1. Introduction

Many key environmental, industrial and energy processes – such as remediation of contaminated groundwater aquifers (Smith et al. Reference Smith, Silva, Munakata-Marr and McCray2008; Hartmann et al. Reference Hartmann2021), recovery of oil from subsurface reservoirs (Durst, Haas & Kaczmar Reference Durst, Haas and Kaczmar1981; Sorbie Reference Sorbie2013) and extraction of heat from geothermal reservoirs (Di Dato et al. Reference Di Dato, D'Angelo, Casasso and Zarlenga2021) – rely on the injection of a fluid into a subsurface porous medium. Such media are formed by sedimentary processes, often leading to vertically layered strata of distinct pore sizes oriented along the direction of macroscopic flow (Freeze Reference Freeze1975; Dagan Reference Dagan2012). The permeability differences between these strata cause uneven fluid partitioning across them, with preferential flow through higher-permeability regions and ‘bypassing’ of lower-permeability regions (Lake & Hirasaki Reference Lake and Hirasaki1981; Di Dato et al. Reference Di Dato, D'Angelo, Casasso and Zarlenga2021). This flow heterogeneity reduces the efficacy of contaminant remediation, oil recovery and heat extraction from bypassed regions – necessitating the development of new ways to spatially homogenize the flow.

Polymer additives have a long history of use in such applications to increase the injected fluid viscosity and thereby suppress instabilities, like viscous fingering, at immiscible (e.g. water–oil) interfaces (Durst et al. Reference Durst, Haas and Kaczmar1981; Smith et al. Reference Smith, Silva, Munakata-Marr and McCray2008; Sorbie Reference Sorbie2013). However, for typically used polymer solutions that do not have appreciable elasticity, this process of conformance control still suffers from the issue of uneven partitioning of flow across different strata due to differences in permeability. Quantitatively, the superficial velocity in a given stratum ![]() $i$ is given by Darcy's law, representing each stratum as a homogeneous medium with uniformly disordered pores of a single mean size:

$i$ is given by Darcy's law, representing each stratum as a homogeneous medium with uniformly disordered pores of a single mean size: ![]() $U_{i}\equiv Q_{i}/A_{i}=(\Delta P/L)k_{i}/\eta _{{app}}$, where

$U_{i}\equiv Q_{i}/A_{i}=(\Delta P/L)k_{i}/\eta _{{app}}$, where ![]() $Q_{i}$ is the volumetric flow rate through the stratum,

$Q_{i}$ is the volumetric flow rate through the stratum, ![]() $\Delta P$ is the pressure drop across a length

$\Delta P$ is the pressure drop across a length ![]() $L$ of the parallel strata,

$L$ of the parallel strata, ![]() $A_{i}$ and

$A_{i}$ and ![]() $k_{i}$ are the cross-sectional area and permeability of the stratum, respectively, and

$k_{i}$ are the cross-sectional area and permeability of the stratum, respectively, and ![]() $\eta _{{app}}$ is the ‘apparent viscosity’ of the polymer solution quantifying the macroscopic resistance to flow through the tortuous pore space. For non-elastic polymer solutions,

$\eta _{{app}}$ is the ‘apparent viscosity’ of the polymer solution quantifying the macroscopic resistance to flow through the tortuous pore space. For non-elastic polymer solutions, ![]() $\eta _{{app}}$ is simply given by the dynamic shear viscosity

$\eta _{{app}}$ is simply given by the dynamic shear viscosity ![]() $\eta$ of the solution, and is typically not strongly dependent on flow rate or porous medium geometry. Therefore, differences in

$\eta$ of the solution, and is typically not strongly dependent on flow rate or porous medium geometry. Therefore, differences in ![]() $k_{i}$ result in differences in

$k_{i}$ result in differences in ![]() $U_{i}$ between strata – leading to uneven partitioning of the flow across the entire stratified medium.

$U_{i}$ between strata – leading to uneven partitioning of the flow across the entire stratified medium.

Conversely, the apparent viscosity of highly elastic polymer solutions (e.g. with molecular weights ![]() ${\gtrsim }1\,\text {MDa}$) can depend on flow rate. For many such solutions,

${\gtrsim }1\,\text {MDa}$) can depend on flow rate. For many such solutions, ![]() $\eta _{{app}}$ strongly increases above a threshold flow rate in a homogeneous porous medium, even though

$\eta _{{app}}$ strongly increases above a threshold flow rate in a homogeneous porous medium, even though ![]() $\eta$ of the bulk solution decreases with increasing shear rate (Marshall & Metzner Reference Marshall and Metzner1967; James & McLaren Reference James and McLaren1975; Chauveteau & Moan Reference Chauveteau and Moan1981; Durst & Haas Reference Durst and Haas1981; Durst et al. Reference Durst, Haas and Kaczmar1981; Kauser et al. Reference Kauser, Dos Santos, Delgado, Muller and Saez1999; Haward & Odell Reference Haward and Odell2003; Odell & Haward Reference Odell and Haward2006; Zamani et al. Reference Zamani, Bondino, Kaufmann and Skauge2015; Clarke et al. Reference Clarke, Howe, Mitchell, Staniland and Hawkes2016; Skauge et al. Reference Skauge, Zamani, Gausdal Jacobsen, Shaker Shiran, Al-Shakry and Skauge2018; Ibezim, Poole & Dennis Reference Ibezim, Poole and Dennis2021). Direct visualization of the flow in a homogeneous medium (Browne & Datta Reference Browne and Datta2021) recently established that this anomalous increase coincides with the onset of a purely elastic flow instability arising from the buildup of polymer elastic stresses during transport (Larson, Shaqfeh & Muller Reference Larson, Shaqfeh and Muller1990; McKinley, Pakdel & Öztekin Reference McKinley, Pakdel and Öztekin1996; Pakdel & McKinley Reference Pakdel and McKinley1996; Shaqfeh Reference Shaqfeh1996; Burghelea et al. Reference Burghelea, Segre, Bar-Joseph, Groisman and Steinberg2004; Rodd et al. Reference Rodd, Cooper-White, Boger and McKinley2007; Afonso, Alves & Pinho Reference Afonso, Alves and Pinho2010; Galindo-Rosales et al. Reference Galindo-Rosales, Campo-Deaño, Pinho, Van Bokhorst, Hamersma, Oliveira and Alves2012; Zilz et al. Reference Zilz, Poole, Alves, Bartolo, Levaché and Lindner2012; Ribeiro et al. Reference Ribeiro, Coelho, Pinho and Alves2014; Clarke et al. Reference Clarke, Howe, Mitchell, Staniland and Hawkes2016; Machado et al. Reference Machado, Bodiguel, Beaumont, Clisson and Colin2016; Kawale et al. Reference Kawale, Marques, Zitha, Kreutzer, Rossen and Boukany2017; Sousa, Pinho & Alves Reference Sousa, Pinho and Alves2018; Browne, Shih & Datta Reference Browne, Shih and Datta2019; Qin et al. Reference Qin, Salipante, Hudson and Arratia2019a; Browne, Shih & Datta Reference Browne, Shih and Datta2020; Walkama, Waisbord & Guasto Reference Walkama, Waisbord and Guasto2020; Haward, Hopkins & Shen Reference Haward, Hopkins and Shen2021). Such an instability gives rise to random flow fluctuations that are, in some cases, reminiscent of inertial turbulence despite the vanishingly small Reynolds numbers

$\eta$ of the bulk solution decreases with increasing shear rate (Marshall & Metzner Reference Marshall and Metzner1967; James & McLaren Reference James and McLaren1975; Chauveteau & Moan Reference Chauveteau and Moan1981; Durst & Haas Reference Durst and Haas1981; Durst et al. Reference Durst, Haas and Kaczmar1981; Kauser et al. Reference Kauser, Dos Santos, Delgado, Muller and Saez1999; Haward & Odell Reference Haward and Odell2003; Odell & Haward Reference Odell and Haward2006; Zamani et al. Reference Zamani, Bondino, Kaufmann and Skauge2015; Clarke et al. Reference Clarke, Howe, Mitchell, Staniland and Hawkes2016; Skauge et al. Reference Skauge, Zamani, Gausdal Jacobsen, Shaker Shiran, Al-Shakry and Skauge2018; Ibezim, Poole & Dennis Reference Ibezim, Poole and Dennis2021). Direct visualization of the flow in a homogeneous medium (Browne & Datta Reference Browne and Datta2021) recently established that this anomalous increase coincides with the onset of a purely elastic flow instability arising from the buildup of polymer elastic stresses during transport (Larson, Shaqfeh & Muller Reference Larson, Shaqfeh and Muller1990; McKinley, Pakdel & Öztekin Reference McKinley, Pakdel and Öztekin1996; Pakdel & McKinley Reference Pakdel and McKinley1996; Shaqfeh Reference Shaqfeh1996; Burghelea et al. Reference Burghelea, Segre, Bar-Joseph, Groisman and Steinberg2004; Rodd et al. Reference Rodd, Cooper-White, Boger and McKinley2007; Afonso, Alves & Pinho Reference Afonso, Alves and Pinho2010; Galindo-Rosales et al. Reference Galindo-Rosales, Campo-Deaño, Pinho, Van Bokhorst, Hamersma, Oliveira and Alves2012; Zilz et al. Reference Zilz, Poole, Alves, Bartolo, Levaché and Lindner2012; Ribeiro et al. Reference Ribeiro, Coelho, Pinho and Alves2014; Clarke et al. Reference Clarke, Howe, Mitchell, Staniland and Hawkes2016; Machado et al. Reference Machado, Bodiguel, Beaumont, Clisson and Colin2016; Kawale et al. Reference Kawale, Marques, Zitha, Kreutzer, Rossen and Boukany2017; Sousa, Pinho & Alves Reference Sousa, Pinho and Alves2018; Browne, Shih & Datta Reference Browne, Shih and Datta2019; Qin et al. Reference Qin, Salipante, Hudson and Arratia2019a; Browne, Shih & Datta Reference Browne, Shih and Datta2020; Walkama, Waisbord & Guasto Reference Walkama, Waisbord and Guasto2020; Haward, Hopkins & Shen Reference Haward, Hopkins and Shen2021). Such an instability gives rise to random flow fluctuations that are, in some cases, reminiscent of inertial turbulence despite the vanishingly small Reynolds numbers ![]() ${Re}$ (Groisman & Steinberg Reference Groisman and Steinberg2000; Pan et al. Reference Pan, Morozov, Wagner and Arratia2013; Qin et al. Reference Qin, Salipante, Hudson and Arratia2019a; Datta et al. Reference Datta2022) – contributing added viscous dissipation that, at least in some cases, primarily generates this anomalous increase in

${Re}$ (Groisman & Steinberg Reference Groisman and Steinberg2000; Pan et al. Reference Pan, Morozov, Wagner and Arratia2013; Qin et al. Reference Qin, Salipante, Hudson and Arratia2019a; Datta et al. Reference Datta2022) – contributing added viscous dissipation that, at least in some cases, primarily generates this anomalous increase in ![]() $\eta _{{app}}$ (Browne & Datta Reference Browne and Datta2021). In a stratified medium, this flow rate dependence of

$\eta _{{app}}$ (Browne & Datta Reference Browne and Datta2021). In a stratified medium, this flow rate dependence of ![]() $\eta _{{app},i}$ in each stratum may provide an avenue to break the proportionality between

$\eta _{{app},i}$ in each stratum may provide an avenue to break the proportionality between ![]() $k_{i}$ and

$k_{i}$ and ![]() $U_{i}$, potentially mitigating the uneven partitioning of the flow across strata. However, this possibility remains unexplored; indeed, it is still unknown how exactly this elastic instability arises in each stratum.

$U_{i}$, potentially mitigating the uneven partitioning of the flow across strata. However, this possibility remains unexplored; indeed, it is still unknown how exactly this elastic instability arises in each stratum.

Here, we demonstrate that this elastic flow instability can help homogenize flow in stratified porous media. Using pore-scale confocal microscopy and macro-scale imaging of passive scalar transport, we visualize the flow in a model porous medium with two distinct parallel strata, imposing a constant flow rate ![]() $Q$ through the entire medium. For small

$Q$ through the entire medium. For small ![]() $Q$, the flow in both strata is laminar, leading to the typical uneven partitioning of flow across the strata. Strikingly, for

$Q$, the flow in both strata is laminar, leading to the typical uneven partitioning of flow across the strata. Strikingly, for ![]() $Q$ above a threshold value, the instability arises solely in the higher-permeability stratum and fluid is redirected to the lower-permeability stratum, helping to homogenize the flow. Above an even larger threshold flow rate, the instability also arises in this lower-permeability stratum, suppressing this flow redirection – leading to a window of flow rates at which this homogenization arises. Guided by these findings, we develop a parallel-resistor model that treats each stratum

$Q$ above a threshold value, the instability arises solely in the higher-permeability stratum and fluid is redirected to the lower-permeability stratum, helping to homogenize the flow. Above an even larger threshold flow rate, the instability also arises in this lower-permeability stratum, suppressing this flow redirection – leading to a window of flow rates at which this homogenization arises. Guided by these findings, we develop a parallel-resistor model that treats each stratum ![]() $i$ as a homogeneous medium with specified

$i$ as a homogeneous medium with specified ![]() $A_i$,

$A_i$, ![]() $k_i$ and, therefore,

$k_i$ and, therefore, ![]() $\eta _{{app},i}$, all coupled at the inlet and outlet. This model quantitatively captures the overall pressure drop across the stratified medium as well as the observed flow redirection with varying flow rate. It also elucidates the underlying cause of this redirection. In particular, above the first threshold flow rate, preferential flow causes the elastic instability to arise solely in the higher-permeability stratum. The corresponding increase in the resistance to flow, as quantified by

$\eta _{{app},i}$, all coupled at the inlet and outlet. This model quantitatively captures the overall pressure drop across the stratified medium as well as the observed flow redirection with varying flow rate. It also elucidates the underlying cause of this redirection. In particular, above the first threshold flow rate, preferential flow causes the elastic instability to arise solely in the higher-permeability stratum. The corresponding increase in the resistance to flow, as quantified by ![]() $\eta _{{app},i}$, redirects flow towards the lower-permeability stratum. Above the larger second threshold flow rate, the onset of the instability and corresponding increase in

$\eta _{{app},i}$, redirects flow towards the lower-permeability stratum. Above the larger second threshold flow rate, the onset of the instability and corresponding increase in ![]() $\eta _{{app},i}$ in the lower-permeability stratum redirects flow back towards the higher-permeability stratum – yielding the experimentally observed optimum in flow homogenization. Finally, we generalize this model, establishing the operating conditions at which this homogenization is optimized for porous media with arbitrarily many strata. Thus, our work provides a new approach to homogenizing fluid and passive scalar transport in heterogeneous porous media. Since many naturally occurring media are stratified, we anticipate these findings to be broadly useful in environmental, industrial and energy processes.

$\eta _{{app},i}$ in the lower-permeability stratum redirects flow back towards the higher-permeability stratum – yielding the experimentally observed optimum in flow homogenization. Finally, we generalize this model, establishing the operating conditions at which this homogenization is optimized for porous media with arbitrarily many strata. Thus, our work provides a new approach to homogenizing fluid and passive scalar transport in heterogeneous porous media. Since many naturally occurring media are stratified, we anticipate these findings to be broadly useful in environmental, industrial and energy processes.

2. Materials and methods

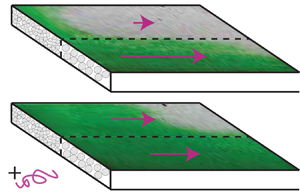

To investigate the spatial distribution of flow in a stratified porous medium, we use imaging at two different length scales: macro-scale (![]() ${\sim }100$ s of pores, figure 1a) and pore-scale (

${\sim }100$ s of pores, figure 1a) and pore-scale (![]() $\sim$1 pore, figure 1b). For clarity regarding nomenclature, we note that different forms of elastic flow instability may arise in different geometries (e.g. those with curvilinear vs parallel streamlines), possibly resulting in flows with distinct power spectra of flow velocity fluctuations (Groisman & Steinberg Reference Groisman and Steinberg2000; Fouxon & Lebedev Reference Fouxon and Lebedev2003; Steinberg Reference Steinberg2021, Reference Steinberg2022; Datta et al. Reference Datta2022). Clarifying the different forms of elastic instability that can arise, and the physics underlying the transition to and spectral features of each instability, is an interesting question for future research. However, the work described in this manuscript instead focuses on the flow resistance, and corresponding partitioning of flow across strata, arising from an elastic instability in porous media – not on the exact nature of the instability or the transition to unstable flow. We therefore use the term ‘elastic flow instability’ to refer more generally to polymer elasticity-generated flow instabilities at low

$\sim$1 pore, figure 1b). For clarity regarding nomenclature, we note that different forms of elastic flow instability may arise in different geometries (e.g. those with curvilinear vs parallel streamlines), possibly resulting in flows with distinct power spectra of flow velocity fluctuations (Groisman & Steinberg Reference Groisman and Steinberg2000; Fouxon & Lebedev Reference Fouxon and Lebedev2003; Steinberg Reference Steinberg2021, Reference Steinberg2022; Datta et al. Reference Datta2022). Clarifying the different forms of elastic instability that can arise, and the physics underlying the transition to and spectral features of each instability, is an interesting question for future research. However, the work described in this manuscript instead focuses on the flow resistance, and corresponding partitioning of flow across strata, arising from an elastic instability in porous media – not on the exact nature of the instability or the transition to unstable flow. We therefore use the term ‘elastic flow instability’ to refer more generally to polymer elasticity-generated flow instabilities at low ![]() $Re \ll 1$, independent of the specific details of the exact nature of the instability, but instead dependent on the flow thickening it causes as shown by our experimental measurements.

$Re \ll 1$, independent of the specific details of the exact nature of the instability, but instead dependent on the flow thickening it causes as shown by our experimental measurements.

Figure 1. Macro-scale and pore-scale characterization of the flow of a highly elastic polymer solution in stratified porous media. (a) Schematic of our Hele-Shaw assembly, with two parallel strata made of close-packed glass beads of distinct sizes. We characterize the macro-scale flow by visualizing the transport of an injected dye, which acts as a passive scalar. (b) Schematic of our microfluidic assembly, again with two parallel strata made of close-packed glass beads of the same distinct sizes as in the Hele-Shaw assembly. We characterize the flow through direct pore-scale visualization of fluorescent tracer particle transport using confocal microscopy, combined with measurements of the pressure drop across the entire medium. (c) Shear stress ![]() $\sigma$ varies nearly linearly with the shear rate

$\sigma$ varies nearly linearly with the shear rate ![]() $\dot {\gamma }$, indicating that the solution approximates a Boger fluid; the dashed line shows the power-law fit

$\dot {\gamma }$, indicating that the solution approximates a Boger fluid; the dashed line shows the power-law fit ![]() $\sigma =A_s\dot {\gamma }^{\alpha _s}$ with

$\sigma =A_s\dot {\gamma }^{\alpha _s}$ with ![]() $A_s=0.3428\pm 0.0002\,\mathrm {Pa}\,\mathrm {s}^{\alpha _s}$ and

$A_s=0.3428\pm 0.0002\,\mathrm {Pa}\,\mathrm {s}^{\alpha _s}$ and ![]() $\alpha _s=0.931\pm 0.001$. (d) First normal stress difference

$\alpha _s=0.931\pm 0.001$. (d) First normal stress difference ![]() $N_1$ also increases with increasing shear rate

$N_1$ also increases with increasing shear rate ![]() $\dot {\gamma }$; the dashed line shows the power-law fit

$\dot {\gamma }$; the dashed line shows the power-law fit ![]() $N_1=A_n\dot {\gamma }^{\alpha _n}$ with

$N_1=A_n\dot {\gamma }^{\alpha _n}$ with ![]() $A_n=1.16\pm 0.03\,\mathrm {Pa}\,\mathrm {s}^{\alpha _n}$ and

$A_n=1.16\pm 0.03\,\mathrm {Pa}\,\mathrm {s}^{\alpha _n}$ and ![]() $\alpha _n=1.25\pm 0.02$. Error bars represent one standard deviation of three measurements.

$\alpha _n=1.25\pm 0.02$. Error bars represent one standard deviation of three measurements.

2.1. Macro-scale experiments in a Hele-Shaw assembly

To characterize the macro-scale partitioning of flow, we fabricate an unconsolidated stratified porous medium in a Hele-Shaw assembly (figure 1a). We 3-D print an open-faced rectangular cell with spanwise (![]() $y$–

$y$–![]() $z$-direction) cross-sectional area

$z$-direction) cross-sectional area ![]() $A=3\,\text {cm}\times 0.4\,\text {cm}$ and streamwise (

$A=3\,\text {cm}\times 0.4\,\text {cm}$ and streamwise (![]() $x$-direction) length

$x$-direction) length ![]() $L=5\,\text {cm}$ using a clear methacrylate-based resin (FLGPCL04, Formlabs Form3). To ensure an even distribution of flow at the boundaries, both the inlet and outlet are split into three equally spaced streams

$L=5\,\text {cm}$ using a clear methacrylate-based resin (FLGPCL04, Formlabs Form3). To ensure an even distribution of flow at the boundaries, both the inlet and outlet are split into three equally spaced streams ![]() ${\approx }2\,\text {cm}$ from the entrance and exit of the porous medium, respectively, with the centre stream spanning the streamwise interface between the parallel strata. We then fill the cell with spherical borosilicate glass beads of distinct diameters arranged in parallel strata using a temporary partition, with bead diameters

${\approx }2\,\text {cm}$ from the entrance and exit of the porous medium, respectively, with the centre stream spanning the streamwise interface between the parallel strata. We then fill the cell with spherical borosilicate glass beads of distinct diameters arranged in parallel strata using a temporary partition, with bead diameters ![]() $d_p=1000$ to 1400

$d_p=1000$ to 1400 ![]() $\mathrm {\mu }$m (Sigma Aldrich) and 212 to 255

$\mathrm {\mu }$m (Sigma Aldrich) and 212 to 255 ![]() $\mathrm {\mu }$m (Mo-Sci) for the higher-permeability coarse (subscript

$\mathrm {\mu }$m (Mo-Sci) for the higher-permeability coarse (subscript ![]() $C$) and lower-permeability fine (subscript

$C$) and lower-permeability fine (subscript ![]() $F$) strata, respectively. The strata have equal cross-sectional areas

$F$) strata, respectively. The strata have equal cross-sectional areas ![]() $A_C\approx A_F\approx A/2$ and thus their area ratio

$A_C\approx A_F\approx A/2$ and thus their area ratio ![]() $\tilde {A}\equiv A_C/A_F\approx 1$. Steel mesh with a 150

$\tilde {A}\equiv A_C/A_F\approx 1$. Steel mesh with a 150 ![]() $\mathrm {\mu }$m pore size cutoff placed over the inlet and outlet tubing prevents the beads from exiting the cell. We tamp down the beads for 30 min to form a dense random packing with a porosity

$\mathrm {\mu }$m pore size cutoff placed over the inlet and outlet tubing prevents the beads from exiting the cell. We tamp down the beads for 30 min to form a dense random packing with a porosity ![]() $\phi _V\sim 0.4$ (Onoda & Liniger Reference Onoda and Liniger1990). We then screw the whole assembly shut with an overlying acrylic sheet cut to size, sandwiching a thin sheet of polydimethylsiloxane to provide a watertight seal. All experiments using this assembly are conducted at

$\phi _V\sim 0.4$ (Onoda & Liniger Reference Onoda and Liniger1990). We then screw the whole assembly shut with an overlying acrylic sheet cut to size, sandwiching a thin sheet of polydimethylsiloxane to provide a watertight seal. All experiments using this assembly are conducted at ![]() ${\approx }21\,^{\circ }\mathrm {C}$.

${\approx }21\,^{\circ }\mathrm {C}$.

For all macro-scale experiments, we use a Harvard Apparatus PHD 2000 syringe pump to first introduce the test fluid – either the polymer solution or the polymer-free solvent, which acts as a Newtonian control – at a constant flow rate ![]() $Q$ for at least the duration needed to fill the entire pore space volume

$Q$ for at least the duration needed to fill the entire pore space volume ![]() $t_{PV}\equiv \phi _V AL/Q$ before imaging to ensure an equilibrated starting condition. We then visualize the macro-scale scalar transport by the fluid by introducing a step change in the concentration of a dilute dye (0.1 wt.% green food colouring, McCormick) and record the infiltration of the dye front using a DSLR camera (Sony

$t_{PV}\equiv \phi _V AL/Q$ before imaging to ensure an equilibrated starting condition. We then visualize the macro-scale scalar transport by the fluid by introducing a step change in the concentration of a dilute dye (0.1 wt.% green food colouring, McCormick) and record the infiltration of the dye front using a DSLR camera (Sony ![]() $\alpha$6300), as shown in figure 1(a). To track the progression of the dye as it is advected by the flow, we determine the ‘breakthrough’ curve half-way along the length of the medium (

$\alpha$6300), as shown in figure 1(a). To track the progression of the dye as it is advected by the flow, we determine the ‘breakthrough’ curve half-way along the length of the medium (![]() $x=L/2$) by measuring the dye intensity

$x=L/2$) by measuring the dye intensity ![]() $C$ averaged across the entire medium cross-section, normalized by the difference in intensities of the final dye-saturated and initial dye-free medium,

$C$ averaged across the entire medium cross-section, normalized by the difference in intensities of the final dye-saturated and initial dye-free medium, ![]() $C_f$ and

$C_f$ and ![]() $C_0$, respectively:

$C_0$, respectively: ![]() $\tilde {C}\equiv (\langle C\rangle _y-\langle C_0\rangle _y)/(\langle C_f\rangle _y-\langle C_0\rangle _y)$ (figure 2b). This procedure averages out slight variations in the dye front along the

$\tilde {C}\equiv (\langle C\rangle _y-\langle C_0\rangle _y)/(\langle C_f\rangle _y-\langle C_0\rangle _y)$ (figure 2b). This procedure averages out slight variations in the dye front along the ![]() $y$- and

$y$- and ![]() $z$-directions, which inevitably arise due to grain-scale spatial fluctuations in the pore geometry (Datta et al. Reference Datta, Chiang, Ramakrishnan and Weitz2013). For all breakthrough curves thereby measured, time

$z$-directions, which inevitably arise due to grain-scale spatial fluctuations in the pore geometry (Datta et al. Reference Datta, Chiang, Ramakrishnan and Weitz2013). For all breakthrough curves thereby measured, time ![]() $t$ is normalized using the time taken to reach this half-way point,

$t$ is normalized using the time taken to reach this half-way point, ![]() $\tilde {t}\equiv t/(0.5t_{PV})$. Repeating this procedure for individual strata (subscript

$\tilde {t}\equiv t/(0.5t_{PV})$. Repeating this procedure for individual strata (subscript ![]() $i$) and tracking the variation of the streamwise position

$i$) and tracking the variation of the streamwise position ![]() $X_i$ at which

$X_i$ at which ![]() $\tilde {C}_i=0.5$ with time provides a measure of the superficial velocity

$\tilde {C}_i=0.5$ with time provides a measure of the superficial velocity ![]() $U_i=\mathrm {d}X_i/\mathrm {d}t$ in each stratum. In between tests at different flow rates, we flush the assembly with the dye-free solution for at least ten pore volumes to remove any residual dye.

$U_i=\mathrm {d}X_i/\mathrm {d}t$ in each stratum. In between tests at different flow rates, we flush the assembly with the dye-free solution for at least ten pore volumes to remove any residual dye.

Figure 2. Imaging reveals that an elastic polymer solution homogenizes the uneven flow between strata, coincident with the onset of the elastic flow instability in the coarser stratum. (a) Visualization of passive scalar transport by the polymer solution in a stratified Hele-Shaw assembly using a green dye. All images are taken at the same ![]() $\tilde {t}\equiv t/(0.5t_{PV})=2.5$, where time

$\tilde {t}\equiv t/(0.5t_{PV})=2.5$, where time ![]() $t$ has been normalized by the time to fill half of the entire pore space volume. Due to the higher permeability of the coarse stratum (bottom), dye infiltrates faster than in the fine stratum (top). However, at the intermediate

$t$ has been normalized by the time to fill half of the entire pore space volume. Due to the higher permeability of the coarse stratum (bottom), dye infiltrates faster than in the fine stratum (top). However, at the intermediate ![]() ${Wi}_I=2.7$, this uneven partitioning of the flow is reduced. (b) Scalar breakthrough curves obtained by measuring the normalized dye concentration

${Wi}_I=2.7$, this uneven partitioning of the flow is reduced. (b) Scalar breakthrough curves obtained by measuring the normalized dye concentration ![]() $\tilde {C}$ at the midpoint

$\tilde {C}$ at the midpoint ![]() $x=L/2$ over time. Uneven flow partitioning at

$x=L/2$ over time. Uneven flow partitioning at ![]() ${Wi}_I=1.4$ leads to distinct jumps and prolongs

${Wi}_I=1.4$ leads to distinct jumps and prolongs ![]() $\tilde {C}$ to long times; by contrast, redirection of flow to the fine stratum at the intermediate

$\tilde {C}$ to long times; by contrast, redirection of flow to the fine stratum at the intermediate ![]() ${Wi}_I=2.7$ leads to more uniform and rapid breakthrough, shown by the smoother and earlier rise in

${Wi}_I=2.7$ leads to more uniform and rapid breakthrough, shown by the smoother and earlier rise in ![]() $\tilde {C}(\tilde {t})$. This homogenization is mitigated at the even larger

$\tilde {C}(\tilde {t})$. This homogenization is mitigated at the even larger ![]() ${Wi}_I=3.3$. (c) Streamline images of representative pores in a stratified microfluidic assembly; black circles are sections through the beads making up the solid matrix, white lines are time projections of the tracer particle pathlines that closely approximate the instantaneous flow streamlines. Imposed flow direction is from left to right. The flow homogenization at the intermediate

${Wi}_I=3.3$. (c) Streamline images of representative pores in a stratified microfluidic assembly; black circles are sections through the beads making up the solid matrix, white lines are time projections of the tracer particle pathlines that closely approximate the instantaneous flow streamlines. Imposed flow direction is from left to right. The flow homogenization at the intermediate ![]() ${Wi}_I=2.7$ (c i,c iii) coincides with the onset of the elastic flow instability solely in the coarse stratum (bottom) – indicated by the emergence of spatio-temporal fluctuations in the flow, shown by the red overlay whose intensity is given by the standard deviation in pixel intensity over the course of the time series of images. The mitigation of this homogenization at the even larger

${Wi}_I=2.7$ (c i,c iii) coincides with the onset of the elastic flow instability solely in the coarse stratum (bottom) – indicated by the emergence of spatio-temporal fluctuations in the flow, shown by the red overlay whose intensity is given by the standard deviation in pixel intensity over the course of the time series of images. The mitigation of this homogenization at the even larger ![]() ${Wi}_I=3.3$ (c ii,c iv) coincides with the additional onset of the instability in the fine stratum, as well (top). (d) Map of the root mean square velocity fluctuations computed from PIV, which confirm that the flow becomes unstable first in the coarse stratum at the intermediate

${Wi}_I=3.3$ (c ii,c iv) coincides with the additional onset of the instability in the fine stratum, as well (top). (d) Map of the root mean square velocity fluctuations computed from PIV, which confirm that the flow becomes unstable first in the coarse stratum at the intermediate ![]() ${Wi}_I=2.7$ (d i,d iii), and then also in the fine stratum at the even larger

${Wi}_I=2.7$ (d i,d iii), and then also in the fine stratum at the even larger ![]() ${Wi}_I=3.3$ (d ii,c iv). (e) Fraction of 10 randomly chosen pores observed in each stratum that exhibit unstable flow, defined as such by identifying whether fluid streamlines cross over the imaging duration. Only a small fraction of pores in the coarse stratum exhibit unstable flow at the intermediate

${Wi}_I=3.3$ (d ii,c iv). (e) Fraction of 10 randomly chosen pores observed in each stratum that exhibit unstable flow, defined as such by identifying whether fluid streamlines cross over the imaging duration. Only a small fraction of pores in the coarse stratum exhibit unstable flow at the intermediate ![]() ${Wi}_I=2.7$, whereas a greater fraction of pores in both strata exhibit unstable flow at the larger

${Wi}_I=2.7$, whereas a greater fraction of pores in both strata exhibit unstable flow at the larger ![]() ${Wi}_I=3.3$ – corroborating the results shown in (c–d).

${Wi}_I=3.3$ – corroborating the results shown in (c–d).

2.2. Pore-scale experiments in microfluidic assemblies

To gain insight into the pore-scale physics, we use experiments in consolidated microfluidic assemblies (figure 2b). We pack spherical borosilicate glass beads (Mo-Sci) in square quartz capillaries (![]() $A= 3.2\,{\rm mm} \times 3.2\,{\rm mm}$; Vitrocom), densify them by tapping and lightly sinter the beads – resulting in dense random packings again with

$A= 3.2\,{\rm mm} \times 3.2\,{\rm mm}$; Vitrocom), densify them by tapping and lightly sinter the beads – resulting in dense random packings again with ![]() $\phi _V\sim 0.4$ (Krummel et al. Reference Krummel, Datta, Münster and Weitz2013). We use this protocol to fabricate three different microfluidic media: a homogeneous higher-permeability coarse medium (

$\phi _V\sim 0.4$ (Krummel et al. Reference Krummel, Datta, Münster and Weitz2013). We use this protocol to fabricate three different microfluidic media: a homogeneous higher-permeability coarse medium (![]() $d_p= 300$ to

$d_p= 300$ to ![]() $355\,\mathrm {\mu }$m), a homogeneous lower-permeability fine medium (

$355\,\mathrm {\mu }$m), a homogeneous lower-permeability fine medium (![]() $d_p= 125$ to

$d_p= 125$ to ![]() $155\,\mathrm {\mu }$m) and a stratified medium with parallel higher-permeability coarse and lower-permeability fine strata, each composed of the same beads used to make the homogeneous media, again with equal cross-section areas,

$155\,\mathrm {\mu }$m) and a stratified medium with parallel higher-permeability coarse and lower-permeability fine strata, each composed of the same beads used to make the homogeneous media, again with equal cross-section areas, ![]() $\tilde {A}\approx 1$ (Datta & Weitz Reference Datta and Weitz2013; Lu et al. Reference Lu, Pahlavan, Browne, Amchin, Stone and Datta2020). We measure the fully developed pressure drop

$\tilde {A}\approx 1$ (Datta & Weitz Reference Datta and Weitz2013; Lu et al. Reference Lu, Pahlavan, Browne, Amchin, Stone and Datta2020). We measure the fully developed pressure drop ![]() $\Delta P$ across each medium using an Omega PX26 differential pressure transducer. All experiments on the microfluidic assemblies are conducted at

$\Delta P$ across each medium using an Omega PX26 differential pressure transducer. All experiments on the microfluidic assemblies are conducted at ![]() ${\approx }21\,^{\circ }\mathrm {C}$.

${\approx }21\,^{\circ }\mathrm {C}$.

For all pore-scale experiments, before each experiment, we infiltrate the medium to be studied first with isopropyl alcohol (IPA) to prevent trapping of air bubbles and then displace the IPA by flushing with water. We then displace the water with the miscible polymer solution, seeded with 5 ppm of fluorescent carboxylated polystyrene tracer particles (Invitrogen), ![]() $D_t=200\,\mathrm {nm}$ in diameter. This solution is injected into the medium at a constant volumetric flow rate

$D_t=200\,\mathrm {nm}$ in diameter. This solution is injected into the medium at a constant volumetric flow rate ![]() $Q$ using Harvard Apparatus syringe pumps – a PHD 2000 for

$Q$ using Harvard Apparatus syringe pumps – a PHD 2000 for ![]() $Q>1\,\text {ml}\,\text {h}^{-1}$ or a Pico Elite for

$Q>1\,\text {ml}\,\text {h}^{-1}$ or a Pico Elite for ![]() $Q<1\,\text {ml}\,\text {h}^{-1}$ – for at least 3 h to reach an equilibrated state before flow characterization. After each subsequent change in

$Q<1\,\text {ml}\,\text {h}^{-1}$ – for at least 3 h to reach an equilibrated state before flow characterization. After each subsequent change in ![]() $Q$, the flow is given 1 h to equilibrate before imaging. We monitor the flow in individual pores using a Nikon A1R+ laser scanning confocal fluorescence microscope with a 488 nm excitation laser and a 500–550 nm sensor detector; the tracer particles have excitation between 480 and 510 nm with an excitation peak at 505 nm, and emission between 505 and 540 nm with an emission peak at 515 nm. These particles are faithful tracers of the underlying flow field since the Péclet number

$Q$, the flow is given 1 h to equilibrate before imaging. We monitor the flow in individual pores using a Nikon A1R+ laser scanning confocal fluorescence microscope with a 488 nm excitation laser and a 500–550 nm sensor detector; the tracer particles have excitation between 480 and 510 nm with an excitation peak at 505 nm, and emission between 505 and 540 nm with an emission peak at 515 nm. These particles are faithful tracers of the underlying flow field since the Péclet number ![]() ${Pe}\equiv (Q/A)D_t/\mathcal {D}>10^5\gg 1$, where

${Pe}\equiv (Q/A)D_t/\mathcal {D}>10^5\gg 1$, where ![]() $\mathcal {D}=k_BT/(3{\rm \pi} \eta D_t)=6\times 10^{-3}\,\mathrm {\mu }\mathrm {m}^2\,\mathrm {s}^{-1}$ is the Stokes–Einstein particle diffusivity. We then visualize the flow using a 10

$\mathcal {D}=k_BT/(3{\rm \pi} \eta D_t)=6\times 10^{-3}\,\mathrm {\mu }\mathrm {m}^2\,\mathrm {s}^{-1}$ is the Stokes–Einstein particle diffusivity. We then visualize the flow using a 10![]() $\times$ objective lens with the confocal resonant scanner, obtaining successive 8

$\times$ objective lens with the confocal resonant scanner, obtaining successive 8 ![]() $\mathrm {\mu }\mathrm {m}$-thick optical slices at a

$\mathrm {\mu }\mathrm {m}$-thick optical slices at a ![]() $z$ depth hundreds of

$z$ depth hundreds of ![]() $\mathrm {\mu }\mathrm {m}$ within the medium. Our imaging probes an

$\mathrm {\mu }\mathrm {m}$ within the medium. Our imaging probes an ![]() $x$–

$x$–![]() $y$ field of view

$y$ field of view ![]() $159\,\mathrm {\mu }\mathrm {m}\times 159\,\mathrm {\mu }\mathrm {m}$ at 60 frames per second for pores with

$159\,\mathrm {\mu }\mathrm {m}\times 159\,\mathrm {\mu }\mathrm {m}$ at 60 frames per second for pores with ![]() $d_p=125$ to

$d_p=125$ to ![]() $155\,\mathrm {\mu }\mathrm {m}$ or

$155\,\mathrm {\mu }\mathrm {m}$ or ![]() $318\,\mathrm {\mu }\mathrm {m}\times 318\,\mathrm {\mu }\mathrm {m}$ at 30 frames per second for pores with

$318\,\mathrm {\mu }\mathrm {m}\times 318\,\mathrm {\mu }\mathrm {m}$ at 30 frames per second for pores with ![]() $d_p=300$ to

$d_p=300$ to ![]() $355\,\mathrm {\mu }\mathrm {m}$.

$355\,\mathrm {\mu }\mathrm {m}$.

To monitor the flow in the different pores over time, we use an ‘intermittent’ imaging protocol. Specifically, we record the flow in multiple pores chosen randomly throughout each medium (19 and 20 pores of the homogeneous coarse and fine media, respectively) for 2 s long intervals every 4 min over the course of 1 h. For the experiments in homogeneous fine and stratified media, we also complement this protocol with ‘continuous’ imaging in which we monitor the flow successively in 10 pores of the homogeneous fine medium for 5 min long intervals each. For ease of visualization, we intensity average the successive images thereby obtained over a time scale ![]() $\approx 2.5\,\mathrm {\mu }\mathrm {m}/(Q/A)$ (figure 2c), producing movies of the tracer particle pathlines that closely approximate the instantaneous flow streamlines. We also measure the instantaneous

$\approx 2.5\,\mathrm {\mu }\mathrm {m}/(Q/A)$ (figure 2c), producing movies of the tracer particle pathlines that closely approximate the instantaneous flow streamlines. We also measure the instantaneous ![]() $x$–

$x$–![]() $y$ velocities

$y$ velocities ![]() $\boldsymbol {u}$ using particle image velocimetry (PIV) (Thielicke & Stamhuis Reference Thielicke and Stamhuis2014). Subtracting off the temporal mean, indicated by

$\boldsymbol {u}$ using particle image velocimetry (PIV) (Thielicke & Stamhuis Reference Thielicke and Stamhuis2014). Subtracting off the temporal mean, indicated by ![]() $\langle \rangle _t$, in each pixel yields the velocity fluctuation

$\langle \rangle _t$, in each pixel yields the velocity fluctuation ![]() $\boldsymbol {u}'=\boldsymbol {u}-\langle \boldsymbol {u}\rangle _t$; we then define an unstable region of the flow as one in which the root mean square velocity fluctuation

$\boldsymbol {u}'=\boldsymbol {u}-\langle \boldsymbol {u}\rangle _t$; we then define an unstable region of the flow as one in which the root mean square velocity fluctuation ![]() $\sqrt {\langle |\boldsymbol {u}'|^2\rangle _t}/\langle |\boldsymbol {u}|\rangle _t>0.3$.

$\sqrt {\langle |\boldsymbol {u}'|^2\rangle _t}/\langle |\boldsymbol {u}|\rangle _t>0.3$.

2.3. Permeability measurements

For each medium, we determine the permeability via Darcy's law using experiments with pure water. For the microfluidic assemblies, we obtain ![]() $k_C=79\,\mathrm {\mu }\mathrm {m}^2$ and

$k_C=79\,\mathrm {\mu }\mathrm {m}^2$ and ![]() $k_F=8.6\,\mathrm {\mu }\mathrm {m}^2$ for the homogeneous coarse and fine media, respectively – comparable to our previously measured values on similar media (Krummel et al. Reference Krummel, Datta, Münster and Weitz2013) and to the prediction of the established Kozeny–Carman relation (Philipse & Pathmamanoharan Reference Philipse and Pathmamanoharan1993). The permeability ratio between the two strata is then

$k_F=8.6\,\mathrm {\mu }\mathrm {m}^2$ for the homogeneous coarse and fine media, respectively – comparable to our previously measured values on similar media (Krummel et al. Reference Krummel, Datta, Münster and Weitz2013) and to the prediction of the established Kozeny–Carman relation (Philipse & Pathmamanoharan Reference Philipse and Pathmamanoharan1993). The permeability ratio between the two strata is then ![]() $\tilde {k}\equiv k_C/k_F\approx 9$. The measured permeability for the entire stratified porous medium is

$\tilde {k}\equiv k_C/k_F\approx 9$. The measured permeability for the entire stratified porous medium is ![]() $k=32\,\mathrm {\mu }\mathrm {m}^2$, in reasonable agreement with the prediction obtained by considering the strata as separated homogeneous media providing parallel resistance to flow,

$k=32\,\mathrm {\mu }\mathrm {m}^2$, in reasonable agreement with the prediction obtained by considering the strata as separated homogeneous media providing parallel resistance to flow, ![]() $k\approx \tilde {A} k_C+(1-\tilde {A})k_F\approx 44\,\mathrm {\mu }\mathrm {m}^2$.

$k\approx \tilde {A} k_C+(1-\tilde {A})k_F\approx 44\,\mathrm {\mu }\mathrm {m}^2$.

The permeability of an isolated stratum in a stratified medium varies as ![]() $\sim d_p^2$, similar to a homogeneous porous medium. Hence, for the Hele-Shaw assembly, we estimate the permeability of each stratum by scaling

$\sim d_p^2$, similar to a homogeneous porous medium. Hence, for the Hele-Shaw assembly, we estimate the permeability of each stratum by scaling ![]() $k_C$ and

$k_C$ and ![]() $k_F$ with the differences in bead size. We thereby estimate

$k_F$ with the differences in bead size. We thereby estimate ![]() $k\approx 440\,\mathrm {\mu }\mathrm {m}^2$ (

$k\approx 440\,\mathrm {\mu }\mathrm {m}^2$ (![]() $\tilde {k}\approx 26$) for the entire stratified medium, in reasonable agreement with the measured

$\tilde {k}\approx 26$) for the entire stratified medium, in reasonable agreement with the measured ![]() $k=270\,\mathrm {\mu }\text {m}^2$.

$k=270\,\mathrm {\mu }\text {m}^2$.

For both assemblies, we define a characteristic shear rate of the entire medium ![]() $\dot {\gamma }_I\equiv Q/(A\sqrt {\phi _V k})$ as the ratio between the characteristic pore flow speed

$\dot {\gamma }_I\equiv Q/(A\sqrt {\phi _V k})$ as the ratio between the characteristic pore flow speed ![]() $Q/(\phi _V A)$ and length scale

$Q/(\phi _V A)$ and length scale ![]() $\sqrt {k/\phi _V}$ (Zami-Pierre et al. Reference Zami-Pierre, De Loubens, Quintard and Davit2016; Berg & van Wunnik Reference Berg and van Wunnik2017). Our experiments explore the range

$\sqrt {k/\phi _V}$ (Zami-Pierre et al. Reference Zami-Pierre, De Loubens, Quintard and Davit2016; Berg & van Wunnik Reference Berg and van Wunnik2017). Our experiments explore the range ![]() $\dot {\gamma }_I\approx 0.2$ to

$\dot {\gamma }_I\approx 0.2$ to ![]() $26\,\mathrm {s}^{-1}$.

$26\,\mathrm {s}^{-1}$.

2.4. Polymer solution rheology

The polymer solution approximates a Boger fluid composed of dilute 300 ppm 18 MDa partially hydrolysed polyacrylamide dissolved in a viscous aqueous solvent composed of 6 wt.% ultrapure milliPore water, 82.6 wt.% glycerol (Sigma Aldrich), 10.4 wt.% dimethylsulfoxide (Sigma Aldrich) and 1 wt.% NaCl. This solution is formulated to precisely match its refractive index to that of the glass beads – thus rendering each medium transparent when saturated. From intrinsic viscosity measurements the overlap concentration is ![]() $c^{*}\approx 0.77/[\eta ]=600\pm 300\,\mathrm {ppm}$ (Browne & Datta Reference Browne and Datta2021) and the radius of gyration is

$c^{*}\approx 0.77/[\eta ]=600\pm 300\,\mathrm {ppm}$ (Browne & Datta Reference Browne and Datta2021) and the radius of gyration is ![]() $R_g\approx 220\,\mathrm {nm}$ (Rubinstein et al. Reference Rubinstein and Colby2003) and therefore our experiments use a dilute polymer solution at

$R_g\approx 220\,\mathrm {nm}$ (Rubinstein et al. Reference Rubinstein and Colby2003) and therefore our experiments use a dilute polymer solution at ![]() $\approx 0.5$ times the overlap concentration. The shear stress

$\approx 0.5$ times the overlap concentration. The shear stress ![]() $\sigma (\dot {\gamma }_I)=A_s\dot {\gamma }^{\alpha _s}$ and first normal stress difference

$\sigma (\dot {\gamma }_I)=A_s\dot {\gamma }^{\alpha _s}$ and first normal stress difference ![]() $N_1(\dot {\gamma }_I)=A_n\dot {\gamma }^{\alpha _n}$ are measured in an Anton Paar MCR301 rheometer, using a

$N_1(\dot {\gamma }_I)=A_n\dot {\gamma }^{\alpha _n}$ are measured in an Anton Paar MCR301 rheometer, using a ![]() $1^{\circ }$ 5 cm diameter conical geometry set at a 50

$1^{\circ }$ 5 cm diameter conical geometry set at a 50 ![]() $\mathrm {\mu }$m gap, yielding the best-fit power laws

$\mathrm {\mu }$m gap, yielding the best-fit power laws ![]() $A_s=0.3428\pm 0.0002\,\mathrm {Pa}\,\mathrm {s}^{\alpha _s}$ with

$A_s=0.3428\pm 0.0002\,\mathrm {Pa}\,\mathrm {s}^{\alpha _s}$ with ![]() $\alpha _s=0.931\pm 0.001$ and

$\alpha _s=0.931\pm 0.001$ and ![]() $A_n=1.16\pm 0.03\,\mathrm {Pa}\,\mathrm {s}^{\alpha _n}$ with

$A_n=1.16\pm 0.03\,\mathrm {Pa}\,\mathrm {s}^{\alpha _n}$ with ![]() $\alpha _n=1.25\pm 0.02$ (figure 1c,d). All rheological measurements are temperature controlled with a Peltier plate at

$\alpha _n=1.25\pm 0.02$ (figure 1c,d). All rheological measurements are temperature controlled with a Peltier plate at ![]() $20.0\pm 0.1\,^{\circ }\mathrm {C}$.

$20.0\pm 0.1\,^{\circ }\mathrm {C}$.

These measurements then enable us to calculate a characteristic interstitial Weissenberg number, which characterizes the role of polymer elasticity in the flow by comparing the magnitude of elastic and viscous stresses, ![]() ${Wi}_I\equiv N_1(\dot {\gamma }_I)/(2\sigma (\dot {\gamma }_I))$, as commonly defined (Pan et al. Reference Pan, Morozov, Wagner and Arratia2013; Qin et al. Reference Qin, Salipante, Hudson and Arratia2019a,Reference Qin, Salipante, Hudson and Arratiab; Browne et al. Reference Browne, Shih and Datta2020; Browne & Datta Reference Browne and Datta2021; Ibezim et al. Reference Ibezim, Poole and Dennis2021; Datta et al. Reference Datta2022). In our experiments this quantity exceeds unity, ranging from 1 to 5.5, suggesting that elastic flow instabilities likely arise in the flow (Larson et al. Reference Larson, Shaqfeh and Muller1990; Pakdel & McKinley Reference Pakdel and McKinley1996; Shaqfeh Reference Shaqfeh1996; Rodd et al. Reference Rodd, Cooper-White, Boger and McKinley2007; Afonso et al. Reference Afonso, Alves and Pinho2010; Galindo-Rosales et al. Reference Galindo-Rosales, Campo-Deaño, Pinho, Van Bokhorst, Hamersma, Oliveira and Alves2012; Zilz et al. Reference Zilz, Poole, Alves, Bartolo, Levaché and Lindner2012; Pan et al. Reference Pan, Morozov, Wagner and Arratia2013; Ribeiro et al. Reference Ribeiro, Coelho, Pinho and Alves2014; Sousa et al. Reference Sousa, Pinho and Alves2018; Browne et al. Reference Browne, Shih and Datta2019, Reference Browne, Shih and Datta2020; Browne & Datta Reference Browne and Datta2021) – as we directly verify using flow visualization, detailed further below.

${Wi}_I\equiv N_1(\dot {\gamma }_I)/(2\sigma (\dot {\gamma }_I))$, as commonly defined (Pan et al. Reference Pan, Morozov, Wagner and Arratia2013; Qin et al. Reference Qin, Salipante, Hudson and Arratia2019a,Reference Qin, Salipante, Hudson and Arratiab; Browne et al. Reference Browne, Shih and Datta2020; Browne & Datta Reference Browne and Datta2021; Ibezim et al. Reference Ibezim, Poole and Dennis2021; Datta et al. Reference Datta2022). In our experiments this quantity exceeds unity, ranging from 1 to 5.5, suggesting that elastic flow instabilities likely arise in the flow (Larson et al. Reference Larson, Shaqfeh and Muller1990; Pakdel & McKinley Reference Pakdel and McKinley1996; Shaqfeh Reference Shaqfeh1996; Rodd et al. Reference Rodd, Cooper-White, Boger and McKinley2007; Afonso et al. Reference Afonso, Alves and Pinho2010; Galindo-Rosales et al. Reference Galindo-Rosales, Campo-Deaño, Pinho, Van Bokhorst, Hamersma, Oliveira and Alves2012; Zilz et al. Reference Zilz, Poole, Alves, Bartolo, Levaché and Lindner2012; Pan et al. Reference Pan, Morozov, Wagner and Arratia2013; Ribeiro et al. Reference Ribeiro, Coelho, Pinho and Alves2014; Sousa et al. Reference Sousa, Pinho and Alves2018; Browne et al. Reference Browne, Shih and Datta2019, Reference Browne, Shih and Datta2020; Browne & Datta Reference Browne and Datta2021) – as we directly verify using flow visualization, detailed further below.

Polymer solutions such as that used here are typically characterized by a broad spectrum of relaxation times, which can be challenging to fully characterize experimentally (Perkins, Smith & Chu Reference Perkins, Smith and Chu1997; Liu, Jun & Steinberg Reference Liu, Jun and Steinberg2007, Reference Liu, Jun and Steinberg2009). For simplicity, we therefore follow Shaqfeh (Reference Shaqfeh1996) and describe our solution using a single polymer relaxation time ![]() $\lambda \equiv {\lim }_{\dot {\gamma }\rightarrow 0}~{\varPsi _1}/({2\eta _p})$, where

$\lambda \equiv {\lim }_{\dot {\gamma }\rightarrow 0}~{\varPsi _1}/({2\eta _p})$, where ![]() $\varPsi _1\equiv N_1/\dot {\gamma }^2$ is the first normal stress coefficient,

$\varPsi _1\equiv N_1/\dot {\gamma }^2$ is the first normal stress coefficient, ![]() $\eta _p\equiv \eta -\eta _s$ is the polymer contribution to the solution viscosity and

$\eta _p\equiv \eta -\eta _s$ is the polymer contribution to the solution viscosity and ![]() $\eta _s=226.8\pm 0.3\,\mathrm {mPa}\,\mathrm {s}$ is the viscosity of the polymer-free solvent. Using the lowest shear rates where each value is accessible on our rheometer, we estimate

$\eta _s=226.8\pm 0.3\,\mathrm {mPa}\,\mathrm {s}$ is the viscosity of the polymer-free solvent. Using the lowest shear rates where each value is accessible on our rheometer, we estimate ![]() ${\lim }_{\dot {\gamma }\rightarrow 0}\varPsi _1\approx 192\pm 7\,\mathrm {mPa}\,\mathrm {s}^2$ and

${\lim }_{\dot {\gamma }\rightarrow 0}\varPsi _1\approx 192\pm 7\,\mathrm {mPa}\,\mathrm {s}^2$ and ![]() ${\lim }_{\dot {\gamma }\rightarrow 0}\eta \approx 427\pm 4\,\mathrm {mPa}\,\mathrm {s}$, yielding

${\lim }_{\dot {\gamma }\rightarrow 0}\eta \approx 427\pm 4\,\mathrm {mPa}\,\mathrm {s}$, yielding ![]() $\lambda \approx 480\pm 30\,\text {ms}$. This value of a characteristic relaxation time is in good agreement with previously reported relaxation times for similar polymer and solvent compositions (Groisman & Steinberg Reference Groisman and Steinberg2000; Galindo-Rosales et al. Reference Galindo-Rosales, Campo-Deaño, Pinho, Van Bokhorst, Hamersma, Oliveira and Alves2012; Pan et al. Reference Pan, Morozov, Wagner and Arratia2013; Clarke et al. Reference Clarke, Howe, Mitchell, Staniland and Hawkes2016; Walkama et al. Reference Walkama, Waisbord and Guasto2020), although we expect the true longest relaxation time of the solution to be larger than this value.

$\lambda \approx 480\pm 30\,\text {ms}$. This value of a characteristic relaxation time is in good agreement with previously reported relaxation times for similar polymer and solvent compositions (Groisman & Steinberg Reference Groisman and Steinberg2000; Galindo-Rosales et al. Reference Galindo-Rosales, Campo-Deaño, Pinho, Van Bokhorst, Hamersma, Oliveira and Alves2012; Pan et al. Reference Pan, Morozov, Wagner and Arratia2013; Clarke et al. Reference Clarke, Howe, Mitchell, Staniland and Hawkes2016; Walkama et al. Reference Walkama, Waisbord and Guasto2020), although we expect the true longest relaxation time of the solution to be larger than this value.

Finally, we also characterize the role of inertia with the Reynolds number ![]() ${Re}=\rho Ud_p/\eta (\dot {\gamma }_I)$, which quantifies the ratio of inertial to viscous stresses for a fluid with density

${Re}=\rho Ud_p/\eta (\dot {\gamma }_I)$, which quantifies the ratio of inertial to viscous stresses for a fluid with density ![]() $\rho$. In our experiments this quantity ranges from

$\rho$. In our experiments this quantity ranges from ![]() ${Re}=2\times 10^{-7}$ to

${Re}=2\times 10^{-7}$ to ![]() $2\times 10^{-5}\ll 1$, indicating that inertial effects are negligible.

$2\times 10^{-5}\ll 1$, indicating that inertial effects are negligible.

3. Results

3.1. Polymer solution homogenizes flow above a threshold Weissenberg number, coinciding with the onset of the elastic flow instability

We use our stratified Hele-Shaw assembly to characterize the uneven partitioning of flow between strata at the macro-scale. First, we impose a small flow rate ![]() $Q=3\,{\rm ml}\,{\rm h}^{-1}$ corresponding to

$Q=3\,{\rm ml}\,{\rm h}^{-1}$ corresponding to ![]() ${Wi}_I=1.4$ – below the onset of the elastic flow instability at

${Wi}_I=1.4$ – below the onset of the elastic flow instability at ![]() ${Wi}_I\approx 2.6$ for homogeneous media (Browne & Datta Reference Browne and Datta2021). As is the case with Newtonian fluids, we observe preferential flow through the coarse stratum, indicated by the infiltrating dye front in figure 2(a i) and in supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.337. The infiltration of dye at different rates through the strata produces two distinct steps in the breakthrough curve (blue line in figure 2b): the first jump from

${Wi}_I\approx 2.6$ for homogeneous media (Browne & Datta Reference Browne and Datta2021). As is the case with Newtonian fluids, we observe preferential flow through the coarse stratum, indicated by the infiltrating dye front in figure 2(a i) and in supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.337. The infiltration of dye at different rates through the strata produces two distinct steps in the breakthrough curve (blue line in figure 2b): the first jump from ![]() $\tilde {C}\approx 0$ to

$\tilde {C}\approx 0$ to ![]() $0.4$ from

$0.4$ from ![]() $0<\tilde {t}\lesssim 3$ corresponds to fluid infiltration of the coarse stratum, and the second jump from

$0<\tilde {t}\lesssim 3$ corresponds to fluid infiltration of the coarse stratum, and the second jump from ![]() $\tilde {C}\approx 0.4$ to

$\tilde {C}\approx 0.4$ to ![]() $0.8$ from

$0.8$ from ![]() $3\lesssim \tilde {t}\lesssim 6$ corresponds to infiltration of the fine stratum. This uneven partitioning of flow is also reflected in the difference between the magnitudes of the superficial velocities

$3\lesssim \tilde {t}\lesssim 6$ corresponds to infiltration of the fine stratum. This uneven partitioning of flow is also reflected in the difference between the magnitudes of the superficial velocities ![]() $U_C=130\,\mathrm {\mu }{\rm m}\,{\rm s}^{-1}$ and

$U_C=130\,\mathrm {\mu }{\rm m}\,{\rm s}^{-1}$ and ![]() $U_F=10\,\mathrm {\mu }{\rm m}\,{\rm s}^{-1}$ in the coarse and fine strata, respectively, corresponding to a ratio of

$U_F=10\,\mathrm {\mu }{\rm m}\,{\rm s}^{-1}$ in the coarse and fine strata, respectively, corresponding to a ratio of ![]() $U_F/U_C=0.075$. We observe similar behaviour with our Newtonian control, which produces a similar ratio of

$U_F/U_C=0.075$. We observe similar behaviour with our Newtonian control, which produces a similar ratio of ![]() $(U_F/U_C)_{0}=0.063$ even at a larger imposed flow rate

$(U_F/U_C)_{0}=0.063$ even at a larger imposed flow rate ![]() $Q=35\,\mathrm {ml}\,\mathrm {h}^{-1}$ (movie 2). Hence, at low

$Q=35\,\mathrm {ml}\,\mathrm {h}^{-1}$ (movie 2). Hence, at low ![]() ${Wi}_I$, polymer solutions recapitulate the uneven partitioning of flow across strata that is characteristic of Newtonian fluids.

${Wi}_I$, polymer solutions recapitulate the uneven partitioning of flow across strata that is characteristic of Newtonian fluids.

Next, we repeat the same experiment as in figure 2(a i) at a larger flow rate of ![]() $Q=25\,\mathrm {ml}\,\mathrm {h}^{-1}$ – corresponding to a larger

$Q=25\,\mathrm {ml}\,\mathrm {h}^{-1}$ – corresponding to a larger ![]() ${Wi}_I=2.7$. Surprisingly, under these conditions, the partitioning of flow is markedly less uneven (figure 2(a ii), movie 3). These observations are reflected in the dye breakthrough curve, as well: the previously distinct jumps in the concentration

${Wi}_I=2.7$. Surprisingly, under these conditions, the partitioning of flow is markedly less uneven (figure 2(a ii), movie 3). These observations are reflected in the dye breakthrough curve, as well: the previously distinct jumps in the concentration ![]() $\tilde {C}$ begin to merge, as shown by comparing the blue and green lines in figure 2(b). Indeed, the ratio between the superficial velocities in the fine and coarse strata

$\tilde {C}$ begin to merge, as shown by comparing the blue and green lines in figure 2(b). Indeed, the ratio between the superficial velocities in the fine and coarse strata ![]() $U_F/U_C=0.16$, is

$U_F/U_C=0.16$, is ![]() ${\sim }3{\times }$ larger than in the laminar baseline given by the Newtonian control and the low

${\sim }3{\times }$ larger than in the laminar baseline given by the Newtonian control and the low ![]() ${Wi}_I=1.4$ solution tests. Therefore, to quantify this net improvement in flow homogenization, we normalize the velocity ratio by its Newtonian value,

${Wi}_I=1.4$ solution tests. Therefore, to quantify this net improvement in flow homogenization, we normalize the velocity ratio by its Newtonian value, ![]() $\tilde {U}_F/\tilde {U}_C\equiv (U_F/U_C)/(U_F/U_C)_{0}=2.6$. This improvement in the flow homogenization is weaker at an even larger flow rate

$\tilde {U}_F/\tilde {U}_C\equiv (U_F/U_C)/(U_F/U_C)_{0}=2.6$. This improvement in the flow homogenization is weaker at an even larger flow rate ![]() $Q=45\,\mathrm {ml}\,\mathrm {h}^{-1}$ (corresponding to

$Q=45\,\mathrm {ml}\,\mathrm {h}^{-1}$ (corresponding to ![]() ${Wi}_I=3.3$), as shown in figure 2(a iii), the red line in figure 2(b), and in movie 4; the corresponding velocity ratio is

${Wi}_I=3.3$), as shown in figure 2(a iii), the red line in figure 2(b), and in movie 4; the corresponding velocity ratio is ![]() $\tilde {U}_F/\tilde {U}_C=1.7$. Taken together, our observations demonstrate that polymer additives can help mitigate uneven partitioning of flow in a stratified porous medium – but that this effect is optimized at intermediate

$\tilde {U}_F/\tilde {U}_C=1.7$. Taken together, our observations demonstrate that polymer additives can help mitigate uneven partitioning of flow in a stratified porous medium – but that this effect is optimized at intermediate ![]() ${Wi}_I$.

${Wi}_I$.

Why does this flow homogenization arise? As described in § 1, for the initially laminar flow, the coarser stratum experiences a higher interstitial flow speed – and therefore shear rate – as prescribed by the differential partitioning of flow across strata following Darcy's law. Thus, the locally defined Weissenberg number is larger in the coarse stratum, which we expect leads to an earlier onset of the elastic instability in this stratum. The corresponding increase in the resistance to flow through the coarse stratum would then redirect fluid to the fine stratum, helping to homogenize the flow. We test this expectation using our ‘continuous’ imaging protocol, which enables us to directly image the flow at the pore scale within the stratified microfluidic assembly. At the intermediate ![]() ${Wi}_I=2.7$ – at which the flow homogenization is optimized – all pores observed in the fine stratum exhibit laminar flow that is steady over time (movie 5; representative pore shown in figure 2c i,d i). By contrast, 20 % of the pores observed in the coarse stratum exhibit strong spatial and temporal fluctuations in the flow (figure 2e). The fluid streamlines continually cross and vary over time, indicating the emergence of the elastic instability, as shown in movie 5 and in figure 2(c iii,d iii) for a representative pore – consistent with our expectation. These random streamline fluctuations are similar to those observed for this instability in a homogeneous medium (Browne & Datta Reference Browne and Datta2021). To highlight the regions of unstable flow, figure 2(c) also includes an overlay in red showing the standard deviation of the fluctuations in the fluorescent intensity over time; figure 2(d) shows the corresponding root mean square velocity fluctuation, which confirms that the flow is unstable in those same regions. At the even larger

${Wi}_I=2.7$ – at which the flow homogenization is optimized – all pores observed in the fine stratum exhibit laminar flow that is steady over time (movie 5; representative pore shown in figure 2c i,d i). By contrast, 20 % of the pores observed in the coarse stratum exhibit strong spatial and temporal fluctuations in the flow (figure 2e). The fluid streamlines continually cross and vary over time, indicating the emergence of the elastic instability, as shown in movie 5 and in figure 2(c iii,d iii) for a representative pore – consistent with our expectation. These random streamline fluctuations are similar to those observed for this instability in a homogeneous medium (Browne & Datta Reference Browne and Datta2021). To highlight the regions of unstable flow, figure 2(c) also includes an overlay in red showing the standard deviation of the fluctuations in the fluorescent intensity over time; figure 2(d) shows the corresponding root mean square velocity fluctuation, which confirms that the flow is unstable in those same regions. At the even larger ![]() ${Wi}_I=3.3$ – at which the improvement in flow homogenization is weaker – a larger fraction of pores in both strata exhibit unstable flow (movie 6; figure 2c ii,iv,d ii,iv, figure 2e). These results thus indicate that macroscopic flow homogenization is indeed linked to the onset of the elastic flow instability in the coarse stratum at sufficiently large

${Wi}_I=3.3$ – at which the improvement in flow homogenization is weaker – a larger fraction of pores in both strata exhibit unstable flow (movie 6; figure 2c ii,iv,d ii,iv, figure 2e). These results thus indicate that macroscopic flow homogenization is indeed linked to the onset of the elastic flow instability in the coarse stratum at sufficiently large ![]() ${Wi}_I$, but is mitigated by the additional onset of the instability in the fine stratum at even larger

${Wi}_I$, but is mitigated by the additional onset of the instability in the fine stratum at even larger ![]() ${Wi}_I$.

${Wi}_I$.

3.2. Flow velocity fluctuations generated by the elastic flow instability lead to an increase in the apparent viscosity

To quantitatively understand the link between pore-scale differences in this flow instability and macro-scale differences in superficial velocity between strata, we consider the resistance to flow in the distinct strata at different ![]() ${Wi}_I$. In particular, we model the strata as parallel fluidic ‘resistors’ – that is, we treat each stratum as a homogeneous porous medium (e.g. coarse

${Wi}_I$. In particular, we model the strata as parallel fluidic ‘resistors’ – that is, we treat each stratum as a homogeneous porous medium (e.g. coarse ![]() $C$ or fine

$C$ or fine ![]() $F$), with the two hydraulically connected only at the inlet and outlet with fully developed flow in each. Because the time-averaged pressure drop

$F$), with the two hydraulically connected only at the inlet and outlet with fully developed flow in each. Because the time-averaged pressure drop ![]() $\langle \Delta P\rangle _t$ is equal across both strata, the imposed constant volumetric flow rate

$\langle \Delta P\rangle _t$ is equal across both strata, the imposed constant volumetric flow rate ![]() $Q$ must partition into the coarse and fine strata with flow rates

$Q$ must partition into the coarse and fine strata with flow rates ![]() $Q_C$ and

$Q_C$ and ![]() $Q_F$, respectively, in proportion to their individual flow resistances via Darcy's law

$Q_F$, respectively, in proportion to their individual flow resistances via Darcy's law

Following our previous study of this elastic flow instability in a homogeneous porous medium (Browne & Datta Reference Browne and Datta2021), we combine macro-scale pressure drop measurements with pore-scale flow visualization to determine and validate a model for the ![]() $\eta _{{app},i}$ of each stratum in isolation. We then use this model to deduce the apparent viscosity and uneven partitioning of flow within a stratified medium.

$\eta _{{app},i}$ of each stratum in isolation. We then use this model to deduce the apparent viscosity and uneven partitioning of flow within a stratified medium.

To do so, we measure the time-averaged pressure drop ![]() $\langle \Delta P\rangle _t$ at different volumetric flow rates

$\langle \Delta P\rangle _t$ at different volumetric flow rates ![]() $Q$ across each microfluidic assembly. We use Darcy's law to determine the corresponding

$Q$ across each microfluidic assembly. We use Darcy's law to determine the corresponding ![]() $\eta _{{app}}$, which we plot as a function of

$\eta _{{app}}$, which we plot as a function of ![]() ${Wi}_I$ in figure 3(a); the data for the coarse medium are taken from Browne & Datta (Reference Browne and Datta2021). As expected, at small

${Wi}_I$ in figure 3(a); the data for the coarse medium are taken from Browne & Datta (Reference Browne and Datta2021). As expected, at small ![]() ${Wi}_I\lesssim 2.6$, the apparent viscosity

${Wi}_I\lesssim 2.6$, the apparent viscosity ![]() $\eta _{{app}}$ is given by the bulk solution shear viscosity

$\eta _{{app}}$ is given by the bulk solution shear viscosity ![]() $\eta (\dot {\gamma }_I)$, indicated by the red dashed line. However, above a threshold

$\eta (\dot {\gamma }_I)$, indicated by the red dashed line. However, above a threshold ![]() ${Wi}_c=2.6$,

${Wi}_c=2.6$, ![]() $\eta _{{app}}$ rises sharply, paralleling previous reports (Marshall & Metzner Reference Marshall and Metzner1967; James & McLaren Reference James and McLaren1975; Durst et al. Reference Durst, Haas and Kaczmar1981; Durst & Haas Reference Durst and Haas1981; Kauser et al. Reference Kauser, Dos Santos, Delgado, Muller and Saez1999; Clarke et al. Reference Clarke, Howe, Mitchell, Staniland and Hawkes2016). Both the homogeneous coarse (dark blue circles) and fine (light blue circles) media exhibit a similar dependence of

$\eta _{{app}}$ rises sharply, paralleling previous reports (Marshall & Metzner Reference Marshall and Metzner1967; James & McLaren Reference James and McLaren1975; Durst et al. Reference Durst, Haas and Kaczmar1981; Durst & Haas Reference Durst and Haas1981; Kauser et al. Reference Kauser, Dos Santos, Delgado, Muller and Saez1999; Clarke et al. Reference Clarke, Howe, Mitchell, Staniland and Hawkes2016). Both the homogeneous coarse (dark blue circles) and fine (light blue circles) media exhibit a similar dependence of ![]() $\eta _{{app}}$ on

$\eta _{{app}}$ on ![]() ${Wi}_I$ – indicating that for our geometrically similar packings,

${Wi}_I$ – indicating that for our geometrically similar packings, ![]() $\eta _{{app}}({Wi}_I)$ does not depend on grain size

$\eta _{{app}}({Wi}_I)$ does not depend on grain size ![]() $d_p$.

$d_p$.

Figure 3. The elastic flow instability produces a similar increase in the macroscopic flow resistance for homogeneous porous media of different permeabilities. (a) Points show the apparent viscosity, normalized by the shear viscosity of the bulk solution, obtained using macroscopic pressure drop measurements. The apparent viscosity increases above a threshold ![]() ${Wi}_I$ due to the onset of the elastic flow instability. Measurements for two different homogeneous media with distinct bead sizes and permeabilities (different colours) show similar behaviour. Grey line shows the predicted apparent viscosity using our power balance ((3.2), neglecting strain history) and the measured power-law fit to

${Wi}_I$ due to the onset of the elastic flow instability. Measurements for two different homogeneous media with distinct bead sizes and permeabilities (different colours) show similar behaviour. Grey line shows the predicted apparent viscosity using our power balance ((3.2), neglecting strain history) and the measured power-law fit to ![]() $\langle \chi \rangle _{t,V}$ shown in (b), with no fitting parameters; the uncertainty associated with the fit yields an uncertainty in this prediction, indicated by the shaded region. At the largest

$\langle \chi \rangle _{t,V}$ shown in (b), with no fitting parameters; the uncertainty associated with the fit yields an uncertainty in this prediction, indicated by the shaded region. At the largest ![]() ${Wi}_I$, the apparent viscosity eventually converges back to the shear viscosity, reflecting the increased relative influence of viscous dissipation from the base laminar flow. (b) Points show the rate of added viscous dissipation due to unstable flow fluctuations averaged over the medium,

${Wi}_I$, the apparent viscosity eventually converges back to the shear viscosity, reflecting the increased relative influence of viscous dissipation from the base laminar flow. (b) Points show the rate of added viscous dissipation due to unstable flow fluctuations averaged over the medium, ![]() $\langle \chi \rangle _{t,V}$, measured from flow visualization. The dissipation sharply increases above the onset of the instability and is not sensitive to the bead size. Error bars represent one standard deviation between pores. We fit the data using an empirical power-law relationship

$\langle \chi \rangle _{t,V}$, measured from flow visualization. The dissipation sharply increases above the onset of the instability and is not sensitive to the bead size. Error bars represent one standard deviation between pores. We fit the data using an empirical power-law relationship ![]() ${\sim }({Wi}_I/{Wi}_c-1)^{2.4}$ above the macroscopic threshold

${\sim }({Wi}_I/{Wi}_c-1)^{2.4}$ above the macroscopic threshold ![]() ${Wi}_c=2.6$, shown by the grey line; the shaded region shows the error in the power-law fit.

${Wi}_c=2.6$, shown by the grey line; the shaded region shows the error in the power-law fit.

To model this dependence of ![]() $\eta _{{app}}$ on

$\eta _{{app}}$ on ![]() ${Wi}_I$, we directly image the pore-scale flow in each homogeneous microfluidic assembly with confocal microscopy using our ‘intermittent’ imaging protocol. We previously reported these measurements solely for the homogeneous coarse medium (Browne & Datta Reference Browne and Datta2021); thus, we first summarize these results. At small

${Wi}_I$, we directly image the pore-scale flow in each homogeneous microfluidic assembly with confocal microscopy using our ‘intermittent’ imaging protocol. We previously reported these measurements solely for the homogeneous coarse medium (Browne & Datta Reference Browne and Datta2021); thus, we first summarize these results. At small ![]() ${Wi}_I<2.6$, the flow is laminar in all pores. Above the threshold

${Wi}_I<2.6$, the flow is laminar in all pores. Above the threshold ![]() ${Wi}_c=2.6$, the flow in some pores becomes unstable, exhibiting strong spatio-temporal fluctuations. At progressively larger

${Wi}_c=2.6$, the flow in some pores becomes unstable, exhibiting strong spatio-temporal fluctuations. At progressively larger ![]() ${Wi}_I$, an increasing fraction of the pores becomes unstable. To directly compute the added viscous dissipation arising from these flow fluctuations, we use our PIV measurements to determine the fluctuating component of the strain rate tensor

${Wi}_I$, an increasing fraction of the pores becomes unstable. To directly compute the added viscous dissipation arising from these flow fluctuations, we use our PIV measurements to determine the fluctuating component of the strain rate tensor ![]() $\boldsymbol{\mathsf{s}}'=(\boldsymbol {\nabla }\boldsymbol {u}'+\boldsymbol {\nabla }\boldsymbol {u}'^{\mathrm {T}})/2$. The rate of added viscous dissipation per unit volume arising from these flow fluctuations is then given directly by

$\boldsymbol{\mathsf{s}}'=(\boldsymbol {\nabla }\boldsymbol {u}'+\boldsymbol {\nabla }\boldsymbol {u}'^{\mathrm {T}})/2$. The rate of added viscous dissipation per unit volume arising from these flow fluctuations is then given directly by ![]() $\langle \chi \rangle _t=\eta \langle \boldsymbol{\mathsf{s}}':\boldsymbol{\mathsf{s}}'\rangle _t$, which can be estimated from the measured

$\langle \chi \rangle _t=\eta \langle \boldsymbol{\mathsf{s}}':\boldsymbol{\mathsf{s}}'\rangle _t$, which can be estimated from the measured ![]() $x$–

$x$–![]() $y$ velocity field (Sharp, Kim & Adrian Reference Sharp, Kim and Adrian2000; Delafosse et al. Reference Delafosse, Collignon, Crine and Toye2011). As anticipated, the overall rate of added dissipation per unit volume

$y$ velocity field (Sharp, Kim & Adrian Reference Sharp, Kim and Adrian2000; Delafosse et al. Reference Delafosse, Collignon, Crine and Toye2011). As anticipated, the overall rate of added dissipation per unit volume ![]() $\langle \chi \rangle _{t,V}$ determined by averaging

$\langle \chi \rangle _{t,V}$ determined by averaging ![]() $\langle \chi \rangle _t$ across all imaged pores increases with

$\langle \chi \rangle _t$ across all imaged pores increases with ![]() ${Wi}_I$ above the threshold

${Wi}_I$ above the threshold ![]() ${Wi}_c=2.6$ (figure 3(b), dark blue circles) as a greater fraction of pores becomes unstable.

${Wi}_c=2.6$ (figure 3(b), dark blue circles) as a greater fraction of pores becomes unstable.

Next, we repeat this procedure in the homogeneous fine medium (figure 3(b), light blue circles). Intriguingly, the overall rate of added dissipation per unit volume ![]() $\langle \chi \rangle _{t,V}$ does not significantly vary between media. Additionally measuring

$\langle \chi \rangle _{t,V}$ does not significantly vary between media. Additionally measuring ![]() $\langle \chi \rangle _{t,V}$ using our ‘continuous’ imaging protocol in the homogeneous fine medium further corroborates this agreement (figure 3(b), light blue squares). We speculate that this collapse reflects that flow fluctuations do not have a characteristic length scale (Browne & Datta Reference Browne and Datta2021); further studies of the influence of confinement on

$\langle \chi \rangle _{t,V}$ using our ‘continuous’ imaging protocol in the homogeneous fine medium further corroborates this agreement (figure 3(b), light blue squares). We speculate that this collapse reflects that flow fluctuations do not have a characteristic length scale (Browne & Datta Reference Browne and Datta2021); further studies of the influence of confinement on ![]() $\langle \chi \rangle _{t,V}$ will be a useful direction for future work. Our data indicate that, for the experiments reported here, differences in grain size between homogeneous porous media are well-captured by

$\langle \chi \rangle _{t,V}$ will be a useful direction for future work. Our data indicate that, for the experiments reported here, differences in grain size between homogeneous porous media are well-captured by ![]() ${Wi}_I$. We therefore fit all the data by the single empirical relationship

${Wi}_I$. We therefore fit all the data by the single empirical relationship ![]() $\langle \chi \rangle _{t,V}=A_x({Wi}_I/{Wi}_c-1)^{\alpha _x}$, with

$\langle \chi \rangle _{t,V}=A_x({Wi}_I/{Wi}_c-1)^{\alpha _x}$, with ![]() $A_x=176\pm 1\,\mathrm {W}\,\mathrm {m}^{-3}$,

$A_x=176\pm 1\,\mathrm {W}\,\mathrm {m}^{-3}$, ![]() $\alpha _x=2.4\pm 0.3$, and

$\alpha _x=2.4\pm 0.3$, and ![]() ${Wi}_c=2.6$, shown by the grey line in figure 3(b).

${Wi}_c=2.6$, shown by the grey line in figure 3(b).

Finally, we follow our previous work (Browne & Datta Reference Browne and Datta2021) to quantitatively link the pore-scale flow fluctuations generated by the elastic flow instability to ![]() $\eta _{{app}}({Wi}_I)$. The power density balance for viscous-dominated flow relates the rate of work done by the fluid pressure

$\eta _{{app}}({Wi}_I)$. The power density balance for viscous-dominated flow relates the rate of work done by the fluid pressure ![]() $P$ to the rate of viscous energy dissipation per unit volume: