1. Introduction

The motion of an elongated bubble confined in a small geometry is typical of many biological and engineering systems. Examples include small-scale reactors, oil recovery, coating processes, microfluidic and biomedical devices (e.g. Ajaev & Homsy Reference Ajaev and Homsy2006; Chhabra Reference Chhabra2007; Zhang et al. Reference Zhang, Hassanizadeh, Liu, Schijven and Karadimitriou2014; Lynn Reference Lynn2016; Khodaparast et al. Reference Khodaparast, Kim, Silpe and Stone2017). In the human body it is important for understanding complex processes such as lung activity (e.g. Grotberg Reference Grotberg1994), air embolism, (e.g. Eckmann & Lomivorotov Reference Eckmann and Lomivorotov2003; Suzuki & Eckman Reference Suzuki and Eckman2003) and targeted microbubbles for drug delivery (e.g. Bull Reference Bull2005).

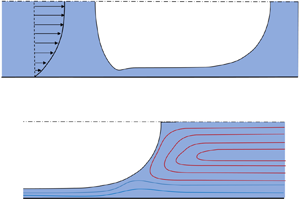

A typical set-up that is commonly used to study the dynamics of elongated bubbles is a horizontal capillary tube of radius ![]() $R$, figure 1. In this setting, viscous forces and surface tension dominate over buoyancy and inertia. When the bubble translates at a constant speed, the gas takes a symmetrical bullet shape, commonly called a Taylor bubble, and a thin film of liquid is maintained between the bubble and the tube wall. Knowledge about the thickness of the film and its relationship with the bubble speed are crucial pieces of information for determining the transport rates in practical problems.

$R$, figure 1. In this setting, viscous forces and surface tension dominate over buoyancy and inertia. When the bubble translates at a constant speed, the gas takes a symmetrical bullet shape, commonly called a Taylor bubble, and a thin film of liquid is maintained between the bubble and the tube wall. Knowledge about the thickness of the film and its relationship with the bubble speed are crucial pieces of information for determining the transport rates in practical problems.

Figure 1. Sketch of the confined bubble that moves at speed ![]() $U$ through a shear-thinning fluid in a channel of half-width

$U$ through a shear-thinning fluid in a channel of half-width ![]() $R$;

$R$; ![]() $U_\infty$ is the average velocity far from the bubble. The shear-thinning fluid and the gaseous bubble are depicted in dark blue and white, respectively. The system of coordinates is placed on the right of the figure just for convenience: in the computation of the rear and front menisci the origin is somewhere in the region

$U_\infty$ is the average velocity far from the bubble. The shear-thinning fluid and the gaseous bubble are depicted in dark blue and white, respectively. The system of coordinates is placed on the right of the figure just for convenience: in the computation of the rear and front menisci the origin is somewhere in the region ![]() $CD$;

$CD$; ![]() $AB$ and

$AB$ and ![]() $EF$ are the spherical caps,

$EF$ are the spherical caps, ![]() $BC$ and

$BC$ and ![]() $DE$ are the film regions, while

$DE$ are the film regions, while ![]() $CD$ is the uniform film thickness region.

$CD$ is the uniform film thickness region.

So far, a wide range of investigations have focused primarily on understanding the dynamics of a Taylor bubble in a Newtonian liquid. The first experiments of Fairbrother & Stubbs (Reference Fairbrother and Stubbs1935) and Taylor (Reference Taylor1961) suggested that the thickness of the lubricating film, ![]() $h$, scales with the square root of the capillary number,

$h$, scales with the square root of the capillary number, ![]() $h/R= 0.5\,Ca^{1/2}$ , where

$h/R= 0.5\,Ca^{1/2}$ , where ![]() $Ca=\mu U/\sigma$ is the capillary number and

$Ca=\mu U/\sigma$ is the capillary number and ![]() $U$,

$U$, ![]() $\mu$,

$\mu$, ![]() $\sigma$ and

$\sigma$ and ![]() $R$ the bubble speed, the fluid viscosity, the surface tension and the pipe radius respectively. The seminal work of Bretherton (Reference Bretherton1961) demonstrated that

$R$ the bubble speed, the fluid viscosity, the surface tension and the pipe radius respectively. The seminal work of Bretherton (Reference Bretherton1961) demonstrated that ![]() $h/R= 1.34\,Ca^{2/3}$ in the limit of small

$h/R= 1.34\,Ca^{2/3}$ in the limit of small ![]() $Ca$, as supported by several measurements (Schwartz, Princen & Kiss Reference Schwartz, Princen and Kiss1986; Aussillous & Quéré Reference Aussillous and Quéré2000). Thereafter, many researchers investigated the effect of finite capillary number and inertia (Cox Reference Cox1962; Reinelt & Saffman Reference Reinelt and Saffman1985; Aussillous & Quéré Reference Aussillous and Quéré2000; Heil Reference Heil2001; de Ryck Reference de Ryck2002; Khodaparast et al. Reference Khodaparast, Magnini, Borhani and Thome2015; Magnini et al. Reference Magnini, Ferrari, Thome and Stone2017), surfactants and variable surface tension, (Ratulowski & Chang Reference Ratulowski and Chang1990; Park Reference Park1992; Stebe & Barthés-Biesel Reference Stebe and Barthés-Biesel1995; Olgac & Muradoglu Reference Olgac and Muradoglu2013; Yu, Khodaparast & Stone Reference Yu, Khodaparast and Stone2017), unsteady flow, (Yu et al. Reference Yu, Zhu, Shim, Eggers and Stone2018), buoyancy, (Leung et al. Reference Leung, Gupta, Fletcher and Haynes2012; Atasi et al. Reference Atasi, Khodaparast, Scheid and Stone2017; Lamstaes & Eggers Reference Lamstaes and Eggers2017) and bubble viscosity, (Chen Reference Chen1986; Hodges, Jensen & Rallinson Reference Hodges, Jensen and Rallinson2004; Balestra, Zhu & Gallaire Reference Balestra, Zhu and Gallaire2018; Shukla et al. Reference Shukla, Kofman, Balestra, Zhu and Gallaire2019).

$Ca$, as supported by several measurements (Schwartz, Princen & Kiss Reference Schwartz, Princen and Kiss1986; Aussillous & Quéré Reference Aussillous and Quéré2000). Thereafter, many researchers investigated the effect of finite capillary number and inertia (Cox Reference Cox1962; Reinelt & Saffman Reference Reinelt and Saffman1985; Aussillous & Quéré Reference Aussillous and Quéré2000; Heil Reference Heil2001; de Ryck Reference de Ryck2002; Khodaparast et al. Reference Khodaparast, Magnini, Borhani and Thome2015; Magnini et al. Reference Magnini, Ferrari, Thome and Stone2017), surfactants and variable surface tension, (Ratulowski & Chang Reference Ratulowski and Chang1990; Park Reference Park1992; Stebe & Barthés-Biesel Reference Stebe and Barthés-Biesel1995; Olgac & Muradoglu Reference Olgac and Muradoglu2013; Yu, Khodaparast & Stone Reference Yu, Khodaparast and Stone2017), unsteady flow, (Yu et al. Reference Yu, Zhu, Shim, Eggers and Stone2018), buoyancy, (Leung et al. Reference Leung, Gupta, Fletcher and Haynes2012; Atasi et al. Reference Atasi, Khodaparast, Scheid and Stone2017; Lamstaes & Eggers Reference Lamstaes and Eggers2017) and bubble viscosity, (Chen Reference Chen1986; Hodges, Jensen & Rallinson Reference Hodges, Jensen and Rallinson2004; Balestra, Zhu & Gallaire Reference Balestra, Zhu and Gallaire2018; Shukla et al. Reference Shukla, Kofman, Balestra, Zhu and Gallaire2019).

In many practical applications the working fluids exhibit a non-Newtonian behaviour (e.g. Savage et al. Reference Savage, Caggioni, Spicer and Cohen2010; Huisman, Friedman & Taborek Reference Huisman, Friedman and Taborek2012). Polymers solutions, suspensions, emulsions and biological fluids, just to mention a few, behave like shear-thinning fluids and, therefore, their viscosity is a function of the imposed shear rate. Specifically, at low shear rates, the shear stresses are proportional to the shear rate and the viscosity approaches a constant value, commonly known as the zero-shear-rate viscosity. At higher shear rates, instead, the viscosity decreases with increasing the shear rate, exhibiting a power-law behaviour. A decreasing viscosity can persist over several decades until, at very high shear rates, the viscosity flattens again, approaching the infinite-shear-rate viscosity. The latter limit is often not considered since fluid degradation may invalidate the rheological measurement, Bird, Armstrong & Hassager (Reference Bird, Armstrong and Hassager1987). Although such features are embedded in several viscosity models, e.g. the Carreau–Yasuda Carreau (Reference Carreau1972) and the Ellis models (Reiner Reference Reiner1965), the models available for describing the dynamics of a confined Taylor bubble in a shear-thinning fluid often ignore those limiting behaviours.

Existing studies on the topic assume that the liquid viscosity can be described by the power-law model (Kamişli & Ryan Reference Kamişli and Ryan1999, Reference Kamişli and Ryan2001; de Sousa et al. Reference de Sousa, Soares, de Queiroz and Thompson2007; Thompson, Soares & Bacchi Reference Thompson, Soares and Bacchi2010). The theory suggests that the lubricating film scales as ![]() $h/R\sim {Ca}^{2/(2n+1)}_{*}$, where

$h/R\sim {Ca}^{2/(2n+1)}_{*}$, where ![]() $n$ is the shear-thinning index and

$n$ is the shear-thinning index and ![]() ${Ca}_{*}$ is a modified capillary number for power-law fluids. Unfortunately, the power-law model has an empirical nature and it does not accurately describe the viscosity at small shear rates, leading to large errors when applied to the multiphase scenario (Picchi et al. Reference Picchi, Poesio, Ullmann and Brauner2017, Reference Picchi, Barmak, Ullmann and Brauner2018a; Picchi, Ullmann & Brauner Reference Picchi, Ullmann and Brauner2018b). Both the local velocity field and integral variables (e.g. pressure drop and film thickness) are poorly predicted in free-surface flows due to the unrealistically and unbounded growth of the viscosity at small shear rates. This is confirmed by the work of Hewson, Kapur & Gaskell (Reference Hewson, Kapur and Gaskell2009) that studied the motion of a Taylor bubble through both power-law and an Ellis fluids. The power-law model generates inconsistencies in resolving the low-shear-rate regions of the velocity profile that can be overcome only accounting for the zero-shear-rate effect, see Hewson et al. (Reference Hewson, Kapur and Gaskell2009). Moreira et al. (Reference Moreira, Rocha, Carneiro, Araújo, Campos and Miranda2020) carried out numerical simulations of Taylor bubbles moving in a Carreau fluid at finite capillary numbers while Kawahara et al. (Reference Kawahara, Sadatomi, Law and Mansour2015) collected experimental data on a train of Taylor bubbles in shear-thinning polymer solutions. Also, lubricating films of shear-thinning liquids have been the subject of investigation in the context of the drag-out problem, i.e. the Landau & Levich (Reference Landau and Levich1942) problem, (Gutfinger & Tallmadge Reference Gutfinger and Tallmadge1965; Tallmadge Reference Tallmadge1966; Spiers, Subbaraman & Wilkinson Reference Spiers, Subbaraman and Wilkinson1975; Afanasiev, Münch & Wagner Reference Afanasiev, Münch and Wagner2007).

${Ca}_{*}$ is a modified capillary number for power-law fluids. Unfortunately, the power-law model has an empirical nature and it does not accurately describe the viscosity at small shear rates, leading to large errors when applied to the multiphase scenario (Picchi et al. Reference Picchi, Poesio, Ullmann and Brauner2017, Reference Picchi, Barmak, Ullmann and Brauner2018a; Picchi, Ullmann & Brauner Reference Picchi, Ullmann and Brauner2018b). Both the local velocity field and integral variables (e.g. pressure drop and film thickness) are poorly predicted in free-surface flows due to the unrealistically and unbounded growth of the viscosity at small shear rates. This is confirmed by the work of Hewson, Kapur & Gaskell (Reference Hewson, Kapur and Gaskell2009) that studied the motion of a Taylor bubble through both power-law and an Ellis fluids. The power-law model generates inconsistencies in resolving the low-shear-rate regions of the velocity profile that can be overcome only accounting for the zero-shear-rate effect, see Hewson et al. (Reference Hewson, Kapur and Gaskell2009). Moreira et al. (Reference Moreira, Rocha, Carneiro, Araújo, Campos and Miranda2020) carried out numerical simulations of Taylor bubbles moving in a Carreau fluid at finite capillary numbers while Kawahara et al. (Reference Kawahara, Sadatomi, Law and Mansour2015) collected experimental data on a train of Taylor bubbles in shear-thinning polymer solutions. Also, lubricating films of shear-thinning liquids have been the subject of investigation in the context of the drag-out problem, i.e. the Landau & Levich (Reference Landau and Levich1942) problem, (Gutfinger & Tallmadge Reference Gutfinger and Tallmadge1965; Tallmadge Reference Tallmadge1966; Spiers, Subbaraman & Wilkinson Reference Spiers, Subbaraman and Wilkinson1975; Afanasiev, Münch & Wagner Reference Afanasiev, Münch and Wagner2007).

Other works focus on more complex non-Newtonian fluids. Mukundakrishnan, Ayyaswamy & Eckmann (Reference Mukundakrishnan, Ayyaswamy and Eckmann2008) studied numerically the motion of a gas bubble through a blood vessel and the blood is described as a Casson fluid; Zamankhan et al. (Reference Zamankhan, Helenbrook, Takayama and Grotberg2012) and Laborie et al. (Reference Laborie, Rouyer, Angelescu and Lorenceau2017) investigated yield-stress fluids. The effect of viscoelasticity was the subject of many theoretical and experimental works (Ho & Leal Reference Ho and Leal1975; Ro & Homsy Reference Ro and Homsy1995; Huzyak & Koelling Reference Huzyak and Koelling1997; Gauri & Koelling Reference Gauri and Koelling1999; Quintella, Souza Mendes & Carvalho Reference Quintella, Souza Mendes and Carvalho2007; Boehm, Sarker & Koelling Reference Boehm, Sarker and Koelling2011) including the studies on thin-film flows of viscoelastic fluids (e.g. Middleman Reference Middleman1978; Campanella, Galazzo & Cerro Reference Campanella, Galazzo and Cerro1986; de Ryck & Quéré Reference de Ryck and Quéré1998; Lee, Shaqfeh & Khomami Reference Lee, Shaqfeh and Khomami2002; Pasquali & Scriven Reference Pasquali and Scriven2002; Romero, Scriven & Carvalho Reference Romero, Scriven and Carvalho2006; Ashmore et al. Reference Ashmore, Shen, Kavehpour, Stone and McKinley2008; Bajaj, Ravi Prakash & Pasquali Reference Bajaj, Ravi Prakash and Pasquali2008).

However, in all the aforementioned studies, a generalized understanding of the bubble motion that embeds both the low- and high-shear-rate behaviours is still missing, including a generalization of the scaling laws for the film thickness and the bubble speed. To fill this gap, the goal of this paper is to study the dynamics of a confined Taylor bubble that moves in a shear-thinning fluid and to clarify the competition of the zero-shear-rate and the shear-thinning effects on bubble characteristics. We propose a theoretical framework that provides the scaling laws for the film thickness and the bubble speed and quantifies the interplay between low- and high-shear-rate behaviours. Our model generalizes Bretherton's results to shear-thinning fluids by identification of a universal scaling law for the effective viscosity and by proposing a generalization of capillary number that applies to both Newtonian and shear-thinning fluids. We also summarize the limitations of the power-law viscosity model discussing the extent to which its use can be legitimized.

With this aim, we derive a lubrication model for a Taylor bubble that moves in a shear-thinning fluid and whose viscosity is described by the Ellis viscosity model (§ 2). The Ellis model suits our scope since it allows for the derivation of the analytical velocity profile in the approximation of unidirectional free-surface flow. We show that the bubble meniscus obeys a third-order ordinary differential equation for the film thickness (§ 2.3). The model allows for the calculation of the front and rear menisci and the identification of the scaling laws for the film thickness, pressure drop and the bubble speed, see § 3. In § 3.2 we show that, if properly re-scaled, the effective viscosity can be described by a universal law that depends only on the two dimensionless numbers that describes the fluid rheology. Our results converge to Bretherton's theory in the Newtonian limit and we prove that the power-law viscosity model is not an accurate approximation in describing the bubble dynamics. The appearance of recirculating flow patterns ahead and behind the bubble is discussed in § 3.5, while pressure drops across the front and the rear menisci and the interfacial velocity in the film region are presented in Appendices B and C, respectively. The results obtained shed light on the mechanisms that control the motion of a Taylor bubble in a realistic shear-thinning fluid.

2. Theoretical derivation

2.1. Problem formulation

We consider a bubble confined in a horizontal planar channel that advances through a shear-thinning fluid as sketched in figure 1. The bubble is assumed inviscid and translates at a steady velocity ![]() $U$ while, far from the bubble, the liquid moves with average velocity

$U$ while, far from the bubble, the liquid moves with average velocity ![]() $U_\infty$. We assume that the bubble is sufficiently long so that a region with uniform film thickness

$U_\infty$. We assume that the bubble is sufficiently long so that a region with uniform film thickness ![]() $h$ exists and that gravity forces can be neglected. In other words, we assume that the macroscopic Bond number is sufficiently small,

$h$ exists and that gravity forces can be neglected. In other words, we assume that the macroscopic Bond number is sufficiently small, ![]() $Bo={\rm \Delta} \rho g R^2/\sigma \ll 1$ (

$Bo={\rm \Delta} \rho g R^2/\sigma \ll 1$ (![]() ${\rm \Delta} \rho$ and

${\rm \Delta} \rho$ and ![]() $g$ are the density difference and the gravitational acceleration, respectively). We start from the continuity and Navier–Stokes equations in the shear-thinning fluid without resolving the velocity field in the gas. We look at equations where inertial forces are unimportant in the thin film and the problem is controlled by the competition between viscous and surface tension forces only. The governing equations in the liquid are

$g$ are the density difference and the gravitational acceleration, respectively). We start from the continuity and Navier–Stokes equations in the shear-thinning fluid without resolving the velocity field in the gas. We look at equations where inertial forces are unimportant in the thin film and the problem is controlled by the competition between viscous and surface tension forces only. The governing equations in the liquid are

where ![]() $p$ and

$p$ and ![]() $\boldsymbol {\tau }$ are the pressure and the shear stress tensor;

$\boldsymbol {\tau }$ are the pressure and the shear stress tensor; ![]() $\boldsymbol {u}= (u,v)$ is the velocity vector with

$\boldsymbol {u}= (u,v)$ is the velocity vector with ![]() $u$ and

$u$ and ![]() $v$ representing the velocity components in the

$v$ representing the velocity components in the ![]() $x$ and

$x$ and ![]() $y$ directions, respectively. The boundary conditions are no slip and no penetration at the channel wall and a free shear-stress condition at the bubble–fluid interface.

$y$ directions, respectively. The boundary conditions are no slip and no penetration at the channel wall and a free shear-stress condition at the bubble–fluid interface.

The shear-thinning fluid is assumed to be an incompressible generalized Newtonian fluid of density ![]() $\rho$ and effective viscosity

$\rho$ and effective viscosity ![]() $\mu$, whose constitutive relation can be formulated as

$\mu$, whose constitutive relation can be formulated as

where ![]() $\boldsymbol {\dot {\gamma }}=\boldsymbol{\nabla} \boldsymbol {u}+(\boldsymbol{\nabla} \boldsymbol {u})^\textrm {T}$ is the rate-of-strain tensor. Since we are interested in understanding the interplay between the shear-thinning and the zero-shear-rate effects on the bubble dynamics, we chose the Ellis viscosity model (Matsuhisa & Bird Reference Matsuhisa and Bird1965; Reiner Reference Reiner1965; Bird et al. Reference Bird, Armstrong and Hassager1987). The constitutive law of an Ellis fluid is given by

$\boldsymbol {\dot {\gamma }}=\boldsymbol{\nabla} \boldsymbol {u}+(\boldsymbol{\nabla} \boldsymbol {u})^\textrm {T}$ is the rate-of-strain tensor. Since we are interested in understanding the interplay between the shear-thinning and the zero-shear-rate effects on the bubble dynamics, we chose the Ellis viscosity model (Matsuhisa & Bird Reference Matsuhisa and Bird1965; Reiner Reference Reiner1965; Bird et al. Reference Bird, Armstrong and Hassager1987). The constitutive law of an Ellis fluid is given by

where ![]() ${\tau }=\sqrt {1/2{(\boldsymbol {\tau }\boldsymbol {:}\boldsymbol {\tau })}}$ is the effective shear stress (or the magnitude of the shear-stress tensor). The model converges to Newtonian viscosity

${\tau }=\sqrt {1/2{(\boldsymbol {\tau }\boldsymbol {:}\boldsymbol {\tau })}}$ is the effective shear stress (or the magnitude of the shear-stress tensor). The model converges to Newtonian viscosity ![]() $\mu _0$, the zero-shear-rate viscosity, at small shear rates. The index

$\mu _0$, the zero-shear-rate viscosity, at small shear rates. The index ![]() $\alpha$ represents the degree of shear thinning and it assumes values

$\alpha$ represents the degree of shear thinning and it assumes values ![]() $\alpha \in [1,\infty )$; the greater the value of

$\alpha \in [1,\infty )$; the greater the value of ![]() $\alpha$, the greater is the extent of shear thinning. The constant

$\alpha$, the greater is the extent of shear thinning. The constant ![]() $\tau _{1/2}$ controls the onset of the shear-thinning effect representing the effective shear stress at which the viscosity is 50 % of the Newtonian limit. The greater the value of

$\tau _{1/2}$ controls the onset of the shear-thinning effect representing the effective shear stress at which the viscosity is 50 % of the Newtonian limit. The greater the value of ![]() $\tau _{1/2}$, the greater is the range of shear rates with the Newtonian viscosity. The Ellis model describes well the viscosity of many aqueous solutions (e.g. carboxymethyl cellulose and Carbopol solutions), where the typical values of the rheological constants are in the range

$\tau _{1/2}$, the greater is the range of shear rates with the Newtonian viscosity. The Ellis model describes well the viscosity of many aqueous solutions (e.g. carboxymethyl cellulose and Carbopol solutions), where the typical values of the rheological constants are in the range ![]() $\alpha \in (1,3 )$ and

$\alpha \in (1,3 )$ and ![]() $\tau _{1/2}= {\textit{O}}(10^{-3}\div 10)$, and the viscosity of many polymers, where

$\tau _{1/2}= {\textit{O}}(10^{-3}\div 10)$, and the viscosity of many polymers, where ![]() $\alpha \in (1,4 )$ and

$\alpha \in (1,4 )$ and ![]() $\tau _{1/2}= {\textit{O}}(1\div 10)$, see Bird et al. (Reference Bird, Armstrong and Hassager1987).

$\tau _{1/2}= {\textit{O}}(1\div 10)$, see Bird et al. (Reference Bird, Armstrong and Hassager1987).

At high shear rates the shear-thinning effect dominates and (2.3) matches the power-law model (de Waele Reference de Waele1923; Ostwald Reference Ostwald1925)

where ![]() $\dot {\gamma }=\sqrt {1/2 (\boldsymbol {\dot {\gamma }}\boldsymbol {:}\boldsymbol {\dot {\gamma }})}$ is the magnitude of the shear-rate tensor.

$\dot {\gamma }=\sqrt {1/2 (\boldsymbol {\dot {\gamma }}\boldsymbol {:}\boldsymbol {\dot {\gamma }})}$ is the magnitude of the shear-rate tensor.

In the next section, we derive a lubrication model for a Taylor bubble when it reaches a steady state and moves along the tube with constant speed ![]() $U$. Specifically, once formed, the uniform film thickness

$U$. Specifically, once formed, the uniform film thickness ![]() $h$ is constant with time in a reference frame that moves at the bubble speed

$h$ is constant with time in a reference frame that moves at the bubble speed ![]() $(x-Ut)$. This assumption is supported by the numerical simulations of Moreira et al. (Reference Moreira, Rocha, Carneiro, Araújo, Campos and Miranda2020) and the experiments of Kawahara et al. (Reference Kawahara, Sadatomi, Law and Mansour2015). Alternatively, in problems where the main interest is in characterizing the transient evolution of the bubble, one should derive an evolution equation for the film thickness in time (see for example Zhang & Lister Reference Zhang and Lister1999; Eggers & Fontelos Reference Eggers and Fontelos2015; Garg et al. Reference Garg, Kamat, Anthony, Thete and Basaran2017). In addition, we assume that the film thickness remains high enough to justify neglecting the effect of long-range intermolecular forces (e.g. van der Waals, disjoining pressure). Therefore, the possible rupture of the film and dewetting of the channel wall due to those destabilizing effects (see Zhang & Lister Reference Zhang and Lister1999; Diez & Kondic Reference Diez and Kondic2007; Garg et al. Reference Garg, Kamat, Anthony, Thete and Basaran2017) are out of the scope of this work.

$(x-Ut)$. This assumption is supported by the numerical simulations of Moreira et al. (Reference Moreira, Rocha, Carneiro, Araújo, Campos and Miranda2020) and the experiments of Kawahara et al. (Reference Kawahara, Sadatomi, Law and Mansour2015). Alternatively, in problems where the main interest is in characterizing the transient evolution of the bubble, one should derive an evolution equation for the film thickness in time (see for example Zhang & Lister Reference Zhang and Lister1999; Eggers & Fontelos Reference Eggers and Fontelos2015; Garg et al. Reference Garg, Kamat, Anthony, Thete and Basaran2017). In addition, we assume that the film thickness remains high enough to justify neglecting the effect of long-range intermolecular forces (e.g. van der Waals, disjoining pressure). Therefore, the possible rupture of the film and dewetting of the channel wall due to those destabilizing effects (see Zhang & Lister Reference Zhang and Lister1999; Diez & Kondic Reference Diez and Kondic2007; Garg et al. Reference Garg, Kamat, Anthony, Thete and Basaran2017) are out of the scope of this work.

2.2. Lubrication model

We consider the portions ![]() $BC$ and

$BC$ and ![]() $DE$ of the bubble in figure 1, where the curvature of the meniscus is established and the interface slope is small,

$DE$ of the bubble in figure 1, where the curvature of the meniscus is established and the interface slope is small, ![]() $|\textrm {d}y_i/{\textrm {d} x}| \ll 1$, with

$|\textrm {d}y_i/{\textrm {d} x}| \ll 1$, with ![]() $y_i$ denoting the location of the interface. The idea is to simplify the governing equations by introducing a small scaling parameter

$y_i$ denoting the location of the interface. The idea is to simplify the governing equations by introducing a small scaling parameter ![]() $\varepsilon$, defined as the ratio of the uniform film thickness

$\varepsilon$, defined as the ratio of the uniform film thickness ![]() $h$ to the unknown length of the film region along the flow direction,

$h$ to the unknown length of the film region along the flow direction, ![]() $h/\varepsilon$. This approach is typical of thin-film lubrication models (Eggers & Fontelos Reference Eggers and Fontelos2015) and, in the limit of

$h/\varepsilon$. This approach is typical of thin-film lubrication models (Eggers & Fontelos Reference Eggers and Fontelos2015) and, in the limit of ![]() $\varepsilon \ll 1$, it allows for the identification of the scaling laws in Landau–Levich–Derjaguin–Bretherton problems (see de Gennes, Brochard-Wyart & Quéré Reference de Gennes, Brochard-Wyart and Quéré2003; Stone Reference Stone2010).

$\varepsilon \ll 1$, it allows for the identification of the scaling laws in Landau–Levich–Derjaguin–Bretherton problems (see de Gennes, Brochard-Wyart & Quéré Reference de Gennes, Brochard-Wyart and Quéré2003; Stone Reference Stone2010).

Assuming that the velocity in the axial direction scales with the bubble speed ![]() $U$, the following dimensionless variables are introduced

$U$, the following dimensionless variables are introduced

where ![]() $V$ is the characteristic scale of velocity in the

$V$ is the characteristic scale of velocity in the ![]() $y$ direction. The continuity equation (2.1a) suggests that

$y$ direction. The continuity equation (2.1a) suggests that ![]() $V=\varepsilon U$, and we chose the zero-shear-rate viscosity

$V=\varepsilon U$, and we chose the zero-shear-rate viscosity ![]() $\mu _0$ as representative scale for the effective viscosity. The pressure in the film region scales with the normal pressure that can be estimated as

$\mu _0$ as representative scale for the effective viscosity. The pressure in the film region scales with the normal pressure that can be estimated as ![]() $p\approx \sigma (\textrm {d}^2y_i/{\textrm {d} x}^2) \sim \sigma \varepsilon ^2/h$. Normalizing the momentum equations (2.1b) using (2.5) yields

$p\approx \sigma (\textrm {d}^2y_i/{\textrm {d} x}^2) \sim \sigma \varepsilon ^2/h$. Normalizing the momentum equations (2.1b) using (2.5) yields

where

are the Reynolds and the capillary numbers both based on the zero-shear-rate viscosity.

Assuming that the scaling parameter is small, ![]() $\varepsilon \ll 1$, and that inertial terms can be neglected,

$\varepsilon \ll 1$, and that inertial terms can be neglected, ![]() $\varepsilon Re \ll 1$, (2.6) simplifies to

$\varepsilon Re \ll 1$, (2.6) simplifies to

Equation (2.9) shows that the viscous stress balances the axial pressure gradient only if ![]() $\varepsilon ^3\approx Ca$ and, therefore, the

$\varepsilon ^3\approx Ca$ and, therefore, the ![]() $\tilde {x}$ variable can be expressed in terms of the capillary number as

$\tilde {x}$ variable can be expressed in terms of the capillary number as ![]() $\tilde {x}= x/{hCa^{-{1}/{3}}}$. This allows simplification of (2.7) to

$\tilde {x}= x/{hCa^{-{1}/{3}}}$. This allows simplification of (2.7) to ![]() ${\partial \tilde {p}}/{\partial \tilde {y}}=0$, whereby the pressure is a function of the axial variable only. Note that the model is not applicable near the cap of the bubble where the curvature scales with the channel half-width

${\partial \tilde {p}}/{\partial \tilde {y}}=0$, whereby the pressure is a function of the axial variable only. Note that the model is not applicable near the cap of the bubble where the curvature scales with the channel half-width ![]() $R$, and the slope of the interface is not small enough to justify the lubrication approximation. The effective shear stress reduces to

$R$, and the slope of the interface is not small enough to justify the lubrication approximation. The effective shear stress reduces to

\begin{equation} \tau=\sqrt{ \left[\tilde{\mu} \left( \frac{\partial \tilde{u}}{\partial \tilde{y}} + \varepsilon^2\frac{\partial \tilde{v}}{\partial \tilde{x}}\right) \right]^2 +2 \varepsilon^2 \left(\tilde{\mu}\frac{\partial \tilde{u}}{\partial \tilde{x}}\right)^2+2\varepsilon^2 \left( \tilde{\mu}\frac{\partial \tilde{v}}{\partial \tilde{y}}\right)^2 } \approx \left| \tilde{\mu} \frac{\partial \tilde{u}}{\partial \tilde{y}}\right|, \end{equation}

\begin{equation} \tau=\sqrt{ \left[\tilde{\mu} \left( \frac{\partial \tilde{u}}{\partial \tilde{y}} + \varepsilon^2\frac{\partial \tilde{v}}{\partial \tilde{x}}\right) \right]^2 +2 \varepsilon^2 \left(\tilde{\mu}\frac{\partial \tilde{u}}{\partial \tilde{x}}\right)^2+2\varepsilon^2 \left( \tilde{\mu}\frac{\partial \tilde{v}}{\partial \tilde{y}}\right)^2 } \approx \left| \tilde{\mu} \frac{\partial \tilde{u}}{\partial \tilde{y}}\right|, \end{equation}

which is equal to the dimensionless shear stress in the film, ![]() $\tilde {\tau }_{xy}\approx \tilde {\mu }{\partial \tilde {u}}/{\partial \tilde {y}}$. The corresponding effective viscosity can be written as

$\tilde {\tau }_{xy}\approx \tilde {\mu }{\partial \tilde {u}}/{\partial \tilde {y}}$. The corresponding effective viscosity can be written as

where ![]() $El$ is the Ellis number. The Ellis number can be interpreted as the ratio between the characteristics shear rate of the fluid,

$El$ is the Ellis number. The Ellis number can be interpreted as the ratio between the characteristics shear rate of the fluid, ![]() $\tau _{1/2}/\mu _0$, and the representative shear rate in the film,

$\tau _{1/2}/\mu _0$, and the representative shear rate in the film, ![]() $U/h$. When

$U/h$. When ![]() $El\rightarrow \infty$ the onset of the shear-thinning effect is delayed to an infinite shear rate and the model reduces to a Newtonian fluid of viscosity

$El\rightarrow \infty$ the onset of the shear-thinning effect is delayed to an infinite shear rate and the model reduces to a Newtonian fluid of viscosity ![]() $\mu _0$ (and

$\mu _0$ (and ![]() $\tilde {\mu }=1$), figure 2(a). We refer to this case as the Newtonian limit. Instead, when the shear rate is sufficiently high, or

$\tilde {\mu }=1$), figure 2(a). We refer to this case as the Newtonian limit. Instead, when the shear rate is sufficiently high, or ![]() $El$ is small such that the Newtonian plateau shrinks to extremely low shear rates, the shear-thinning effects dominates in (2.11) and the viscosity matches that of a power-law fluid with a slope

$El$ is small such that the Newtonian plateau shrinks to extremely low shear rates, the shear-thinning effects dominates in (2.11) and the viscosity matches that of a power-law fluid with a slope ![]() $(1-\alpha )/\alpha$, figure 2. As

$(1-\alpha )/\alpha$, figure 2. As ![]() $\alpha \rightarrow 1$ the fluid exhibits a power-law behaviour almost in the entire range of shear rates, while for

$\alpha \rightarrow 1$ the fluid exhibits a power-law behaviour almost in the entire range of shear rates, while for ![]() $\alpha =1$,

$\alpha =1$, ![]() $\tilde {\mu }=1/2$.

$\tilde {\mu }=1/2$.

Figure 2. Dimensionless effective viscosity ![]() $\tilde {\mu }=\mu /\mu _0$ as a function of the dimensionless shear rate, the Ellis number,

$\tilde {\mu }=\mu /\mu _0$ as a function of the dimensionless shear rate, the Ellis number, ![]() $El$ and the degree of shear thinning,

$El$ and the degree of shear thinning, ![]() $\alpha$: (a)

$\alpha$: (a) ![]() $\alpha =2$; (b)

$\alpha =2$; (b) ![]() $El=0.1$. The power-law limit is also plotted (red-dashed line).

$El=0.1$. The power-law limit is also plotted (red-dashed line).

At the interface we ensure the continuity of normal and tangential stresses and the boundary conditions read

\begin{gather} -\tilde{p}|_\eta + \left.2 {Ca}\, \varepsilon^{{-}1} \tilde{\mu}\frac{\partial \tilde{v}}{\partial \tilde{y}}\right|_\eta = \frac{ \left.\dfrac{\partial^2 \eta}{\partial \tilde{x}^2}\right|_\eta }{\left[ 1+\varepsilon^2\left(\left.\dfrac{\partial \eta}{\partial \tilde{x}}\right|_\eta \right)^2 \right]^{3/2}} , \quad \textrm{with} \ \eta=\frac{y_i}{h}, \end{gather}

\begin{gather} -\tilde{p}|_\eta + \left.2 {Ca}\, \varepsilon^{{-}1} \tilde{\mu}\frac{\partial \tilde{v}}{\partial \tilde{y}}\right|_\eta = \frac{ \left.\dfrac{\partial^2 \eta}{\partial \tilde{x}^2}\right|_\eta }{\left[ 1+\varepsilon^2\left(\left.\dfrac{\partial \eta}{\partial \tilde{x}}\right|_\eta \right)^2 \right]^{3/2}} , \quad \textrm{with} \ \eta=\frac{y_i}{h}, \end{gather}

Since ![]() $Ca\approx \varepsilon ^3$ and

$Ca\approx \varepsilon ^3$ and ![]() $\varepsilon \ll 1$, (2.12) further simplifies to

$\varepsilon \ll 1$, (2.12) further simplifies to

\begin{equation} -\tilde{p}|_\eta = \left.\frac{\partial^2 \eta}{\partial \tilde{x}^2}\right|_\eta. \end{equation}

\begin{equation} -\tilde{p}|_\eta = \left.\frac{\partial^2 \eta}{\partial \tilde{x}^2}\right|_\eta. \end{equation}

The assumption that ![]() $\varepsilon \ll 1$ implies that the slope of the interface in the film region is small, namely

$\varepsilon \ll 1$ implies that the slope of the interface in the film region is small, namely ![]() $d\eta /{\rm d} \tilde {x} \ll Ca^{-1/3}$. A formulation of the boundary condition that relaxes this constraint is discussed in Park & Homsy (Reference Park and Homsy1984) and Reinelt (Reference Reinelt1987).

$d\eta /{\rm d} \tilde {x} \ll Ca^{-1/3}$. A formulation of the boundary condition that relaxes this constraint is discussed in Park & Homsy (Reference Park and Homsy1984) and Reinelt (Reference Reinelt1987).

2.3. Film equation

We integrate (2.9) subjected to (2.13) at ![]() $\tilde {y}=\eta$ and the no-slip condition at

$\tilde {y}=\eta$ and the no-slip condition at ![]() $\tilde {y}=0$ to obtain the (instantaneous) velocity profile of shear-thinning fluid

$\tilde {y}=0$ to obtain the (instantaneous) velocity profile of shear-thinning fluid

where ![]() $\tilde {y}\in [0,\eta ]$. The velocity profile is composed by a Newtonian and a shear-thinning parts, reflecting the structure of the Ellis rheological model that can be seen as the sum of a Newtonian and a power-law viscosity model, see Gutfinger & Tallmadge (Reference Gutfinger and Tallmadge1965). The details concerning the derivation of the velocity profile are listed in Appendix A. Then, we compute the volume flux by integrating the velocity profile (2.15) over the film thickness

$\tilde {y}\in [0,\eta ]$. The velocity profile is composed by a Newtonian and a shear-thinning parts, reflecting the structure of the Ellis rheological model that can be seen as the sum of a Newtonian and a power-law viscosity model, see Gutfinger & Tallmadge (Reference Gutfinger and Tallmadge1965). The details concerning the derivation of the velocity profile are listed in Appendix A. Then, we compute the volume flux by integrating the velocity profile (2.15) over the film thickness

where ![]() $\tilde {Q}=Q/hU$ with

$\tilde {Q}=Q/hU$ with ![]() $Q$ the dimensional flux in the film.

$Q$ the dimensional flux in the film.

Looking at the problem from a reference frame moving with the bubble at the speed ![]() $U$, the mass balance between the region of uniform thickness

$U$, the mass balance between the region of uniform thickness ![]() $CD$ and the film region

$CD$ and the film region ![]() $CB$ (see figure 1) yields

$CB$ (see figure 1) yields

In the region ![]() $CD$ the liquid is at rest since

$CD$ the liquid is at rest since ![]() $\eta =1$ and the pressure is constant from (2.14). In terms of dimensionless coordinates, (2.17) becomes

$\eta =1$ and the pressure is constant from (2.14). In terms of dimensionless coordinates, (2.17) becomes

Combining (2.16) and (2.18) and using the boundary condition (2.14) to express the driving force, ![]() ${\rm d} \tilde {p}/{\rm d} \tilde {x}=-{\rm d} ^3\eta /{\rm d} \tilde {x}^3$, we obtain

${\rm d} \tilde {p}/{\rm d} \tilde {x}=-{\rm d} ^3\eta /{\rm d} \tilde {x}^3$, we obtain

\begin{equation} \frac{\textrm{d}^3\eta}{{\rm d} \tilde{x}^3} + \frac{3}{(\alpha + 2)El^{\alpha -1}}\frac{\textrm{d}^3\eta}{{\rm d} \tilde{x}^3}\left|-\frac{\textrm{d}^3\eta}{{\rm d}\tilde{x}^3}\right|^{\alpha-1} \eta^{\alpha-1}= 3 \frac{\eta - 1}{\eta^3}. \end{equation}

\begin{equation} \frac{\textrm{d}^3\eta}{{\rm d} \tilde{x}^3} + \frac{3}{(\alpha + 2)El^{\alpha -1}}\frac{\textrm{d}^3\eta}{{\rm d} \tilde{x}^3}\left|-\frac{\textrm{d}^3\eta}{{\rm d}\tilde{x}^3}\right|^{\alpha-1} \eta^{\alpha-1}= 3 \frac{\eta - 1}{\eta^3}. \end{equation}

Defining ![]() $\xi = 3^{1/3}\tilde{x}=x/[h(3Ca)^{-1/3}]$ we finally get the following ordinary differential equation for

$\xi = 3^{1/3}\tilde{x}=x/[h(3Ca)^{-1/3}]$ we finally get the following ordinary differential equation for ![]() $\eta$

$\eta$

\begin{equation} \underbrace{\frac{\textrm{d}^3\eta}{{\rm d} \xi^3}}_{\mathcal{I}} + \underbrace{\frac{3^\alpha}{(\alpha + 2)El^{\alpha -1}}\frac{\textrm{d}^3\eta}{{\rm d} \xi^3}\left|-\frac{\textrm{d}^3\eta}{{\rm d} \xi^3}\right|^{\alpha-1} \eta^{\alpha-1}}_{\mathcal{II}}= \frac{\eta - 1}{\eta^3}, \end{equation}

\begin{equation} \underbrace{\frac{\textrm{d}^3\eta}{{\rm d} \xi^3}}_{\mathcal{I}} + \underbrace{\frac{3^\alpha}{(\alpha + 2)El^{\alpha -1}}\frac{\textrm{d}^3\eta}{{\rm d} \xi^3}\left|-\frac{\textrm{d}^3\eta}{{\rm d} \xi^3}\right|^{\alpha-1} \eta^{\alpha-1}}_{\mathcal{II}}= \frac{\eta - 1}{\eta^3}, \end{equation}

where the bubble profile ![]() $\eta$ is a function of

$\eta$ is a function of ![]() $\xi$,

$\xi$, ![]() $\alpha$ and

$\alpha$ and ![]() $El$ only. Equation (2.20) describes the meniscus between the uniform film and the caps at both the bubble ends in a moving reference frame

$El$ only. Equation (2.20) describes the meniscus between the uniform film and the caps at both the bubble ends in a moving reference frame ![]() $(x-Ut)$. The left-hand side of (2.20) is composed of a Newtonian and a shear-thinning term, indicated as

$(x-Ut)$. The left-hand side of (2.20) is composed of a Newtonian and a shear-thinning term, indicated as ![]() $\mathcal {I}$ and

$\mathcal {I}$ and ![]() $\mathcal {II}$, respectively.

$\mathcal {II}$, respectively.

When the ![]() $\mathcal {II}$ becomes negligible, (2.20) converges to the classical result obtained by Bretherton (Reference Bretherton1961) for a Newtonian liquid,

$\mathcal {II}$ becomes negligible, (2.20) converges to the classical result obtained by Bretherton (Reference Bretherton1961) for a Newtonian liquid,

We recover the Newtonian liquid either for ![]() $El\rightarrow \infty$, or for specific combinations of

$El\rightarrow \infty$, or for specific combinations of ![]() $El$ and

$El$ and ![]() $\alpha$ so that the shear-thinning effect vanishes, see figure 2. Also, when the third derivative goes to zero,

$\alpha$ so that the shear-thinning effect vanishes, see figure 2. Also, when the third derivative goes to zero, ![]() ${\rm d} ^3\eta /{\rm d} \xi ^3\rightarrow 0$, (2.20) reduces to (2.21), as it will be discussed in detail in § 3.1. If we artificially remove the term

${\rm d} ^3\eta /{\rm d} \xi ^3\rightarrow 0$, (2.20) reduces to (2.21), as it will be discussed in detail in § 3.1. If we artificially remove the term ![]() $\mathcal {I}$ from (2.20), we recover the equation for a power-law fluid

$\mathcal {I}$ from (2.20), we recover the equation for a power-law fluid

\begin{equation} \frac{\textrm{d}^3\eta}{{\rm d} \xi^3}\left|-\frac{\textrm{d}^3\eta}{{\rm d} \xi^3}\right|^{\alpha-1} = \frac{(\alpha + 2)^{{1}/{\alpha}}El^{({\alpha -1})/{\alpha}}}{3} \frac{(\eta - 1)}{\eta^{{2+\alpha}}}. \end{equation}

\begin{equation} \frac{\textrm{d}^3\eta}{{\rm d} \xi^3}\left|-\frac{\textrm{d}^3\eta}{{\rm d} \xi^3}\right|^{\alpha-1} = \frac{(\alpha + 2)^{{1}/{\alpha}}El^{({\alpha -1})/{\alpha}}}{3} \frac{(\eta - 1)}{\eta^{{2+\alpha}}}. \end{equation}

Equation (2.22) holds only when the shear-thinning term dominates and, assuming that ![]() ${\rm d} ^3\eta /{\rm d} \xi ^3\geq 0$, i.e. considering the front of the bubble only, (2.22) is equivalent to the one derived by Kamişli & Ryan (Reference Kamişli and Ryan1999, Reference Kamişli and Ryan2001) for power-law fluids. Although mathematically correct, the model for power-law fluid leads to non-physical results when integrated starting from the uniform thickness region and the extent to which its use could be legitimized will be discussed in § 3.1.

${\rm d} ^3\eta /{\rm d} \xi ^3\geq 0$, i.e. considering the front of the bubble only, (2.22) is equivalent to the one derived by Kamişli & Ryan (Reference Kamişli and Ryan1999, Reference Kamişli and Ryan2001) for power-law fluids. Although mathematically correct, the model for power-law fluid leads to non-physical results when integrated starting from the uniform thickness region and the extent to which its use could be legitimized will be discussed in § 3.1.

The general solution of (2.20) can be found numerically starting from the region ![]() $CD$ and integrating in the directions of the front and rear menisci. To do that, it is convenient to discuss few limiting cases where the solution can be obtained analytically (§ 2.4).

$CD$ and integrating in the directions of the front and rear menisci. To do that, it is convenient to discuss few limiting cases where the solution can be obtained analytically (§ 2.4).

2.4. Scaling of the film equation

In regions near ![]() $C$ and near

$C$ and near ![]() $D$ the film thickness approaches a uniform value (

$D$ the film thickness approaches a uniform value (![]() $y_i\simeq h$) and we can write

$y_i\simeq h$) and we can write

Upon substituting (2.23) into (2.20) we obtain

Expanding the two binomials in (2.24) into Taylor series, truncating after the second term and recalling that ![]() $\eta _1=\eta -1$, we obtain an approximation of the film equation near the uniform film

$\eta _1=\eta -1$, we obtain an approximation of the film equation near the uniform film

If ![]() $\textit{O}( 3^\alpha |{\rm d} ^3 \eta /{\rm d} \xi ^3|^{\alpha }/ (\alpha +2)El^{\alpha -1} ) \ll 1$, (2.25) reduces to

$\textit{O}( 3^\alpha |{\rm d} ^3 \eta /{\rm d} \xi ^3|^{\alpha }/ (\alpha +2)El^{\alpha -1} ) \ll 1$, (2.25) reduces to

and it admits an analytical solution

\begin{equation} \eta=1+ae^{\xi}+be^{-\xi/2}\cos{\left(\frac{\sqrt{3}}{2}\xi\right)} +ce^{-\xi/2}\sin{\left(\frac{\sqrt{3}}{2}\xi\right)}, \end{equation}

\begin{equation} \eta=1+ae^{\xi}+be^{-\xi/2}\cos{\left(\frac{\sqrt{3}}{2}\xi\right)} +ce^{-\xi/2}\sin{\left(\frac{\sqrt{3}}{2}\xi\right)}, \end{equation}

where ![]() $a$,

$a$, ![]() $b$,

$b$, ![]() $c$ are constants. This is the same approximation valid for Newtonian fluids and it holds also for an Ellis fluid since the third derivative in this region is small,

$c$ are constants. This is the same approximation valid for Newtonian fluids and it holds also for an Ellis fluid since the third derivative in this region is small, ![]() ${\rm d} ^3 \eta /{\rm d} \xi ^3\ll 1$; this assumption will be justified a posteriori in § 3.1. In the following, we refer to portions of the bubble where (2.27) applies as the exponential regions, see figure 3.

${\rm d} ^3 \eta /{\rm d} \xi ^3\ll 1$; this assumption will be justified a posteriori in § 3.1. In the following, we refer to portions of the bubble where (2.27) applies as the exponential regions, see figure 3.

Figure 3. Numerical solution (red), the exponential initial condition (dashed black) and the parabolic region for ![]() $El=1$ and

$El=1$ and ![]() $\alpha =2$ for the (a) bubble front, (b) bubble rear. The solutions have been shifted along

$\alpha =2$ for the (a) bubble front, (b) bubble rear. The solutions have been shifted along ![]() $\xi$ to ensure that the coefficient

$\xi$ to ensure that the coefficient ![]() $Q$ in (2.29) is

$Q$ in (2.29) is ![]() $Q=0$ .

$Q=0$ .

In regions where ![]() $\eta \gg 1$ and the slope of the interface is small enough,

$\eta \gg 1$ and the slope of the interface is small enough, ![]() $dy_i/{\textrm {d} x}\ll 1$ (or, in terms of dimensionless variables

$dy_i/{\textrm {d} x}\ll 1$ (or, in terms of dimensionless variables ![]() $d\eta /{\rm d} \xi \ll Ca^{-1/3}$), so that the lubrication approximation holds, (2.20) reduces to

$d\eta /{\rm d} \xi \ll Ca^{-1/3}$), so that the lubrication approximation holds, (2.20) reduces to

Integration yields a parabolic behaviour with respect to ![]() $\xi$

$\xi$

where ![]() $P$,

$P$, ![]() $W$ and

$W$ and ![]() $Z$ are constants to be determined from the numerical solution of (2.20), see § 2.5. Specifically, the coefficient

$Z$ are constants to be determined from the numerical solution of (2.20), see § 2.5. Specifically, the coefficient ![]() $P$ is the dimensionless curvature of the meniscus when

$P$ is the dimensionless curvature of the meniscus when ![]() $\eta \gg 1$, i.e. the second derivative of

$\eta \gg 1$, i.e. the second derivative of ![]() $\eta$ with respect to

$\eta$ with respect to ![]() $\xi$,

$\xi$, ![]() $P={\rm d} ^2\eta /{\rm d} \xi ^2$. Given

$P={\rm d} ^2\eta /{\rm d} \xi ^2$. Given ![]() $El$ and

$El$ and ![]() $\alpha$, the value of

$\alpha$, the value of ![]() $P$ can be obtained from the numerical solution far from the uniform film region for both the front and the rear menisci. The determination of the coefficients

$P$ can be obtained from the numerical solution far from the uniform film region for both the front and the rear menisci. The determination of the coefficients ![]() $W$ and

$W$ and ![]() $Z$ requires numerical fitting:

$Z$ requires numerical fitting: ![]() $W$ is made zero by shifting the solution along

$W$ is made zero by shifting the solution along ![]() $\xi$, while

$\xi$, while ![]() $Z$ is fitted from a window that gives, in the Newtonian limit, the same value obtained by Bretherton (Reference Bretherton1961) (

$Z$ is fitted from a window that gives, in the Newtonian limit, the same value obtained by Bretherton (Reference Bretherton1961) (![]() $Z=2.79$ in the front and

$Z=2.79$ in the front and ![]() $Z=-0.72$ in the rear). The portions of the bubble where (2.29) applies are referred as the parabolic regions, see figure 3.

$Z=-0.72$ in the rear). The portions of the bubble where (2.29) applies are referred as the parabolic regions, see figure 3.

2.5. Boundary conditions and numerical solution

The film shape between the uniform film and the caps at both ends is obtained by solving (2.20) using the fully implicit solver ode15i of Matlab. The front and the rear menisci are treated separately integrating (2.20) with a different set of boundary conditions.

The front meniscus is obtained by integrating (2.20) starting from somewhere near ![]() $C$ (figure 1) towards positive

$C$ (figure 1) towards positive ![]() $\xi$. We chose to set the origin at

$\xi$. We chose to set the origin at ![]() $\xi =0$, assuming that the uniform film region extends to

$\xi =0$, assuming that the uniform film region extends to ![]() $\xi \rightarrow - \infty$, or, alternatively, that

$\xi \rightarrow - \infty$, or, alternatively, that ![]() $\eta (-\infty )=1$. This means that, near

$\eta (-\infty )=1$. This means that, near ![]() $C$, we can approximate the solution with the exponential approximation (2.27). In the front, the cosine and sine terms in (2.27) are small due to the damping effect of the negative exponentials, and (2.27) can be simplified as

$C$, we can approximate the solution with the exponential approximation (2.27). In the front, the cosine and sine terms in (2.27) are small due to the damping effect of the negative exponentials, and (2.27) can be simplified as

For specified values of ![]() $El$ and

$El$ and ![]() $\alpha$, the solution is unique. Starting the integration from

$\alpha$, the solution is unique. Starting the integration from ![]() $\xi =0$ we set

$\xi =0$ we set ![]() $a=10^{-5}$ and

$a=10^{-5}$ and

Different values of ![]() $a$ result only in a shift in the origin of

$a$ result only in a shift in the origin of ![]() $\xi$. The (translated) front profile is shown in figure 3(a). The exponential solution is also plotted indicating that, as

$\xi$. The (translated) front profile is shown in figure 3(a). The exponential solution is also plotted indicating that, as ![]() $\xi$ increases, the numerical solution diverges from (2.30).

$\xi$ increases, the numerical solution diverges from (2.30).

The profile in the rear meniscus is obtained by integrating (2.20) towards negative ![]() $\xi$ starting from the boundary condition

$\xi$ starting from the boundary condition ![]() $\eta (\infty )=1$. Near

$\eta (\infty )=1$. Near ![]() $D$, we can approximate the solution with the exponential function (2.27) that, for negative

$D$, we can approximate the solution with the exponential function (2.27) that, for negative ![]() $\xi$, can be simplified neglecting the positive exponential as

$\xi$, can be simplified neglecting the positive exponential as

\begin{equation} \eta \simeq 1+be^{-\xi/2}\cos{\left(\frac{\sqrt{3}}{2}\xi\right)} +ce^{-\xi/2}\sin{\left(\frac{\sqrt{3}}{2}\xi\right)}. \end{equation}

\begin{equation} \eta \simeq 1+be^{-\xi/2}\cos{\left(\frac{\sqrt{3}}{2}\xi\right)} +ce^{-\xi/2}\sin{\left(\frac{\sqrt{3}}{2}\xi\right)}. \end{equation}

Choosing ![]() $\xi =0$ as the origin we get

$\xi =0$ as the origin we get

In (2.33a–d) there are two disposable constants: ![]() $b$ has the effect of shifting the origin of the bubble profile only and we arbitrarily set the value to

$b$ has the effect of shifting the origin of the bubble profile only and we arbitrarily set the value to ![]() $b=10^{-4}$. The other constant determines the curvature of the menisci at

$b=10^{-4}$. The other constant determines the curvature of the menisci at ![]() $\eta \gg 1$, i.e. for

$\eta \gg 1$, i.e. for ![]() $\xi \rightarrow -\infty$. It is a common choice to assume that the curvature in the rear matches the one in the front, see Bretherton (Reference Bretherton1961), imposing

$\xi \rightarrow -\infty$. It is a common choice to assume that the curvature in the rear matches the one in the front, see Bretherton (Reference Bretherton1961), imposing

\begin{equation} \left. \frac{\textrm{d}^2 \eta_{rear}}{{\rm d} \xi^2}\right|_{\xi \rightarrow -\infty}= \left. \frac{\textrm{d}^2 \eta_{front}}{{\rm d} \xi^2}\right |_{\xi \rightarrow + \infty}. \end{equation}

\begin{equation} \left. \frac{\textrm{d}^2 \eta_{rear}}{{\rm d} \xi^2}\right|_{\xi \rightarrow -\infty}= \left. \frac{\textrm{d}^2 \eta_{front}}{{\rm d} \xi^2}\right |_{\xi \rightarrow + \infty}. \end{equation}

The boundary condition is satisfied by an iterative loop on the constant ![]() $c$ in (2.33a–d); this loop imposes that the second derivative – the curvature – of

$c$ in (2.33a–d); this loop imposes that the second derivative – the curvature – of ![]() $\eta$ in the parabolic region equals the one of the front meniscus calculated for given values of

$\eta$ in the parabolic region equals the one of the front meniscus calculated for given values of ![]() $El$ and

$El$ and ![]() $\alpha$. A plot of the calculated rear meniscus is given in 3(b). Differently from the front meniscus that is monotonic, the rear meniscus develops the typical oscillations. A discussion about the relaxation of the boundary condition (2.34) is given in Appendix D.

$\alpha$. A plot of the calculated rear meniscus is given in 3(b). Differently from the front meniscus that is monotonic, the rear meniscus develops the typical oscillations. A discussion about the relaxation of the boundary condition (2.34) is given in Appendix D.

3. Results and discussion

3.1. Characteristics of the front meniscus

We compute the front meniscus as described in § 2.5 aiming at exploring the effect of the rheology of the shear-thinning liquid on bubble characteristics. Differently from the Newtonian case, where the profile is uniquely determined by the dimensionless variables ![]() $\eta$ and

$\eta$ and ![]() $\xi$, here, the profile also depends on

$\xi$, here, the profile also depends on ![]() $El$ and

$El$ and ![]() $\alpha$.

$\alpha$.

The Ellis number controls the onset of the shear-thinning effect. When ![]() $El \rightarrow \infty$, the front meniscus converges to the Newtonian limit and the problem does not depend anymore on

$El \rightarrow \infty$, the front meniscus converges to the Newtonian limit and the problem does not depend anymore on ![]() $\alpha$, figure 4(a). Instead, as

$\alpha$, figure 4(a). Instead, as ![]() $El$ decreases, the Newtonian plateau in the viscosity curve shrinks, see figure 2(a), and the dimensionless curvature of the meniscus

$El$ decreases, the Newtonian plateau in the viscosity curve shrinks, see figure 2(a), and the dimensionless curvature of the meniscus ![]() ${\rm d} ^2\eta /{\rm d} \xi ^2$ when

${\rm d} ^2\eta /{\rm d} \xi ^2$ when ![]() $\eta \gg 1$ decreases, see figure 4(b). The change in the meniscus shape is an effect of the local variation in the effective viscosity of the liquid, as demonstrated in figure 5. The effective viscosity

$\eta \gg 1$ decreases, see figure 4(b). The change in the meniscus shape is an effect of the local variation in the effective viscosity of the liquid, as demonstrated in figure 5. The effective viscosity ![]() $\tilde {\mu }|_w$ is computed using (2.11) based on the shear rate at the channel wall (

$\tilde {\mu }|_w$ is computed using (2.11) based on the shear rate at the channel wall (![]() $\tilde {y}=0$) defined as

$\tilde {y}=0$) defined as

\begin{equation} \left. \frac{\textrm{d} \tilde{u}}{\textrm{d}\tilde{y}}\right |_w={-} \frac{\textrm{d}\tilde{p}}{\textrm{d}\tilde{x}}\eta-{El^{1-\alpha}}\frac{\textrm{d}\tilde{p}}{\textrm{d}\tilde{x}}\left|\frac{\textrm{d}\tilde{p}}{\textrm{d}\tilde{x}}\right| ^{\alpha-1} \eta^\alpha . \end{equation}

\begin{equation} \left. \frac{\textrm{d} \tilde{u}}{\textrm{d}\tilde{y}}\right |_w={-} \frac{\textrm{d}\tilde{p}}{\textrm{d}\tilde{x}}\eta-{El^{1-\alpha}}\frac{\textrm{d}\tilde{p}}{\textrm{d}\tilde{x}}\left|\frac{\textrm{d}\tilde{p}}{\textrm{d}\tilde{x}}\right| ^{\alpha-1} \eta^\alpha . \end{equation}

In the vicinity of the uniform thickness region, the effective viscosity is ![]() $\tilde {\mu }|_w=1$ since the fluid is at rest. This means that we can always identify a region of the bubble where the liquid exhibits a Newtonian behaviour. The existence of a high (Newtonian) viscosity region within the uniform film thickness is indeed confirmed by the viscosity field obtained from numerical simulations by Moreira et al. (Reference Moreira, Rocha, Carneiro, Araújo, Campos and Miranda2020). To quantify the shear-thinning effect, the weights of the Newtonian and shear-thinning terms are plotted in figure 5 as

$\tilde {\mu }|_w=1$ since the fluid is at rest. This means that we can always identify a region of the bubble where the liquid exhibits a Newtonian behaviour. The existence of a high (Newtonian) viscosity region within the uniform film thickness is indeed confirmed by the viscosity field obtained from numerical simulations by Moreira et al. (Reference Moreira, Rocha, Carneiro, Araújo, Campos and Miranda2020). To quantify the shear-thinning effect, the weights of the Newtonian and shear-thinning terms are plotted in figure 5 as

where ![]() $\mathcal {I}$ and

$\mathcal {I}$ and ![]() $\mathcal {II}$ refers to (2.20). For

$\mathcal {II}$ refers to (2.20). For ![]() $El=10$ the shear-thinning term is negligible over the entire meniscus and the profile is almost indistinguishable from a Newtonian profile. Instead, for

$El=10$ the shear-thinning term is negligible over the entire meniscus and the profile is almost indistinguishable from a Newtonian profile. Instead, for ![]() $El=1, 10^{-1}, 10^{-5}$ we can identify a region of the bubble where the shear-thinning term in (2.20) is comparable to the Newtonian one, figure 5(c), or entirely dominates the solution, figure 5(d). We define the shear-thinning region (depicted in grey) when

$El=1, 10^{-1}, 10^{-5}$ we can identify a region of the bubble where the shear-thinning term in (2.20) is comparable to the Newtonian one, figure 5(c), or entirely dominates the solution, figure 5(d). We define the shear-thinning region (depicted in grey) when ![]() $\mathcal {I}_N\leq 0.95$.

$\mathcal {I}_N\leq 0.95$.

Figure 4. Bubble meniscus at the front, (a) and dimensionless curvature, (b), as a function of the Ellis number for a shear-thinning fluid with ![]() $\alpha =2$.

$\alpha =2$.

Figure 5. Front meniscus and effective viscosity computed based on the shear rate at the wall for a shear-thinning fluid with ![]() $\alpha =2$ and (a)

$\alpha =2$ and (a) ![]() $El=10$; (b)

$El=10$; (b) ![]() $El=1$; (c)

$El=1$; (c) ![]() $El=10^{-1}$; (d)

$El=10^{-1}$; (d) ![]() $El=10^{-5}$. The Newtonian region (white) and the shear-thinning region (grey) are highlighted. The insets show the weight of the Newtonian,

$El=10^{-5}$. The Newtonian region (white) and the shear-thinning region (grey) are highlighted. The insets show the weight of the Newtonian, ![]() $\mathcal {I}_N$, and the shear-thinning,

$\mathcal {I}_N$, and the shear-thinning, ![]() $\mathcal {I}_{PL}$, terms in (2.20).

$\mathcal {I}_{PL}$, terms in (2.20).

The terms (3.2a,b) suggest that the shear-thinning effect is important only when the film starts growing rapidly before entering the parabolic region. There, the shear rate has a maximum that corresponds to a minimum in the effective viscosity. As expected, the lower ![]() $El$ is, the lower is the minimum of

$El$ is, the lower is the minimum of ![]() $\tilde {\mu }|_w$. Far from the uniform thickness region where

$\tilde {\mu }|_w$. Far from the uniform thickness region where ![]() $\eta$ is large, the third derivative

$\eta$ is large, the third derivative ![]() ${\rm d} ^3\eta /{\rm d} \xi ^3\rightarrow 0$ and, as a consequence, the effective viscosity reduces rapidly, see (3.1). Although this would imply the tendency of reaching the Newtonian limit again, we remind that the model is not applicable too far from the region

${\rm d} ^3\eta /{\rm d} \xi ^3\rightarrow 0$ and, as a consequence, the effective viscosity reduces rapidly, see (3.1). Although this would imply the tendency of reaching the Newtonian limit again, we remind that the model is not applicable too far from the region ![]() $CD$.

$CD$.

The fact that the shear-thinning effect arises only in a small portion of the bubble indicates that the use of the power-law model for describing the meniscus is physically incorrect. In particular, since in the vicinity of the uniform film region, the problem is dominated by the Newtonian term (figure 5), the integration of (2.22) would lead to non-physical results. The power-law effective viscosity would grow to the infinite near the origin since ![]() ${\rm d} \tilde {u}/{\rm d} \tilde {y}\approx 0$. The choice made by Kamişli & Ryan (Reference Kamişli and Ryan1999) of solving (2.22) starting from a Newtonian initial condition, but not accounting for the Newtonian term, does not seem a correct representation of the physics of the problem.

${\rm d} \tilde {u}/{\rm d} \tilde {y}\approx 0$. The choice made by Kamişli & Ryan (Reference Kamişli and Ryan1999) of solving (2.22) starting from a Newtonian initial condition, but not accounting for the Newtonian term, does not seem a correct representation of the physics of the problem.

The shear-thinning effect also delays the transition to the parabolic region that is characterized by a constant dimensionless curvature and ![]() ${\rm d} ^3\eta /{\rm d} \xi ^3 \approx 0$, see § 2.4. As

${\rm d} ^3\eta /{\rm d} \xi ^3 \approx 0$, see § 2.4. As ![]() $El$ decreases, the starting point of the parabolic region shifts to higher

$El$ decreases, the starting point of the parabolic region shifts to higher ![]() $\xi$, as can be seen by analysis of the rate at which the third derivative approaches a zero value. In the Newtonian limit,

$\xi$, as can be seen by analysis of the rate at which the third derivative approaches a zero value. In the Newtonian limit,

the third derivative in (2.21) decays proportionally to ![]() $1/\eta ^2$. In case the shear-thinning effect dominates, such as for

$1/\eta ^2$. In case the shear-thinning effect dominates, such as for ![]() $El=10^{-5}$ in figure 5(d), the third derivative in (2.22) decays proportionally to

$El=10^{-5}$ in figure 5(d), the third derivative in (2.22) decays proportionally to ![]() $1/\eta ^{({1+\alpha })/{\alpha }}$,

$1/\eta ^{({1+\alpha })/{\alpha }}$,

Since ![]() $\alpha >1$, the onset of the parabolic region is delayed.

$\alpha >1$, the onset of the parabolic region is delayed.

Changes in the degree of shear thinning ![]() $\alpha$ result in two different behaviours. When the shear rate is smaller than 0.2 (the value at which

$\alpha$ result in two different behaviours. When the shear rate is smaller than 0.2 (the value at which ![]() $\tilde {\mu }=1/2$), the system tends to the Newtonian limit for

$\tilde {\mu }=1/2$), the system tends to the Newtonian limit for ![]() $\alpha \rightarrow \infty$. Instead, when the shear rate is greater than 0.2, an increase in

$\alpha \rightarrow \infty$. Instead, when the shear rate is greater than 0.2, an increase in ![]() $\alpha$ translates in a decrease of the effective viscosity, see figure 2(b). Accordingly, in figure 6, the front meniscus approaches the Newtonian limit for

$\alpha$ translates in a decrease of the effective viscosity, see figure 2(b). Accordingly, in figure 6, the front meniscus approaches the Newtonian limit for ![]() $El=1$ while it shows the opposite behaviour for

$El=1$ while it shows the opposite behaviour for ![]() $El=10^{-2}$. Since the effective shear rate of the problem scales as

$El=10^{-2}$. Since the effective shear rate of the problem scales as ![]() $\dot {\gamma }_e\sim 1/El$, the two opposing behaviours depend on whether the Ellis number is greater or smaller of a critical value. For

$\dot {\gamma }_e\sim 1/El$, the two opposing behaviours depend on whether the Ellis number is greater or smaller of a critical value. For ![]() $\alpha =1$ we recover a Newtonian fluid with

$\alpha =1$ we recover a Newtonian fluid with ![]() $\tilde {\mu }=1/2$ and the meniscus is identical to the one obtained in the Newtonian limit with a change of variables

$\tilde {\mu }=1/2$ and the meniscus is identical to the one obtained in the Newtonian limit with a change of variables ![]() $\xi ^*=\xi /\sqrt [3]{2}$.

$\xi ^*=\xi /\sqrt [3]{2}$.

Figure 6. Effect of the degree of shear thinning ![]() $\alpha$ on the shape of front meniscus for (a)

$\alpha$ on the shape of front meniscus for (a) ![]() $El=1$ ; (b)

$El=1$ ; (b) ![]() $El=10^{-2}$.

$El=10^{-2}$.

The characteristics of the front meniscus can be summarized looking at the scaling behaviour of the coefficients in the parabolic solution (2.29). Figure 7(a) shows ![]() $P$ as a function of

$P$ as a function of ![]() $El$ and

$El$ and ![]() $\alpha$. When

$\alpha$. When ![]() $El\rightarrow \infty$ all the curves approach the Newtonian limit and

$El\rightarrow \infty$ all the curves approach the Newtonian limit and ![]() $P= 0.643$ as obtained by Bretherton (Reference Bretherton1961). The curvature of the Newtonian limit is the maximal curvature that the meniscus can assume. As

$P= 0.643$ as obtained by Bretherton (Reference Bretherton1961). The curvature of the Newtonian limit is the maximal curvature that the meniscus can assume. As ![]() $El\rightarrow 0$, instead, the curvature decreases significantly and, when

$El\rightarrow 0$, instead, the curvature decreases significantly and, when ![]() $\alpha \rightarrow 1$, the shear-thinning effect delays the transition to the Newtonian limit to much higher

$\alpha \rightarrow 1$, the shear-thinning effect delays the transition to the Newtonian limit to much higher ![]() $El$. Figure 7(b) shows the trends for the coefficient

$El$. Figure 7(b) shows the trends for the coefficient ![]() $Z$ in (2.29).

$Z$ in (2.29).

Figure 7. Coefficients ![]() $P$ and

$P$ and ![]() $Z$ in (2.29) that characterize the front meniscus in the parabolic region as a function of the Ellis number and the degree of shear thinning

$Z$ in (2.29) that characterize the front meniscus in the parabolic region as a function of the Ellis number and the degree of shear thinning ![]() $\alpha$. Note that the coefficient

$\alpha$. Note that the coefficient ![]() $P$ is also the dimensionless curvature of the meniscus for

$P$ is also the dimensionless curvature of the meniscus for ![]() $\eta \gg 1$,

$\eta \gg 1$, ![]() $P={\rm d} ^2\eta /{\rm d} \xi ^2$.

$P={\rm d} ^2\eta /{\rm d} \xi ^2$.

3.2. Scaling of the film thickness and generalization of the capillary number

The model for the film thickness is obtained by matching the curvature of the parabolic region near ![]() $B$ with the curvature of the spherical cap

$B$ with the curvature of the spherical cap ![]() $AB$, see figure 1. Specifically, near

$AB$, see figure 1. Specifically, near ![]() $B$ the curvature is constant

$B$ the curvature is constant

while in the spherical cap the curvature scales as ![]() ${\rm d} ^2 y_i/{\textrm {d} x}^2\sim 1/R$. By matching the two curvatures we obtain

${\rm d} ^2 y_i/{\textrm {d} x}^2\sim 1/R$. By matching the two curvatures we obtain

where ![]() $P(El,\alpha )$ is a function of the Ellis number and

$P(El,\alpha )$ is a function of the Ellis number and ![]() $\alpha$ only. Differently from the Newtonian case, the film thickness is determined by the interplay of three dimensionless numbers,

$\alpha$ only. Differently from the Newtonian case, the film thickness is determined by the interplay of three dimensionless numbers, ![]() $h(Ca,El,\alpha )$, and it converges to the correlation proposed by Bretherton (Reference Bretherton1961) in the Newtonian limit. The scaling law for

$h(Ca,El,\alpha )$, and it converges to the correlation proposed by Bretherton (Reference Bretherton1961) in the Newtonian limit. The scaling law for ![]() $h/R$ is summarized in figure 8. The film thickness decreases with decreasing of the Ellis number since the effective viscosity of the problem diminishes, figure 8(a). Therefore, when the shear-thinning effect dominates (i.e. low

$h/R$ is summarized in figure 8. The film thickness decreases with decreasing of the Ellis number since the effective viscosity of the problem diminishes, figure 8(a). Therefore, when the shear-thinning effect dominates (i.e. low ![]() $El$), the bubble forms a thinner film compared with a Newtonian fluid with the same capillary number. Variations in the degree of shear thinning

$El$), the bubble forms a thinner film compared with a Newtonian fluid with the same capillary number. Variations in the degree of shear thinning ![]() $\alpha$ produce two opposite behaviours depending on whether the effective shear rate (or

$\alpha$ produce two opposite behaviours depending on whether the effective shear rate (or ![]() $1/El$) exceeds the critical value, see 8(b,c).

$1/El$) exceeds the critical value, see 8(b,c).

Figure 8. (a–c) Dimensionless film thickness, ![]() $h/R$, as a function of the capillary number,

$h/R$, as a function of the capillary number, ![]() $Ca$, the Ellis number,

$Ca$, the Ellis number, ![]() $El$, and the degree of shear thinning,

$El$, and the degree of shear thinning, ![]() $\alpha$.

$\alpha$.

The model for the film thickness (3.6) is still based on the definition of the capillary number defined with the zero-shear-rate viscosity, see (2.8a,b). It would be desirable to obtain a formulation of the capillary number that embeds both the zero-shear-rate and the shear-thinning effects. With this aim, we can recast (3.6) in the following form introducing the effective capillary number ![]() $Ca_e$

$Ca_e$

where ![]() $\mu _e$ is the effective viscosity defined as

$\mu _e$ is the effective viscosity defined as

\begin{equation} {\mu_e}=\mu_0 \left(\frac{P}{0.643}\right)^{{3}/{2}}. \end{equation}

\begin{equation} {\mu_e}=\mu_0 \left(\frac{P}{0.643}\right)^{{3}/{2}}. \end{equation}

A plot of the effective viscosity as a function of the effective shear rate ![]() $1/El$ is provided in figure 9(a). Since the determination of

$1/El$ is provided in figure 9(a). Since the determination of ![]() $P$ requires the numerical solution of (2.20), we use the numerical results to get a fitting curve for the effective viscosity. The data of figure 9(a) collapse over the same master curve, figure 9(b), if we define

$P$ requires the numerical solution of (2.20), we use the numerical results to get a fitting curve for the effective viscosity. The data of figure 9(a) collapse over the same master curve, figure 9(b), if we define

\begin{equation} \frac{\mu_e}{\mu_0}= \left\{ \begin{array}{@{}ll} 1, & \textrm{if} \ El \rightarrow \infty, \\ 0.725 \dfrac{17\alpha-12 }{5\alpha}{{El}^{{(\alpha-1)}/{\alpha}}} , & \textrm{if} \ El \rightarrow 0. \end{array} \right. \end{equation}

\begin{equation} \frac{\mu_e}{\mu_0}= \left\{ \begin{array}{@{}ll} 1, & \textrm{if} \ El \rightarrow \infty, \\ 0.725 \dfrac{17\alpha-12 }{5\alpha}{{El}^{{(\alpha-1)}/{\alpha}}} , & \textrm{if} \ El \rightarrow 0. \end{array} \right. \end{equation}

The scaling law for ![]() $El\rightarrow 0$ has been inspired by the definition of the effective viscosity for a power-law fluid

$El\rightarrow 0$ has been inspired by the definition of the effective viscosity for a power-law fluid

where ![]() $\tilde {\kappa }=0.725(17\alpha -12)/5\alpha$ and

$\tilde {\kappa }=0.725(17\alpha -12)/5\alpha$ and ![]() $n=1/\alpha$. Equation (3.9) is the universal scaling for the effective viscosity for a confined Taylor bubble that moves in a shear-thinning liquid and it allows for the definition of a generalized capillary number for the problem.

$n=1/\alpha$. Equation (3.9) is the universal scaling for the effective viscosity for a confined Taylor bubble that moves in a shear-thinning liquid and it allows for the definition of a generalized capillary number for the problem.

Figure 9. (a) Effective viscosity as a function of the effective shear rate, ![]() $1/El$, and the degree of shear thinning

$1/El$, and the degree of shear thinning ![]() $\alpha$. (b) Collapsing of all the viscosity curves around the master curve (3.9).

$\alpha$. (b) Collapsing of all the viscosity curves around the master curve (3.9).

The trends of figure 8 are in a qualitative agreement with the simulations of Moreira et al. (Reference Moreira, Rocha, Carneiro, Araújo, Campos and Miranda2020). In particular, the film thickness decreases with increasing of the degree of shear thinning at a fixed capillary number. Unfortunately, their data cannot be used to validate our model since the flow rates necessary to define the capillary number are not reported in the manuscript. Also, the data collected by Kamişli & Ryan (Reference Kamişli and Ryan1999) and by Kawahara et al. (Reference Kawahara, Sadatomi, Law and Mansour2015) cannot be considered to validate the scaling law for the film thickness because the rheological data do not include the low-shear-rate behaviour and only the power-law behaviour has been provided. For a complete validation of our model, more experiments or simulations performed with realistic shear-thinning fluids would be valuable and are encouraged.

3.3. Bubble speed

A measure of the ratio between the bubble speed ![]() $U$ and the average velocity of the fluid ahead of the bubble

$U$ and the average velocity of the fluid ahead of the bubble ![]() $U_\infty$ is a critical parameter in the design of many applications that involve bubbles and trains of bubbles. We can derive the scaling law for

$U_\infty$ is a critical parameter in the design of many applications that involve bubbles and trains of bubbles. We can derive the scaling law for ![]() $U/U_\infty$ applying the mass balance to the problem. Specifically, if we write the balance between the open tube and the uniform film region in a reference frame that moves with the bubble speed

$U/U_\infty$ applying the mass balance to the problem. Specifically, if we write the balance between the open tube and the uniform film region in a reference frame that moves with the bubble speed ![]() $U$

$U$

we obtain

Combining (3.12) with (3.6) or (3.7) we obtain the scaling law valid for the two-plate geometry

The bubble always flows faster compared with the fluid ahead from the bubble, ![]() $U/U_\infty >1$, and, only in the limit of

$U/U_\infty >1$, and, only in the limit of ![]() $Ca\rightarrow 0$, the speed of the bubble is almost indistinguishable from

$Ca\rightarrow 0$, the speed of the bubble is almost indistinguishable from ![]() $U_\infty$, see figure 10. In general, when the shear-thinning effect plays a role (i.e. low

$U_\infty$, see figure 10. In general, when the shear-thinning effect plays a role (i.e. low ![]() $El$), the bubble flows slowly compared with a Newtonian bubble with the same capillary number

$El$), the bubble flows slowly compared with a Newtonian bubble with the same capillary number ![]() $Ca$. The lower the effective viscosity is, the slower is the bubble compared with

$Ca$. The lower the effective viscosity is, the slower is the bubble compared with ![]() $U_\infty$. The effect of

$U_\infty$. The effect of ![]() $\alpha$ is summarized in figure 10(b,c), where we see that increasing the degree of shear thinning can increase the bubble velocity at

$\alpha$ is summarized in figure 10(b,c), where we see that increasing the degree of shear thinning can increase the bubble velocity at ![]() $El=1$. As expected the scaling law for

$El=1$. As expected the scaling law for ![]() $U/U_\infty$ converges to the one obtained by Bretherton (Reference Bretherton1961) for

$U/U_\infty$ converges to the one obtained by Bretherton (Reference Bretherton1961) for ![]() $El\rightarrow \infty$. The trends of figure 10 are in a qualitative agreement with the simulations of Moreira et al. (Reference Moreira, Rocha, Carneiro, Araújo, Campos and Miranda2020) where the bubble speed decreases with increasing of the degree of shear thinning at a fixed capillary number.

$El\rightarrow \infty$. The trends of figure 10 are in a qualitative agreement with the simulations of Moreira et al. (Reference Moreira, Rocha, Carneiro, Araújo, Campos and Miranda2020) where the bubble speed decreases with increasing of the degree of shear thinning at a fixed capillary number.

Figure 10. (a–c) Ratio of the bubble speed to the average velocity of the fluid ahead of the bubble, ![]() $U/U_\infty$, as a function of the capillary number,

$U/U_\infty$, as a function of the capillary number, ![]() $Ca$, the Ellis number,

$Ca$, the Ellis number, ![]() $El$, and the degree of shear thinning,

$El$, and the degree of shear thinning, ![]() $\alpha$. (d) Value of

$\alpha$. (d) Value of ![]() $U/U_\infty$ as a function of the generalized capillary number,