{\frac{3(1-\unicode[STIX]{x1D6FC}_{l}+\unicode[STIX]{x1D6FC}_{nuc})}{\unicode[STIX]{x1D6FC}_{l}4\unicode[STIX]{x03C0}n_{b}}},\end{eqnarray}$$

$$\begin{eqnarray}R(\unicode[STIX]{x1D6FC}_{l})=\sqrt[3]{\frac{3(1-\unicode[STIX]{x1D6FC}_{l}+\unicode[STIX]{x1D6FC}_{nuc})}{\unicode[STIX]{x1D6FC}_{l}4\unicode[STIX]{x03C0}n_{b}}},\end{eqnarray}$$ where  $n_{b}$ is the nucleus density which defines the number of bubbles per volume of liquid. The reciprocal bubble radius can be written as follows:

$n_{b}$ is the nucleus density which defines the number of bubbles per volume of liquid. The reciprocal bubble radius can be written as follows:

$$\begin{eqnarray}\frac{1}{R(\unicode[STIX]{x1D6FC}_{l})}=\left(\frac{4\unicode[STIX]{x03C0}n_{b}}{3}\frac{\unicode[STIX]{x1D6FC}_{l}}{1+\unicode[STIX]{x1D6FC}_{nuc}-\unicode[STIX]{x1D6FC}_{l}}\right)^{1/3}.\end{eqnarray}$$

$$\begin{eqnarray}\frac{1}{R(\unicode[STIX]{x1D6FC}_{l})}=\left(\frac{4\unicode[STIX]{x03C0}n_{b}}{3}\frac{\unicode[STIX]{x1D6FC}_{l}}{1+\unicode[STIX]{x1D6FC}_{nuc}-\unicode[STIX]{x1D6FC}_{l}}\right)^{1/3}.\end{eqnarray}$$ To avoid singularities in (3.15), the volume fraction owing to the presence of initial gas nuclei,  $\unicode[STIX]{x1D6FC}_{nuc}$, is related to the minimum bubble radius.

$\unicode[STIX]{x1D6FC}_{nuc}$, is related to the minimum bubble radius.

Following this approach, the source terms for the pressure equation (3.11) are defined as follows:

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\displaystyle S_{p,v}=\left\{\begin{array}{@{}l@{}}\displaystyle (-C_{v})\frac{1}{R(\unicode[STIX]{x1D6FC}_{l})}\left(\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\frac{1}{\unicode[STIX]{x1D70C}_{v}}\right)(1-\unicode[STIX]{x1D6FC}_{l})\unicode[STIX]{x1D6FC}_{l}\frac{3\unicode[STIX]{x1D70C}_{l}\unicode[STIX]{x1D70C}_{v}}{\unicode[STIX]{x1D70C}}\sqrt{\frac{2}{3\unicode[STIX]{x1D70C}_{l}|p-p_{v}|}}\quad \text{if }p<p_{v}\quad \\ 0\quad \text{else},\quad \end{array}\right.\\ \displaystyle S_{p,c}=\left\{\begin{array}{@{}l@{}}\displaystyle C_{c}\frac{1}{R(\unicode[STIX]{x1D6FC}_{l})}\left(\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\frac{1}{\unicode[STIX]{x1D70C}_{v}}\right)(1-\unicode[STIX]{x1D6FC}_{l})\unicode[STIX]{x1D6FC}_{l}\frac{3\unicode[STIX]{x1D70C}_{l}\unicode[STIX]{x1D70C}_{v}}{\unicode[STIX]{x1D70C}}\sqrt{\frac{2}{3\unicode[STIX]{x1D70C}_{l}|p-p_{v}|}}\quad \text{if }p\geqslant p_{v}\quad \\ 0\quad \text{else}.\quad \end{array}\right.\end{array}\!\!\!\!\!\!\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\displaystyle S_{p,v}=\left\{\begin{array}{@{}l@{}}\displaystyle (-C_{v})\frac{1}{R(\unicode[STIX]{x1D6FC}_{l})}\left(\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\frac{1}{\unicode[STIX]{x1D70C}_{v}}\right)(1-\unicode[STIX]{x1D6FC}_{l})\unicode[STIX]{x1D6FC}_{l}\frac{3\unicode[STIX]{x1D70C}_{l}\unicode[STIX]{x1D70C}_{v}}{\unicode[STIX]{x1D70C}}\sqrt{\frac{2}{3\unicode[STIX]{x1D70C}_{l}|p-p_{v}|}}\quad \text{if }p<p_{v}\quad \\ 0\quad \text{else},\quad \end{array}\right.\\ \displaystyle S_{p,c}=\left\{\begin{array}{@{}l@{}}\displaystyle C_{c}\frac{1}{R(\unicode[STIX]{x1D6FC}_{l})}\left(\frac{1}{\unicode[STIX]{x1D70C}_{l}}-\frac{1}{\unicode[STIX]{x1D70C}_{v}}\right)(1-\unicode[STIX]{x1D6FC}_{l})\unicode[STIX]{x1D6FC}_{l}\frac{3\unicode[STIX]{x1D70C}_{l}\unicode[STIX]{x1D70C}_{v}}{\unicode[STIX]{x1D70C}}\sqrt{\frac{2}{3\unicode[STIX]{x1D70C}_{l}|p-p_{v}|}}\quad \text{if }p\geqslant p_{v}\quad \\ 0\quad \text{else}.\quad \end{array}\right.\end{array}\!\!\!\!\!\!\right\}\end{eqnarray}$$Despite this simplified approach to modelling the processes of vaporisation and condensation, in most technical flows this approach enables us to sufficiently predict the behaviour of macroscopic cavitation structures. To simulate the growth and collapse behaviour of single cavitation bubbles, this approach cannot be used, because it does not consider any dynamics during these processes.

Turbulence in a flow may crucially influence cavitation inception and cavitation behaviour. To simulate cavitation behaviour correctly, a suitable approach to model turbulence needs to be selected. Based on a RANS approach, we modelled turbulence using the  $k$–

$k$– $\unicode[STIX]{x1D714}$-SST (shear stress transport) two-equation turbulence model that switches between a standard

$\unicode[STIX]{x1D714}$-SST (shear stress transport) two-equation turbulence model that switches between a standard  $k$–

$k$– $\unicode[STIX]{x1D714}$ approach in near-wall regions and a behaviour similar to the

$\unicode[STIX]{x1D714}$ approach in near-wall regions and a behaviour similar to the  $k$–

$k$– $\unicode[STIX]{x1D716}$ turbulence model in the far field. Reboud, Stutz & Coutier-Delgosha (Reference Reboud, Stutz and Coutier-Delgosha1998) found that the commonly used two-equation turbulence models are not suited to model turbulence for cavitating flows, because they assume a linear dependence of the turbulent viscosity,

$\unicode[STIX]{x1D716}$ turbulence model in the far field. Reboud, Stutz & Coutier-Delgosha (Reference Reboud, Stutz and Coutier-Delgosha1998) found that the commonly used two-equation turbulence models are not suited to model turbulence for cavitating flows, because they assume a linear dependence of the turbulent viscosity,  $\unicode[STIX]{x1D707}_{t}$, in the mixture region of the two phases resulting in an overprediction of

$\unicode[STIX]{x1D707}_{t}$, in the mixture region of the two phases resulting in an overprediction of  $\unicode[STIX]{x1D707}_{t}$. The overpredicted turbulent viscosity in the mixture region prevents the occurrence of unsteady or periodic cavitation. This happens, for example, when the re-entrant jet mechanism causes the shedding of cloud cavitation. Reboud et al. (Reference Reboud, Stutz and Coutier-Delgosha1998) proposed an approach to reduce

$\unicode[STIX]{x1D707}_{t}$. The overpredicted turbulent viscosity in the mixture region prevents the occurrence of unsteady or periodic cavitation. This happens, for example, when the re-entrant jet mechanism causes the shedding of cloud cavitation. Reboud et al. (Reference Reboud, Stutz and Coutier-Delgosha1998) proposed an approach to reduce  $\unicode[STIX]{x1D707}_{t}$ in the mixture region, where the turbulent viscosity is calculated as follows:

$\unicode[STIX]{x1D707}_{t}$ in the mixture region, where the turbulent viscosity is calculated as follows:

$$\begin{eqnarray}\unicode[STIX]{x1D707}_{t}=f(\unicode[STIX]{x1D70C})C_{\unicode[STIX]{x1D707}}k/\unicode[STIX]{x1D714},\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D707}_{t}=f(\unicode[STIX]{x1D70C})C_{\unicode[STIX]{x1D707}}k/\unicode[STIX]{x1D714},\end{eqnarray}$$ where  $k$ is the turbulent kinetic energy,

$k$ is the turbulent kinetic energy,  $\unicode[STIX]{x1D714}$ is the specific turbulence dissipation and

$\unicode[STIX]{x1D714}$ is the specific turbulence dissipation and  $C_{\unicode[STIX]{x1D707}}=0.09$. The function

$C_{\unicode[STIX]{x1D707}}=0.09$. The function  $f(\unicode[STIX]{x1D70C})$ replaces the linear response in the mixture region as follows:

$f(\unicode[STIX]{x1D70C})$ replaces the linear response in the mixture region as follows:

$$\begin{eqnarray}f(\unicode[STIX]{x1D70C})=\unicode[STIX]{x1D70C}_{v}+\frac{(\unicode[STIX]{x1D70C}-\unicode[STIX]{x1D70C}_{v})^{n}}{(\unicode[STIX]{x1D70C}_{l}-\unicode[STIX]{x1D70C}_{v})^{n-1}},\quad \text{with }n=10.\end{eqnarray}$$

$$\begin{eqnarray}f(\unicode[STIX]{x1D70C})=\unicode[STIX]{x1D70C}_{v}+\frac{(\unicode[STIX]{x1D70C}-\unicode[STIX]{x1D70C}_{v})^{n}}{(\unicode[STIX]{x1D70C}_{l}-\unicode[STIX]{x1D70C}_{v})^{n-1}},\quad \text{with }n=10.\end{eqnarray}$$Using this correction of the turbulent viscosity enabled us to simulate periodic shedding of cloud cavitation. Moreover, we took into account that turbulence increases the possibility of cavitation inception. In experimental tests, Singhal et al. (Reference Singhal, Athavale, Li and Jiang2002) showed that turbulent pressure variations affect the local vapour pressure. They found that more turbulence in a flow promotes cavitation inception, which can be accounted for by calculating the turbulent pressure fluctuation as follows:

$$\begin{eqnarray}p_{turb}^{\prime }=0.39\unicode[STIX]{x1D70C}k.\end{eqnarray}$$

$$\begin{eqnarray}p_{turb}^{\prime }=0.39\unicode[STIX]{x1D70C}k.\end{eqnarray}$$ The turbulent pressure fluctuation is then added to the theoretical saturation pressure,  $p_{sat}$, to obtain a new local vapour pressure as follows:

$p_{sat}$, to obtain a new local vapour pressure as follows:

$$\begin{eqnarray}p_{v}=p_{sat}+\frac{p_{turb}^{\prime }}{2},\end{eqnarray}$$

$$\begin{eqnarray}p_{v}=p_{sat}+\frac{p_{turb}^{\prime }}{2},\end{eqnarray}$$which is higher than the theoretical value of the saturation pressure and induces earlier cavitation inception.

3.2 Single bubble transport

Motions of a fluid particle can be considered from two different perspectives. The Eulerian perspective describes the motion of fluid particles from a fixed location, whereas the Lagrangian perspective follows a fluid particle and hence the flow, using a local coordinate system to calculate the particle’s momentum. We selected the Lagrangian approach to calculate motion and dynamics of discrete spherical cavitation bubbles. This allowed us to determine bubble traces that deviate from streamlines of the flow. Based on the general theory of Hsiao et al. (Reference Hsiao, Chahine and Liu2000), Oweis et al. (Reference Oweis, van der Hout, Iyer, Tryggvason and Ceccio2005) and Abdel-Maksoud et al. (Reference Abdel-Maksoud, Hänel and Lantermann2010) and the application of Newton’s second law, the Lagrangian equation of motion for a single bubble reads as follows:

$$\begin{eqnarray}m_{b}\frac{\text{d}\boldsymbol{u}_{b}}{\text{d}t}=\mathop{\sum }_{i}\boldsymbol{F}_{i},\end{eqnarray}$$

$$\begin{eqnarray}m_{b}\frac{\text{d}\boldsymbol{u}_{b}}{\text{d}t}=\mathop{\sum }_{i}\boldsymbol{F}_{i},\end{eqnarray}$$ where  $m_{b}$ is the bubble’s mass and

$m_{b}$ is the bubble’s mass and  $\boldsymbol{u}_{b}$ is the bubble’s velocity. The volume of a spherical bubble is

$\boldsymbol{u}_{b}$ is the bubble’s velocity. The volume of a spherical bubble is  $V_{b}=\frac{4}{3}\unicode[STIX]{x03C0}R^{3}$, with

$V_{b}=\frac{4}{3}\unicode[STIX]{x03C0}R^{3}$, with  $R$ being the bubble radius. Vector

$R$ being the bubble radius. Vector  $\boldsymbol{F}_{i}$ comprises forces acting on the bubble. The relative velocity of the bubble, being the difference between carrier fluid velocity (index ‘

$\boldsymbol{F}_{i}$ comprises forces acting on the bubble. The relative velocity of the bubble, being the difference between carrier fluid velocity (index ‘ $c$’) and bubble velocity (index ‘

$c$’) and bubble velocity (index ‘ $b$’) is:

$b$’) is:  $\boldsymbol{u}_{c}-\boldsymbol{u}_{b}$. Properties of the carrier fluid are the same as properties of the homogeneous mixture of liquid and vapour inside the considered control volumes.

$\boldsymbol{u}_{c}-\boldsymbol{u}_{b}$. Properties of the carrier fluid are the same as properties of the homogeneous mixture of liquid and vapour inside the considered control volumes.

The primary Bjerknes force, also known as the pressure gradient force, is written as follows:

$$\begin{eqnarray}\boldsymbol{F}_{pg}=-V_{b}\unicode[STIX]{x1D735}p=V_{b}\unicode[STIX]{x1D70C}_{c}\frac{\text{d}\boldsymbol{u}_{c}}{\text{d}t}=\frac{m_{b}\unicode[STIX]{x1D70C}_{c}}{\unicode[STIX]{x1D70C}_{b}}\frac{\text{d}\boldsymbol{u}_{c}}{\text{d}t},\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{F}_{pg}=-V_{b}\unicode[STIX]{x1D735}p=V_{b}\unicode[STIX]{x1D70C}_{c}\frac{\text{d}\boldsymbol{u}_{c}}{\text{d}t}=\frac{m_{b}\unicode[STIX]{x1D70C}_{c}}{\unicode[STIX]{x1D70C}_{b}}\frac{\text{d}\boldsymbol{u}_{c}}{\text{d}t},\end{eqnarray}$$ where the substitution of the pressure gradient follows from the momentum equation. Test simulations confirmed that the effect of diffusion on the pressure gradient surrounding the bubble is negligibly small and the diffusion term can, therefore, be neglected to calculate the pressure gradient as  $\unicode[STIX]{x1D70C}_{c}\text{d}\boldsymbol{u}_{c}/\text{d}t=-\unicode[STIX]{x1D735}p$. We did not consider secondary Bjerknes forces, because substantial computational effort would have been necessary to evaluate bubble–bubble interaction. Moreover, Lagrangian bubbles were mostly isolated, whereas coherent bubble structures were treated in the Eulerian frame.

$\unicode[STIX]{x1D70C}_{c}\text{d}\boldsymbol{u}_{c}/\text{d}t=-\unicode[STIX]{x1D735}p$. We did not consider secondary Bjerknes forces, because substantial computational effort would have been necessary to evaluate bubble–bubble interaction. Moreover, Lagrangian bubbles were mostly isolated, whereas coherent bubble structures were treated in the Eulerian frame.

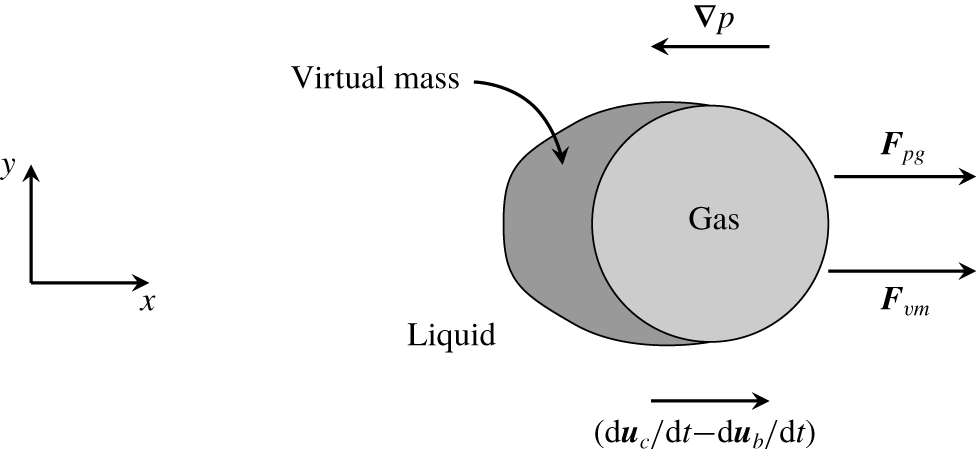

Part of the liquid surrounding the bubble is accelerated with the bubble, resulting in a virtual mass force defined as follows:

$$\begin{eqnarray}\boldsymbol{F}_{vm}=0.5\unicode[STIX]{x1D70C}_{c}V_{b}\left(\frac{\text{d}\boldsymbol{u}_{c}}{\text{d}t}-\frac{\text{d}\boldsymbol{u}_{b}}{\text{d}t}\right).\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{F}_{vm}=0.5\unicode[STIX]{x1D70C}_{c}V_{b}\left(\frac{\text{d}\boldsymbol{u}_{c}}{\text{d}t}-\frac{\text{d}\boldsymbol{u}_{b}}{\text{d}t}\right).\end{eqnarray}$$ The virtual mass of a sphere is  $0.5\unicode[STIX]{x1D70C}_{c}V_{b}$ and can be described as the difference between accelerations of carrier fluid and bubble. Below, we will use this formulation to move the term proportional to

$0.5\unicode[STIX]{x1D70C}_{c}V_{b}$ and can be described as the difference between accelerations of carrier fluid and bubble. Below, we will use this formulation to move the term proportional to  $\text{d}u_{b}/\text{d}t$ to the left-hand side of (3.23) and combine the pressure gradient force and the virtual mass force. Figure 3 sketches the pressure gradient force and the virtual mass force acting on a bubble. The pressure gradient force,

$\text{d}u_{b}/\text{d}t$ to the left-hand side of (3.23) and combine the pressure gradient force and the virtual mass force. Figure 3 sketches the pressure gradient force and the virtual mass force acting on a bubble. The pressure gradient force,  $\boldsymbol{F}_{pg}$, acts in the positive

$\boldsymbol{F}_{pg}$, acts in the positive  $x$-direction, i.e. in the direction of the negative pressure gradient, and this force causes the bubble to be attracted towards low pressure regions. The virtual mass force,

$x$-direction, i.e. in the direction of the negative pressure gradient, and this force causes the bubble to be attracted towards low pressure regions. The virtual mass force,  $\boldsymbol{F}_{vm}$, is proportional to the relative acceleration between carrier fluid and bubble,

$\boldsymbol{F}_{vm}$, is proportional to the relative acceleration between carrier fluid and bubble,  $(\text{d}\boldsymbol{u}_{c}/\text{d}t-\text{d}\boldsymbol{u}_{b}/\text{d}t)$, and it points also in positive

$(\text{d}\boldsymbol{u}_{c}/\text{d}t-\text{d}\boldsymbol{u}_{b}/\text{d}t)$, and it points also in positive  $x$-direction.

$x$-direction.

Figure 3. Forces acting on a bubble owing to pressure gradient and virtual mass.

Rapid growth and collapse processes of a bubble introduce a force that depends on the rate of change of the bubble’s volume. According to Johnson & Hsieh (Reference Johnson and Hsieh1966) this force is written as follows:

$$\begin{eqnarray}\boldsymbol{F}_{volume}=\frac{\unicode[STIX]{x1D70C}_{c}}{2}\frac{\text{d}V_{b}}{\text{d}t}(\boldsymbol{u}_{c}-\boldsymbol{u}_{b})=\frac{3}{2}\unicode[STIX]{x1D70C}_{c}V_{b}\frac{{\dot{R}}}{R}(\boldsymbol{u}_{c}-\boldsymbol{u}_{b}),\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{F}_{volume}=\frac{\unicode[STIX]{x1D70C}_{c}}{2}\frac{\text{d}V_{b}}{\text{d}t}(\boldsymbol{u}_{c}-\boldsymbol{u}_{b})=\frac{3}{2}\unicode[STIX]{x1D70C}_{c}V_{b}\frac{{\dot{R}}}{R}(\boldsymbol{u}_{c}-\boldsymbol{u}_{b}),\end{eqnarray}$$ where  ${\dot{R}}$ is the radius growth rate or velocity of the bubble wall. The radius growth rate as well as the relative velocity between carrier fluid and bubble determine the direction of this force. The relative velocity causes also a drag force exerted on the bubble, which is written as follows:

${\dot{R}}$ is the radius growth rate or velocity of the bubble wall. The radius growth rate as well as the relative velocity between carrier fluid and bubble determine the direction of this force. The relative velocity causes also a drag force exerted on the bubble, which is written as follows:

$$\begin{eqnarray}\boldsymbol{F}_{drag}=\frac{3}{4}c_{D}m_{eff}\unicode[STIX]{x1D707}_{c}\frac{1}{\unicode[STIX]{x1D70C}_{b}(2.0R)^{2}}|\boldsymbol{u}_{c}-\boldsymbol{u}_{b}|(\boldsymbol{u}_{c}-\boldsymbol{u}_{b}).\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{F}_{drag}=\frac{3}{4}c_{D}m_{eff}\unicode[STIX]{x1D707}_{c}\frac{1}{\unicode[STIX]{x1D70C}_{b}(2.0R)^{2}}|\boldsymbol{u}_{c}-\boldsymbol{u}_{b}|(\boldsymbol{u}_{c}-\boldsymbol{u}_{b}).\end{eqnarray}$$ The effective mass of the bubble,  $m_{eff}=m_{b}+m_{a}$, consists of the bubble mass,

$m_{eff}=m_{b}+m_{a}$, consists of the bubble mass,  $m_{b}=\unicode[STIX]{x1D70C}_{b}V_{b}$, and the added mass,

$m_{b}=\unicode[STIX]{x1D70C}_{b}V_{b}$, and the added mass,  $m_{a}=\frac{1}{2}\unicode[STIX]{x1D70C}_{c}V_{b}$. The drag coefficient according to Haberman & Morton (Reference Haberman and Morton1953) reads as follows:

$m_{a}=\frac{1}{2}\unicode[STIX]{x1D70C}_{c}V_{b}$. The drag coefficient according to Haberman & Morton (Reference Haberman and Morton1953) reads as follows:

$$\begin{eqnarray}c_{D}=24.0(1.0+0.197Re_{b}^{0.63}+2.6\cdot 10^{-4}Re_{b}^{1.38}),\end{eqnarray}$$

$$\begin{eqnarray}c_{D}=24.0(1.0+0.197Re_{b}^{0.63}+2.6\cdot 10^{-4}Re_{b}^{1.38}),\end{eqnarray}$$ where  $Re_{b}=(\unicode[STIX]{x1D70C}_{c}|\boldsymbol{u}_{c}-\boldsymbol{u}_{b}|2R)/\unicode[STIX]{x1D707}_{c}$ is the bubble Reynolds number. In fluids where the effects of gravity exceed the effects from the flow, the drag force is alternatively defined as follows (Darmana, Deen & Kuipers Reference Darmana, Deen and Kuipers2006):

$Re_{b}=(\unicode[STIX]{x1D70C}_{c}|\boldsymbol{u}_{c}-\boldsymbol{u}_{b}|2R)/\unicode[STIX]{x1D707}_{c}$ is the bubble Reynolds number. In fluids where the effects of gravity exceed the effects from the flow, the drag force is alternatively defined as follows (Darmana, Deen & Kuipers Reference Darmana, Deen and Kuipers2006):

$$\begin{eqnarray}\boldsymbol{F}_{drag,grav}={\textstyle \frac{1}{2}}c_{D,E\ddot{o} }\unicode[STIX]{x1D70C}_{c}\unicode[STIX]{x03C0}R^{2}|\boldsymbol{u}_{c}-\boldsymbol{u}_{b}|(\boldsymbol{u}_{c}-\boldsymbol{u}_{b}).\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{F}_{drag,grav}={\textstyle \frac{1}{2}}c_{D,E\ddot{o} }\unicode[STIX]{x1D70C}_{c}\unicode[STIX]{x03C0}R^{2}|\boldsymbol{u}_{c}-\boldsymbol{u}_{b}|(\boldsymbol{u}_{c}-\boldsymbol{u}_{b}).\end{eqnarray}$$ In this case, the drag coefficient is  $c_{D,E\ddot{o} }=\frac{8}{3}E\ddot{o} /(E\ddot{o} +4)$ with the Eötvös number

$c_{D,E\ddot{o} }=\frac{8}{3}E\ddot{o} /(E\ddot{o} +4)$ with the Eötvös number  $E\ddot{o} =(\unicode[STIX]{x1D70C}_{c}-\unicode[STIX]{x1D70C}_{b})\boldsymbol{g}(2R)^{2}/\unicode[STIX]{x1D70E}$, and

$E\ddot{o} =(\unicode[STIX]{x1D70C}_{c}-\unicode[STIX]{x1D70C}_{b})\boldsymbol{g}(2R)^{2}/\unicode[STIX]{x1D70E}$, and  $\boldsymbol{g}=(0,0,-9.81)~\text{m}~\text{s}^{-2}$ is the vector of gravitational acceleration.

$\boldsymbol{g}=(0,0,-9.81)~\text{m}~\text{s}^{-2}$ is the vector of gravitational acceleration.

According to Saffman (Reference Saffman1965) bubbles are subject to lift forces caused by the surrounding shear flows. This lift force is defined as follows:

$$\begin{eqnarray}\boldsymbol{F}_{lift}={\textstyle \frac{3}{8}}c_{L}\unicode[STIX]{x1D70C}_{c}V_{b}\frac{(\boldsymbol{u}_{c}-\boldsymbol{u}_{b})}{\unicode[STIX]{x1D6FC}_{S}}\times \unicode[STIX]{x1D74E},\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{F}_{lift}={\textstyle \frac{3}{8}}c_{L}\unicode[STIX]{x1D70C}_{c}V_{b}\frac{(\boldsymbol{u}_{c}-\boldsymbol{u}_{b})}{\unicode[STIX]{x1D6FC}_{S}}\times \unicode[STIX]{x1D74E},\end{eqnarray}$$ with the lift coefficient,  $c_{L}$, and the dimensionless shear rate

$c_{L}$, and the dimensionless shear rate

$$\begin{eqnarray}\unicode[STIX]{x1D6FC}_{S}=\frac{|\unicode[STIX]{x1D74E}|R}{|\boldsymbol{u}_{c}-\boldsymbol{u}_{b}|},\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D6FC}_{S}=\frac{|\unicode[STIX]{x1D74E}|R}{|\boldsymbol{u}_{c}-\boldsymbol{u}_{b}|},\end{eqnarray}$$ where  $\unicode[STIX]{x1D74E}=\unicode[STIX]{x1D735}\times \boldsymbol{u}_{c}$ is the vorticity of the flow. The lift coefficient,

$\unicode[STIX]{x1D74E}=\unicode[STIX]{x1D735}\times \boldsymbol{u}_{c}$ is the vorticity of the flow. The lift coefficient,  $c_{L}$, depends on the bubble’s Reynolds number and the dimensionless shear rate.

$c_{L}$, depends on the bubble’s Reynolds number and the dimensionless shear rate.

Owing to the density difference between carrier fluid and the vapour-filled bubble, a buoyancy force

$$\begin{eqnarray}\boldsymbol{F}_{gravity}=(\unicode[STIX]{x1D70C}_{b}-\unicode[STIX]{x1D70C}_{c})\boldsymbol{g}V_{b}\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{F}_{gravity}=(\unicode[STIX]{x1D70C}_{b}-\unicode[STIX]{x1D70C}_{c})\boldsymbol{g}V_{b}\end{eqnarray}$$acts on the bubble, which lets bubbles rise in liquids of higher density.

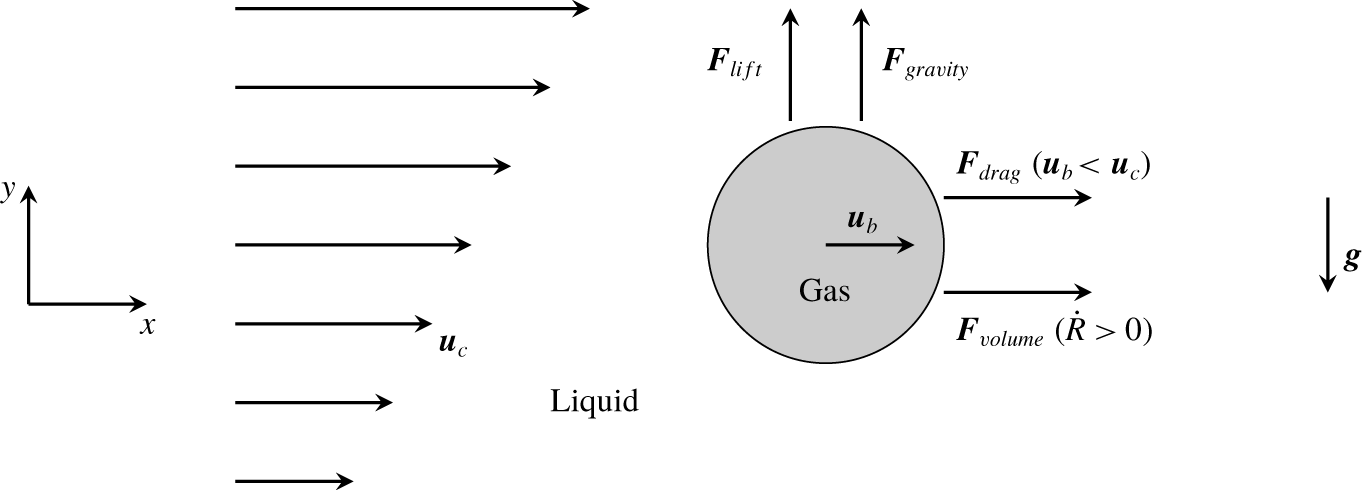

Figure 4 depicts the forces owing to Saffman lift, gravity, drag and volume variation, which influence the bubble’s momentum. With  $u_{c,x}$ as the

$u_{c,x}$ as the  $x$-component of velocity,

$x$-component of velocity,  $\boldsymbol{u}$, the lift force results from the positive velocity gradient in the

$\boldsymbol{u}$, the lift force results from the positive velocity gradient in the  $y$-direction,

$y$-direction,  $\unicode[STIX]{x2202}u_{c,x}/\unicode[STIX]{x2202}y$. The high flow velocity along the bubble’s top wall generates a low pressure region, and the lower flow velocity along the bubble’s bottom wall generates a high pressure region. This pressure difference causes a lift force,

$\unicode[STIX]{x2202}u_{c,x}/\unicode[STIX]{x2202}y$. The high flow velocity along the bubble’s top wall generates a low pressure region, and the lower flow velocity along the bubble’s bottom wall generates a high pressure region. This pressure difference causes a lift force,  $\boldsymbol{F}_{lift}$, pointing in the positive

$\boldsymbol{F}_{lift}$, pointing in the positive  $y$-direction. The gravitational acceleration acts in the negative

$y$-direction. The gravitational acceleration acts in the negative  $y$-direction, generating a rising force,

$y$-direction, generating a rising force,  $\boldsymbol{F}_{gravity}$, on the bubble that is attributed to the lower gas density inside the bubble compared to the density of the surrounding liquid. The drag force,

$\boldsymbol{F}_{gravity}$, on the bubble that is attributed to the lower gas density inside the bubble compared to the density of the surrounding liquid. The drag force,  $\boldsymbol{F}_{drag}$, acts in the positive

$\boldsymbol{F}_{drag}$, acts in the positive  $x$-direction because the bubble’s velocity,

$x$-direction because the bubble’s velocity,  $\boldsymbol{u}_{b}$, and the carrier fluid velocity,

$\boldsymbol{u}_{b}$, and the carrier fluid velocity,  $\boldsymbol{u}_{c}$, act in this direction (and

$\boldsymbol{u}_{c}$, act in this direction (and  $\boldsymbol{u}_{b}<\boldsymbol{u}_{c}$). The relative velocity between carrier fluid and bubble,

$\boldsymbol{u}_{b}<\boldsymbol{u}_{c}$). The relative velocity between carrier fluid and bubble,  $(\boldsymbol{u}_{c}-\boldsymbol{u}_{b})$, and the bubble growth rate,

$(\boldsymbol{u}_{c}-\boldsymbol{u}_{b})$, and the bubble growth rate,  ${\dot{R}}$, point in the positive

${\dot{R}}$, point in the positive  $x$-direction and, therefore, cause a volume variation force,

$x$-direction and, therefore, cause a volume variation force,  $\boldsymbol{F}_{volume}$, that is also positive.

$\boldsymbol{F}_{volume}$, that is also positive.

Figure 4. Forces acting on a bubble owing to Saffman lift, gravity, drag and volume variation.

The virtual mass force (3.25) comprises two parts. One part is proportional to the bubble’s acceleration,  $\text{d}\boldsymbol{u}_{b}/\text{d}t$; the other part, to the acceleration of the surrounding liquid,

$\text{d}\boldsymbol{u}_{b}/\text{d}t$; the other part, to the acceleration of the surrounding liquid,  $\text{d}\boldsymbol{u}_{c}/\text{d}t$. Moving the part proportional to bubble acceleration to the left-hand side and the term proportional to the fluid acceleration to the right-hand side of (3.23) yields the following expression:

$\text{d}\boldsymbol{u}_{c}/\text{d}t$. Moving the part proportional to bubble acceleration to the left-hand side and the term proportional to the fluid acceleration to the right-hand side of (3.23) yields the following expression:

$$\begin{eqnarray}m_{eff}\frac{\text{d}\boldsymbol{u}_{b}}{\text{d}t}=\mathop{\sum }_{i}\boldsymbol{F}_{i}.\end{eqnarray}$$

$$\begin{eqnarray}m_{eff}\frac{\text{d}\boldsymbol{u}_{b}}{\text{d}t}=\mathop{\sum }_{i}\boldsymbol{F}_{i}.\end{eqnarray}$$ Thus, the part of the virtual mass force proportional to  $\text{d}\boldsymbol{u}_{c}/\text{d}t$ and the pressure force are considered together, and time integration via a semi-implicit approach then gives velocities

$\text{d}\boldsymbol{u}_{c}/\text{d}t$ and the pressure force are considered together, and time integration via a semi-implicit approach then gives velocities

$$\begin{eqnarray}\boldsymbol{u}_{b}^{n+1}+\frac{\unicode[STIX]{x0394}t}{m_{eff}}\boldsymbol{F}^{n+1}=\boldsymbol{u}_{b}^{n}+\frac{\unicode[STIX]{x0394}t}{m_{eff}}\boldsymbol{F}^{n},\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{u}_{b}^{n+1}+\frac{\unicode[STIX]{x0394}t}{m_{eff}}\boldsymbol{F}^{n+1}=\boldsymbol{u}_{b}^{n}+\frac{\unicode[STIX]{x0394}t}{m_{eff}}\boldsymbol{F}^{n},\end{eqnarray}$$ where  $\boldsymbol{u}_{b}^{n+1}$ is the bubble velocity of the next time step,

$\boldsymbol{u}_{b}^{n+1}$ is the bubble velocity of the next time step,  $\boldsymbol{u}_{b}^{n}$ the bubble velocity of the last time step and

$\boldsymbol{u}_{b}^{n}$ the bubble velocity of the last time step and  $\unicode[STIX]{x0394}t$ the time step. The implicitly treated forces, denoted as

$\unicode[STIX]{x0394}t$ the time step. The implicitly treated forces, denoted as  $\boldsymbol{F}^{n+1}$, represent parts of the drag and volume variation forces proportional to the bubble velocity. Parts of the drag and volume variation forces proportional to the carrier fluid velocity are naturally included in the explicit forces, denoted as

$\boldsymbol{F}^{n+1}$, represent parts of the drag and volume variation forces proportional to the bubble velocity. Parts of the drag and volume variation forces proportional to the carrier fluid velocity are naturally included in the explicit forces, denoted as  $\boldsymbol{F}^{n}$. All other forces are treated explicitly. Integrating the bubble velocity over time then yields the bubble position,

$\boldsymbol{F}^{n}$. All other forces are treated explicitly. Integrating the bubble velocity over time then yields the bubble position,  $\boldsymbol{x}_{b}$:

$\boldsymbol{x}_{b}$:

$$\begin{eqnarray}\frac{\text{d}\boldsymbol{x}_{b}}{\text{d}t}=\boldsymbol{u}_{b}.\end{eqnarray}$$

$$\begin{eqnarray}\frac{\text{d}\boldsymbol{x}_{b}}{\text{d}t}=\boldsymbol{u}_{b}.\end{eqnarray}$$3.3 Single bubble dynamics

Computations based on different forms of the Rayleigh–Plesset equation (Rayleigh Reference Rayleigh1917; Plesset Reference Plesset1949) give the dynamics of spherical bubbles. Following the formulation of Brennen (Reference Brennen2005) and including the effect of relative velocity (Hsiao et al. Reference Hsiao, Chahine and Liu2000) the Rayleigh–Plesset equation is written as follows:

$$\begin{eqnarray}\frac{p_{b}-p}{\unicode[STIX]{x1D70C}_{l}}=R\ddot{R}+\frac{3}{2}{\dot{R}}^{2}+\frac{4\unicode[STIX]{x1D708}_{l}{\dot{R}}}{R}+\frac{2\unicode[STIX]{x1D70E}}{\unicode[STIX]{x1D70C}_{l}R}-\frac{(\boldsymbol{u}-\boldsymbol{u}_{b})^{2}}{4},\end{eqnarray}$$

$$\begin{eqnarray}\frac{p_{b}-p}{\unicode[STIX]{x1D70C}_{l}}=R\ddot{R}+\frac{3}{2}{\dot{R}}^{2}+\frac{4\unicode[STIX]{x1D708}_{l}{\dot{R}}}{R}+\frac{2\unicode[STIX]{x1D70E}}{\unicode[STIX]{x1D70C}_{l}R}-\frac{(\boldsymbol{u}-\boldsymbol{u}_{b})^{2}}{4},\end{eqnarray}$$ where  $R$,

$R$,  ${\dot{R}}$,

${\dot{R}}$,  $\ddot{R}$ are the bubble radius, bubble wall velocity and bubble wall acceleration, respectively;

$\ddot{R}$ are the bubble radius, bubble wall velocity and bubble wall acceleration, respectively;  $p$ is the pressure in the carrier fluid at the bubble position,

$p$ is the pressure in the carrier fluid at the bubble position,  $\unicode[STIX]{x1D70E}$ is the surface tension of water and

$\unicode[STIX]{x1D70E}$ is the surface tension of water and  $\unicode[STIX]{x1D708}_{c}$ is the kinematic viscosity of the carrier fluid;

$\unicode[STIX]{x1D708}_{c}$ is the kinematic viscosity of the carrier fluid;  $p_{b}=p_{v}+p_{g}$ is the pressure in the bubble with the pressure of non-condensable gas in the bubble,

$p_{b}=p_{v}+p_{g}$ is the pressure in the bubble with the pressure of non-condensable gas in the bubble,  $p_{g}$. The gas changes its state isentropically according to the relation

$p_{g}$. The gas changes its state isentropically according to the relation  $p_{g}=p_{g0}(R_{0}/R)^{3\unicode[STIX]{x1D6FE}}$, where

$p_{g}=p_{g0}(R_{0}/R)^{3\unicode[STIX]{x1D6FE}}$, where  $p_{g0}$ and

$p_{g0}$ and  $R_{0}$ are the initial gas pressure and the initial nuclei radius, respectively. The isentropic exponent of

$R_{0}$ are the initial gas pressure and the initial nuclei radius, respectively. The isentropic exponent of  $\unicode[STIX]{x1D6FE}=\frac{4}{3}$ represents an adiabatic process. Depending on the flow problem considered, for bubbles with volumes greater than the volumes of the cells they are located in, the pressure in the carrier fluid,

$\unicode[STIX]{x1D6FE}=\frac{4}{3}$ represents an adiabatic process. Depending on the flow problem considered, for bubbles with volumes greater than the volumes of the cells they are located in, the pressure in the carrier fluid,  $p$, and the velocity in the carrier fluid

$p$, and the velocity in the carrier fluid  $\boldsymbol{u}$, are averaged based on the values of control volumes at multiple coordinates at the outer bubble wall (Hsiao et al. Reference Hsiao, Chahine and Liu2000). This approach prevents a bubble growing unrealistically large when its centre is located inside a low pressure region although its surface is already located in a higher pressure region. This enables a more realistic description of bubble behaviour (Hsiao et al. Reference Hsiao, Chahine and Liu2003). For bubbles, with volumes smaller than the volume of the cell they are located in, the last term on the right-hand side of (3.36), proportional to the relative velocity between bubble and carrier fluid, is neglected because it is multiple orders of magnitude smaller than the other terms (e.g. terms proportional to surface tension or

$\boldsymbol{u}$, are averaged based on the values of control volumes at multiple coordinates at the outer bubble wall (Hsiao et al. Reference Hsiao, Chahine and Liu2000). This approach prevents a bubble growing unrealistically large when its centre is located inside a low pressure region although its surface is already located in a higher pressure region. This enables a more realistic description of bubble behaviour (Hsiao et al. Reference Hsiao, Chahine and Liu2003). For bubbles, with volumes smaller than the volume of the cell they are located in, the last term on the right-hand side of (3.36), proportional to the relative velocity between bubble and carrier fluid, is neglected because it is multiple orders of magnitude smaller than the other terms (e.g. terms proportional to surface tension or  $(p_{b}-p)$).

$(p_{b}-p)$).

According to Tomita & Shima (Reference Tomita and Shima1977), during bubble collapse, the bubble wall attains velocities in the range of the speed of sound of the liquid. The effect of liquid compressibility must be considered because shock waves form after the collapse affecting the behaviour of subsequent bubble rebounds. Based on this equation for a spherical bubble in a viscous compressible liquid, Mathew, Keith & Nikolaidis (Reference Mathew, Keith and Nikolaidis2006) formulated the following expression for bubble dynamics:

$$\begin{eqnarray}\frac{p_{r=R}-p}{\unicode[STIX]{x1D716}\unicode[STIX]{x1D70C}_{c}}+\frac{R{\dot{p}}_{r=R}}{\unicode[STIX]{x1D716}\unicode[STIX]{x1D70C}_{c}c_{\infty }}=R\ddot{R}\left[1-(1+\unicode[STIX]{x1D716})\frac{{\dot{R}}}{c_{\infty }}\right]+\frac{3}{2}{\dot{R}}^{2}\left(\frac{4-\unicode[STIX]{x1D716}}{3}-\frac{4}{3}\frac{{\dot{R}}}{c_{\infty }}\right),\end{eqnarray}$$

$$\begin{eqnarray}\frac{p_{r=R}-p}{\unicode[STIX]{x1D716}\unicode[STIX]{x1D70C}_{c}}+\frac{R{\dot{p}}_{r=R}}{\unicode[STIX]{x1D716}\unicode[STIX]{x1D70C}_{c}c_{\infty }}=R\ddot{R}\left[1-(1+\unicode[STIX]{x1D716})\frac{{\dot{R}}}{c_{\infty }}\right]+\frac{3}{2}{\dot{R}}^{2}\left(\frac{4-\unicode[STIX]{x1D716}}{3}-\frac{4}{3}\frac{{\dot{R}}}{c_{\infty }}\right),\end{eqnarray}$$with

$$\begin{eqnarray}\unicode[STIX]{x1D716}=1-\frac{\unicode[STIX]{x1D70C}_{b}}{\unicode[STIX]{x1D70C}_{c}}=0.99881.\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D716}=1-\frac{\unicode[STIX]{x1D70C}_{b}}{\unicode[STIX]{x1D70C}_{c}}=0.99881.\end{eqnarray}$$ Applying the first-order correction to the pressure  $p_{r=R}$ at the bubble wall leads to the following relation (Tomita & Shima Reference Tomita and Shima1977):

$p_{r=R}$ at the bubble wall leads to the following relation (Tomita & Shima Reference Tomita and Shima1977):

$$\begin{eqnarray}p_{r=R}=p_{g,0}\left(\frac{R_{0}}{R}\right)^{3\unicode[STIX]{x1D6FE}}-\frac{2\unicode[STIX]{x1D70E}}{R}-\unicode[STIX]{x1D716}4\unicode[STIX]{x1D707}_{c}\frac{{\dot{R}}}{R},\end{eqnarray}$$

$$\begin{eqnarray}p_{r=R}=p_{g,0}\left(\frac{R_{0}}{R}\right)^{3\unicode[STIX]{x1D6FE}}-\frac{2\unicode[STIX]{x1D70E}}{R}-\unicode[STIX]{x1D716}4\unicode[STIX]{x1D707}_{c}\frac{{\dot{R}}}{R},\end{eqnarray}$$and its derivative

$$\begin{eqnarray}{\dot{p}}_{r=R}=-3\unicode[STIX]{x1D6FE}p_{g,0}\frac{{\dot{R}}}{R}\left(\frac{R_{0}}{R}\right)^{3\unicode[STIX]{x1D6FE}}+\frac{2\unicode[STIX]{x1D70E}}{R^{2}}{\dot{R}}-\unicode[STIX]{x1D716}4\unicode[STIX]{x1D707}_{c}\frac{\ddot{R}R-{\dot{R}}^{2}}{R^{2}}.\end{eqnarray}$$

$$\begin{eqnarray}{\dot{p}}_{r=R}=-3\unicode[STIX]{x1D6FE}p_{g,0}\frac{{\dot{R}}}{R}\left(\frac{R_{0}}{R}\right)^{3\unicode[STIX]{x1D6FE}}+\frac{2\unicode[STIX]{x1D70E}}{R^{2}}{\dot{R}}-\unicode[STIX]{x1D716}4\unicode[STIX]{x1D707}_{c}\frac{\ddot{R}R-{\dot{R}}^{2}}{R^{2}}.\end{eqnarray}$$ Depending on the sign of the bubble wall velocity from the previous time step, equation (3.36) (growth) or equation (3.37) (collapse) is solved to obtain  $\ddot{R}$ for each bubble individually. Although the difference in computational cost is negligible for most hybrid simulations, whether equation (3.36) or equation (3.37) is solved, it becomes more remarkable for larger numbers of bubbles. Then,

$\ddot{R}$ for each bubble individually. Although the difference in computational cost is negligible for most hybrid simulations, whether equation (3.36) or equation (3.37) is solved, it becomes more remarkable for larger numbers of bubbles. Then,  ${\dot{R}}$ and

${\dot{R}}$ and  $R$ are calculated using the trapezoidal rule for the implicit second-order time integration. Adaptive time stepping enables the efficient calculation of

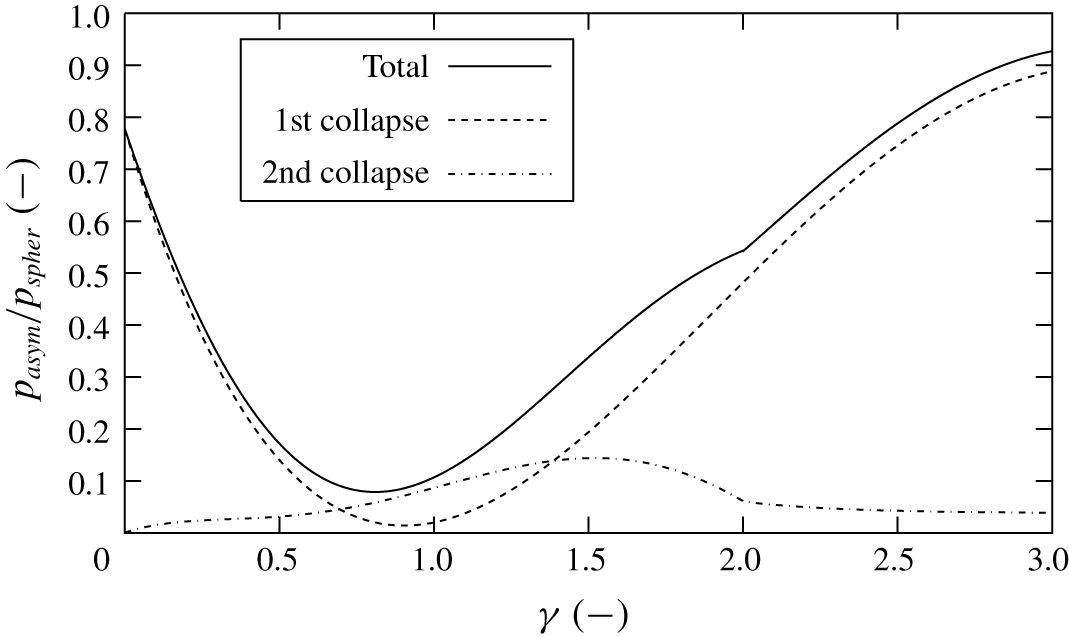

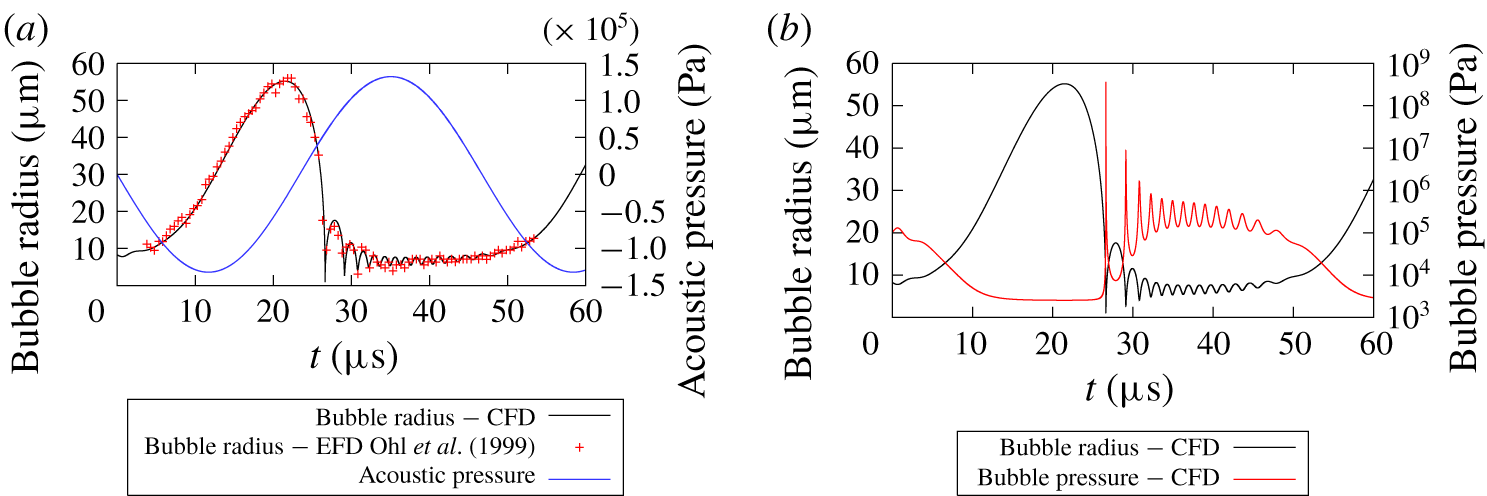

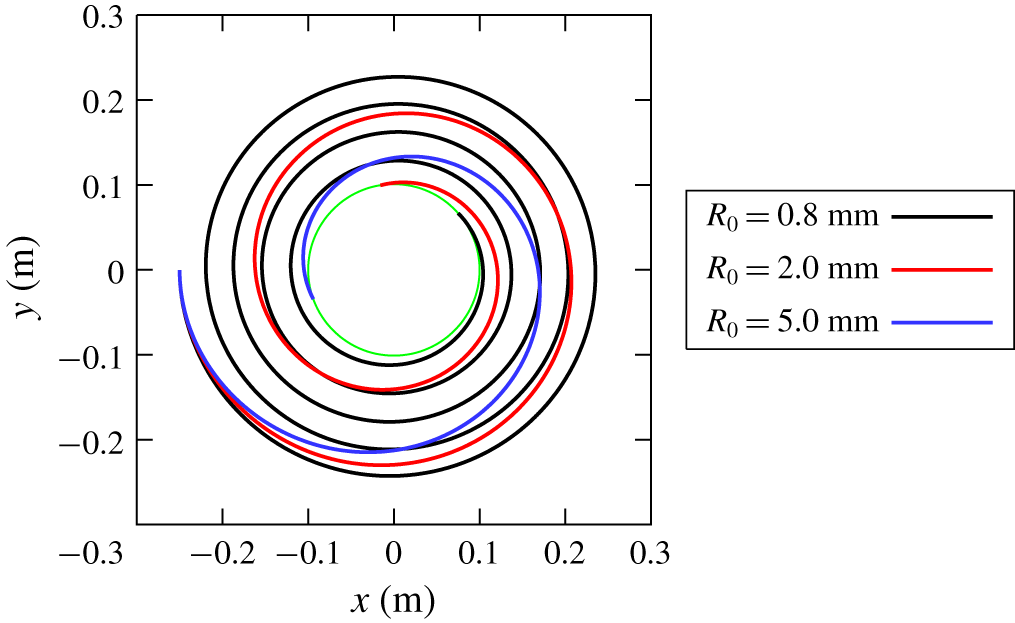

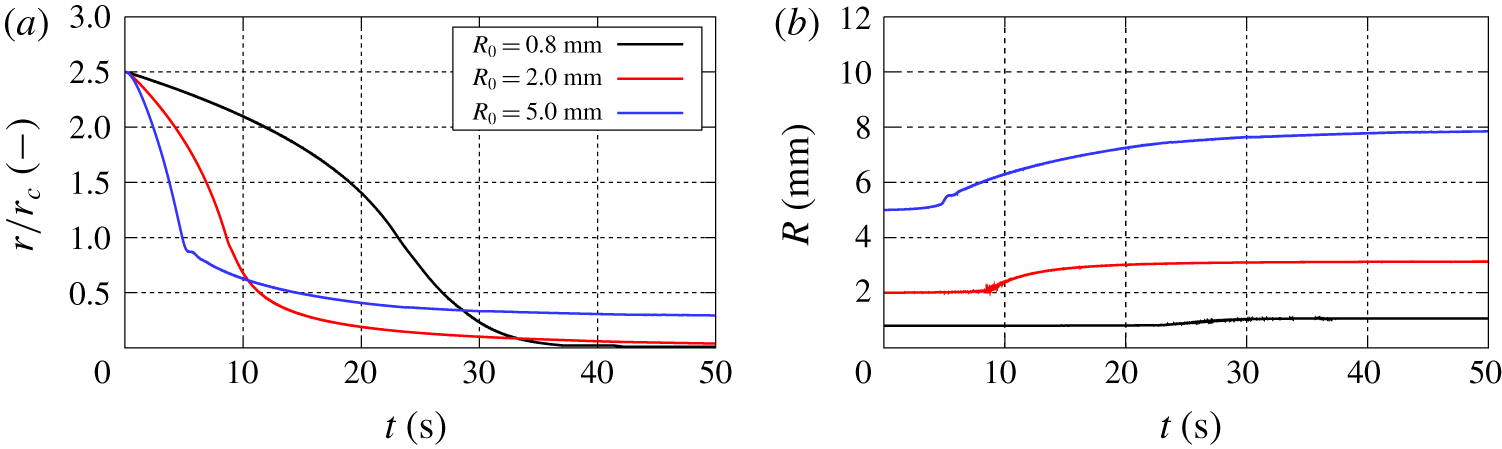

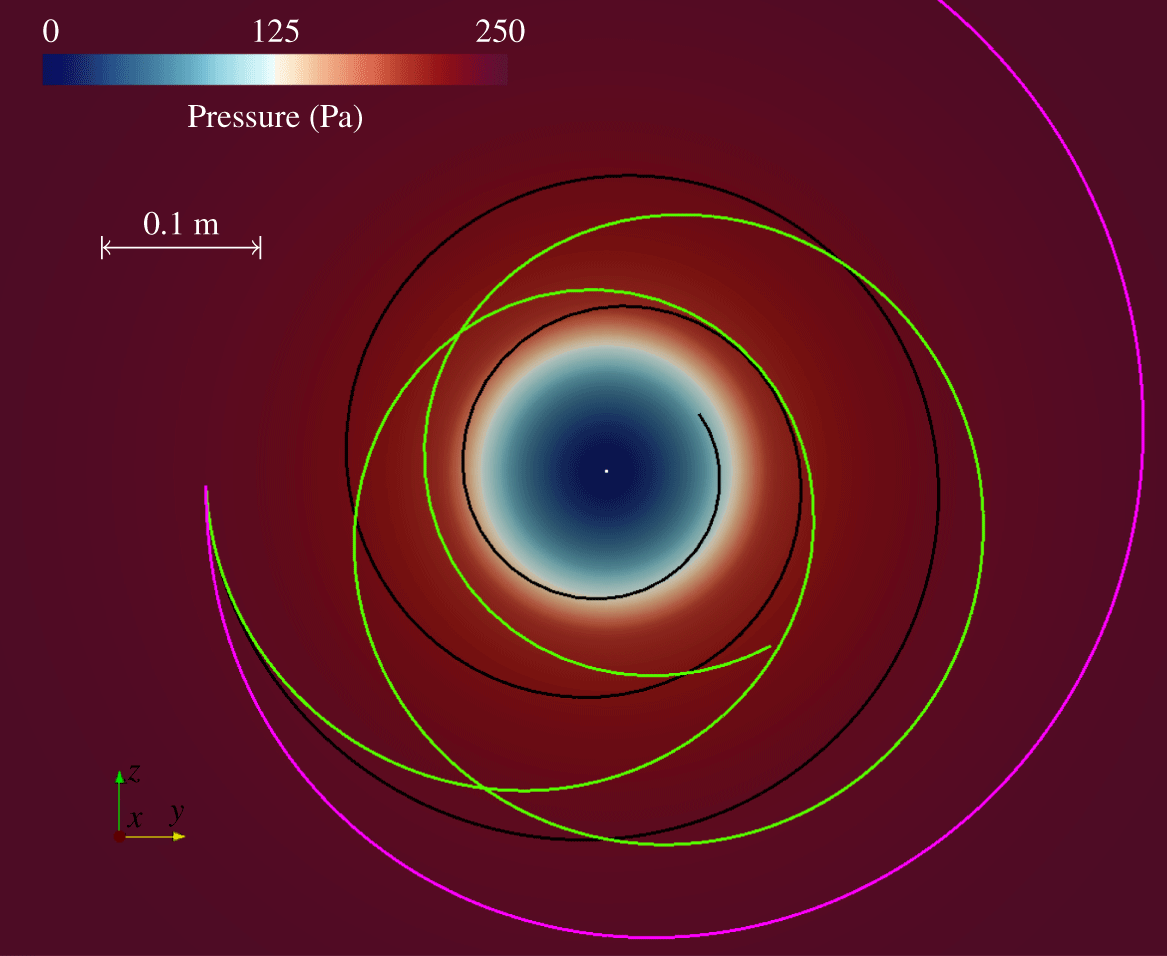

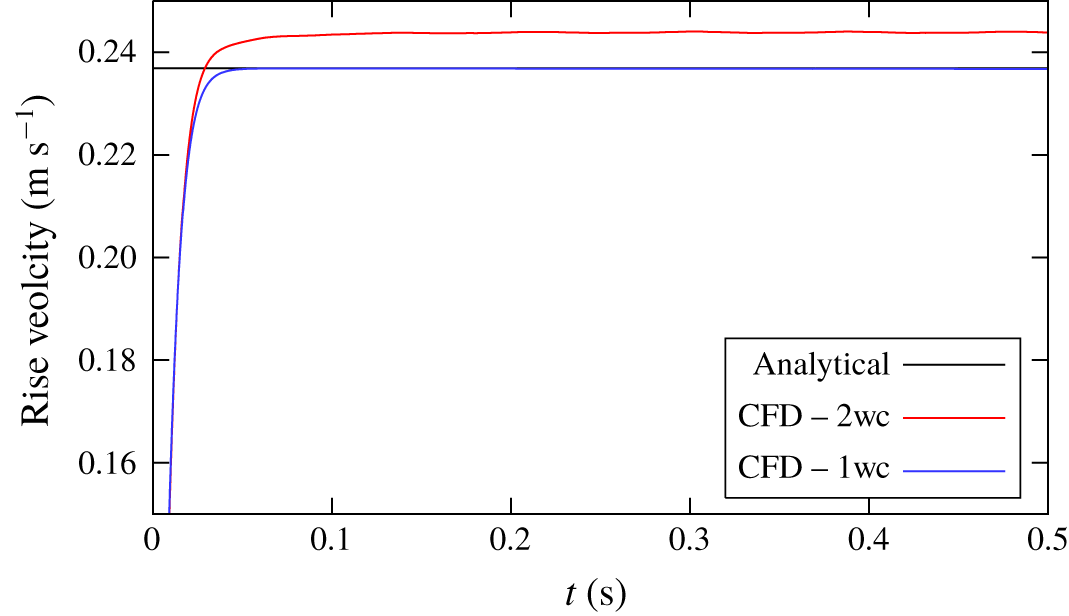

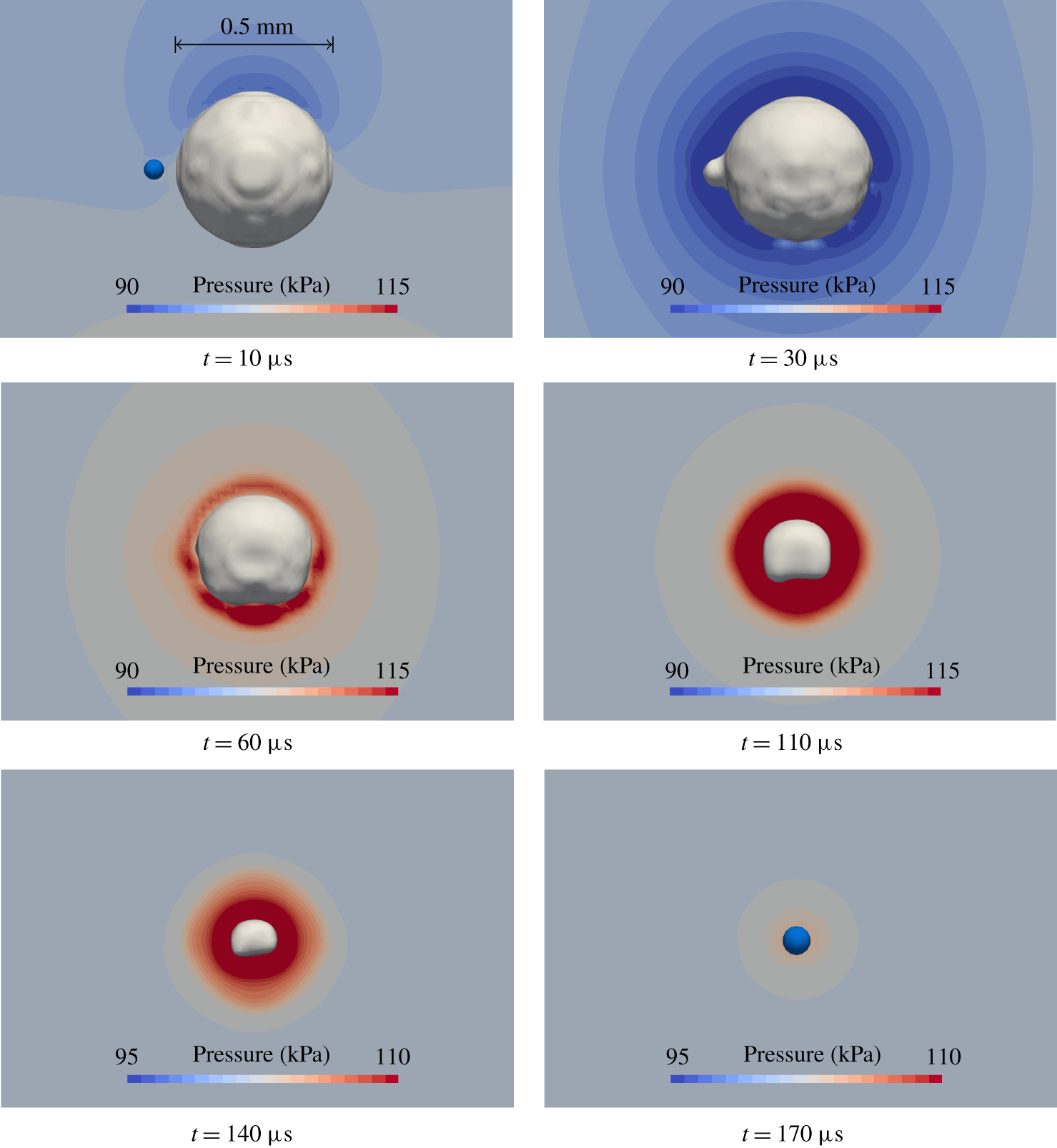

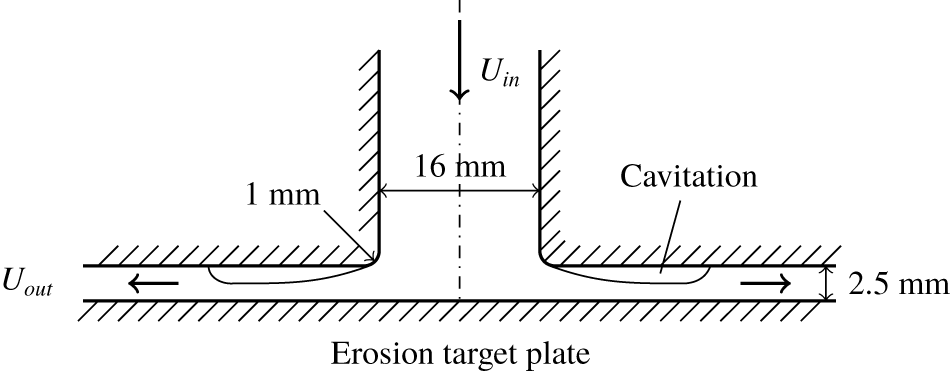

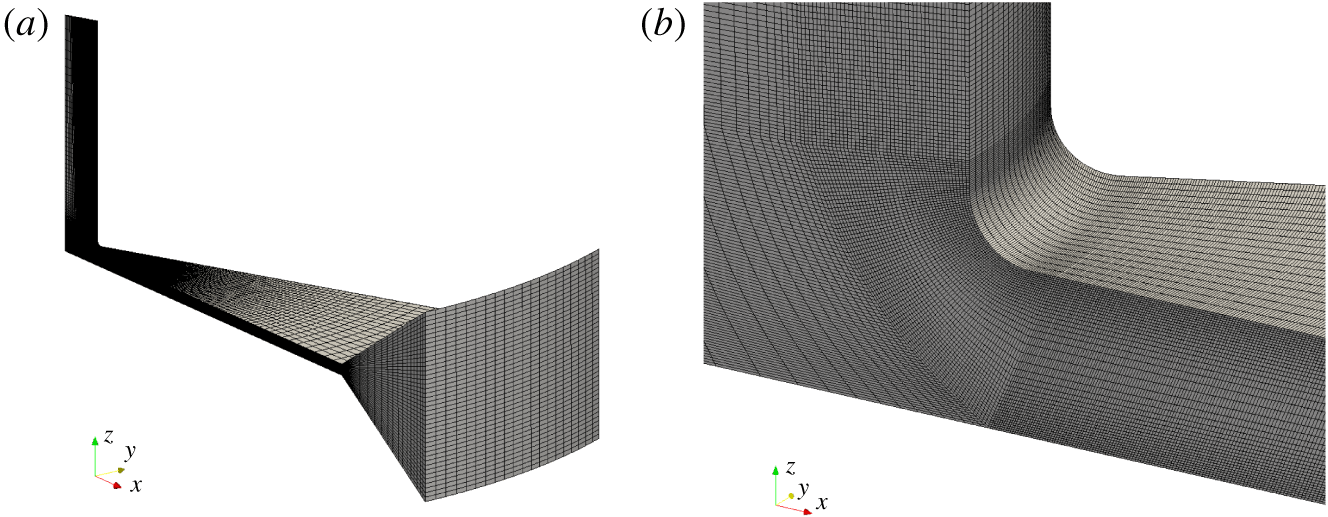

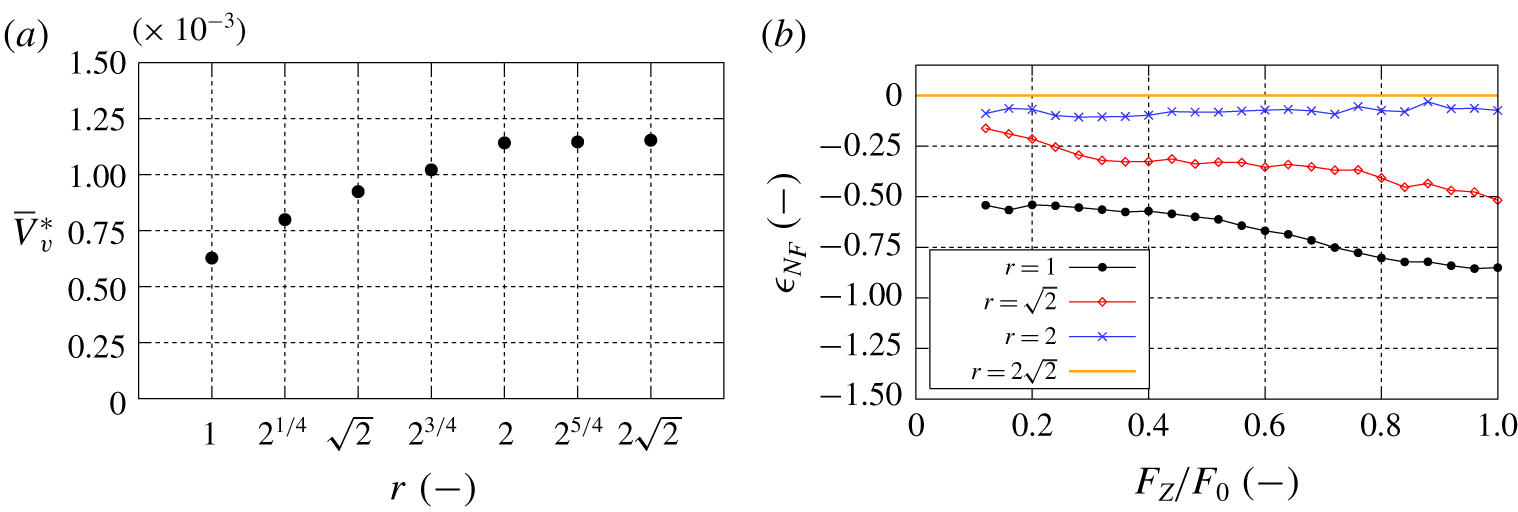

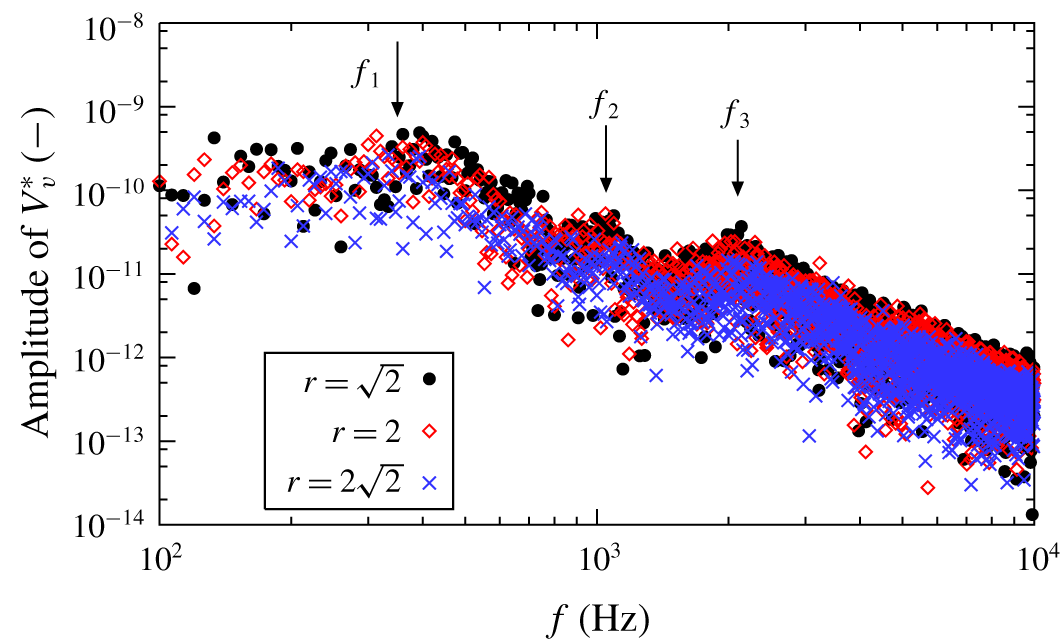

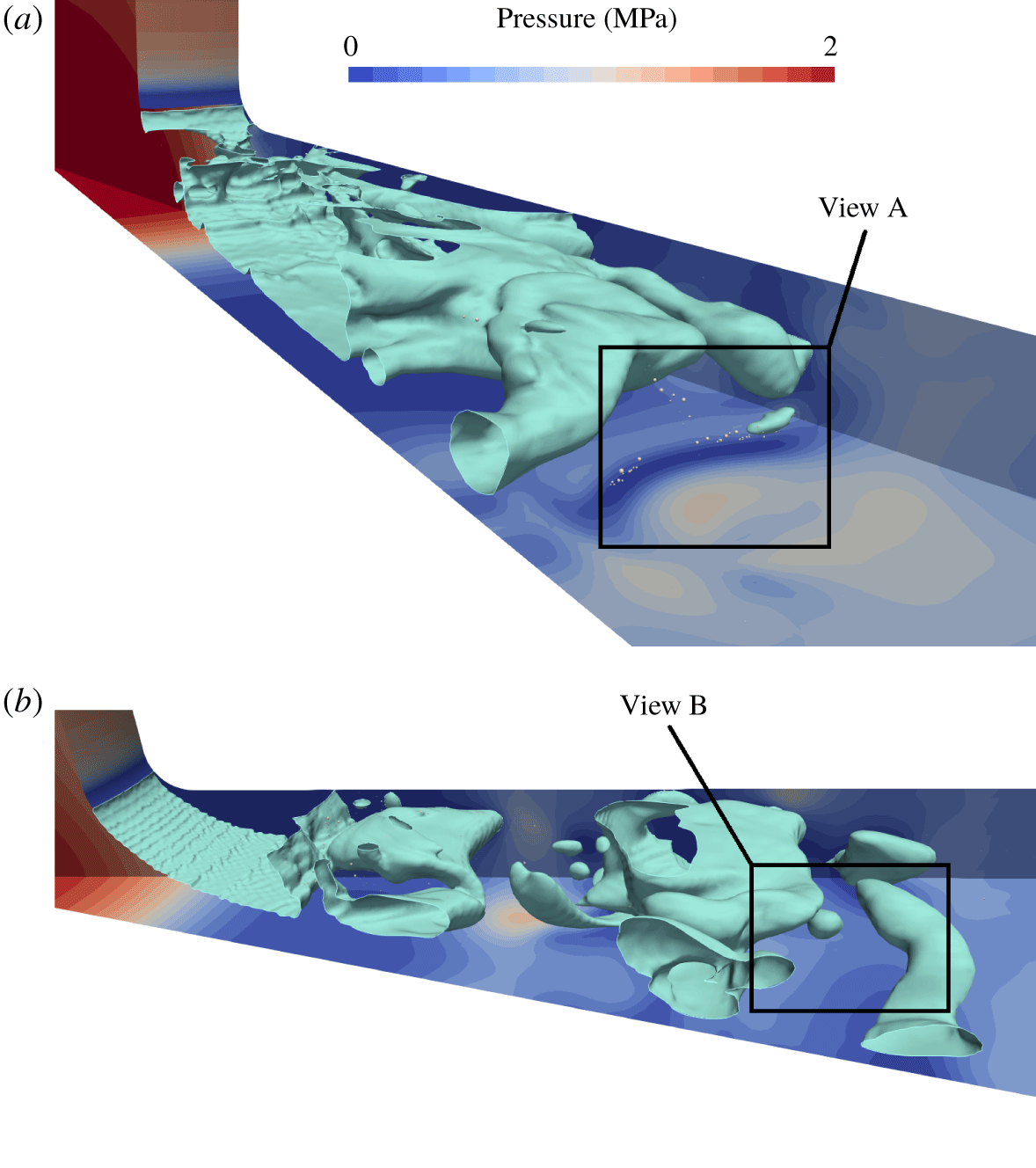

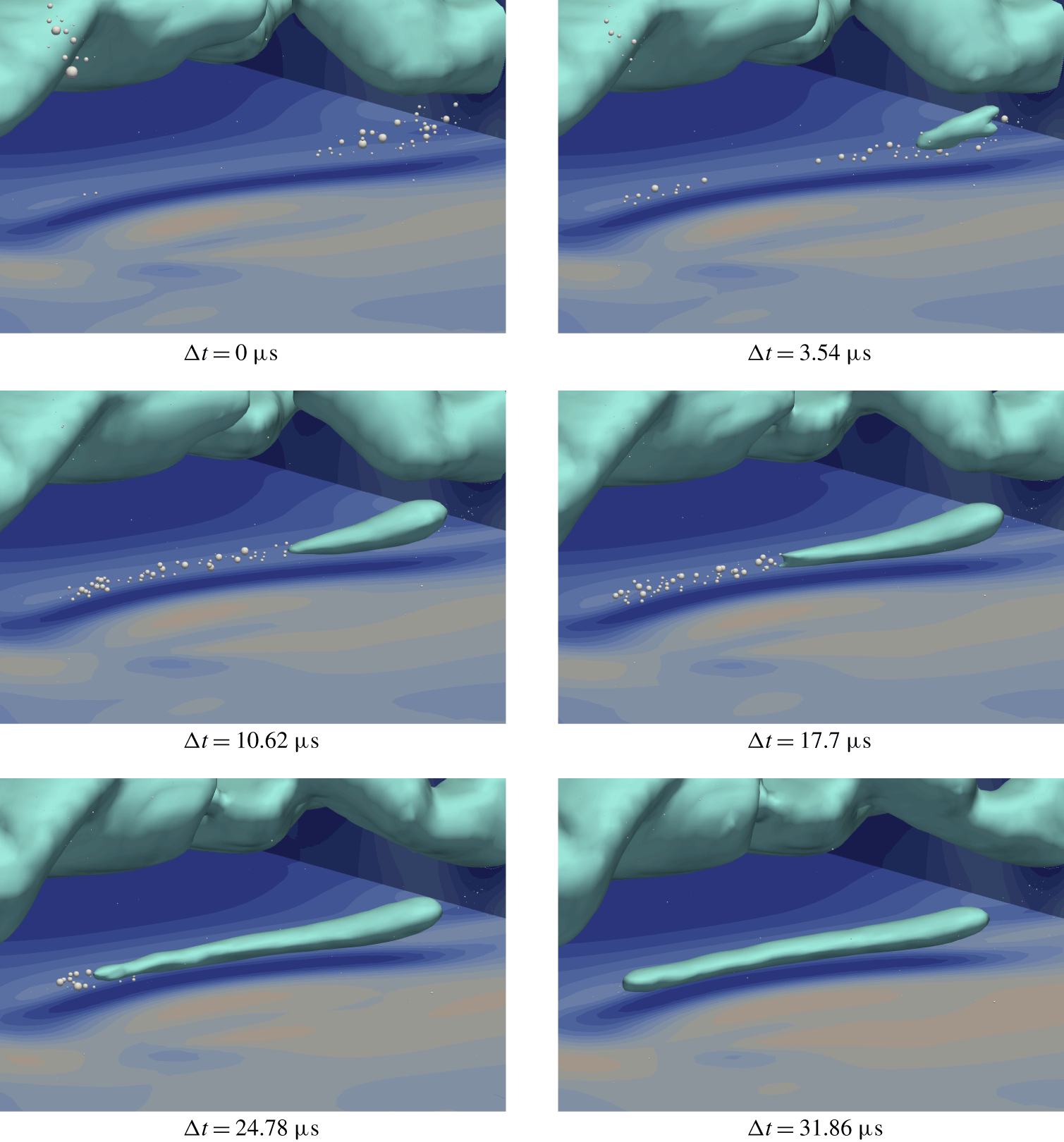

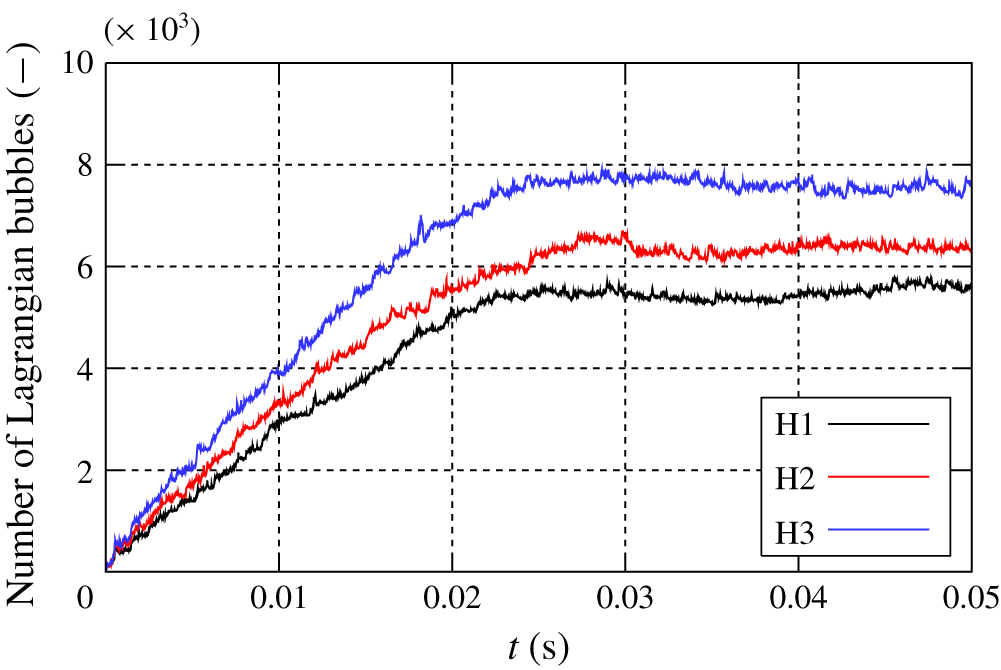

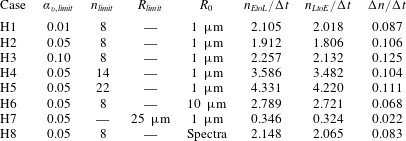

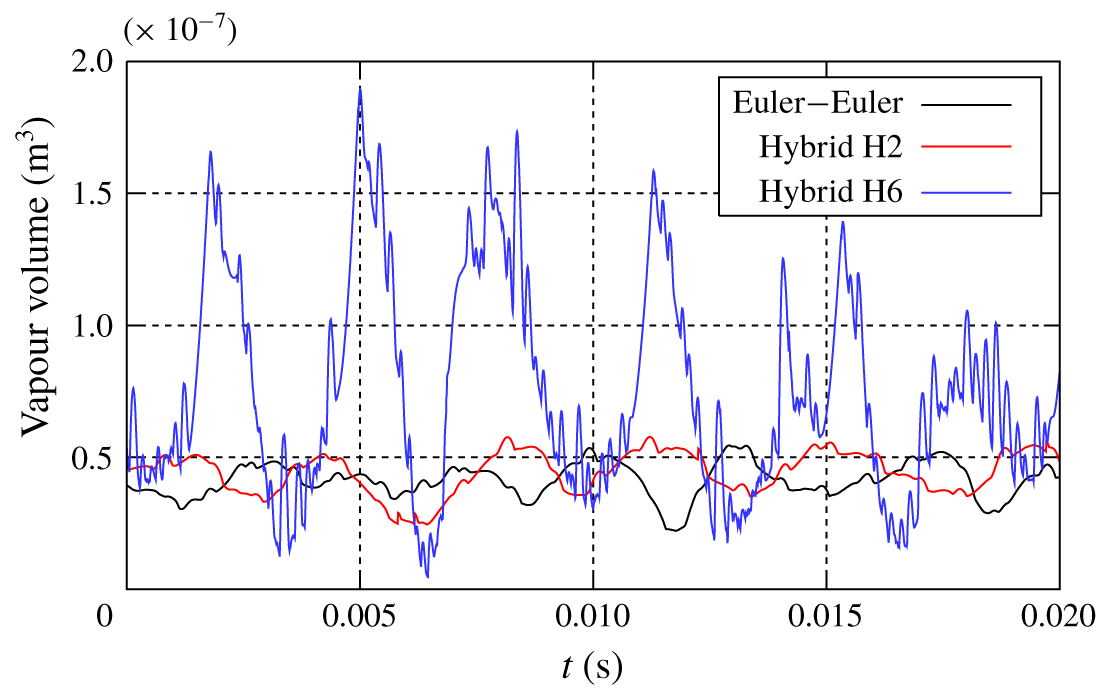

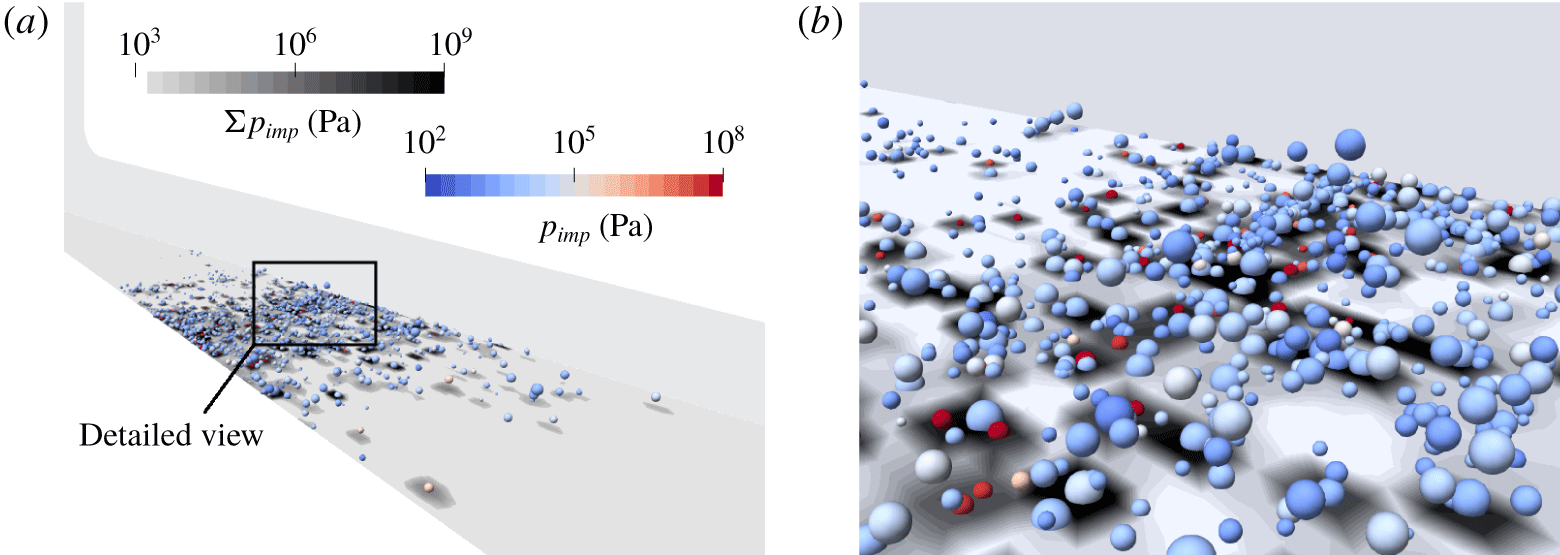

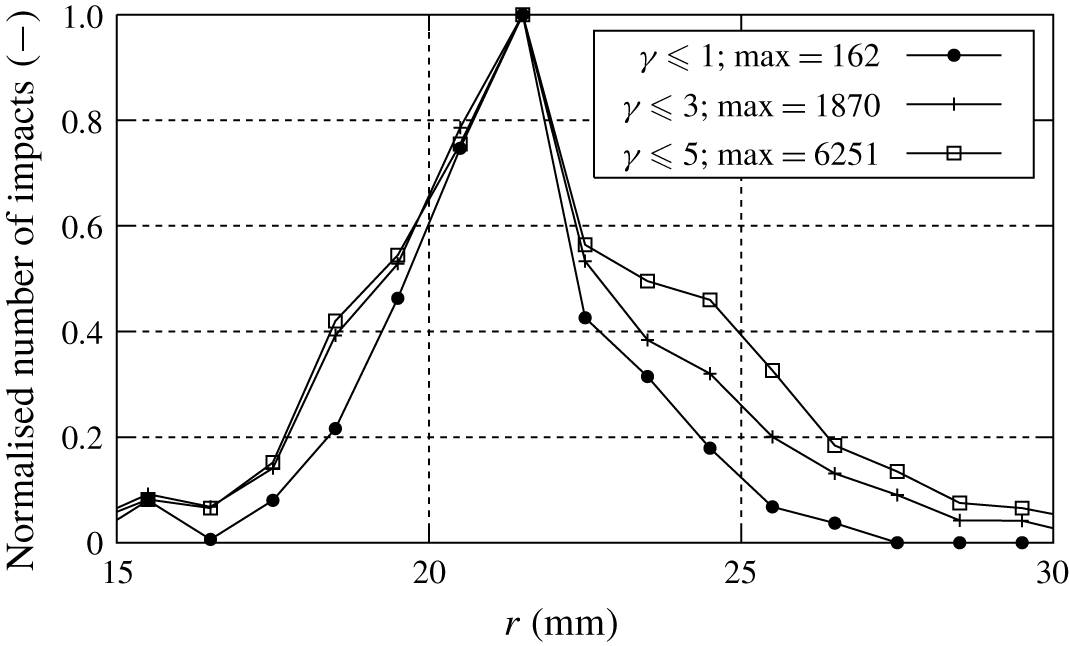

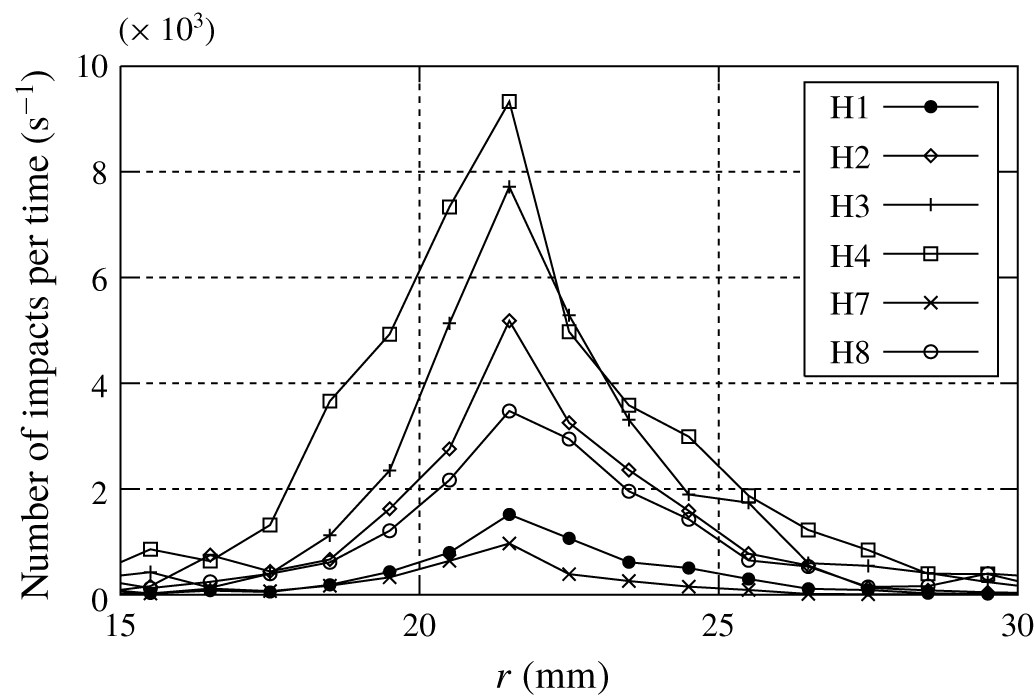

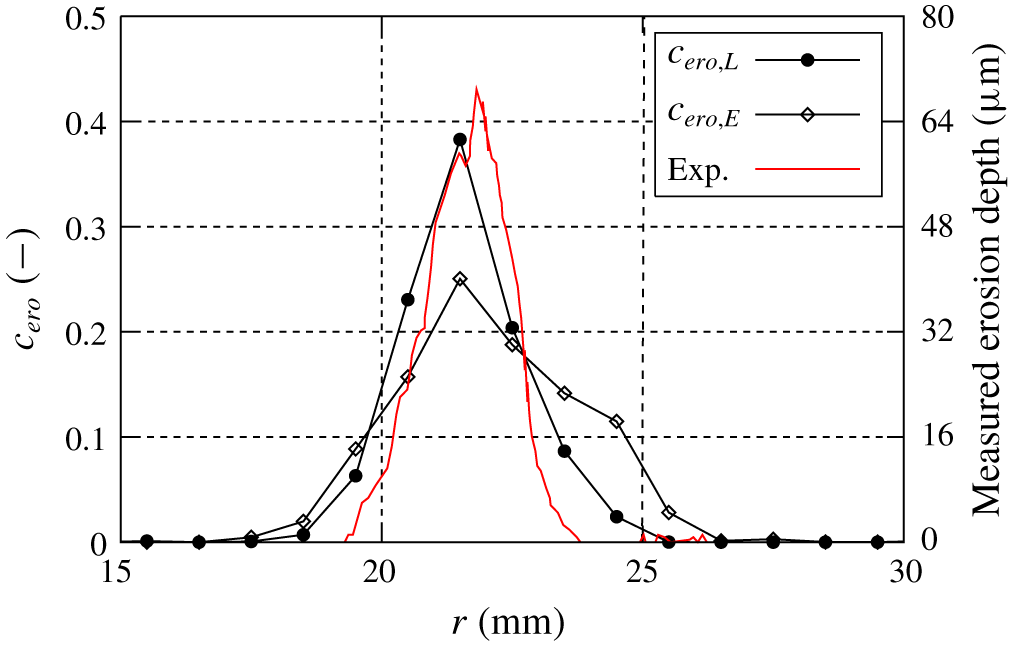

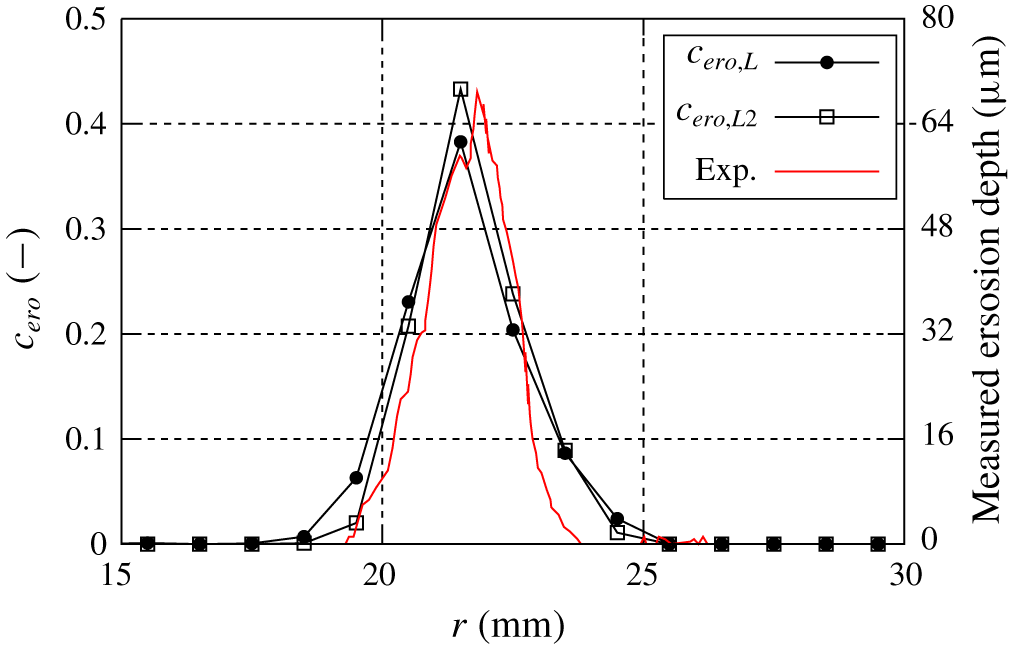

$R$ are calculated using the trapezoidal rule for the implicit second-order time integration. Adaptive time stepping enables the efficient calculation of  $\ddot{R}$ over the relatively long growth phase and the shorter collapse phase. The bubble dynamics equation is time integrated over the entire time step of the Eulerian flow solution.