Article contents

Granular particle-shape heterogeneous mixtures discharging through a silo

Published online by Cambridge University Press: 11 February 2021

Abstract

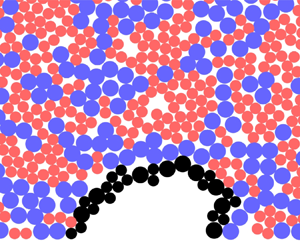

Process industries often involve handling non-cohesive solid materials which vary in size and shape. A comprehensive understanding of such systems helps in effective handling of industrial operations. Here, we studied heterogeneous mixtures of dumbbells and discs flowing out of a two-dimensional silo using discrete element method simulations. We analysed discharge dynamics of the mixtures in two regimes, namely the free-flow regime ( $W/d>=15$) and the interrupted flow regime (

$W/d>=15$) and the interrupted flow regime ( $W/d<=10$), where

$W/d<=10$), where  $W$ and

$W$ and  $d$ are the orifice width and diameter of each of the circles of a dumbbell. One of the intriguing results is a decrease in the flow rate

$d$ are the orifice width and diameter of each of the circles of a dumbbell. One of the intriguing results is a decrease in the flow rate  $Q$ of mixtures with an increase in the fraction of dumbbells

$Q$ of mixtures with an increase in the fraction of dumbbells  $X_{db}$ in both of the regimes analysed. This can be attributed to the geometrical interlocking among the particles and a hindrance to the rotation of dumbbells. The time-averaged (coarse-grained) flow fields reveal an increase in the size of the stagnant zone beside the orifice with an increase in

$X_{db}$ in both of the regimes analysed. This can be attributed to the geometrical interlocking among the particles and a hindrance to the rotation of dumbbells. The time-averaged (coarse-grained) flow fields reveal an increase in the size of the stagnant zone beside the orifice with an increase in  $X_{db}$. The stagnant zone hinders the particles flowing next to it, which is another reason for a decrease in

$X_{db}$. The stagnant zone hinders the particles flowing next to it, which is another reason for a decrease in  $Q$ with an increase in

$Q$ with an increase in  $X_{db}$. In the interrupted flow regime, we investigated clogged states of the mixtures using arch morphology, the fraction of dumbbells and number of particles in an arch, and avalanche sizes.

$X_{db}$. In the interrupted flow regime, we investigated clogged states of the mixtures using arch morphology, the fraction of dumbbells and number of particles in an arch, and avalanche sizes.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2021. Published by Cambridge University Press

Footnotes

Present address: University of Notre Dame, Notre Dame, IN 46556, USA.

References

REFERENCES

- 7

- Cited by