1. Introduction

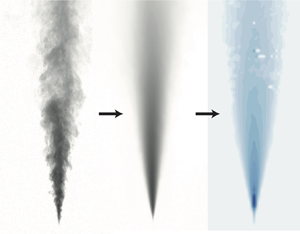

Solvent exchange can be employed to extract specific components from mixtures. The process finds various industrial applications, such as liquid–liquid extraction (Lohse Reference Lohse2016), drug delivery (Lepeltier, Bourgaux & Couvreur Reference Lepeltier, Bourgaux and Couvreur2014), resource recycling (Zimmermann et al. Reference Zimmermann, Niewersch, Lenz, Kül, Corvini, Schäffer and Wintgens2014) and oil recovery (Sun et al. Reference Sun, Zhang, Chen and Gai2017). Such solvent exchange processes consist of a ternary liquid system, where mixing between a good solvent and a poor one takes place, leading to oversaturation of the solute originally dissolved in the good solvent. This in turn triggers nucleation of the solute droplets. Such droplet nucleation is called spontaneous emulsification, or is known by its popular name ‘ouzo effect’. In this process, metastable droplets are formed in the liquid, creating a milky appearance due to Mie scattering, as for the case of watered-down ouzo beverage. In recent decades, numerous efforts have been made to understand such a complex multicomponent and multiphase flow; see the review by Lohse & Zhang (Reference Lohse and Zhang2020). Vitale & Katz (Reference Vitale and Katz2003) and Sitnikova et al. (Reference Sitnikova, Sprik, Wegdam and Eiser2005) were among the earliest studies of the ouzo effect, using divinylbenzene and trans-anethole as the solute, respectively. They both located the position of the metastable region in the ternary phase diagram, and experimentally revealed the diffusive growth process of the droplets and their size distribution.

To quantitatively study the diffusion dynamics of the multicomponent droplets, Su & Needham (Reference Su and Needham2013) extended the classic work of Epstein & Plesset (Reference Epstein and Plesset1950) on the dissolution and growth of a gas bubble in surrounding liquid to the case of a droplet. Chu & Prosperetti (Reference Chu and Prosperetti2016) further analytically investigated the droplet growth and dissolution of multicomponent droplets, broadening the theoretical framework of droplet diffusion dynamics, making it more applicable to real-world applications, such as liquid–liquid extraction. Corresponding molecular dynamics simulation was done by Maheshwari et al. (Reference Maheshwari, Van der Hoef, Prosperetti and Lohse2017). Tan et al. (Reference Tan, Diddens, Mohammed, Li, Versluis, Zhang and Lohse2019) studied the micro-droplet nucleation of the water–ethanol drop in host anise oil. They combined the multicomponent diffusion model, thermodynamic equilibrium and a scaling analysis of Marangoni and buoyancy forces. With this, they could successfully predict the spontaneous emulsification by the convection-enhanced diffusion process.

While the aforementioned cases are homogeneous nucleation in the bulk, the ouzo effect has also been widely investigated on the surface of microfluidic channels, so-called surface droplet formation via heterogeneous nucleation. Hajian & Hardt (Reference Hajian and Hardt2015) studied the droplet nucleation and its radial migration in a micro-channel, measuring the concentration field formed by the solvent exchange and the following diffusive mass transfer. For controlled solvent exchange in microfluidic set-ups, Zhang et al. (Reference Zhang, Lu, Tan, Bao, He, Sun and Lohse2015) found that the volume of the nucleated droplets scales as ![]() $Pe^{3/4}$, with Péclet number

$Pe^{3/4}$, with Péclet number ![]() $Pe = {Q}/{wD}$, where

$Pe = {Q}/{wD}$, where ![]() $Q$ is the volume flow rate,

$Q$ is the volume flow rate, ![]() $w$ the channel width and

$w$ the channel width and ![]() $D$ the diffusion coefficient. Following this finding, the universality of the phenomenon has been demonstrated, including the effect of the solution composition (Lu et al. Reference Lu, Xu, Zeng and Zhang2015; Lu, Peng & Zhang Reference Lu, Peng and Zhang2016), confining of the flow geometry (Lu et al. Reference Lu, Schaarsberg, Zhu, Yeo, Lohse and Zhang2017; Zeng et al. Reference Zeng, Wang, Zhang and Lohse2019) and formation (Li et al. Reference Li, Bao, Yu and Zhang2018) and growth (Dyett et al. Reference Dyett, Kiyama, Rump, Yoshiyuki Tagawa and Zhang2018) of the surface nanodroplets. For related work, Li et al. (Reference Li, Chong, Bazyar, Lammertink and Lohse2021) implemented a Hele-Shaw-like thin cell with a porous section to better collect the nucleated droplets. For this geometry, they formulated a theoretical model based on the ternary diagram and the diffusion equation, and found and explained the scaling of the volume of the nucleated droplets in the oversaturation front to be proportional to

$D$ the diffusion coefficient. Following this finding, the universality of the phenomenon has been demonstrated, including the effect of the solution composition (Lu et al. Reference Lu, Xu, Zeng and Zhang2015; Lu, Peng & Zhang Reference Lu, Peng and Zhang2016), confining of the flow geometry (Lu et al. Reference Lu, Schaarsberg, Zhu, Yeo, Lohse and Zhang2017; Zeng et al. Reference Zeng, Wang, Zhang and Lohse2019) and formation (Li et al. Reference Li, Bao, Yu and Zhang2018) and growth (Dyett et al. Reference Dyett, Kiyama, Rump, Yoshiyuki Tagawa and Zhang2018) of the surface nanodroplets. For related work, Li et al. (Reference Li, Chong, Bazyar, Lammertink and Lohse2021) implemented a Hele-Shaw-like thin cell with a porous section to better collect the nucleated droplets. For this geometry, they formulated a theoretical model based on the ternary diagram and the diffusion equation, and found and explained the scaling of the volume of the nucleated droplets in the oversaturation front to be proportional to ![]() $Pe^{1/2}$.

$Pe^{1/2}$.

While solvent exchange is thus reasonably and in part even quantitatively understood, the scope of quantitative studies has up to now been limited to small scales and the laminar flow regime. For industrial-scale applications such as liquid–liquid extraction, however, processes on larger scales are generally less controlled than those in microfluidic devices due to turbulence. It is therefore highly desirable to unveil the diffusion dynamics of the ternary liquid system in turbulent environments, where intense mixing and nucleation appear. The turbulent jet is one of the most fundamental and well-studied forms of turbulent shear flow (see e.g. Pope Reference Pope2000), which makes it an ideal candidate to bridge the fields of solvent exchange and turbulence.

Built upon the classic single phase studies for turbulent jets and plumes (Morton, Taylor & Turner Reference Morton, Taylor and Turner1956; Fischer et al. Reference Fischer, List, Koh, Imberger and Brooks1979; List Reference List1982; Turner Reference Turner1986; Pope Reference Pope2000), the case of multiphase flow has drawn extensive interest due to its common occurrence in environmental fluid mechanics (Woods Reference Woods2010) and industrial applications such as combustion (Raman & Fox Reference Raman and Fox2016) and aerosol formation (Lesniewski & Friedlander Reference Lesniewski and Friedlander1998; Neuber et al. Reference Neuber, Kronenburg, Stein and Cleary2017). The Deepwater Horizon Oil Spill further triggered a series of investigations into such types of multiphase flow (McNutt et al. Reference McNutt, Camilli, Crone, Guthrie, Hsieh, Ryerson, Savas and Shaffer2012; Reddy et al. Reference Reddy2012; Ryerson et al. Reference Ryerson2012). With turbulent entrainment, bubbles or droplets can grow and dissolve in a jet, inducing significant buoyancy variation in the flow. Chu & Prosperetti (Reference Chu and Prosperetti2019) analytically identified key parameters for the multiphase plume dynamics, including the droplet dissolution rate, the density change rate due to dissolution, the droplet velocity and the plume velocity.

In addition to the dissolution, considerations of chemical reaction have advanced the line of research further to tackle real-world complex problems. There are two major perspectives of research on reactive jets and plumes. On the one hand, the ambient fluid reacts with the dispersed phase in the jet or plume. This category serves as an extension of the works on bubbles or droplets dissolution, focusing on the buoyancy variation accompanying the reactions, see Cardoso & McHugh (Reference Cardoso and McHugh2010) and Domingos & Cardoso (Reference Domingos and Cardoso2013). These authors also discussed the competition between stratification and reaction as the dominant source of buoyancy variation.

On the other hand, the ambient fluid reacts with the carrier phase of the jet, or simply with the single phase injected fluid. Studies on such a type of flow shed new light on the interplay among entrainment, mixing and reactions as the flow develops, enabling the disentanglement of these effects by comparing the corresponding length and time scales. Ülpre, Eames & Greig (Reference Ülpre, Eames and Greig2013) injected a single phase acidic jet into an alkaline environment, reporting a model combining chemistry and the fluid dynamics of turbulent plumes to predict the neutralization distance. Domingos & Cardoso (Reference Domingos and Cardoso2015) studied single phase reacting thermals, distinguishing fast and slow reactions. Their experimental findings show that the reactions only occurred preferentially in part of the thermals for the instantaneous case, while for the slow reactions the thermals were homogeneous in composition. Mingotti & Cardoso (Reference Mingotti and Cardoso2019) experimentally compared the slow and instantaneous reactions in turbulent plumes, discovering preferential reaction for the instantaneous case as well, which appeared on the edge of the eddies. They formulated a theoretical prediction for the concentration evolution in reacting plumes using scale analysis of entrainment, mixing and reactions. Solvent exchange in our case is fundamentally different from a chemical reaction in terms of driving mechanism. The product of solvent exchange, namely the nucleated droplets, is driven by the degree of oversaturation, while the products of chemical reactions result from chemical kinetics. Also, considering chemical reaction and mixing, Guilbert & Villermaux (Reference Guilbert and Villermaux2021) experimentally studied the effect of reaction on the concentration distribution of the product in a randomly stirred mixture, distinguishing between diffusion-controlled and reaction-controlled regimes (Guilbert, Almarcha & Villermaux Reference Guilbert, Almarcha and Villermaux2021), and showing a compressed distribution profile for reactive mixtures (Guilbert & Villermaux Reference Guilbert and Villermaux2021). In spite of such a difference, the cases of instantaneous reactions in the aforementioned studies are highly insightful for our attempt to understand the solvent exchange process in a turbulent buoyant jet, not only because the time scales to generate the product are both extremely small, but also because the turbulent entrainment and mixing might play key roles in both processes.

The present experimental study aims to investigate the solvent exchange process in a multiphase turbulent buoyant jet in the upward direction, bridging the gap between the ouzo effect and turbulent shear flow. We will employ trans-anethole and refer to it as oil throughout the paper as it is the oil phase in the ternary liquids system. We will use a vertical ethanol-oil jet being injected in a quiescent water bath, creating an ’ouzo’ mixture close to the needle. We utilize a novel method to construct the averaged oversaturation (concentration) field for the ouzo solution using titration, a light attenuation technique and minimization using an axisymmetric discretization. We compare the ouzo case with the nucleation-free case of injecting only dyed ethanol, revealing the distinct features of the ouzo case in the radial concentration profile, the centreline evolution and the oversaturation flow rate. Adapting the mixing-limited arguments for the prolonged depletion of the reacting plume of Mingotti & Cardoso (Reference Mingotti and Cardoso2019), the extended lifetime of the droplet-laden respiratory puff of Chong et al. (Reference Chong, Ng, Hori, Yang, Verzicco and Lohse2021) and of the evaporating spray of de Rivas & Villermaux (Reference de Rivas and Villermaux2016) and Villermaux et al. (Reference Villermaux, Moutte, Amielh and Meunier2017), we provide a qualitative explanation for the continuous nucleation downstream and the widespread location of the micro-droplet nucleation across the jet.

The paper is structured as follow: in § 2 we detail the experimental set-up and the methods to measure the velocity field and the concentration field, and to resolve the nucleated droplets. The concentration fields can be reconstructed by combining the information from two cameras, as presented in § 3. The results extracted from the concentration fields are presented in § 4, with supporting discussion and qualitative analysis in § 5. Conclusions and future prospects are presented in § 6.

2. Experimental method

2.1. Set-up

We have conducted several experiments to study the solvent exchange process in a turbulent buoyant jet (ouzo jet). The jet experiments were operated in a glass tank with dimensions ![]() $25\ {\rm cm} \times 25\,{\rm cm} \times 50\,{\rm cm}$ (W

$25\ {\rm cm} \times 25\,{\rm cm} \times 50\,{\rm cm}$ (W ![]() $\times$ L

$\times$ L ![]() $\times$ H) as in figure 1. The tank was filled with decalcified water before each run of experiments. The injected fluid consisted of mixtures of ethanol (Boom, 100 %) and trans-anethole (Sigma Aldrich,

$\times$ H) as in figure 1. The tank was filled with decalcified water before each run of experiments. The injected fluid consisted of mixtures of ethanol (Boom, 100 %) and trans-anethole (Sigma Aldrich, ![]() $\geq$99 %) with varying weight ratios, and the fluid was injected by a Harvard 2000 syringe pump at selected flow rates, forming an upwards turbulent buoyant jet through a round needle with inner diameter 0.51 mm, outer diameter 0.82 mm and length 12.7 mm. Reference cases were also conducted by injection of dyed ethanol, offering comparison between the common passive scalar jet and the ouzo jet. The water and the injected liquid were kept at room temperature (

$\geq$99 %) with varying weight ratios, and the fluid was injected by a Harvard 2000 syringe pump at selected flow rates, forming an upwards turbulent buoyant jet through a round needle with inner diameter 0.51 mm, outer diameter 0.82 mm and length 12.7 mm. Reference cases were also conducted by injection of dyed ethanol, offering comparison between the common passive scalar jet and the ouzo jet. The water and the injected liquid were kept at room temperature (![]() $20\,^\circ {\rm C}\pm 1\,{\rm K}$) for all the experiments to minimize the effect of the temperature dependence of the solubility in the ternary liquids system. The experimental conditions are listed in table 1.

$20\,^\circ {\rm C}\pm 1\,{\rm K}$) for all the experiments to minimize the effect of the temperature dependence of the solubility in the ternary liquids system. The experimental conditions are listed in table 1.

Figure 1. Experimental set-up. The inset shows the photo of the needle for injection with inner diameter (ID), outer diameter (OD) and length (L). Note that the laser was only activated for PIV.

Table 1. Experimental conditions. Each experiment was repeated three times to confirm the repeatability of the data. Experiments 1–4 correspond to the ouzo jets with empty ![]() $C_{{dye}}$ column, and experiments 5–6 correspond to the dyed ethanol jets with empty

$C_{{dye}}$ column, and experiments 5–6 correspond to the dyed ethanol jets with empty ![]() $w_e/w_o$ column:

$w_e/w_o$ column: ![]() $w_e/w_o$ denotes the weight ratio between ethanol and the oil in the injected fluid;

$w_e/w_o$ denotes the weight ratio between ethanol and the oil in the injected fluid; ![]() $Q$ is the volume flow rate regulated by the syringe pump, leading to different characteristic lengths

$Q$ is the volume flow rate regulated by the syringe pump, leading to different characteristic lengths ![]() $L_m$, initial velocities

$L_m$, initial velocities ![]() $u_0$ and initial Reynolds numbers

$u_0$ and initial Reynolds numbers ![]() $Re_0=Qd/({\rm \pi} d^2 \nu /4)$, where

$Re_0=Qd/({\rm \pi} d^2 \nu /4)$, where ![]() $d=0.51$ mm is the inner diameter of the needle. Here,

$d=0.51$ mm is the inner diameter of the needle. Here, ![]() $L_m = M^{3/4}/B^{1/2}$, where

$L_m = M^{3/4}/B^{1/2}$, where ![]() $M=Q^2/({\rm \pi} d^2/4)$ is the initial momentum flux, and

$M=Q^2/({\rm \pi} d^2/4)$ is the initial momentum flux, and ![]() $B=Qg(\rho _{{jet}}-\rho _{{amb}})/\rho _{{amb}}$ is the initial buoyancy flux. The value of

$B=Qg(\rho _{{jet}}-\rho _{{amb}})/\rho _{{amb}}$ is the initial buoyancy flux. The value of ![]() $B=1.635 \times 10^{-7}\,\text {m}^{{4}}\,\text {s}^{{-3}}$ is constant throughout our experiments as the density of the oil is negligible, i.e. we consider the jet density

$B=1.635 \times 10^{-7}\,\text {m}^{{4}}\,\text {s}^{{-3}}$ is constant throughout our experiments as the density of the oil is negligible, i.e. we consider the jet density ![]() $\rho _{{jet}}$ to be solely determined by the ethanol. The viscosity of the oil was also neglected, leading to a constant viscosity

$\rho _{{jet}}$ to be solely determined by the ethanol. The viscosity of the oil was also neglected, leading to a constant viscosity ![]() $\nu = \nu _{{e}} = 1.5 \times 10^{-6}\,\text {m}^{{2}}\,\text {s}^{-1}$, which is used to calculate

$\nu = \nu _{{e}} = 1.5 \times 10^{-6}\,\text {m}^{{2}}\,\text {s}^{-1}$, which is used to calculate ![]() $Re_0$.

$Re_0$.

To measure the local concentration we use a light attenuation technique. For this we use an LED back lighting with diffuser and recorded using two Photron FASTCAM Mini AX200 high speed cameras with ![]() $1024 \times 1024$ pixels resolution at 50 f.p.s., one from afar with a Sigma 50 mm objective to capture the entire jet evolution, and the other with a Zeiss 100 mm objective placed closer to the tank and zoomed in to the region right above the injection needle. The injection and the recording lasted for 40–50 s, providing 2000–2500 frames for each experiment. To obtain the velocity field of the turbulent buoyant jets, we relied on particle image velocimetry (PIV) with laser activation and using different cameras, which will be detailed in § 2.5.

$1024 \times 1024$ pixels resolution at 50 f.p.s., one from afar with a Sigma 50 mm objective to capture the entire jet evolution, and the other with a Zeiss 100 mm objective placed closer to the tank and zoomed in to the region right above the injection needle. The injection and the recording lasted for 40–50 s, providing 2000–2500 frames for each experiment. To obtain the velocity field of the turbulent buoyant jets, we relied on particle image velocimetry (PIV) with laser activation and using different cameras, which will be detailed in § 2.5.

2.2. Titration and oversaturation

To study the nucleation and the solvent exchange process quantitatively, knowledge of oversaturation of the nucleated component is required (Li et al. Reference Li, Bao, Yu and Zhang2018, Reference Li, Chong, Bazyar, Lammertink and Lohse2021). This means that the first step is to obtain the binodal curve, namely the saturation curve by titration. Normally, the titration results of such a ternary system are determined visually by checking the change of appearance. However, this is extremely difficult since we operated in the regime with extremely small amounts of oil. We therefore opted for cameras for accurate determination of the point of saturation. The camera-assisted titration was conducted by stepwise adding water into the oil-ethanol solution, followed by one minute of thorough mixing and then an idle time of around 15 minutes to ensure the temperature stabilized to ![]() $20\,^\circ {\rm C}\pm 1\,{\rm K}$ and the light intensity variation was less than

$20\,^\circ {\rm C}\pm 1\,{\rm K}$ and the light intensity variation was less than ![]() $1\,\%$ . Note that ethanol-water mixing is an exothermic process, which, due to the local heating, affects the solubility and thus the oversaturation and the light intensity. We took 100 frames to obtain the averaged light intensity of the mixture. The water-addition process lasted until the solution turned opaque enough, after which we obtained the intensity-to-concentration graph; see the black points in figure 2(a). Based on the data points we performed a second-order polynomial curve fit to obtain the titration curve, from which we define the

$1\,\%$ . Note that ethanol-water mixing is an exothermic process, which, due to the local heating, affects the solubility and thus the oversaturation and the light intensity. We took 100 frames to obtain the averaged light intensity of the mixture. The water-addition process lasted until the solution turned opaque enough, after which we obtained the intensity-to-concentration graph; see the black points in figure 2(a). Based on the data points we performed a second-order polynomial curve fit to obtain the titration curve, from which we define the ![]() $1\,\%$ drop of the light intensity as the point of saturation, as marked by the red star in figure 2(a). We repeated such a titration procedure for 25 different initial compositions of the ethanol-oil mixture, with weight ratios

$1\,\%$ drop of the light intensity as the point of saturation, as marked by the red star in figure 2(a). We repeated such a titration procedure for 25 different initial compositions of the ethanol-oil mixture, with weight ratios ![]() $w_e:w_o$ ranging from

$w_e:w_o$ ranging from ![]() $10:1$ to

$10:1$ to ![]() $300:1$, forming the binodal curve as shown in figure 2(b).

$300:1$, forming the binodal curve as shown in figure 2(b).

Figure 2. (a) Camera-assisted titration to determine the saturation point for a specific ![]() $w_e/w_o$. The black data points are obtained by averaging the light intensity of the entire domain, and the error bar denotes the standard deviation of the light intensity within the domain. The star marks the water concentration (

$w_e/w_o$. The black data points are obtained by averaging the light intensity of the entire domain, and the error bar denotes the standard deviation of the light intensity within the domain. The star marks the water concentration (![]() $C_{{water}}$) causing 1 % drop of the light intensity. (b) A simplified ternary diagram to illustrate the titration process and the constructed binodal curve. (c) Shows the binodal curve and the theoretical diffusion path for the case

$C_{{water}}$) causing 1 % drop of the light intensity. (b) A simplified ternary diagram to illustrate the titration process and the constructed binodal curve. (c) Shows the binodal curve and the theoretical diffusion path for the case ![]() $w_e/w_o=33$. (d) The relation between the water concentration and oil oversaturation can then be built from (c) for the following calibration in § 2.3.

$w_e/w_o=33$. (d) The relation between the water concentration and oil oversaturation can then be built from (c) for the following calibration in § 2.3.

Together with the diffusion path, the acquired binodal curve as in figure 2(b) was then used to quantify the amount of oversaturation, see figure 2(c). Ruschak & Miller (Reference Ruschak and Miller1972) first formulated the diffusion path theory, which was later applied to the study of nanodroplet formation on surfaces (Lu et al. Reference Lu, Schaarsberg, Zhu, Yeo, Lohse and Zhang2017; Li et al. Reference Li, Chong, Bazyar, Lammertink and Lohse2021). The diffusion path can be understood as the trajectory of the local fraction of all three phases during the mixing process. As rigorously evaluated in Li et al. (Reference Li, Chong, Bazyar, Lammertink and Lohse2021), we assume the diffusion coefficients of water and oil to be the same, meaning that the diffusion path becomes a straight line in the ternary diagram; shown by the dashed arrows in figure 2(b). For ease of interpretation, figure 2(c) can be obtained by coordinate transformation from the water-rich side of figure 2(b) to a Cartesian coordinate system, mapping the binodal curve and the diffusion path. With the straight-line assumption, the diffusion path depends solely on the initial ethanol-oil ratio. While there is only one binodal curve for all the different compositions, the diffusion path varies with the composition ![]() $w_e/w_o$. For a specific water fraction, its saturation concentration is first identified on the binodal curve in figure 2(c). Then, we connect the saturation point on the binodal curve to the endpoint of the pure oil phase (Li et al. Reference Li, Chong, Bazyar, Lammertink and Lohse2021), at coordinate

$w_e/w_o$. For a specific water fraction, its saturation concentration is first identified on the binodal curve in figure 2(c). Then, we connect the saturation point on the binodal curve to the endpoint of the pure oil phase (Li et al. Reference Li, Chong, Bazyar, Lammertink and Lohse2021), at coordinate ![]() $(0,1)$, shown as the light green dashed line in figure 2(c). The connection between the saturation point and the pure oil phase stems from the consideration that the ethanol-to-water ratio in the mixture remains unchanged in a fluid parcel during oil nucleation (Lu et al. Reference Lu, Peng and Zhang2016). From the light green dashed line we can extract the length of the segment between the diffusion path and the binodal curve as the oversaturation, displayed as the green solid segment in figure 2(c).

$(0,1)$, shown as the light green dashed line in figure 2(c). The connection between the saturation point and the pure oil phase stems from the consideration that the ethanol-to-water ratio in the mixture remains unchanged in a fluid parcel during oil nucleation (Lu et al. Reference Lu, Peng and Zhang2016). From the light green dashed line we can extract the length of the segment between the diffusion path and the binodal curve as the oversaturation, displayed as the green solid segment in figure 2(c).

The oil oversaturation is related to the water concentration as in figure 2(d). Figure 2(d) not only displays the significant dependence of the oversaturation on the initial composition, ![]() $w_e/w_o$, but also reveals the existence of an upper bound for the oversaturation. The existence of the upper bound might seem counter-intuitive in the first place, as one might expect a monotonic increase with more water introduction. This is, however, not the case in such a ternary liquid system. Further mixing with water beyond the critical fraction makes the nucleated oil re-dissolve into the solution, lowering the oversaturation. While figure 2(c) already reveals that the segment length seems to decrease at larger water fraction, figure 2(d) clearly displays this fact, which is also later confirmed by the recorded intensity in the concentration calibration, as shown in figure 3. The water concentration

$w_e/w_o$, but also reveals the existence of an upper bound for the oversaturation. The existence of the upper bound might seem counter-intuitive in the first place, as one might expect a monotonic increase with more water introduction. This is, however, not the case in such a ternary liquid system. Further mixing with water beyond the critical fraction makes the nucleated oil re-dissolve into the solution, lowering the oversaturation. While figure 2(c) already reveals that the segment length seems to decrease at larger water fraction, figure 2(d) clearly displays this fact, which is also later confirmed by the recorded intensity in the concentration calibration, as shown in figure 3. The water concentration ![]() $C_{{water}}$ is the selected value used in the concentration calibration, which will be described below.

$C_{{water}}$ is the selected value used in the concentration calibration, which will be described below.

Figure 3. (a) Calibration cell. The red frame (![]() $x= 0\,{\rm cm}$,

$x= 0\,{\rm cm}$, ![]() $z= 10\,{\rm cm}$) denotes the selected

$z= 10\,{\rm cm}$) denotes the selected ![]() $5 \times 5$ pixel working unit whose calibration curves are shown in (b–e). (b) Calibration curve for the reference dye case. Here,

$5 \times 5$ pixel working unit whose calibration curves are shown in (b–e). (b) Calibration curve for the reference dye case. Here, ![]() $\varPhi$ denotes the degree of light attenuation per unit depth,

$\varPhi$ denotes the degree of light attenuation per unit depth, ![]() $\log ({I_{{ref}}}/{I})/d$, where

$\log ({I_{{ref}}}/{I})/d$, where ![]() $d$ is the cell thickness. (c,d) The calibration curve for the two ouzo cases. The abscissa

$d$ is the cell thickness. (c,d) The calibration curve for the two ouzo cases. The abscissa ![]() $C_{{oil,sat}}$ is the oversaturation of the oil. For (b–d) the black error bar represents the standard error of the mean

$C_{{oil,sat}}$ is the oversaturation of the oil. For (b–d) the black error bar represents the standard error of the mean ![]() $\varPhi$, which is small throughout the calibration. (e) The rescaled calibration curves as in (c,d).

$\varPhi$, which is small throughout the calibration. (e) The rescaled calibration curves as in (c,d).

2.3. Light attenuation technique and calibration

To characterize the concentration of the nucleated oil in the flow, we implemented a light attenuation technique. Unlike passive scalar studies, the droplet nucleation makes the flow almost opaque, rendering the commonly used laser induced fluorescence (LIF) not feasible. We therefore use a light attenuation technique to measure the local concentration. This technique has been widely adapted in turbulent jet and plume studies based on the pioneering work of Cenedese & Dalziel (Reference Cenedese and Dalziel1998), from single phase cases with dye as in Kikkert, Davidson & Nokes (Reference Kikkert, Davidson and Nokes2007), Allgayer & Hunt (Reference Allgayer and Hunt2012), Van Sommeren, Caulfield & Woods (Reference Van Sommeren, Caulfield and Woods2012) and Mingotti & Cardoso (Reference Mingotti and Cardoso2019), to multiphase ones as in Leppinen & Dalziel (Reference Leppinen and Dalziel2001) and Mingotti & Woods (Reference Mingotti and Woods2015). The method is based on the Lambert–Beer law, relating the recorded depth-integrated intensity to the concentration field, namely

where ![]() $I$ is the recorded intensity of the averaged images,

$I$ is the recorded intensity of the averaged images, ![]() $I_{{ref}}$ the reference intensity of the background,

$I_{{ref}}$ the reference intensity of the background, ![]() $\gamma$ the light absorption property of the dye determined from calibration,

$\gamma$ the light absorption property of the dye determined from calibration, ![]() $d$ the depth of the substance in the line of sight and

$d$ the depth of the substance in the line of sight and ![]() $C$ the desired line-of-sight average concentration. The line-of-sight averaged concentration used in the aforementioned papers, however, is not a solution for the nonlinear response we see here. In a pioneering work, Sutherland, Lee & Ansong (Reference Sutherland, Lee and Ansong2012) analysed the averaged image based on the axisymmetric discretization, converting the depth-integrated recorded image to the concentration field as a function of radius and height, which serves as a very good strategy for our interests to obtain the oversaturation field as a function of radius and height in the domain.

$C$ the desired line-of-sight average concentration. The line-of-sight averaged concentration used in the aforementioned papers, however, is not a solution for the nonlinear response we see here. In a pioneering work, Sutherland, Lee & Ansong (Reference Sutherland, Lee and Ansong2012) analysed the averaged image based on the axisymmetric discretization, converting the depth-integrated recorded image to the concentration field as a function of radius and height, which serves as a very good strategy for our interests to obtain the oversaturation field as a function of radius and height in the domain.

We performed our calibration in a 10 mm thick cell, as shown in figure 3(a). The calibration cell is immersed in the tank, which is filled with water, and the illumination and the camera magnification are exactly the same as in the jet experiments, ensuring an in situ calibration. In spite of efforts to regulate the fluid temperature during the calibration and before the real experiments, the exothermic nature of the mixing between water and ethanol in the jet will raise the local temperature. Although the local temperature variation might alter the oversaturation, leading to less accurate calibration, such a deviation is simply beyond control or even monitoring during the experiments. With more than 35 l of water in the ambient and less than 60 ml injected fluid, it is safe to assume that the large volume of water at ![]() $20\,^\circ {\rm C}\pm 1\,{\rm K}$ is sufficient to mitigate the temperature increase quickly, and wait for future numerical efforts to validate our assumption. As the reference case, the calibration curve for the dyed ethanol is shown in figure 3(b), which was used to calculate the concentration field for the dyed ethanol jet. Red food dye (JO-LA) was added step-by-step followed by taking 200 frames to obtain the averaged light intensity for every

$20\,^\circ {\rm C}\pm 1\,{\rm K}$ is sufficient to mitigate the temperature increase quickly, and wait for future numerical efforts to validate our assumption. As the reference case, the calibration curve for the dyed ethanol is shown in figure 3(b), which was used to calculate the concentration field for the dyed ethanol jet. Red food dye (JO-LA) was added step-by-step followed by taking 200 frames to obtain the averaged light intensity for every ![]() $5 \times 5$ pixel working window. Although the linear relation indeed holds within a certain range of dye concentration, we fit a second-order polynomial to increase its applicability. The nonlinear calibration curve does not appear for the first time. Van Sommeren et al. (Reference Van Sommeren, Caulfield and Woods2012) also observed a nonlinear response in their experiment, which they fitted with polynomials, confirming that in situ calibration also functions well with nonlinear optical response.

$5 \times 5$ pixel working window. Although the linear relation indeed holds within a certain range of dye concentration, we fit a second-order polynomial to increase its applicability. The nonlinear calibration curve does not appear for the first time. Van Sommeren et al. (Reference Van Sommeren, Caulfield and Woods2012) also observed a nonlinear response in their experiment, which they fitted with polynomials, confirming that in situ calibration also functions well with nonlinear optical response.

On the other hand, for the ouzo cases, the cell was first filled with a mixture of ethanol and oil at the specific ![]() $w_e/w_o$ ratio, and water was then added gradually. Averaging the intensity over 200 frames for every 5

$w_e/w_o$ ratio, and water was then added gradually. Averaging the intensity over 200 frames for every 5 ![]() $\times$ 5 pixel working window, the calibration curves as in figure 3(c) and figure 3(d) were built for every working window locally in the entire domain, which, however, reveals a completely different calibration curve from the dye case. The

$\times$ 5 pixel working window, the calibration curves as in figure 3(c) and figure 3(d) were built for every working window locally in the entire domain, which, however, reveals a completely different calibration curve from the dye case. The ![]() $x$-axes in these two figures, namely the oil oversaturation, were derived from figure 2(d). The upper bounds for the ouzo calibration curve in figure 3(c) and figure 3(d) are imposed by the theoretical maximum oversaturation shown in figure 2(d), namely 0.0023 for

$x$-axes in these two figures, namely the oil oversaturation, were derived from figure 2(d). The upper bounds for the ouzo calibration curve in figure 3(c) and figure 3(d) are imposed by the theoretical maximum oversaturation shown in figure 2(d), namely 0.0023 for ![]() $w_e/w_o=100$, and 0.0087 for

$w_e/w_o=100$, and 0.0087 for ![]() $w_e/w_o=33$. Such theoretical upper bounds are only valid if the diffusion path does not deviate too much from the straight-line assumption as in figure 2(c). In the calibration, we did observe that the light attenuation level and the oversaturation decreased as more water was added; see the cluster of data points close to the peak in figure 3(c,d).

$w_e/w_o=33$. Such theoretical upper bounds are only valid if the diffusion path does not deviate too much from the straight-line assumption as in figure 2(c). In the calibration, we did observe that the light attenuation level and the oversaturation decreased as more water was added; see the cluster of data points close to the peak in figure 3(c,d).

For the case of ouzo, the combination of a logistic function and a linear function fits our calibration data well, written as

\begin{equation} \varPhi(C) = \frac{\log \left( \dfrac{I_{{ref}}}{I} \right)}{d}= \frac{a_0}{1+a_1e^{a_2(C-a_3)}}+\frac{a_4(C-a_5)}{1+a_1e^{a_2(C-a_3)}}, \end{equation}

\begin{equation} \varPhi(C) = \frac{\log \left( \dfrac{I_{{ref}}}{I} \right)}{d}= \frac{a_0}{1+a_1e^{a_2(C-a_3)}}+\frac{a_4(C-a_5)}{1+a_1e^{a_2(C-a_3)}}, \end{equation}

where ![]() $a_0$,

$a_0$, ![]() $a_1$,

$a_1$, ![]() $a_2$,

$a_2$, ![]() $a_3$,

$a_3$, ![]() $a_4$ and

$a_4$ and ![]() $a_5$ are the fitting parameters, and

$a_5$ are the fitting parameters, and ![]() $C$ is the oil oversaturation, equivalent to the

$C$ is the oil oversaturation, equivalent to the ![]() $C_{oil,sat}$ in figure 3(c). Note that other fits are possible, but for our purpose we simply need a good approximation of the experimental curve

$C_{oil,sat}$ in figure 3(c). Note that other fits are possible, but for our purpose we simply need a good approximation of the experimental curve ![]() $\varPhi (C)$. To compare the calibration curve for the two

$\varPhi (C)$. To compare the calibration curve for the two ![]() $w_e/w_o$ ratios, the oversaturation and the attenuation were both rescaled, showing a reasonable collapse, see figure 3(e). The abscissa

$w_e/w_o$ ratios, the oversaturation and the attenuation were both rescaled, showing a reasonable collapse, see figure 3(e). The abscissa ![]() $\tilde {C}_{{oil,sat}}$ in figure 3(e) is the rescaled oversaturation, which is obtained from

$\tilde {C}_{{oil,sat}}$ in figure 3(e) is the rescaled oversaturation, which is obtained from ![]() $\tilde {C}_{{oil,sat}} = (C_{{oil,sat}}-C_{{thresh}})/(C_{{max}}-C_{{thresh}})$, where

$\tilde {C}_{{oil,sat}} = (C_{{oil,sat}}-C_{{thresh}})/(C_{{max}}-C_{{thresh}})$, where ![]() $C_{{thresh}}$ is the oversaturation where the attenuation reaches 0.1 % of the highest attenuation, as indicated by the black star in (c,d), and

$C_{{thresh}}$ is the oversaturation where the attenuation reaches 0.1 % of the highest attenuation, as indicated by the black star in (c,d), and ![]() $C_{{max}}$ is the theoretical upper bound discussed earlier. The rescaled oversaturation also eliminates the flat section of the logistic function for low oversaturation, creating a one-to-one injective map for the calibration. Note that the reason behind such nonlinear optical response is beyond the scope of this research and remains unclear. Figure 4(a) shows a snapshot of the turbulent jet with oil droplet nucleation, while figure 4(b) shows the averaged image over 2000–2500 frames of the instantaneous image as shown in figure 4(a). The intensity field of a certain height is only included in the averaging operation after the jet has reached that height. The averaged image contains the upstream section only with

$C_{{max}}$ is the theoretical upper bound discussed earlier. The rescaled oversaturation also eliminates the flat section of the logistic function for low oversaturation, creating a one-to-one injective map for the calibration. Note that the reason behind such nonlinear optical response is beyond the scope of this research and remains unclear. Figure 4(a) shows a snapshot of the turbulent jet with oil droplet nucleation, while figure 4(b) shows the averaged image over 2000–2500 frames of the instantaneous image as shown in figure 4(a). The intensity field of a certain height is only included in the averaging operation after the jet has reached that height. The averaged image contains the upstream section only with ![]() $z\leq 30\,{\rm cm}$ since the low density dark layer accumulated on top of the tank grew and interfered with the ascending jet, causing the intensity field above

$z\leq 30\,{\rm cm}$ since the low density dark layer accumulated on top of the tank grew and interfered with the ascending jet, causing the intensity field above ![]() $z= 30\,{\rm cm}$ to be averaged relatively poorly (less than 20 s). Figure 4(c) shows a horizontal cross-section of the jet, illustrating the discretization scheme similar to Sutherland et al. (Reference Sutherland, Lee and Ansong2012), where

$z= 30\,{\rm cm}$ to be averaged relatively poorly (less than 20 s). Figure 4(c) shows a horizontal cross-section of the jet, illustrating the discretization scheme similar to Sutherland et al. (Reference Sutherland, Lee and Ansong2012), where ![]() $dy_{mn}$ can be directly obtained as a function of

$dy_{mn}$ can be directly obtained as a function of ![]() $dr$ solely based on geometric relations, where

$dr$ solely based on geometric relations, where ![]() $m$ denotes

$m$ denotes ![]() $x$ position on the recorded images, and

$x$ position on the recorded images, and ![]() $n$ the axisymmetric elements in the

$n$ the axisymmetric elements in the ![]() $r$ direction. Note that

$r$ direction. Note that ![]() $m\leq n$ always holds, and we calculate the left half (

$m\leq n$ always holds, and we calculate the left half (![]() $x<0$) and right half (

$x<0$) and right half (![]() $x>0$) of the jet separately, that is,

$x>0$) of the jet separately, that is, ![]() $C_n\neq C^{*}_n$. While the concentrations

$C_n\neq C^{*}_n$. While the concentrations ![]() $C_n$ remain as unknowns, the recorded intensity

$C_n$ remain as unknowns, the recorded intensity ![]() $I_m$ at a specific location from figure 4(b) can then be expressed as the integration of the converted intensity calculated from the calibration curve over every discretization element on the light path. For the reference dye case with the second-order polynomial calibration curve, the concentration can be obtained by minimization of

$I_m$ at a specific location from figure 4(b) can then be expressed as the integration of the converted intensity calculated from the calibration curve over every discretization element on the light path. For the reference dye case with the second-order polynomial calibration curve, the concentration can be obtained by minimization of ![]() $m$ equations with

$m$ equations with ![]() $n$ variables, written as

$n$ variables, written as

\begin{equation} \log{\left(\frac{I_{ref}}{I_m}\right)} = \sum_{n=0}^{N-1} dy_{mn} \left(a_0 + a_1C_n + a_2C_n^2\right), \end{equation}

\begin{equation} \log{\left(\frac{I_{ref}}{I_m}\right)} = \sum_{n=0}^{N-1} dy_{mn} \left(a_0 + a_1C_n + a_2C_n^2\right), \end{equation}while for the ouzo cases with calibration curve as (2.2), the equations for minimization are written as

\begin{equation} \log{\left(\frac{I_{ref}}{I_m}\right)} = \sum_{n=0}^{N-1} dy_{mn} \left( \frac{a_0}{1+a_1e^{a_2(C_n-a_3)}}+\frac{a_4(C_n-a_5)}{1+a_1e^{a_2(C_n-a_3)}}\right). \end{equation}

\begin{equation} \log{\left(\frac{I_{ref}}{I_m}\right)} = \sum_{n=0}^{N-1} dy_{mn} \left( \frac{a_0}{1+a_1e^{a_2(C_n-a_3)}}+\frac{a_4(C_n-a_5)}{1+a_1e^{a_2(C_n-a_3)}}\right). \end{equation}The calculation procedure is repeated for every height, leading to the oversaturation fields, as in figure 7. We detail the procedures of the optimization process and the evaluation of the results in Appendix A.

Figure 4. (a) The instantaneous image obtained by dividing the recorded frame by the background frame. (b) The mean image derived by averaging the frames as in (a) over 30 s; ![]() $Re_0=1387$ in the image. (c) A horizontal cross-section of the axisymmetric discretization, similar to that in Sutherland et al. (Reference Sutherland, Lee and Ansong2012). Here, we do not impose symmetry for the left half (

$Re_0=1387$ in the image. (c) A horizontal cross-section of the axisymmetric discretization, similar to that in Sutherland et al. (Reference Sutherland, Lee and Ansong2012). Here, we do not impose symmetry for the left half (![]() $x<0$) and the right half (

$x<0$) and the right half (![]() $x>0$) of the jet. The averaged image in (b) can be converted to a concentration field by the calibration curve in figure 3 for every

$x>0$) of the jet. The averaged image in (b) can be converted to a concentration field by the calibration curve in figure 3 for every ![]() $5 \times 5$ pixels, together with the optimization algorithm constructed based on the scheme in (c).

$5 \times 5$ pixels, together with the optimization algorithm constructed based on the scheme in (c).

We add a note of care: the superposition of attenuation level across the layers of axisymmetric unit illustrated in figure 4(c) might be questionable for a scattering medium. The summation in (2.4) is fully applicable if the level of attenuation is proportional to the depth of the medium; however, such an algorithm does not hold when the light propagates through a scattering medium. Despite the fact that our scattering is relatively low, the proposed method and the obtained results in this paper should be further evaluated in the future. We will discuss this issue in more detail in Appendix C.

2.4. Droplet size detection

Nucleated droplets through solvent exchange are generally referred to as micro- or even nano-sized droplets. However, experimentally measured sizes are based on cases with no flow (Tan et al. Reference Tan, Diddens, Mohammed, Li, Versluis, Zhang and Lohse2019) or laminar flow (Hajian & Hardt Reference Hajian and Hardt2015; Lu et al. Reference Lu, Xu, Zeng and Zhang2015). To measure the sizes of the nucleated droplets in the case of a turbulent jet, we utilize a Navitar 12 ![]() $\times$ objective on a Photron FASTCAM Mini AX200 camera, achieving a resolution of

$\times$ objective on a Photron FASTCAM Mini AX200 camera, achieving a resolution of ![]() $3\,\mathrm {\mu }{\rm m}\,{\rm pixel}^{-1}$, see figure 5. Figure 5(a) clearly shows the nucleated droplets in the plume after the injection stopped, which are similar to the laminar flow scenario in the aforementioned literature. Comparing figures 5(b) and 5(c), we see that the droplets were indeed micro-sized (

$3\,\mathrm {\mu }{\rm m}\,{\rm pixel}^{-1}$, see figure 5. Figure 5(a) clearly shows the nucleated droplets in the plume after the injection stopped, which are similar to the laminar flow scenario in the aforementioned literature. Comparing figures 5(b) and 5(c), we see that the droplets were indeed micro-sized (![]() ${\textit{O}}(10\,\mathrm {\mu }{\rm m})$) for both turbulent cases. The droplets for

${\textit{O}}(10\,\mathrm {\mu }{\rm m})$) for both turbulent cases. The droplets for ![]() $w_e/w_o=33$ are larger and thus easier to identify, which is in line with the findings of Vitale & Katz (Reference Vitale and Katz2003).

$w_e/w_o=33$ are larger and thus easier to identify, which is in line with the findings of Vitale & Katz (Reference Vitale and Katz2003).

Figure 5. Identification of nucleated droplets. For comparison, we show a droplet of 25 ![]() $\mathrm {\mu }$m diameter in all three cases. (a) The nucleated droplets for

$\mathrm {\mu }$m diameter in all three cases. (a) The nucleated droplets for ![]() $w_e/w_o=100$ when the injection just stopped (i.e.

$w_e/w_o=100$ when the injection just stopped (i.e. ![]() $u_z$ approached

$u_z$ approached ![]() $0$). (a) Serves as a reference laminar case where the droplet nucleation can be easily identified. (b) The nucleated drops of a jet with

$0$). (a) Serves as a reference laminar case where the droplet nucleation can be easily identified. (b) The nucleated drops of a jet with ![]() $w_e/w_o=100$ in the turbulent regime for

$w_e/w_o=100$ in the turbulent regime for ![]() $Re_0 = 555$. The black thin sheets are the fluid interfaces due to refraction, while the black dots in the inset are the nucleated droplets with 17

$Re_0 = 555$. The black thin sheets are the fluid interfaces due to refraction, while the black dots in the inset are the nucleated droplets with 17![]() $\times$ magnification, which are obviously smaller than

$\times$ magnification, which are obviously smaller than ![]() $25\,\mathrm {\mu }{\rm m}$. (c) The nucleated droplets for

$25\,\mathrm {\mu }{\rm m}$. (c) The nucleated droplets for ![]() $Re_0 = 555$ and

$Re_0 = 555$ and ![]() $w_e/w_o=33$, which are larger and easier to identify.

$w_e/w_o=33$, which are larger and easier to identify.

2.5. PIV

While the light attenuation technique resolved the mean oversaturation field, we relied on PIV to measure the velocity field. Ethanol seeded with 20–50 ![]() $\mathrm {\mu }{\rm m}$ fluorescent particles was injected into the water-filled tank, which was also seeded with the same particles in order to prevent measuring a velocity that is solely based on entrained or injected liquid. Note that we used the obtained velocity field of the ethanol jet to represent that of the ouzo jet, assuming that the micro-sized nucleated oil droplets can be considered as tracer particles which barely affect the velocity field. The Photron cameras were replaced with LaVision Imager sCMOS cameras with resolution

$\mathrm {\mu }{\rm m}$ fluorescent particles was injected into the water-filled tank, which was also seeded with the same particles in order to prevent measuring a velocity that is solely based on entrained or injected liquid. Note that we used the obtained velocity field of the ethanol jet to represent that of the ouzo jet, assuming that the micro-sized nucleated oil droplets can be considered as tracer particles which barely affect the velocity field. The Photron cameras were replaced with LaVision Imager sCMOS cameras with resolution ![]() $2560 \times 2160$ pixels, capturing the image pairs on the 1 mm thick laser sheet created by a dual cavity laser (Quantel Evergreen 145 laser, 532 nm). The velocity fields are calculated using the multi-pass method with a starting window size

$2560 \times 2160$ pixels, capturing the image pairs on the 1 mm thick laser sheet created by a dual cavity laser (Quantel Evergreen 145 laser, 532 nm). The velocity fields are calculated using the multi-pass method with a starting window size ![]() $64 \times 64$ pixels to a final size

$64 \times 64$ pixels to a final size ![]() $16 \times 16$ pixels with 25 % overlap.

$16 \times 16$ pixels with 25 % overlap.

Considering that the velocity decreases drastically as the jet travels downstream, the experiments were performed with two different time intervals ![]() ${\rm d}t$ between image pairs to resolve both the far field and the near field, followed by averaging over 1000 frames to obtain the mean velocity fields. Note that the region below

${\rm d}t$ between image pairs to resolve both the far field and the near field, followed by averaging over 1000 frames to obtain the mean velocity fields. Note that the region below ![]() $z= 3\,{\rm cm}$ cannot be resolved because the jet is thinner than the 1 mm laser thickness.

$z= 3\,{\rm cm}$ cannot be resolved because the jet is thinner than the 1 mm laser thickness.

Obtained from the velocity field, figure 6(a,c) shows the mean centreline evolution of velocity in the ![]() $z$-direction,

$z$-direction, ![]() $u_m$. Theoretical models prediction for a pure jet and a pure plume are also presented

$u_m$. Theoretical models prediction for a pure jet and a pure plume are also presented

\begin{equation} \left. \begin{gathered} u_{{m,jet}}= 4.2M^{1/2}z^{{-}1}, \\ u_{{m,plume}}= 3.2B^{1/3}z^{{-}1/3}, \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} u_{{m,jet}}= 4.2M^{1/2}z^{{-}1}, \\ u_{{m,plume}}= 3.2B^{1/3}z^{{-}1/3}, \end{gathered} \right\} \end{equation}

where ![]() $M=Q^2/({\rm \pi} d^2/4)$ is the initial momentum flux, and

$M=Q^2/({\rm \pi} d^2/4)$ is the initial momentum flux, and ![]() $B=Qg(\rho _{{jet}}-\rho _{{amb}})/\rho _{{amb}}$ is the initial buoyancy flux, see the caption in table 1.

$B=Qg(\rho _{{jet}}-\rho _{{amb}})/\rho _{{amb}}$ is the initial buoyancy flux, see the caption in table 1.

Figure 6. The mean velocity field obtained by PIV measurements at (a,b) ![]() $Re_0=555$, and (c,d)

$Re_0=555$, and (c,d) ![]() $Re_0=1387$. (a,c) The centreline velocity in the

$Re_0=1387$. (a,c) The centreline velocity in the ![]() $z$-direction,

$z$-direction, ![]() $u_m$, from the theoretical model and the valid measurements of both near and far fields. (b,d) The measured and fitted radial profile of the streamwise velocity

$u_m$, from the theoretical model and the valid measurements of both near and far fields. (b,d) The measured and fitted radial profile of the streamwise velocity ![]() $u_z$. Kur in the legend stands for kurtosis.

$u_z$. Kur in the legend stands for kurtosis.

The coefficients obtained from our measurements are lower than the values in the fully turbulent jet and plumes, which are 5–7.5 for the jet and 3.4–3.9 for the plume (Fischer et al. Reference Fischer, List, Koh, Imberger and Brooks1979; List Reference List1982). We attribute such difference to the relatively low Reynolds number in this study, where the jet regime lies right after the laminar-to-turbulent transition.

Such comparison with the models reveals that the initial ethanol jet quickly transitioned toward a plume under a strong buoyancy effect. Figure 6(b,d) shows the radial flow profiles of the streamwise velocity ![]() $u_z$, which are later used to calculate the oversaturation flow rate as in figure 13.

$u_z$, which are later used to calculate the oversaturation flow rate as in figure 13.

3. Oversaturation field

Following the procedure detailed in § 2.3, the optimization problem was solved to construct the oversaturation field, figure 7. As shown in figure 3(a–d), the calculated ![]() $\tilde {C}_{{oil,oversat}}$ in most of the domain falls below 1. Such results suggest that the aforementioned procedures in § 2 work appropriately, including titration, the straight diffusion path assumption, calibration, and the optimization. As for the region very close to the needle in the near field, the local oversaturation exceeds the theoretical upper bound, leading to

$\tilde {C}_{{oil,oversat}}$ in most of the domain falls below 1. Such results suggest that the aforementioned procedures in § 2 work appropriately, including titration, the straight diffusion path assumption, calibration, and the optimization. As for the region very close to the needle in the near field, the local oversaturation exceeds the theoretical upper bound, leading to ![]() $\tilde {C}_{{oil,oversat}}>1$. While the actual cause of such results remains uncertain, we believe that the most probable cause is the violation of the straight diffusion path assumption in that region. Such a violation might have resulted from the intense mixing and cross-component diffusion upon the onset of turbulence in the initial shear layer.

$\tilde {C}_{{oil,oversat}}>1$. While the actual cause of such results remains uncertain, we believe that the most probable cause is the violation of the straight diffusion path assumption in that region. Such a violation might have resulted from the intense mixing and cross-component diffusion upon the onset of turbulence in the initial shear layer.

Figure 7. Calculated rescaled oversaturation fields for different ![]() $Re_0$ and

$Re_0$ and ![]() $w_e/w_o$. Panels (a–d) show the results derived from the far view camera, while (e–h) exhibit the results obtained from the zoomed-in camera, which correspond to the black squares in (a–d), respectively, with the same colour scheme below

$w_e/w_o$. Panels (a–d) show the results derived from the far view camera, while (e–h) exhibit the results obtained from the zoomed-in camera, which correspond to the black squares in (a–d), respectively, with the same colour scheme below ![]() $\tilde {C}_{{oil,oversat}}=1$. The white spots in the contour map are caused by the local minima found during optimization, which have little effect on the analysis in § 4 as we exclude those defects for curve fitting. Note that the abscissa is converted from

$\tilde {C}_{{oil,oversat}}=1$. The white spots in the contour map are caused by the local minima found during optimization, which have little effect on the analysis in § 4 as we exclude those defects for curve fitting. Note that the abscissa is converted from ![]() $x$ to

$x$ to ![]() $r$ using the axisymmetric transformation in figure 4(c).

$r$ using the axisymmetric transformation in figure 4(c).

As the far view results at the initial shear layer might be biased by the resolution constraint, the results obtained from zoomed-in recordings are presented in figure 3(e–h), corresponding to the regions marked by the black frame in figure 3(a–d). Although the oversaturation might not be quantitatively correct in this region, the zoomed-in view results further confirm the intense nucleation in the initial shear layer. In their study of aerosol formation in turbulent gas jets, Lesniewski & Friedlander (Reference Lesniewski and Friedlander1998) also pointed out that the nucleation of the target substance is largely confined to the initial shear layer, especially when the vapour mole fraction of the target substance is low. While the system of the current work is different from that of the aerosol study, the two processes both couple the variation of thermodynamic states and ambient turbulent shear flow, leading to the nucleation of droplets or particles.

Considering the opaque nature of the ouzo jet flow, the calculated results cannot be verified by other concentration detection methods such as LIF. Bearing this limitation in mind, what we can do is to check the consistency of the results by repeatability tests and comparing between the far view and the zoomed-in view results obtained from two different cameras. While the repeatability will be demonstrated in § 4, figure 16 in Appendix B shows a quantitative comparison between the two recordings using the centreline evolution and the radial profile. As detailed in Appendix B, for the region with ![]() $\tilde {C}_{{oil,oversat}}\leq 1$, the proposed method delivers consistent results between the far view and zoomed-in view recordings.

$\tilde {C}_{{oil,oversat}}\leq 1$, the proposed method delivers consistent results between the far view and zoomed-in view recordings.

Note that the turbulence started to develop after a certain laminar length (Hassanzadeh, Eslami & Taghavi Reference Hassanzadeh, Eslami and Taghavi2021), which is subtracted to obtain the virtual origin in the ![]() $z$-direction for the analysis in § 4. The concentration fields for the dyed ethanol injection were also obtained by the same method, which are not shown here but will be exploited as reference cases in the analysis in § 4.

$z$-direction for the analysis in § 4. The concentration fields for the dyed ethanol injection were also obtained by the same method, which are not shown here but will be exploited as reference cases in the analysis in § 4.

4. Results

4.1. Generalized normal distribution

To better capture the radial profile of the oversaturation field in figure 7, we fitted the results by a generalization of a normal distribution,

where ![]() $C_m$ is the centreline oversaturation, where

$C_m$ is the centreline oversaturation, where ![]() $\sigma$ is the width of the jet,

$\sigma$ is the width of the jet, ![]() $\kappa$ the parameter to characterize the potential non-Gaussian profile and

$\kappa$ the parameter to characterize the potential non-Gaussian profile and ![]() $C_0$ the background offset of the oversaturation, which is also very close to zero. When

$C_0$ the background offset of the oversaturation, which is also very close to zero. When ![]() $\kappa = 2$ the profile becomes the standard Gaussian case. Figure 8 showcases the quality of the fitting, where the centre received less weight than the outer region based on the amount of information contained, that is, the area of the corresponding discretized annulus region in figure 4(c). Also, we exclude the data at any specific height with less than 5 data points to optimize the quality of the fitting. The fitted variables and the fitted profile are then used in the following sections to analyse the evolution of the centreline oversaturation and the jet profile.

$\kappa = 2$ the profile becomes the standard Gaussian case. Figure 8 showcases the quality of the fitting, where the centre received less weight than the outer region based on the amount of information contained, that is, the area of the corresponding discretized annulus region in figure 4(c). Also, we exclude the data at any specific height with less than 5 data points to optimize the quality of the fitting. The fitted variables and the fitted profile are then used in the following sections to analyse the evolution of the centreline oversaturation and the jet profile.

Figure 8. The radial oversaturation profiles for different ![]() $Re_0$ and

$Re_0$ and ![]() $w_e/w_o$. The dots are the data points and the dashed lines are curves fitted with (4.1). The table next to the figure gives the obtained fitting parameters

$w_e/w_o$. The dots are the data points and the dashed lines are curves fitted with (4.1). The table next to the figure gives the obtained fitting parameters ![]() $\sigma /z$ and

$\sigma /z$ and ![]() $\kappa$ for a variety of heights.

$\kappa$ for a variety of heights.

As discussed, ![]() $\tilde {C}_{{oil,oversat}}>1$ in figure 7 suggests that the data there are less reliable. We hope to obtain the profile and centreline value based only on reliable data points, therefore, data points with

$\tilde {C}_{{oil,oversat}}>1$ in figure 7 suggests that the data there are less reliable. We hope to obtain the profile and centreline value based only on reliable data points, therefore, data points with ![]() $\tilde {C}_{{oil,oversat}}>1$ are also excluded from curve fitting, but larger fitted

$\tilde {C}_{{oil,oversat}}>1$ are also excluded from curve fitting, but larger fitted ![]() $\tilde {C}_{{oil,oversat}}$ is allowed. Such a fitting strategy somehow affects the centreline value in the near field, where

$\tilde {C}_{{oil,oversat}}$ is allowed. Such a fitting strategy somehow affects the centreline value in the near field, where ![]() $\tilde {C}_{{oil,oversat}}>1$. We present and discuss the difference in centreline values between the minimization and the following curve fitting in Appendix B. The current method cannot work properly in the initial shear layer; we would like to remind the reader that the results in that region cannot be interpreted by our curve-fitting procedures nor our minimization procedure, we therefore should keep this in mind when interpreting the analysis in § 4.

$\tilde {C}_{{oil,oversat}}>1$. We present and discuss the difference in centreline values between the minimization and the following curve fitting in Appendix B. The current method cannot work properly in the initial shear layer; we would like to remind the reader that the results in that region cannot be interpreted by our curve-fitting procedures nor our minimization procedure, we therefore should keep this in mind when interpreting the analysis in § 4.

4.2. Radial profile

In the classic jet and plume studies, the jet width of the concentration field ![]() $b_T(z)$ is usually determined by the position where the value drops to

$b_T(z)$ is usually determined by the position where the value drops to ![]() $1/e$ of the centreline value. For a self-similar flow,

$1/e$ of the centreline value. For a self-similar flow, ![]() $b_T(z)/z$ is a constant at around

$b_T(z)/z$ is a constant at around ![]() $0.127$ for a pure jet, and

$0.127$ for a pure jet, and ![]() $0.12$ for a pure plume (Fischer et al. Reference Fischer, List, Koh, Imberger and Brooks1979). When the radial flow profile is Gaussian, the jet width determined from the definition above,

$0.12$ for a pure plume (Fischer et al. Reference Fischer, List, Koh, Imberger and Brooks1979). When the radial flow profile is Gaussian, the jet width determined from the definition above, ![]() $b_T(z)$, and

$b_T(z)$, and ![]() $\sigma$ obtained from (4.1) are the same. However, from figure 9, we can tell that the radial profile is non-Gaussian for the ouzo cases, therefore, we implemented the traditional definition of

$\sigma$ obtained from (4.1) are the same. However, from figure 9, we can tell that the radial profile is non-Gaussian for the ouzo cases, therefore, we implemented the traditional definition of ![]() $b_T(z)$ to characterize the jet width and plot the evolution of

$b_T(z)$ to characterize the jet width and plot the evolution of ![]() $b_T(z)/z$ in figure 9(a,b). While the reference dye cases match well with the constant value reported in the literature (Fischer et al. Reference Fischer, List, Koh, Imberger and Brooks1979), the ouzo cases exhibit a continuously decreasing trend after the initial shear layer, starting with twice the value of the reference case and approaching the reference value as the jet evolved downstream. The larger jet width suggests a wider spread of the nucleation front, following the turbulent entrainment and mixing at the meandering turbulent/non-turbulent interface (TNTI) (Westerweel et al. Reference Westerweel, Fukushima, Pedersen and Hunt2009; Watanabe, Naito & Sakai Reference Watanabe, Naito and Sakai2015a). Neuber et al. (Reference Neuber, Kronenburg, Stein and Cleary2017) numerically investigated the nucleation and condensation of aerosol in gas turbulent jets, showing that the largest supersaturation level and nucleation rate are both not located in the centreline. While we do believe that the nucleation is most intense at the TNTI, the radial dispersion of the droplets nucleated there and the streamwise dispersion of the dense droplets nucleated in the initial shear layer contribute to the relatively higher centreline value in the mean profile. As the oil, originally dissolved in the injected fluid, nucleates and gradually gets consumed with increasing

$b_T(z)/z$ in figure 9(a,b). While the reference dye cases match well with the constant value reported in the literature (Fischer et al. Reference Fischer, List, Koh, Imberger and Brooks1979), the ouzo cases exhibit a continuously decreasing trend after the initial shear layer, starting with twice the value of the reference case and approaching the reference value as the jet evolved downstream. The larger jet width suggests a wider spread of the nucleation front, following the turbulent entrainment and mixing at the meandering turbulent/non-turbulent interface (TNTI) (Westerweel et al. Reference Westerweel, Fukushima, Pedersen and Hunt2009; Watanabe, Naito & Sakai Reference Watanabe, Naito and Sakai2015a). Neuber et al. (Reference Neuber, Kronenburg, Stein and Cleary2017) numerically investigated the nucleation and condensation of aerosol in gas turbulent jets, showing that the largest supersaturation level and nucleation rate are both not located in the centreline. While we do believe that the nucleation is most intense at the TNTI, the radial dispersion of the droplets nucleated there and the streamwise dispersion of the dense droplets nucleated in the initial shear layer contribute to the relatively higher centreline value in the mean profile. As the oil, originally dissolved in the injected fluid, nucleates and gradually gets consumed with increasing ![]() $z$, the ratio

$z$, the ratio ![]() $b_T(z)/z$ also approaches the reference dye case. Note that the spatial evolution of

$b_T(z)/z$ also approaches the reference dye case. Note that the spatial evolution of ![]() $b_T(z)/z$ is nearly independent of

$b_T(z)/z$ is nearly independent of ![]() $Re_0$ and

$Re_0$ and ![]() $w_e/w_o$ upstream, while the dependence appears downstream. Higher initial oil fraction and higher

$w_e/w_o$ upstream, while the dependence appears downstream. Higher initial oil fraction and higher ![]() $Re_0$ can both extend the wider profile further downstream.

$Re_0$ can both extend the wider profile further downstream.

Figure 9. The radial oversaturation profile of the buoyant jets. The error bars represent the uncertainty of the curve fitting discussed in § 4.1. Panels (a,b) show the spatial evolution of the jet width (![]() $b_T(z)$) divided by the vertical distance

$b_T(z)$) divided by the vertical distance ![]() $z$ by probing the radial position where the concentration reaches 1/e of the fitted peak. For each parameter set we show the results of two repeated experiments, denoted by subscripts a,b. (c,d) Display the jet width ratio between the oversaturation (concentration) profile

$z$ by probing the radial position where the concentration reaches 1/e of the fitted peak. For each parameter set we show the results of two repeated experiments, denoted by subscripts a,b. (c,d) Display the jet width ratio between the oversaturation (concentration) profile ![]() $b_T$ and the velocity profile

$b_T$ and the velocity profile ![]() $b_u$.

$b_u$.

Figure 9(c,d) shows the jet width ratio between the oversaturation profile and the velocity profile. The ratio for the reference cases reveals that the concentration spreads slightly wider than the momentum, namely ![]() $b_T/b_u$ is slightly larger than 1, which is consistent with the literature value. For the ouzo jets, the jet width ratio is roughly two times larger upstream, and gradually decreases as the flow evolves downstream.

$b_T/b_u$ is slightly larger than 1, which is consistent with the literature value. For the ouzo jets, the jet width ratio is roughly two times larger upstream, and gradually decreases as the flow evolves downstream.

As the ratio ![]() $b_T(z)/z$ for the ouzo jet is larger than the dye case, we wonder how the nucleation changes the distribution of the radial profile. To characterize the radial profile, we calculate the spatial evolution of the kurtosis from the fitted parameter

$b_T(z)/z$ for the ouzo jet is larger than the dye case, we wonder how the nucleation changes the distribution of the radial profile. To characterize the radial profile, we calculate the spatial evolution of the kurtosis from the fitted parameter ![]() $\kappa$ of (4.1), see figure 10(a,b) for the results. We can interpret the concentration profile in (4.1) as a probability density function of the concentration

$\kappa$ of (4.1), see figure 10(a,b) for the results. We can interpret the concentration profile in (4.1) as a probability density function of the concentration ![]() $\textrm {p.d.f.}(C)$ for which we find that

$\textrm {p.d.f.}(C)$ for which we find that ![]() $C_m$,

$C_m$, ![]() $\sigma$ and

$\sigma$ and ![]() $\kappa$ are constraint in such a way that

$\kappa$ are constraint in such a way that ![]() $\int \nolimits _{-\infty }^\infty \textrm {p.d.f.}(C)\,\textrm {d}r=1$, as per the definition of the p.d.f. From that, we can express

$\int \nolimits _{-\infty }^\infty \textrm {p.d.f.}(C)\,\textrm {d}r=1$, as per the definition of the p.d.f. From that, we can express ![]() $C_m$ in terms of

$C_m$ in terms of ![]() $\kappa$ and

$\kappa$ and ![]() $\sigma$. The kurtosis can then be calculated from its definition in terms of the second and fourth central moments

$\sigma$. The kurtosis can then be calculated from its definition in terms of the second and fourth central moments

\begin{gather} \text{p.d.f.}(C) = \dfrac{\kappa ^{{-}1/\kappa }}{2 \sigma \varGamma \left(1+\dfrac{1}{\kappa }\right)} \exp\left({-\dfrac{| r| ^{\kappa }}{\kappa \sigma^\kappa}}\right), \end{gather}

\begin{gather} \text{p.d.f.}(C) = \dfrac{\kappa ^{{-}1/\kappa }}{2 \sigma \varGamma \left(1+\dfrac{1}{\kappa }\right)} \exp\left({-\dfrac{| r| ^{\kappa }}{\kappa \sigma^\kappa}}\right), \end{gather} \begin{gather}\text{kurtosis} = \dfrac{\int _{-\infty}^\infty r^4 \text{p.d.f.}(C)\,{\rm d}r}{\left( \int _{-\infty}^\infty r^2 \text{p.d.f.}(C)\,{\rm d}r \right)^2} = \dfrac{\varGamma \left(\dfrac{1}{\kappa }\right) \varGamma \left(\dfrac{5}{\kappa }\right)}{\varGamma \left(\dfrac{3}{\kappa }\right)^2}, \end{gather}

\begin{gather}\text{kurtosis} = \dfrac{\int _{-\infty}^\infty r^4 \text{p.d.f.}(C)\,{\rm d}r}{\left( \int _{-\infty}^\infty r^2 \text{p.d.f.}(C)\,{\rm d}r \right)^2} = \dfrac{\varGamma \left(\dfrac{1}{\kappa }\right) \varGamma \left(\dfrac{5}{\kappa }\right)}{\varGamma \left(\dfrac{3}{\kappa }\right)^2}, \end{gather}

where ![]() $\varGamma (x) \equiv \int \nolimits _0^\infty \eta ^{x-1}\textrm {e}^{-\eta }\,\textrm {d}\eta$ is the (complete) gamma function. While the kurtosis for the dye cases is around 3, as expected for a Gaussian distribution, for the ouzo cases it starts with a very high value below

$\varGamma (x) \equiv \int \nolimits _0^\infty \eta ^{x-1}\textrm {e}^{-\eta }\,\textrm {d}\eta$ is the (complete) gamma function. While the kurtosis for the dye cases is around 3, as expected for a Gaussian distribution, for the ouzo cases it starts with a very high value below ![]() $z=3\,\textrm {cm}$, which corresponds to the initial shear layer in figure 7 with

$z=3\,\textrm {cm}$, which corresponds to the initial shear layer in figure 7 with ![]() $\tilde {C}_{{oil,oversat}} > 1$, and thus we remain doubtful about claiming a regime with super-Gaussian kurtosis. Then, the kurtosis sharply decreases to a value close to 2, entering a regime with sub-Gaussian kurtosis, and only slightly increases and approaches 3 as the flow develops.

$\tilde {C}_{{oil,oversat}} > 1$, and thus we remain doubtful about claiming a regime with super-Gaussian kurtosis. Then, the kurtosis sharply decreases to a value close to 2, entering a regime with sub-Gaussian kurtosis, and only slightly increases and approaches 3 as the flow develops.

Figure 10. Kurtosis calculated from the fitted parameter ![]() $\kappa$ for (a)

$\kappa$ for (a) ![]() $Re_0=555$ and (b)

$Re_0=555$ and (b) ![]() $Re_0=1387$.

$Re_0=1387$.

The spatial evolutions of the jet width and of the kurtosis in the far field both reveal the radially spread nucleation front following the TNTI in the ouzo jets, whose effect becomes weaker downstream with the consumption of the dissolved oil. Compared with the reference case, the profile with sub-Gaussian kurtosis suggests a wider radial distribution, leading to a more uniform concentration distribution in the domain. Such distribution is in line with the finding of the reactive mixing study reported in Guilbert & Villermaux (Reference Guilbert and Villermaux2021), where the reaction makes the gamma probability distribution of the product narrower, expediting the mixing process toward uniformity.

4.3. Centreline scaling

The centreline evolution of the concentration has always been the focus of turbulent jet and plume studies, as the scaling between the dilution and streamwise length is crucial to the self-similarity of the flow. In figure 11, we present the centreline evolution for the dyed ethanol jet and the ouzo jet for different ![]() $Re_0$. As the dye concentration dropped monotonically due to dilution, the oversaturation of the ouzo jets experienced several stages, from increasing sharply right above the needle, tightly followed by a sudden decrease and finally entering a mild dilution regime. In figure 11(a,b) we normalized the height

$Re_0$. As the dye concentration dropped monotonically due to dilution, the oversaturation of the ouzo jets experienced several stages, from increasing sharply right above the needle, tightly followed by a sudden decrease and finally entering a mild dilution regime. In figure 11(a,b) we normalized the height ![]() $z$ with the characteristic length scale for the jet–plume transition,

$z$ with the characteristic length scale for the jet–plume transition, ![]() $L_m = M^{3/4}/B^{1/2}$, where

$L_m = M^{3/4}/B^{1/2}$, where ![]() $M=Q^2/({\rm \pi} d^2/4)$ is the initial momentum flux, and

$M=Q^2/({\rm \pi} d^2/4)$ is the initial momentum flux, and ![]() $B=Qg(\rho _{{jet}}-\rho _{{amb}})/\rho _{{amb}}$ is the initial buoyancy flux; see the caption of table 1. For

$B=Qg(\rho _{{jet}}-\rho _{{amb}})/\rho _{{amb}}$ is the initial buoyancy flux; see the caption of table 1. For ![]() $z/L_m < 1$, the flow is characterized as a momentum-dominated jet, followed by a gradual transition to the buoyancy-dominated plume as the flow reaches

$z/L_m < 1$, the flow is characterized as a momentum-dominated jet, followed by a gradual transition to the buoyancy-dominated plume as the flow reaches ![]() $z/L_m = 5$. Figure 11(a,b) displays the centreline evolution for

$z/L_m = 5$. Figure 11(a,b) displays the centreline evolution for ![]() $Re_0 = 555$ and

$Re_0 = 555$ and ![]() $Re_0 = 1387$. For the ouzo cases, we can clearly identify three different regimes: (I) a fast nucleation stage where the concentration climbs quickly; (II) a fast dilution stage, which is only absent for the

$Re_0 = 1387$. For the ouzo cases, we can clearly identify three different regimes: (I) a fast nucleation stage where the concentration climbs quickly; (II) a fast dilution stage, which is only absent for the ![]() $Re_0 =555,$

$Re_0 =555,$ ![]() $w_e/w_o=100$ case and (III) a mild dilution stage in the downstream location, where the nucleation is competing with the dilution. A higher initial oil composition (smaller