1. Introduction

Wind turbines are becoming increasingly important contributors to global energy supplies, as they represent a low-carbon alternative to traditional power-generation technologies that rely on the combustion of fossil fuels. If wind power is to comprise a larger share of global energy production, the efficiency and power density of wind farms will need to be improved (Jacobson & Archer Reference Jacobson and Archer2012). The critical limitation of these large arrays is not the efficiency of individual wind turbines, which already operate at efficiencies approaching their theoretical maximum (Betz Reference Betz1920), but rather the dynamics of wind-turbine wakes and its effects on downstream turbines (Stevens & Meneveau Reference Stevens and Meneveau2017). The efficiency of the large-scale deployment of wind power thus depends largely on a more careful consideration of the wake dynamics of wind turbines.

Horizontal-axis wind turbines (HAWTs) typically have very long wakes that extend up to 20 turbine diameters (![]() $D$) downstream of the turbine itself (Vermeer, Sørensen & Crespo Reference Vermeer, Sørensen and Crespo2003; Meyers & Meneveau Reference Meyers and Meneveau2012; Hau Reference Hau2013; Stevens & Meneveau Reference Stevens and Meneveau2017), although wake persistence may vary with field conditions (e.g. Nygaard & Newcombe Reference Nygaard and Newcombe2018). HAWTs placed in closely packed arrays therefore generally incur significant losses from the wakes of upstream turbines (e.g. Barthelmie et al. Reference Barthelmie, Frandsen, Nielsen, Pryor, Rethore and Jørgensen2007; Barthelmie & Jensen Reference Barthelmie and Jensen2010; Barthelmie et al. Reference Barthelmie, Pryor, Frandsen, Hansen, Schepers, Rados, Schlez, Neubert, Jensen and Neckelmann2010). Vertical-axis wind-turbine (VAWT) wakes, by contrast, have been observed to recover their kinetic energy within 4 to 6

$D$) downstream of the turbine itself (Vermeer, Sørensen & Crespo Reference Vermeer, Sørensen and Crespo2003; Meyers & Meneveau Reference Meyers and Meneveau2012; Hau Reference Hau2013; Stevens & Meneveau Reference Stevens and Meneveau2017), although wake persistence may vary with field conditions (e.g. Nygaard & Newcombe Reference Nygaard and Newcombe2018). HAWTs placed in closely packed arrays therefore generally incur significant losses from the wakes of upstream turbines (e.g. Barthelmie et al. Reference Barthelmie, Frandsen, Nielsen, Pryor, Rethore and Jørgensen2007; Barthelmie & Jensen Reference Barthelmie and Jensen2010; Barthelmie et al. Reference Barthelmie, Pryor, Frandsen, Hansen, Schepers, Rados, Schlez, Neubert, Jensen and Neckelmann2010). Vertical-axis wind-turbine (VAWT) wakes, by contrast, have been observed to recover their kinetic energy within 4 to 6 ![]() $D$ downstream of the turbine, albeit with lower individual coefficients of thrust and power (Kinzel, Mulligan & Dabiri Reference Kinzel, Mulligan and Dabiri2012; Kinzel, Araya & Dabiri Reference Kinzel, Araya and Dabiri2015; Ryan et al. Reference Ryan, Coletti, Elkins, Dabiri and Eaton2016). VAWTs can also be arranged in pairs, to capitalize on synergistic fluid interactions between the turbines (e.g. Rajagopalan, Rickerl & Klimas Reference Rajagopalan, Rickerl and Klimas1990; Ahmadi-Baloutaki, Carriveau & Ting Reference Ahmadi-Baloutaki, Carriveau and Ting2016; Brownstein, Kinzel & Dabiri Reference Brownstein, Kinzel and Dabiri2016; Hezaveh et al. Reference Hezaveh, Bou-Zeid, Dabiri, Kinzel, Cortina and Martinelli2018; Brownstein, Wei & Dabiri Reference Brownstein, Wei and Dabiri2019). Taken together, these factors imply that arrays of VAWTs can potentially achieve power densities an order of magnitude higher than those of conventional wind farms (Dabiri Reference Dabiri2011).

$D$ downstream of the turbine, albeit with lower individual coefficients of thrust and power (Kinzel, Mulligan & Dabiri Reference Kinzel, Mulligan and Dabiri2012; Kinzel, Araya & Dabiri Reference Kinzel, Araya and Dabiri2015; Ryan et al. Reference Ryan, Coletti, Elkins, Dabiri and Eaton2016). VAWTs can also be arranged in pairs, to capitalize on synergistic fluid interactions between the turbines (e.g. Rajagopalan, Rickerl & Klimas Reference Rajagopalan, Rickerl and Klimas1990; Ahmadi-Baloutaki, Carriveau & Ting Reference Ahmadi-Baloutaki, Carriveau and Ting2016; Brownstein, Kinzel & Dabiri Reference Brownstein, Kinzel and Dabiri2016; Hezaveh et al. Reference Hezaveh, Bou-Zeid, Dabiri, Kinzel, Cortina and Martinelli2018; Brownstein, Wei & Dabiri Reference Brownstein, Wei and Dabiri2019). Taken together, these factors imply that arrays of VAWTs can potentially achieve power densities an order of magnitude higher than those of conventional wind farms (Dabiri Reference Dabiri2011).

The dynamics of VAWT wakes is therefore relevant to the design of large-scale wind farms with higher energy densities, and accordingly has been analysed in several recent studies. The replenishment of momentum in both HAWT and VAWT wakes has been shown to be dependent on turbulent entrainment of fluid from above the turbine array, through modelling (Meneveau Reference Meneveau2012; Luzzatto-Fegiz & Caulfield Reference Luzzatto-Fegiz and Caulfield2018), simulations (Calaf, Meneveau & Meyers Reference Calaf, Meneveau and Meyers2010; Hezaveh & Bou-Zeid Reference Hezaveh and Bou-Zeid2018), wind-tunnel experiments (Chamorro & Porté-Agel Reference Chamorro and Porté-Agel2009; Cal et al. Reference Cal, Lebrón, Castillo, Kang and Meneveau2010) and field experiments (Kinzel et al. Reference Kinzel, Araya and Dabiri2015). VAWTs also exhibit large-scale vortical structures in their wakes that may further augment wake recovery. This vortex dynamics has been observed in scale-model studies of varying geometric fidelity, from rotating circular cylinders (Craig, Dabiri & Koseff Reference Craig, Dabiri and Koseff2016) to complete rotors (e.g. Tescione et al. Reference Tescione, Ragni, He, Ferreira and Van Bussel2014; Brownstein et al. Reference Brownstein, Wei and Dabiri2019). The inherently three-dimensional nature of these vortical structures, coupled with the high Reynolds numbers of operational VAWTs, complicates experimental and numerical studies of the dynamics of VAWT wakes.

Accordingly, numerical simulations with varying levels of complexity have been applied to study VAWT wakes. For studies of wake interactions within arrays, two-dimensional (2-D) Reynolds-averaged Navier-Stokes (RANS) simulations have often been employed (e.g. Bremseth & Duraisamy Reference Bremseth and Duraisamy2016; Zanforlin & Nishino Reference Zanforlin and Nishino2016). Large-eddy simulation (LES) studies have generally used actuator-line models to approximate the effects of the individual blades on the flow (e.g. Shamsoddin & Porté-Agel Reference Shamsoddin and Porté-Agel2014, Reference Shamsoddin and Porté-Agel2016; Abkar & Dabiri Reference Abkar and Dabiri2017; Abkar Reference Abkar2018; Hezaveh & Bou-Zeid Reference Hezaveh and Bou-Zeid2018). Posa et al. (Reference Posa, Parker, Leftwich and Balaras2016) and Posa & Balaras (Reference Posa and Balaras2018) were able to resolve the unsteady vortex shedding of individual blades in the spanwise component of vorticity using LES with periodic boundary conditions in the spanwise direction, which meant that tip-vortex shedding was not captured. More recently, Villeneuve, Boudreau & Dumas (Reference Villeneuve, Boudreau and Dumas2020) used delayed detached-eddy simulations and a fully three-dimensional turbine model in a rotating overset mesh to study the effects of end plates on VAWT wakes, resolving 3-D vortex shedding and the wake dynamics up to 10 ![]() $D$ into the wake. Numerical simulations have thus continued to improve in their capacity to resolve the salient dynamics in the wakes of VAWTs.

$D$ into the wake. Numerical simulations have thus continued to improve in their capacity to resolve the salient dynamics in the wakes of VAWTs.

Laboratory- and field-scale experiments have been extensively employed to characterize the wake dynamics of HAWTs over a large range of configurations and inflow conditions (e.g. Chamorro & Porté-Agel Reference Chamorro and Porté-Agel2009; Bastankhah & Porté-Agel Reference Bastankhah and Porté-Agel2017; Schottler et al. Reference Schottler, Reinke, Hölling, Whale, Peinke and Hölling2017; Bartl et al. Reference Bartl, Mühle, Schottler, Sætran, Peinke, Adaramola and Hölling2018), and similar laboratory-scale experiments have proved invaluable for the analysis of the wake structures of VAWTs as well. Experiments with VAWTs, however, have generally been limited to planar measurements in the laboratory (e.g. Brochier, Fraunie & Beguierj Reference Brochier, Fraunie and Beguierj1986; Ferreira et al. Reference Ferreira, van Kuik, van Bussel and Scarano2009; Battisti et al. Reference Battisti, Zanne, Dell'Anna, Dossena, Persico and Paradiso2011). The deployment of stereoscopic particle-image velocimetry (stereo-PIV) has allowed some three-dimensional effects to be captured (Tescione et al. Reference Tescione, Ragni, He, Ferreira and Van Bussel2014; Rolin & Porté-Agel Reference Rolin and Porté-Agel2015, Reference Rolin and Porté-Agel2018), as has the use of planar PIV with multiple imaging planes (Parker & Leftwich Reference Parker and Leftwich2016; Araya, Colonius & Dabiri Reference Araya, Colonius and Dabiri2017; Parker, Araya & Leftwich Reference Parker, Araya and Leftwich2017). These planar techniques have been successful in identifying characteristic vortex phenomena, such as dynamic stall on turbine blades (Ferreira et al. Reference Ferreira, van Kuik, van Bussel and Scarano2009; Buchner et al. Reference Buchner, Lohry, Martinelli, Soria and Smits2015; Dunne & McKeon Reference Dunne and McKeon2015; Buchner et al. Reference Buchner, Soria, Honnery and Smits2018) and tip-vortex shedding from the ends of individual blades (Hofemann et al. Reference Hofemann, Ferreira, Dixon, Van Bussel, Van Kuik and Scarano2008; Tescione et al. Reference Tescione, Ragni, He, Ferreira and Van Bussel2014). Generally, however, it is difficult to compute all three components of vorticity or the circulation of vortical structures with purely planar measurements. The analysis of the three-dimensional character of vortical structures in the wake is therefore greatly facilitated by fully three-dimensional flow-field measurements. Such experiments have only recently been carried out in laboratory settings. Using tomographic PIV, Caridi et al. (Reference Caridi, Ragni, Sciacchitano and Scarano2016) resolved the three-dimensional structure of tip vortices shed by a VAWT blade within a small measurement volume with a maximum dimension of 5.5 blade chord lengths. Ryan et al. (Reference Ryan, Coletti, Elkins, Dabiri and Eaton2016) obtained 3-D time-averaged velocity and vorticity measurements of the full wake of a model VAWT using magnetic-resonance velocimetry. Most recently, Brownstein et al. (Reference Brownstein, Wei and Dabiri2019) used 3-D particle-tracking velocimetry (PTV) to obtain time-averaged measurements of the wakes of isolated and paired VAWTs. These studies were all carried out at laboratory-scale Reynolds numbers, which fell between one and two orders of magnitude below those typical of operational VAWTs. Miller et al. (Reference Miller, Duvvuri, Brownstein, Lee, Dabiri and Hultmark2018a) attained Reynolds numbers up to ![]() $Re_D = 5\times 10^{6}$ using a compressed-air wind tunnel, and their measurements of the coefficients of power demonstrated a Reynolds number invariance for

$Re_D = 5\times 10^{6}$ using a compressed-air wind tunnel, and their measurements of the coefficients of power demonstrated a Reynolds number invariance for ![]() $Re_D > 1.5\times 10^{6}$. These power measurements suggest that Reynolds numbers of the order of

$Re_D > 1.5\times 10^{6}$. These power measurements suggest that Reynolds numbers of the order of ![]() $10^{6}$ may be required to fully capture the wake dynamics of field-scale turbines. As an alternative to laboratory experiments at lower

$10^{6}$ may be required to fully capture the wake dynamics of field-scale turbines. As an alternative to laboratory experiments at lower ![]() $Re_D$, experiments in field conditions at full scale are possible, but these have been limited to pointwise anemometry (Kinzel et al. Reference Kinzel, Mulligan and Dabiri2012, Reference Kinzel, Araya and Dabiri2015) or 2-D planar velocity measurements (Hong et al. Reference Hong, Toloui, Chamorro, Guala, Howard, Riley, Tucker and Sotiropoulos2014). Thus, for the validation and extension of existing experimental work on the wake dynamics of VAWTs, 3-D flow measurements around full-scale VAWTs in field conditions are desirable.

$Re_D$, experiments in field conditions at full scale are possible, but these have been limited to pointwise anemometry (Kinzel et al. Reference Kinzel, Mulligan and Dabiri2012, Reference Kinzel, Araya and Dabiri2015) or 2-D planar velocity measurements (Hong et al. Reference Hong, Toloui, Chamorro, Guala, Howard, Riley, Tucker and Sotiropoulos2014). Thus, for the validation and extension of existing experimental work on the wake dynamics of VAWTs, 3-D flow measurements around full-scale VAWTs in field conditions are desirable.

The additional benefit of 3-D flow measurements is that they enable the effects of complex turbine geometries on wake structures to be investigated. This is particularly useful for VAWTs, since several distinct geometric variations exist. Because of the planar constraints of most experimental and numerical studies, VAWTs with straight blades and constant spanwise cross-sections have primarily been studied due to their symmetry and simplicity of construction. However, there exist several VAWT designs that incorporate curved blades. Large-scale Darrieus-type turbines have blades that are bowed outward along the span, and these have historically reached larger sizes and power-generation capacities than straight-bladed turbines (Möllerström et al. Reference Möllerström, Gipe, Beurskens and Ottermo2019). Similarly, many modern VAWTs have helical blades that twist around the axis of rotation, following the design of the Gorlov Helical Turbine (Gorlov Reference Gorlov1995), to reduce fatigue from unsteady loads on the turbine blades. Relatively few studies have investigated the flow physics of these helical-bladed VAWTs in any kind of detail. Schuerich & Brown (Reference Schuerich and Brown2011) used a vorticity-transport model for this purpose, and Cheng et al. (Reference Cheng, Liu, Ji, Kim and Yang2017) approached the problem using unsteady RANS, 2-D LES and wind-tunnel experiments. Aliferis et al. (Reference Aliferis, Jessen, Bracchi and Hearst2019) studied the 2-D planar wake structure of a Savonius-type VAWT with helical blades using a Cobra probe on a traverse. Lastly, Ouro et al. (Reference Ouro, Runge, Luo and Stoesser2019) analysed turbulence quantities in the wake of a helical-bladed VAWT in a water channel using pointwise velocity measurements from an anemometer on a traverse. A full treatment of the effects of the helical blades on the three-dimensional vorticity fields and corresponding vortical structures in the wake has yet to be undertaken.

Thus, the purpose of this work is to study the three-dimensional flow features of operational VAWTs in the field. The work revolves around two primary contributions: the development of a field-deployed 3-D PTV measurement system, and the analysis of topological and dynamical characteristics of vortical structures in the wakes of full-scale VAWTs. Firstly, the characterization of the artificial-snow-based technique for obtaining three-dimensional, three-component measurements of velocity and vorticity in field experiments around full-scale VAWTs will be documented (§ 2). Experiments with two VAWTs, one with straight blades and one with helical blades and each at two tip-speed ratios, will then be outlined. Velocity and vorticity fields from these experiments will be presented, and a difference in the three-dimensional structure of the wake between the two types of turbines will be identified (§§ 3.1 and 3.2). This tilted-wake behaviour will be analysed further, to establish a connection between blade geometry and wake topology (§ 3.3). The results from these analyses shed light on the dynamics that governs the near wake of VAWTs (up to ![]() ${\sim }3$

${\sim }3$ ![]() $D$ downstream, cf. Araya et al. Reference Araya, Colonius and Dabiri2017), and implications of these findings for future studies and for the design and optimization of VAWT wind farms will be discussed (§§ 3.4 and 3.5). This work represents the first full-scale, fully three-dimensional flow-field study on operational VAWTs in field conditions, and therefore provides fundamental insights into the wake dynamics at high Reynolds numbers and the fluid mechanics of wind energy.

$D$ downstream, cf. Araya et al. Reference Araya, Colonius and Dabiri2017), and implications of these findings for future studies and for the design and optimization of VAWT wind farms will be discussed (§§ 3.4 and 3.5). This work represents the first full-scale, fully three-dimensional flow-field study on operational VAWTs in field conditions, and therefore provides fundamental insights into the wake dynamics at high Reynolds numbers and the fluid mechanics of wind energy.

2. Experimental methods

In this section, the set-up of the field experiments is outlined, and a novel technique for 3-D PTV measurements in field conditions is introduced. The experimental procedure is discussed, and the post-processing steps for computing velocity and vorticity fields are described. Additional details and characterizations of the measurement system are given in appendices A and B.

2.1. Field site and turbine characterization

Experiments were carried out during the nights of 9–11 August 2018 at the Field Laboratory for Optimized Wind Energy (FLOWE), located on a flat, arid segment of land near Lancaster, California, USA. Details regarding the geography of the site are provided by Kinzel et al. (Reference Kinzel, Mulligan and Dabiri2012). Wind conditions at the site were measured with an anemometer (First Class, Thies Clima) and a wind vane (Model 024A, Met One), which recorded data at 1 Hz with accuracies of ![]() ${\pm }3\,\%$ and

${\pm }3\,\%$ and ![]() ${\pm }5^{\circ }$, respectively. These were mounted on a meteorological tower (Model M-10M, Aluma Tower Co.) at a height of 10 m above the ground. The tower also recorded air temperature, which was used to interpolate air density from a density–temperature table. A datalogger (CR1000, Campbell Scientific) recorded these data at 1 and 10 minute intervals. The height difference between the anemometer and the VAWTs was corrected using a fit of an atmospheric boundary-layer profile to data collected previously at the site at multiple heights (cf. Kinzel et al. Reference Kinzel, Mulligan and Dabiri2012). The correction resulted in a 3 % change in the free-stream velocity, which compared more favourably with the particle-based flow-field measurements than the uncorrected readings. The measured wind conditions at the site during experiments were uniform in both magnitude and direction: the wind speed was

${\pm }5^{\circ }$, respectively. These were mounted on a meteorological tower (Model M-10M, Aluma Tower Co.) at a height of 10 m above the ground. The tower also recorded air temperature, which was used to interpolate air density from a density–temperature table. A datalogger (CR1000, Campbell Scientific) recorded these data at 1 and 10 minute intervals. The height difference between the anemometer and the VAWTs was corrected using a fit of an atmospheric boundary-layer profile to data collected previously at the site at multiple heights (cf. Kinzel et al. Reference Kinzel, Mulligan and Dabiri2012). The correction resulted in a 3 % change in the free-stream velocity, which compared more favourably with the particle-based flow-field measurements than the uncorrected readings. The measured wind conditions at the site during experiments were uniform in both magnitude and direction: the wind speed was ![]() $11.01\pm 1.36\ \textrm {ms}^{-1}$, and the wind direction was from the southwest at

$11.01\pm 1.36\ \textrm {ms}^{-1}$, and the wind direction was from the southwest at ![]() $248\pm 3^{\circ }$. These statistics were calculated from sensor data that had been averaged by the datalogger into ten minute readouts, and are summarized in the wind rose shown in figure 1(a).

$248\pm 3^{\circ }$. These statistics were calculated from sensor data that had been averaged by the datalogger into ten minute readouts, and are summarized in the wind rose shown in figure 1(a).

Figure 1. (a) Wind rose for conditions during experiments (9–11 August 2018). The plotted wind speeds and directions are those recorded by the tower-mounted anemometer, located 10 m above the ground, and have been binned in ten minute averages by ![]() $1\ \textrm {ms}^{-1}$ and

$1\ \textrm {ms}^{-1}$ and ![]() $5^{\circ }$, respectively. (b) Wind speeds and directions, from a single experiment (three eight minute data sets), binned in one minute averages.

$5^{\circ }$, respectively. (b) Wind speeds and directions, from a single experiment (three eight minute data sets), binned in one minute averages.

For these experiments, two types of VAWTs were employed. A 1-kW, three-bladed VAWT with helical blades, built by Urban Green Energy (UGE), was compared with a 2-kW, five-bladed VAWT with straight blades from Wing Power Energy (WPE). The blades of both turbines had constant cross-sectional geometries. The blade twist of the helical-bladed turbine, representing the angle of twist with respect to the axis of rotation per unit length along the span of the turbine, was ![]() $\tau = 0.694\ \textrm {rad}\ \textrm {m}^{-1}$. Photos and details of these two turbines, referred to in this work by their manufacturer's acronyms (UGE and WPE), are given in figure 2. Each turbine was tested at two different tip-speed ratios, defined as

$\tau = 0.694\ \textrm {rad}\ \textrm {m}^{-1}$. Photos and details of these two turbines, referred to in this work by their manufacturer's acronyms (UGE and WPE), are given in figure 2. Each turbine was tested at two different tip-speed ratios, defined as

where ![]() $\omega$ is the rotation rate of the turbine (

$\omega$ is the rotation rate of the turbine (![]() $\textrm {rad}\ \textrm {s}^{-1}$),

$\textrm {rad}\ \textrm {s}^{-1}$), ![]() $R$ is the radius of the turbine (m) and

$R$ is the radius of the turbine (m) and ![]() $U_\infty$ is the magnitude of the free-stream velocity (

$U_\infty$ is the magnitude of the free-stream velocity (![]() $\textrm {ms}^{-1}$). The turbines had different solidities, quantified as the ratio of the blade area to the swept area of the rotating blades. This was defined as

$\textrm {ms}^{-1}$). The turbines had different solidities, quantified as the ratio of the blade area to the swept area of the rotating blades. This was defined as

where ![]() $n$ is the number of blades,

$n$ is the number of blades, ![]() $c$ is the chord length of each blade and

$c$ is the chord length of each blade and ![]() $D$ is the turbine diameter. The parameters for the four experiments presented in this work are given in table 1.

$D$ is the turbine diameter. The parameters for the four experiments presented in this work are given in table 1.

Figure 2. Photographs (a,c) and specifications (b,d) of the helical-bladed UGE turbine (a,b) and the straight-bladed WPE turbine (c,d). The blade twist of the UGE turbine is ![]() $\tau = 0.694\ \textrm {rad}\ \textrm {m}^{-1}$.

$\tau = 0.694\ \textrm {rad}\ \textrm {m}^{-1}$.

Table 1. Experimental parameters for the four test cases presented in this work. From the left, the first two experiments were carried out on 9 August 2018, the third on 10 August and the fourth on 11 August. The non-dimensional duration ![]() $T^{*}$ represents the number of convective time units

$T^{*}$ represents the number of convective time units ![]() $D/U_\infty$ captured by each experiment. Uncertainties from the average values represent one standard deviation over time.

$D/U_\infty$ captured by each experiment. Uncertainties from the average values represent one standard deviation over time.

The turbines were mounted on the same tower for experiments, setting the mid-span location of each at a height of 8.2 m above the ground. A Hall-effect sensor (Model 55505, Hamlin) on the tower measured the rotation rate of the WPE turbine by recording the blade passing frequency. This method could not be implemented with the UGE turbine due to its different construction. Therefore, the rotation rate of the UGE turbine was calculated from videos of the turbine in operation, taken at 120 frames per second with a CMOS camera (Hero4, GoPro), by autocorrelating the pixel-intensity signal to establish a blade passing time. Electrical power outputs from the turbines were measured and recorded in 10-minute intervals using a second datalogger (CR1000, Campbell Scientific). The coefficient of power was then calculated as

where ![]() $P$ is the power produced by the turbine,

$P$ is the power produced by the turbine, ![]() $\rho$ is the density of air and

$\rho$ is the density of air and ![]() $S$ is the turbine span. The computed coefficients of power of the two turbines for each of the tested tip-speed ratios are shown in figure 3. The

$S$ is the turbine span. The computed coefficients of power of the two turbines for each of the tested tip-speed ratios are shown in figure 3. The ![]() $C_p$ values for both turbines agree with measurements from previous experiments at the FLOWE field site reported by Miller et al. (Reference Miller, Duvvuri, Brownstein, Lee, Dabiri and Hultmark2018a) that suggested that the optimal tip-speed ratio for maximizing

$C_p$ values for both turbines agree with measurements from previous experiments at the FLOWE field site reported by Miller et al. (Reference Miller, Duvvuri, Brownstein, Lee, Dabiri and Hultmark2018a) that suggested that the optimal tip-speed ratio for maximizing ![]() $C_p$ was of the order of

$C_p$ was of the order of ![]() $\lambda \approx 1$ for the WPE turbine. This operating tip-speed ratio is low compared to those of larger-scale VAWTs with lower solidities (cf. Möllerström et al. Reference Möllerström, Gipe, Beurskens and Ottermo2019), but is consistent with those of turbines of the same power-production class (e.g. Han et al. Reference Han, Heo, Choi, Nam, Choi and Kim2018). The results also agree with the findings of other studies that the optimal tip-speed ratio for power production decreases with increasing solidity (Miller et al. Reference Miller, Duvvuri, Kelly and Hultmark2018b; Rezaeiha, Montazeri & Blocken Reference Rezaeiha, Montazeri and Blocken2018).

$\lambda \approx 1$ for the WPE turbine. This operating tip-speed ratio is low compared to those of larger-scale VAWTs with lower solidities (cf. Möllerström et al. Reference Möllerström, Gipe, Beurskens and Ottermo2019), but is consistent with those of turbines of the same power-production class (e.g. Han et al. Reference Han, Heo, Choi, Nam, Choi and Kim2018). The results also agree with the findings of other studies that the optimal tip-speed ratio for power production decreases with increasing solidity (Miller et al. Reference Miller, Duvvuri, Kelly and Hultmark2018b; Rezaeiha, Montazeri & Blocken Reference Rezaeiha, Montazeri and Blocken2018).

Figure 3. Coefficient of power as a function of tip-speed ratio for the four experiments outlined in table 1.

2.2. Particle-tracking velocimetry

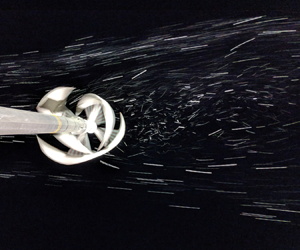

A new method for volumetric flow measurements in field conditions was developed to obtain three-dimensional velocity measurements in a large measurement volume encapsulating the near wake of full-scale turbines. Because of the arid climate at the field site, natural precipitation could not be relied on to populate the required measurement volume with seeding particles (cf. Hong et al. Reference Hong, Toloui, Chamorro, Guala, Howard, Riley, Tucker and Sotiropoulos2014). Therefore, to quantify the flow around the turbines, artificial snow particles were used as seeding particles for the flow. These were produced by four snow machines (Silent Storm DMX, Ultratec Special Effects) that were suspended by cables from two poles approximately four turbine diameters (![]() $D$) upstream of the turbine tower. The machines could be raised to different heights with respect to the turbine, to adjust the distribution of particles in the measurement volume. The particles were illuminated by two construction floodlights (MLT3060, Magnum), so that their images contrasted the night sky. Six CMOS video cameras (Hero4, GoPro) were mounted on frames and installed in a semicircle on the ground to capture the particles in the turbine wake from several different angles. The layout of the entire experiment (excluding the upstream meteorological tower) is shown in figure 4. The low seeding density and high visibility of the particles under these conditions meant that unambiguous particle trajectories could be extracted from the camera images, making PTV a natural choice for obtaining three-dimensional, three-component volumetric velocity measurements.

$D$) upstream of the turbine tower. The machines could be raised to different heights with respect to the turbine, to adjust the distribution of particles in the measurement volume. The particles were illuminated by two construction floodlights (MLT3060, Magnum), so that their images contrasted the night sky. Six CMOS video cameras (Hero4, GoPro) were mounted on frames and installed in a semicircle on the ground to capture the particles in the turbine wake from several different angles. The layout of the entire experiment (excluding the upstream meteorological tower) is shown in figure 4. The low seeding density and high visibility of the particles under these conditions meant that unambiguous particle trajectories could be extracted from the camera images, making PTV a natural choice for obtaining three-dimensional, three-component volumetric velocity measurements.

Figure 4. Schematic (a) and photograph (b) of the field experiment. The snow machines in (a) are not drawn to scale. The video cameras are labelled as Cam 1 through Cam 6. The direction of rotation for the turbine in the diagram is clockwise, and the ![]() $Z$-coordinate points vertically upward from the ground. The WPE turbine (

$Z$-coordinate points vertically upward from the ground. The WPE turbine (![]() $S = 3.7$ m) is shown in the photo. The artificial snow particles are visible moving with the flow toward the left of the frame.

$S = 3.7$ m) is shown in the photo. The artificial snow particles are visible moving with the flow toward the left of the frame.

The degree to which the artificial snow particles follow the flow was an important factor for the accuracy of the PTV measurements, and their aerodynamic characteristics were accordingly considered in detail. The particles were composed of an air-filled soap foam with an average effective diameter of ![]() $d_p = 11.2\pm 4.2$ mm and an average density of

$d_p = 11.2\pm 4.2$ mm and an average density of ![]() $\rho = 6.57\pm 0.32\ \textrm {kg}\ \textrm {m}^{-3}$. Since the particles were relatively large and non-spherical, experiments were conducted in laboratory conditions to establish their aerodynamic characteristics. A detailed description of the experiments, results and analyses regarding particle response and resulting experimental error is given in appendix A. By releasing the particles into a wind tunnel as a jet in cross-flow and tracking them using 3-D PTV with four cameras, the particle-response time scale

$\rho = 6.57\pm 0.32\ \textrm {kg}\ \textrm {m}^{-3}$. Since the particles were relatively large and non-spherical, experiments were conducted in laboratory conditions to establish their aerodynamic characteristics. A detailed description of the experiments, results and analyses regarding particle response and resulting experimental error is given in appendix A. By releasing the particles into a wind tunnel as a jet in cross-flow and tracking them using 3-D PTV with four cameras, the particle-response time scale ![]() $\tau _p$ and slip velocity

$\tau _p$ and slip velocity ![]() $V_s$ were computed. Comparing

$V_s$ were computed. Comparing ![]() $\tau _p$ with the relevant flow time scale,

$\tau _p$ with the relevant flow time scale, ![]() $\tau _f = D/U_\infty$, yielded a particle Stokes number of

$\tau _f = D/U_\infty$, yielded a particle Stokes number of ![]() $Sk = \tau _p/\tau _f \approx 0.23$. The worst-case slip velocities for the field experiments were estimated to be

$Sk = \tau _p/\tau _f \approx 0.23$. The worst-case slip velocities for the field experiments were estimated to be ![]() $V_{s} \lesssim 0.170\ \textrm {ms}^{-1}$, or less than 2 % of the average wind speed. Therefore, the particles were found to follow the flow with sufficient accuracy to resolve the large-scale structures encountered in VAWT wakes in the field.

$V_{s} \lesssim 0.170\ \textrm {ms}^{-1}$, or less than 2 % of the average wind speed. Therefore, the particles were found to follow the flow with sufficient accuracy to resolve the large-scale structures encountered in VAWT wakes in the field.

To ensure that the entire measurement domain was sampled with sufficient numbers of particles, multiple iterations of each experimental case were conducted, focusing on different regions of the measurement volume. This was accomplished by raising the snow machines to three distinct heights with respect to the turbine: at the turbine mid-span, above the turbine mid-span and at the top of the turbine (approximately 8, 9 and 10 m above the ground, respectively). Vector fields obtained from the data for each case were combined, so that each experiment listed in table 1 represents the combination of three separate recording periods. The effects of time averaging are further discussed in § 2.4.

The six video cameras were arranged in a semicircle around the near-wake region of the turbines, up to 7 to 8 ![]() $D$ downstream of the turbine. They recorded video at 120 frames per second and a resolution of

$D$ downstream of the turbine. They recorded video at 120 frames per second and a resolution of ![]() $1920\times 1080$ pixels, with an exposure time of 1/480 s and an image sensitivity (ISO) of 6400. The test cases outlined in table 1 thus represent between 161 000 and 175 000 images per camera of the measurement volume. Because the cameras were all positioned on the downstream side of the turbine, some flow regions adjacent to the turbine were masked by the turbine itself, and thus could not be measured. This, however, did not affect the measurement of the wake dynamics downstream of the turbine. The total measurement volume was approximately

$1920\times 1080$ pixels, with an exposure time of 1/480 s and an image sensitivity (ISO) of 6400. The test cases outlined in table 1 thus represent between 161 000 and 175 000 images per camera of the measurement volume. Because the cameras were all positioned on the downstream side of the turbine, some flow regions adjacent to the turbine were masked by the turbine itself, and thus could not be measured. This, however, did not affect the measurement of the wake dynamics downstream of the turbine. The total measurement volume was approximately ![]() $10\ \textrm {m} \times 7\ \textrm {m} \times 7\ \textrm {m}$, extending up to 2

$10\ \textrm {m} \times 7\ \textrm {m} \times 7\ \textrm {m}$, extending up to 2 ![]() $D$ upstream of the turbine and at least 3

$D$ upstream of the turbine and at least 3 ![]() $D$ downstream into the wake.

$D$ downstream into the wake.

To achieve the 3-D reconstruction of the artificial snow particles in physical space from the 2-D camera images, a wand-based calibration procedure following that of Theriault et al. (Reference Theriault, Fuller, Jackson, Bluhm, Evangelista, Wu, Betke and Hedrick2014) was carried out. A description of the procedure and its precision is included in appendix B.1. The two calibrations collected at the field site resulted in reconstruction errors of distances between cameras of ![]() $0.74\pm 0.39\,\%$ and

$0.74\pm 0.39\,\%$ and ![]() $0.83\pm 0.41\,\%$, and reconstruction errors in the spans of the turbines of

$0.83\pm 0.41\,\%$, and reconstruction errors in the spans of the turbines of ![]() $0.21\,\%$ and

$0.21\,\%$ and ![]() $0.32\,\%$. The calibrations therefore allowed particle positions to be triangulated accurately in physical space.

$0.32\,\%$. The calibrations therefore allowed particle positions to be triangulated accurately in physical space.

2.3. Experimental procedure

The collection of data for the field experiments was undertaken as follows. The rotation rate of the turbine was controlled via electrical loading to change the tip-speed ratio between experiments. The snow machines were hoisted to the desired height relative to the turbine, and artificial snow particles were advected through the measurement domain by the ambient wind. All six cameras were then initiated to record 420 to 560 seconds of video. Wind speed and direction measurements from the meteorological tower were averaged and recorded in one minute bins over the duration of the recording period. The procedure was then repeated for the three different snow-machine heights listed in § 2.2, corresponding to three data sets in total for each experimental case.

2.4. Data processing and analysis

The procedure and algorithms used to obtain accurate time-averaged velocity fields from the raw camera images are presented in detail in appendix B.2, along with an analysis of the statistical convergence of the averaged data. An overview of the procedure is given here.

Particles were isolated in the raw images through background subtraction and masking. Because the cameras were not synchronized via their hardware, the images from the camera views were temporally aligned using an LED band (RGBW LED strip, Supernight) that was mounted on the turbine tower below the turbine blades and flashed at one minute intervals. Particles were then identified in the synchronized images by thresholding based on pixel intensities. The particles were mapped to 3-D locations in physical space using epipolar geometry (Hartley & Zisserman Reference Hartley and Zisserman2003). A multi-frame predictive-tracking algorithm developed by Ouellette, Xu & Bodenschatz (Reference Ouellette, Xu and Bodenschatz2006) and Xu (Reference Xu2008) computed Lagrangian particle trajectories and velocities from these locations. Velocity data recorded with the snow machines set at different heights were combined into a single unstructured volume of instantaneous velocity vectors. This field was averaged into discrete cubic voxels with side lengths of 25 cm. The standard deviation of the velocity magnitude over all vectors in these voxels was below 5 % of the average value for over 50 % of the voxels in the measurement domain. This quantity can be interpreted as an analogue for measurement precision, though some variation due to turbulence across vectors within the voxels was expected. In the wake of the turbine, the volume of interest for the analyses presented in this work, 87 % of voxels had standard deviations below 5 %, with 58 % having values below 2 %. The best-case precision for highly sampled voxels was below 1 %. A more thorough account of these statistical-convergence studies is provided in appendix B.2. The velocity fields were finally filtered to enforce a zero-divergence condition (Schiavazzi et al. Reference Schiavazzi, Coletti, Iaccarino and Eaton2014) and were used to compute vorticity fields.

It is important to briefly consider the effect of time averaging, which was inherent to this PTV method. Temporal averaging removed the presence of turbulence fluctuations in the data, and thus the resulting velocity and vorticity fields necessarily contained only flow phenomena that were present in the mean flow. Conjectures regarding the effects of turbulence fluctuations on momentum transfer into the wake are therefore not possible based on these measurements. These effects are expected to dominate the far wake, whereas the near wake is characterized by large-scale vortical structures. Therefore, for the purposes of this study, it was deemed acceptable to forgo the resolution of turbulence fluctuations. Similarly, unsteady vortex dynamics was not resolved in these experiments. However, the effects of vortex dynamics occurring at large scales can still be observed in the time-averaged flow fields, as will be shown in the following section. It is thus possible to infer connections between the time-averaged results of these experiments and the underlying unsteady dynamics observed in previous studies (e.g. Battisti et al. Reference Battisti, Zanne, Dell'Anna, Dossena, Persico and Paradiso2011; Tescione et al. Reference Tescione, Ragni, He, Ferreira and Van Bussel2014; Parker & Leftwich Reference Parker and Leftwich2016; Araya et al. Reference Araya, Colonius and Dabiri2017; Rolin & Porté-Agel Reference Rolin and Porté-Agel2018).

3. Experimental results

In this section, the results of the field experiments described in the previous section are presented and further analysed. Firstly, the velocity fields for the four experimental cases given in table 1 are shown to highlight three-dimensional flow features. Next, the vorticity fields for these cases are presented, and a tilted wake is observed for the helical-bladed turbine. The tilted wake is then analysed further, and a connection between turbine-blade geometry and wake tilt is established. Finally, the dynamics of the identified vortical structures is considered, and the implications of the results for arrays of VAWTs are outlined.

3.1. Velocity fields

Velocity fields for the time-averaged streamwise-velocity component ![]() $U$ on three orthogonal planar cross-sections are given in figures 5 and 6 for the helical-bladed (UGE) and straight-bladed (WPE) turbines at tip-speed ratios of

$U$ on three orthogonal planar cross-sections are given in figures 5 and 6 for the helical-bladed (UGE) and straight-bladed (WPE) turbines at tip-speed ratios of ![]() $\lambda = 1.19$ and

$\lambda = 1.19$ and ![]() $\lambda = 1.20$, respectively. The wake structure was not observed to change significantly with the changes in

$\lambda = 1.20$, respectively. The wake structure was not observed to change significantly with the changes in ![]() $\lambda$ achieved in these experiments. A more detailed analysis of the wake velocity fields for both turbines, including comparisons with previous wake studies at lower

$\lambda$ achieved in these experiments. A more detailed analysis of the wake velocity fields for both turbines, including comparisons with previous wake studies at lower ![]() $Re_D$, is provided in appendix C.1. As this study seeks to ascertain the effects of turbine-blade geometry on the 3-D structure of the near wake, two key differences between the velocity fields of the two turbines are highlighted.

$Re_D$, is provided in appendix C.1. As this study seeks to ascertain the effects of turbine-blade geometry on the 3-D structure of the near wake, two key differences between the velocity fields of the two turbines are highlighted.

Figure 5. Three orthogonal time-averaged planar fields of the streamwise velocity ![]() $U$ for the helical-bladed turbine, taken at

$U$ for the helical-bladed turbine, taken at ![]() $Z/D = 0$,

$Z/D = 0$, ![]() $Y/D = 0$ and

$Y/D = 0$ and ![]() $X/D = 1.5$ (counter-clockwise, from top left). A slight tilt from the vertical in the clockwise direction, shown by a fit to minima in the streamwise velocity (dashed green line), is visible in the velocity-deficit region in the

$X/D = 1.5$ (counter-clockwise, from top left). A slight tilt from the vertical in the clockwise direction, shown by a fit to minima in the streamwise velocity (dashed green line), is visible in the velocity-deficit region in the ![]() $YZ$ cross-section.

$YZ$ cross-section.

Figure 6. Three orthogonal time-averaged planar fields of the streamwise velocity ![]() $U$ for the straight-bladed turbine, taken at

$U$ for the straight-bladed turbine, taken at ![]() $Z/D = 0$,

$Z/D = 0$, ![]() $Y/D = 0$ and

$Y/D = 0$ and ![]() $X/D = 1.5$ (counter-clockwise, from top left). In contrast to figure 5, no wake tilt is present in the

$X/D = 1.5$ (counter-clockwise, from top left). In contrast to figure 5, no wake tilt is present in the ![]() $YZ$ cross-section, as evidenced by the relatively vertical alignment of the fit to the wake profile (dashed green line).

$YZ$ cross-section, as evidenced by the relatively vertical alignment of the fit to the wake profile (dashed green line).

Firstly, in ![]() $YZ$ cross-sections of

$YZ$ cross-sections of ![]() $U$ downstream of the turbine, topological differences were evident in the wake region, where the local streamwise velocity fell below the free-stream velocity. This region was observed to tilt in the clockwise direction when viewed from downstream in the case of the helical-bladed turbine (figure 5), while no such tilt was observed in the case of the straight-bladed turbine (figure 6). This tilted-wake behaviour will be analysed in detail in § 3.3, and it will be shown that this topological difference was a consequence of the blade shape of the helical-bladed turbine.

$U$ downstream of the turbine, topological differences were evident in the wake region, where the local streamwise velocity fell below the free-stream velocity. This region was observed to tilt in the clockwise direction when viewed from downstream in the case of the helical-bladed turbine (figure 5), while no such tilt was observed in the case of the straight-bladed turbine (figure 6). This tilted-wake behaviour will be analysed in detail in § 3.3, and it will be shown that this topological difference was a consequence of the blade shape of the helical-bladed turbine.

Secondly, a slice of the time-averaged vertical-velocity component ![]() $W$ through the central axis of the turbine further implied the existence of a more complex three-dimensional dynamics in the wake of the helical-bladed turbine (figure 7). The vector field at

$W$ through the central axis of the turbine further implied the existence of a more complex three-dimensional dynamics in the wake of the helical-bladed turbine (figure 7). The vector field at ![]() $Y/D=0$ for the straight-bladed turbine showed a downward sweep of fluid from above the turbine and an upward sweep of fluid from below the turbine, as would be expected from a bluff body in cross-flow (figure 7b). The corresponding field for the helical-bladed turbine showed a very different scenario, in which a uniform central updraft was present (figure 7a). At planar slices of

$Y/D=0$ for the straight-bladed turbine showed a downward sweep of fluid from above the turbine and an upward sweep of fluid from below the turbine, as would be expected from a bluff body in cross-flow (figure 7b). The corresponding field for the helical-bladed turbine showed a very different scenario, in which a uniform central updraft was present (figure 7a). At planar slices of ![]() $Y/D$ on either side of

$Y/D$ on either side of ![]() $Y/D=0$, corresponding uniform downward motions of fluid were observed. These differences in the vertical-velocity fields implied that the 3-D structure of the helical-bladed turbine had an effect on the wake dynamics that could not be resolved simply by examining the velocity fields. A three-dimensional analysis of the vortical structures present in the wakes of these VAWTs is required to explain these observed differences. This will be provided in § 3.2.

$Y/D=0$, corresponding uniform downward motions of fluid were observed. These differences in the vertical-velocity fields implied that the 3-D structure of the helical-bladed turbine had an effect on the wake dynamics that could not be resolved simply by examining the velocity fields. A three-dimensional analysis of the vortical structures present in the wakes of these VAWTs is required to explain these observed differences. This will be provided in § 3.2.

Figure 7. Time-averaged planar fields of the vertical velocity ![]() $W$ for (a) the helical-bladed turbine at

$W$ for (a) the helical-bladed turbine at ![]() $\lambda = 1.19$ and (b) the straight-bladed turbine at

$\lambda = 1.19$ and (b) the straight-bladed turbine at ![]() $\lambda = 1.20$, taken at

$\lambda = 1.20$, taken at ![]() $Y/D=0$. The wake of the straight-bladed turbine is characterized by symmetric sweeps of high-momentum fluid into the wake from above and below. In contrast, the wake of the helical-bladed turbine exhibits a uniform updraft at

$Y/D=0$. The wake of the straight-bladed turbine is characterized by symmetric sweeps of high-momentum fluid into the wake from above and below. In contrast, the wake of the helical-bladed turbine exhibits a uniform updraft at ![]() $Y/D=0$. This difference suggests that the helical blades have a pronounced three-dimensional effect on the wake structure.

$Y/D=0$. This difference suggests that the helical blades have a pronounced three-dimensional effect on the wake structure.

3.2. Vortical structures and wake topology

An analysis of the vortical structures in the streamwise direction (![]() $\omega _x$) demonstrates the importance of three-dimensional considerations to the wake dynamics of these VAWTs. Streamwise planar slices of

$\omega _x$) demonstrates the importance of three-dimensional considerations to the wake dynamics of these VAWTs. Streamwise planar slices of ![]() $\omega _x$ are shown in figures 8 and 9. The structures visible in these plots comprised a horseshoe-shaped vortex induced by the rotation of the turbine, observed previously by Rolin & Porté-Agel (Reference Rolin and Porté-Agel2018) and Brownstein et al. (Reference Brownstein, Wei and Dabiri2019). While in the case of the straight-bladed turbine, the two branches of the vortex were symmetric about the mid-span of the turbine, the corresponding structure for the helical-bladed turbine was asymmetric. The offset of the upper branch with respect to the lower branch induced the central updraft of fluid observed in figure 7(a). It will be argued in § 3.3 that this asymmetry was a result of the blade twist of the helical-bladed turbine, which skewed the overall wake profile and thereby affected the alignment of the streamwise vortical structures.

$\omega _x$ are shown in figures 8 and 9. The structures visible in these plots comprised a horseshoe-shaped vortex induced by the rotation of the turbine, observed previously by Rolin & Porté-Agel (Reference Rolin and Porté-Agel2018) and Brownstein et al. (Reference Brownstein, Wei and Dabiri2019). While in the case of the straight-bladed turbine, the two branches of the vortex were symmetric about the mid-span of the turbine, the corresponding structure for the helical-bladed turbine was asymmetric. The offset of the upper branch with respect to the lower branch induced the central updraft of fluid observed in figure 7(a). It will be argued in § 3.3 that this asymmetry was a result of the blade twist of the helical-bladed turbine, which skewed the overall wake profile and thereby affected the alignment of the streamwise vortical structures.

Figure 8. Streamwise slices of the streamwise vorticity ![]() $\omega _x$ in the case of the helical-bladed turbine for

$\omega _x$ in the case of the helical-bladed turbine for ![]() $\lambda = 1.19$. The

$\lambda = 1.19$. The ![]() $X$-axis is stretched on

$X$-axis is stretched on ![]() $0.5\leq X/D \leq 3$ to show the slices more clearly. These fields show marked asymmetry and a vertical misalignment in the two branches of the horseshoe vortex induced by the rotation of the turbine, compared to those shown in figure 9.

$0.5\leq X/D \leq 3$ to show the slices more clearly. These fields show marked asymmetry and a vertical misalignment in the two branches of the horseshoe vortex induced by the rotation of the turbine, compared to those shown in figure 9.

Figure 9. Streamwise slices of the streamwise vorticity ![]() $\omega _x$ in the case of the straight-bladed turbine for

$\omega _x$ in the case of the straight-bladed turbine for ![]() $\lambda = 1.20$. The

$\lambda = 1.20$. The ![]() $X$-axis is stretched on

$X$-axis is stretched on ![]() $0.5\leq X/D \leq 3$ to show the slices more clearly. Compared to the wake of the helical-bladed turbine (figure 8), the streamwise vortical structures are symmetric about the

$0.5\leq X/D \leq 3$ to show the slices more clearly. Compared to the wake of the helical-bladed turbine (figure 8), the streamwise vortical structures are symmetric about the ![]() $Z/D=0$ plane. Small counter-rotating secondary vortices are also present to the right of each main streamwise vortex, possibly similar to those observed in full-scale HAWTs by Yang et al. (Reference Yang, Hong, Barone and Sotiropoulos2016).

$Z/D=0$ plane. Small counter-rotating secondary vortices are also present to the right of each main streamwise vortex, possibly similar to those observed in full-scale HAWTs by Yang et al. (Reference Yang, Hong, Barone and Sotiropoulos2016).

Similar asymmetric behaviour in the wake of the helical-bladed turbine was observed in the vertical vortical structures (![]() $\omega _z$), shown in streamwise slices in figures 10 and 11. In both cases, the structure with positively signed vorticity initially had a linear shape and was oriented vertically, while the structure with negatively signed vorticity was bent towards the positive

$\omega _z$), shown in streamwise slices in figures 10 and 11. In both cases, the structure with positively signed vorticity initially had a linear shape and was oriented vertically, while the structure with negatively signed vorticity was bent towards the positive ![]() $Y$ direction. This initial geometry was related to the mechanics of formation of these vortices. The positively signed structure was composed of vortices shed from turbine blades as they rotated into the wind, which formed a vortex line that was advected downstream. These vortices have been observed in two dimensions for straight-bladed turbines by Tescione et al. (Reference Tescione, Ragni, He, Ferreira and Van Bussel2014), Parker & Leftwich (Reference Parker and Leftwich2016) and Araya et al. (Reference Araya, Colonius and Dabiri2017), and in 3-D simulations of straight-bladed turbines by Villeneuve et al. (Reference Villeneuve, Boudreau and Dumas2020). The arched shape of the negatively signed structures was a consequence of the low-velocity wake region. Behind the straight-bladed turbine, these two structures remained vertically oriented and relatively parallel. In contrast, behind the helical-bladed turbine, these structures began to tilt with respect to the vertical as they were advected downstream. This tilt was analogous to that observed in the horseshoe vortex (figure 8). Since the structures in

$Y$ direction. This initial geometry was related to the mechanics of formation of these vortices. The positively signed structure was composed of vortices shed from turbine blades as they rotated into the wind, which formed a vortex line that was advected downstream. These vortices have been observed in two dimensions for straight-bladed turbines by Tescione et al. (Reference Tescione, Ragni, He, Ferreira and Van Bussel2014), Parker & Leftwich (Reference Parker and Leftwich2016) and Araya et al. (Reference Araya, Colonius and Dabiri2017), and in 3-D simulations of straight-bladed turbines by Villeneuve et al. (Reference Villeneuve, Boudreau and Dumas2020). The arched shape of the negatively signed structures was a consequence of the low-velocity wake region. Behind the straight-bladed turbine, these two structures remained vertically oriented and relatively parallel. In contrast, behind the helical-bladed turbine, these structures began to tilt with respect to the vertical as they were advected downstream. This tilt was analogous to that observed in the horseshoe vortex (figure 8). Since the structures in ![]() $\omega _z$ were formed by vortex shedding from the turbine blades, we hypothesize that the helical blades of the UGE turbine were the cause of this observed asymmetric wake behaviour.

$\omega _z$ were formed by vortex shedding from the turbine blades, we hypothesize that the helical blades of the UGE turbine were the cause of this observed asymmetric wake behaviour.

Figure 10. Streamwise slices of the vertical vorticity ![]() $\omega _z$ downstream of the helical-bladed turbine for

$\omega _z$ downstream of the helical-bladed turbine for ![]() $\lambda = 1.19$. As in the previous figures, the

$\lambda = 1.19$. As in the previous figures, the ![]() $X$-axis is stretched on

$X$-axis is stretched on ![]() $0.5\leq X/D \leq 3$. These structures exhibit a tendency to tilt with increasing streamwise distance from the turbine, as evidenced by fits to the zero-vorticity region between the structures (dashed green lines).

$0.5\leq X/D \leq 3$. These structures exhibit a tendency to tilt with increasing streamwise distance from the turbine, as evidenced by fits to the zero-vorticity region between the structures (dashed green lines).

Figure 11. Streamwise slices of the vertical vorticity ![]() $\omega _z$ downstream of the straight-bladed turbine for

$\omega _z$ downstream of the straight-bladed turbine for ![]() $\lambda = 1.20$. The

$\lambda = 1.20$. The ![]() $X$-axis is again stretched on

$X$-axis is again stretched on ![]() $0.5\leq X/D \leq 3$. These structures remain upright with respect to the vertical (again denoted by dashed green lines), in contrast to their counterparts from the helical-bladed turbine.

$0.5\leq X/D \leq 3$. These structures remain upright with respect to the vertical (again denoted by dashed green lines), in contrast to their counterparts from the helical-bladed turbine.

The spanwise vortical structures (![]() $\omega _y$) did not show any significant signs of asymmetry (appendix C.2, figures 28 and 29). These structures represented time-averaged tip vortices shed by the passing turbine blades, as documented by Tescione et al. (Reference Tescione, Ragni, He, Ferreira and Van Bussel2014), and were thus not expected to change in geometry in these experiments. Together, the blade-shedding structures in

$\omega _y$) did not show any significant signs of asymmetry (appendix C.2, figures 28 and 29). These structures represented time-averaged tip vortices shed by the passing turbine blades, as documented by Tescione et al. (Reference Tescione, Ragni, He, Ferreira and Van Bussel2014), and were thus not expected to change in geometry in these experiments. Together, the blade-shedding structures in ![]() $\omega _y$ and

$\omega _y$ and ![]() $\omega _z$ bounded the near wake. Their time-averaged profiles outlined and encapsulated the regions of streamwise-velocity deficit in the wake shown in figures 5 and 6. This topological correspondence suggested that vortex shedding from the turbine blades has a dominant effect on the overall shape of the near wake.

$\omega _z$ bounded the near wake. Their time-averaged profiles outlined and encapsulated the regions of streamwise-velocity deficit in the wake shown in figures 5 and 6. This topological correspondence suggested that vortex shedding from the turbine blades has a dominant effect on the overall shape of the near wake.

3.3. Effect of blade twist

In the previous section, connections between vortex shedding from VAWT blades and the 3-D topology of VAWT wakes were observed. A more thorough investigation of the tilted wake is now undertaken to develop a more comprehensive description of the dynamics in the near wake.

The results presented thus far have shown that the wake of the helical-bladed turbine was tilted at some angle with respect to the vertical, whereas the wake of the straight-bladed turbine was not. To quantify this effect, two measures were employed: the angle of the velocity-deficit region, and the angle of the region of zero vorticity between the two vertical vortical structures. These two measures were selected on the premise that the dynamics of the vertical vortical structures is tied to the geometry of the near wake. Both were computed on slices parallel to the ![]() $YZ$ plane, taken at several streamwise positions downstream of each turbine. For the first measure, the location of minimum velocity was identified at every

$YZ$ plane, taken at several streamwise positions downstream of each turbine. For the first measure, the location of minimum velocity was identified at every ![]() $Z$-position in each slice, and a linear fit through these points on each slice was computed to approximate the slope of the velocity-deficit region. For the second measure, the location of minimum vorticity between the two vertical vortical structures was identified at every

$Z$-position in each slice, and a linear fit through these points on each slice was computed to approximate the slope of the velocity-deficit region. For the second measure, the location of minimum vorticity between the two vertical vortical structures was identified at every ![]() $Z$-position in each slice using linear interpolation, and a linear fit through these points on each slice represented the orientation of the structures. For both measures, confidence intervals of one standard deviation on the slope of the linear fit served as error bounds. The results of this procedure are shown in figure 12(a) for the velocity-deficit measure and figure 12(b) for the vortical-structure measure. The results demonstrated that the wake orientation of the straight-bladed turbine did not exhibit a strong deviation from the vertical in the near-wake region. In contrast, the wake orientation of the helical-bladed turbine increased monotonically with streamwise distance for both of the tip-speed ratios tested in the experiments. These measures thus quantified the various observations from the previous section regarding changes in the wake topology between the two turbines.

$Z$-position in each slice using linear interpolation, and a linear fit through these points on each slice represented the orientation of the structures. For both measures, confidence intervals of one standard deviation on the slope of the linear fit served as error bounds. The results of this procedure are shown in figure 12(a) for the velocity-deficit measure and figure 12(b) for the vortical-structure measure. The results demonstrated that the wake orientation of the straight-bladed turbine did not exhibit a strong deviation from the vertical in the near-wake region. In contrast, the wake orientation of the helical-bladed turbine increased monotonically with streamwise distance for both of the tip-speed ratios tested in the experiments. These measures thus quantified the various observations from the previous section regarding changes in the wake topology between the two turbines.

Figure 12. Wake-orientation measurements from all four experimental cases, computed from (a) the locations of minima in the velocity-deficit region, ![]() $U_{min}$, and (b) the coordinates of the zero-vorticity strip between the two vertical vortical structures,

$U_{min}$, and (b) the coordinates of the zero-vorticity strip between the two vertical vortical structures, ![]() $|\omega _z|_{min}$. The wake orientation of the helical-bladed turbine increases monotonically, while that of the straight-bladed turbine does not exhibit a strong trend away from zero.

$|\omega _z|_{min}$. The wake orientation of the helical-bladed turbine increases monotonically, while that of the straight-bladed turbine does not exhibit a strong trend away from zero.

The wake-orientation measurements shed light on the mechanism responsible for the tilted wake observed for the helical-bladed turbine. Firstly, the orientation profiles were very consistent between the two measures, supporting the hypothesis that the shape of the near wake is directly tied to the dynamics of the vertical vortical structures. Additionally, the profiles did not show a strong dependence on turbine solidity, and no significant dependence on tip-speed ratio over the limited range of ![]() $\lambda$ tested in these experiments was observed. Though the measurements did separate into two classes corresponding to the two turbine geometries, the three-dimensional nature of the tilted-wake behaviour made it unlikely that solidity, which is not defined using three-dimensional geometric parameters, was the dominant factor. These results thus isolate the geometry of the turbine blades as the primary contributing factor to the observed differences in wake topology.

$\lambda$ tested in these experiments was observed. Though the measurements did separate into two classes corresponding to the two turbine geometries, the three-dimensional nature of the tilted-wake behaviour made it unlikely that solidity, which is not defined using three-dimensional geometric parameters, was the dominant factor. These results thus isolate the geometry of the turbine blades as the primary contributing factor to the observed differences in wake topology.

A mechanism by which turbine-blade geometry can affect the wake topology is now proposed. As described previously, the vortical structures visible in the time-averaged fields of ![]() $\omega _z$ represent the profiles of vortex lines shed from the rotating turbine blades and advected away from the turbine by the free stream. We expect that the shape of these vortex lines will depend on the shape of the blades: a straight blade will shed a straight vortex line, while a helical blade will shed a vortex line with non-zero curvature. The latter hypothesis is drawn from the fact that a helical blade, in contrast to a straight blade, is yawed relative to the incoming flow and experiences a range of local angles of attack along its span as it rotates around the turbine. A yawed or swept blade with respect to the incoming flow exhibits strongly three-dimensional vortex shedding in dynamic stall (Visbal & Garmann Reference Visbal and Garmann2019), due in part to a net transport of vorticity along the span of the blade (Smith & Jones Reference Smith and Jones2019). A linearly increasing spanwise angle-of-attack profile in dynamic stall similarly induces a spanwise transport of vorticity that affects the stability of the leading-edge vortex and thus the character of the vortex shedding from the blade (Wong, laBastide & Rival Reference Wong, laBastide and Rival2017). Given these observations, we conclude that the spanwise non-uniformity of the flow over helical VAWT blades makes the vortex lines shed by the dynamic-stall mechanism inherently nonlinear and three-dimensional.

$\omega _z$ represent the profiles of vortex lines shed from the rotating turbine blades and advected away from the turbine by the free stream. We expect that the shape of these vortex lines will depend on the shape of the blades: a straight blade will shed a straight vortex line, while a helical blade will shed a vortex line with non-zero curvature. The latter hypothesis is drawn from the fact that a helical blade, in contrast to a straight blade, is yawed relative to the incoming flow and experiences a range of local angles of attack along its span as it rotates around the turbine. A yawed or swept blade with respect to the incoming flow exhibits strongly three-dimensional vortex shedding in dynamic stall (Visbal & Garmann Reference Visbal and Garmann2019), due in part to a net transport of vorticity along the span of the blade (Smith & Jones Reference Smith and Jones2019). A linearly increasing spanwise angle-of-attack profile in dynamic stall similarly induces a spanwise transport of vorticity that affects the stability of the leading-edge vortex and thus the character of the vortex shedding from the blade (Wong, laBastide & Rival Reference Wong, laBastide and Rival2017). Given these observations, we conclude that the spanwise non-uniformity of the flow over helical VAWT blades makes the vortex lines shed by the dynamic-stall mechanism inherently nonlinear and three-dimensional.

To model the evolution of these vortex lines as they are advected downstream, the principle of Biot–Savart self-induction can be applied. In an inviscid flow field, the self-induced velocity at any point ![]() $\boldsymbol {r}$ on a single vortex line with finite core size

$\boldsymbol {r}$ on a single vortex line with finite core size ![]() $\mu$, defined by the curve

$\mu$, defined by the curve ![]() $\boldsymbol {r'}$ and parameterized by the arc length

$\boldsymbol {r'}$ and parameterized by the arc length ![]() $s'$, can be written as

$s'$, can be written as

\begin{equation} \frac{\partial\boldsymbol{r}}{\partial t} ={-}\frac{\varGamma}{4{\rm \pi}} \int \frac{(\boldsymbol{r}-\boldsymbol{r'})\times \dfrac{\partial \boldsymbol{r'}}{\partial s'}}{(\left|\boldsymbol{r}-\boldsymbol{r'}\right|^{2}+\mu^{2})^{3/2}}\,\textrm{d} s', \end{equation}

\begin{equation} \frac{\partial\boldsymbol{r}}{\partial t} ={-}\frac{\varGamma}{4{\rm \pi}} \int \frac{(\boldsymbol{r}-\boldsymbol{r'})\times \dfrac{\partial \boldsymbol{r'}}{\partial s'}}{(\left|\boldsymbol{r}-\boldsymbol{r'}\right|^{2}+\mu^{2})^{3/2}}\,\textrm{d} s', \end{equation}

where the integration is performed over the length of the vortex line (Leonard Reference Leonard1985). This model for the self-induced deformation of curved vortex lines has been studied numerically using both approximate methods (Arms & Hama Reference Arms and Hama1965) and exact simulations (Moin, Leonard & Kim Reference Moin, Leonard and Kim1986). The quantity ![]() $(\boldsymbol {r}-\boldsymbol {r'}) \times {\partial \boldsymbol {r'}}/{\partial s'}$ in the numerator of the integrand is only non-zero when the displacement vector between two points on the vortex line does not align with the direction of the vortex line. Therefore, a vortex line with curvature or piecewise changes in alignment will undergo deformation under self-induction, while a purely linear vortex line will not. Self-induced deformations of a similar nature have been observed in curved and tilted vortex lines in numerous computational and experimental contexts (e.g. Hama & Nutant Reference Hama and Nutant1961; Boulanger, Meunier & Dizès Reference Boulanger, Meunier and Dizès2008).

$(\boldsymbol {r}-\boldsymbol {r'}) \times {\partial \boldsymbol {r'}}/{\partial s'}$ in the numerator of the integrand is only non-zero when the displacement vector between two points on the vortex line does not align with the direction of the vortex line. Therefore, a vortex line with curvature or piecewise changes in alignment will undergo deformation under self-induction, while a purely linear vortex line will not. Self-induced deformations of a similar nature have been observed in curved and tilted vortex lines in numerous computational and experimental contexts (e.g. Hama & Nutant Reference Hama and Nutant1961; Boulanger, Meunier & Dizès Reference Boulanger, Meunier and Dizès2008).

Given that the precise shape of the curved vortex lines shed by the helical-bladed turbine cannot be extracted from the time-averaged vorticity fields, (3.1) cannot be applied quantitatively in this case. However, it can still be used qualitatively to connect the development of the tilted wake to blade geometry. We therefore consider a helical vortex line that corresponds to the helical shape of the UGE turbine blades, shed from a blade as it rotates upstream into the prevailing wind. This model system accounts for the three-dimensional blade geometry while abstracting the precise dynamics of the vortex-shedding mechanism on the blades. The curve is parameterized for ![]() $Z \in [-S/2, S/2]$ as

$Z \in [-S/2, S/2]$ as ![]() $X = -a R \sin (\tau Z)$ and

$X = -a R \sin (\tau Z)$ and ![]() $Y = - R \cos (\tau Z)$. The constant

$Y = - R \cos (\tau Z)$. The constant ![]() $a$ accounts for stretching of the vortex line in the streamwise direction due to differences between the tip-speed velocity of the turbine and advection from the free stream. The selection

$a$ accounts for stretching of the vortex line in the streamwise direction due to differences between the tip-speed velocity of the turbine and advection from the free stream. The selection ![]() $a = 1/\lambda$, for example, recovers the expected asymptotic result that the curved vortex line will become a straight vertical line as

$a = 1/\lambda$, for example, recovers the expected asymptotic result that the curved vortex line will become a straight vertical line as ![]() $\lambda \rightarrow \infty$. The initial induced velocities along this vortex line, computed numerically from (3.1), apply a stretching in the

$\lambda \rightarrow \infty$. The initial induced velocities along this vortex line, computed numerically from (3.1), apply a stretching in the ![]() $Y$ direction that corresponds directly with the previous observations of the tilted wake (figure 13). The streamwise and vertical induced velocities are not addressed in this analysis since they do not contribute to the tilted wake. The computed vectors also do not represent the full time evolution of the vortex line, as only the initial induced velocities

$Y$ direction that corresponds directly with the previous observations of the tilted wake (figure 13). The streamwise and vertical induced velocities are not addressed in this analysis since they do not contribute to the tilted wake. The computed vectors also do not represent the full time evolution of the vortex line, as only the initial induced velocities ![]() $\boldsymbol {u}(\boldsymbol {r}(t=0))$ are given. The demonstration shows qualitatively that the mechanism of Biot–Savart self-induction provides a direct connection between blade geometry and the evolution of the wake topology.

$\boldsymbol {u}(\boldsymbol {r}(t=0))$ are given. The demonstration shows qualitatively that the mechanism of Biot–Savart self-induction provides a direct connection between blade geometry and the evolution of the wake topology.

Figure 13. Schematic of the ![]() $Y$ component of the induced velocities,

$Y$ component of the induced velocities, ![]() $V_{induced}$, along a helical vortex line due to Biot–Savart self-induction (3.1). The scale of the vectors and the streamwise location of the vortex line are both arbitrary, and the streamwise and vertical components of the induced velocity are not shown for clarity. The stretching induced on the vortex line matches the behaviour of the tilted wake.

$V_{induced}$, along a helical vortex line due to Biot–Savart self-induction (3.1). The scale of the vectors and the streamwise location of the vortex line are both arbitrary, and the streamwise and vertical components of the induced velocity are not shown for clarity. The stretching induced on the vortex line matches the behaviour of the tilted wake.

Based on these results, the propagation of the influence of turbine-blade geometry in the dynamics of the near wake can be outlined. The shape of the blades determines the shape of the vortex lines shed by the blades as they rotate around the turbine. The shape of these vortex lines in turn drives their evolution downstream of the turbine. As these structures bound the wake region, topological changes in the vortex lines are reflected in the shape of the velocity-deficit region of the wake. These developments affect the shape of the horseshoe vortex, which is not directly affected by differences in blade geometry but is necessarily bound to the shape of the wake region. The connection between blade twist and wake tilt described in this section therefore provides a unifying framework that accounts for the trends previously observed in the wake velocity and vorticity fields.

3.4. Wake dynamics

In the previous section, it was hypothesized that the shape of VAWT blades dictates the near-wake topology through Biot–Savart self-induction of shed vortex lines. The wake dynamics is now analysed in detail, to quantify the evolution of the vortical structures in the wake and to identify their contributions to wake recovery. The circulation of the wake structures in each direction, ![]() $\varGamma _i$, was calculated as a function of downstream distance from the turbine. The circulation was computed at a series of streamwise positions

$\varGamma _i$, was calculated as a function of downstream distance from the turbine. The circulation was computed at a series of streamwise positions ![]() $X/D$ by integrating the vorticity component in question over a square

$X/D$ by integrating the vorticity component in question over a square ![]() $D \times D$ window, which was oriented normal to the direction of the vorticity component. This window was placed at the centre of the vortex at several points along the vortex line. The centre was identified at each point by applying a threshold based on the standard deviation of the vorticity field and computing the centre of mass of the isolated vorticity distribution. The values of the circulation along the vortex line, computed with these windows, were averaged to obtain a representative circulation for the structure. Error bars were determined by propagating the standard deviations of the components of individual velocity vectors from the particle trajectories in each voxel through the curl operator and the circulation integration. This computation was done independently for the positively and negatively signed vortical structures. The resulting circulations in

$D \times D$ window, which was oriented normal to the direction of the vorticity component. This window was placed at the centre of the vortex at several points along the vortex line. The centre was identified at each point by applying a threshold based on the standard deviation of the vorticity field and computing the centre of mass of the isolated vorticity distribution. The values of the circulation along the vortex line, computed with these windows, were averaged to obtain a representative circulation for the structure. Error bars were determined by propagating the standard deviations of the components of individual velocity vectors from the particle trajectories in each voxel through the curl operator and the circulation integration. This computation was done independently for the positively and negatively signed vortical structures. The resulting circulations in ![]() $X$,

$X$, ![]() $Y$ and